High-strength antifriction double-layered iron base powder metallurgy material and preparation method thereof

An iron-based powder metallurgy and surface material technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of unstable friction contact interface and lubrication state, low strength and hardness of anti-friction layer, poor wear resistance, etc. Achieve the effect of reducing precious alloy components, meeting the requirements of hardness and wear resistance, and high bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

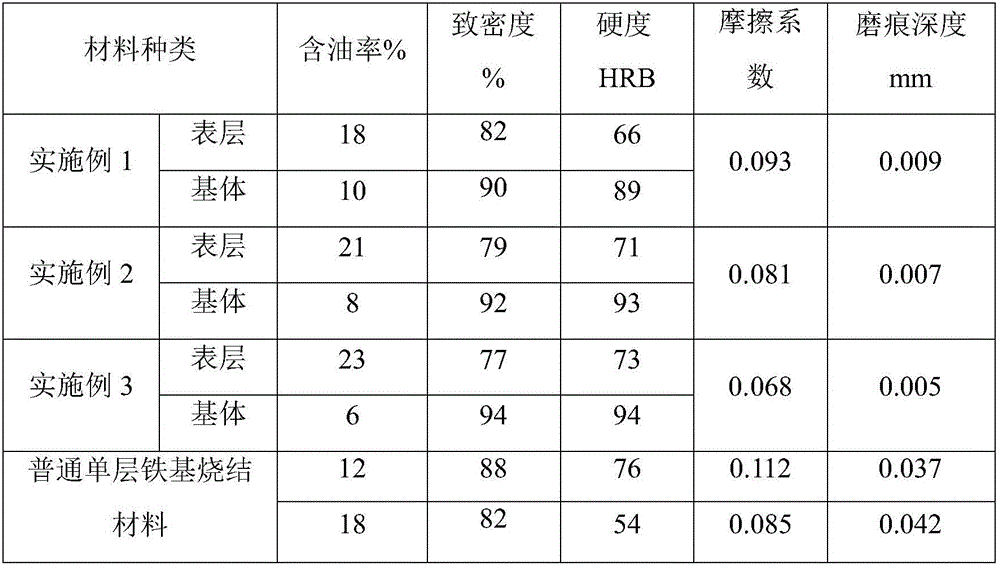

Embodiment 1

[0024] The high-strength anti-friction double-layer iron-based powder metallurgy material in this embodiment is composed of a surface layer material and a matrix material, and the thickness of the surface layer material is 1 / 5 of the thickness of the double-layer iron-based powder metallurgy material.

[0025] The raw materials of the surface material are constituted by mass percentage: reduced iron powder 5.04g (84%), copper powder 0.6g (10%), nickel powder 0.15g (2.5%), molybdenum powder 0.03g (0.5%), graphite powder 0.03 g (0.5%), ferrophosphorus powder 0.03g (0.5%), titanium hydride powder 0.06g (1%) and zinc stearate powder 0.06g (1%).

[0026] The raw materials of the base material are constituted by mass percentage: reduced iron powder 21.6g (90%), copper powder 1.2g (5%), nickel powder 0.6g (2.5%), molybdenum powder 0.12g (0.5%), graphite powder 0.12 g (0.5%), ferrophosphorus powder 0.12g (0.5%) and densifier COM-XZ5 0.24g (1%).

[0027] The preparation method of the ...

Embodiment 2

[0034] The high-strength anti-friction double-layer iron-based powder metallurgy material in this embodiment is composed of a surface layer material and a matrix material, and the thickness of the surface layer material is 2 / 5 of the thickness of the double-layer iron-based powder metallurgy material.

[0035] The raw materials of the surface material are constituted by mass percentage: reduced iron powder 9.84g (82%), copper powder 1.2g (10%), nickel powder 0.3g (2.5%), molybdenum powder 0.06g (0.5%), graphite powder 0.06 g (0.5%), ferrophosphorus powder 0.06g (0.5%), titanium hydride powder 0.36g (3%) and zinc stearate powder 0.12g (1%).

[0036]The raw materials of the matrix material are constituted by mass percentage: reduced iron powder 16.78g (93.2%), copper powder 0.9g (5%), nickel powder 0g (0%), molybdenum powder 0.04g (0.2%), graphite powder 0.09g (0.5%), ferrophosphorus powder 0.09g (0.5%) and densifier Best-1000 0.11g (0.6%).

[0037] The preparation method of th...

Embodiment 3

[0040] The high-strength anti-friction double-layer iron-based powder metallurgy material in this embodiment is composed of a surface layer material and a matrix material, and the thickness of the surface layer material is 3 / 5 of the thickness of the double-layer iron-based powder metallurgy material.

[0041] The raw materials of the surface material are constituted by mass percentage: reduced iron powder 14.4g (80%), copper powder 1.8g (10%), nickel powder 0.45g (2.5%), molybdenum powder 0.09g (0.5%), graphite powder 0.09 g (0.5%), ferrophosphorus powder 0.09g (0.5%), titanium hydride powder 0.9g (5%) and zinc stearate powder 0.18g (1%).

[0042] The raw materials of the base material are constituted by mass percentage: reduced iron powder 11.17g (93.1%), copper powder 0.6g (5%), nickel powder 0g (0%), molybdenum powder 0.02g (0.2%), graphite powder 0.06g (0.5%), ferrophosphorus powder 0.06g (0.5%) and densifier COM-XZ5 0.04g (0.3%) and Best-1000 0.05g (0.4%).

[0043] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com