Method for preparing Fe/C composite material of porous structure by using sedimentary siderite

A porous structure and siderite technology, applied in chemical instruments and methods, water/sewage treatment, biological water/sewage treatment, etc., can solve the problems of low calorific value of liquid fuel, complex composition, carbon deposits in boilers, etc., to eliminate Tar, large pore volume, effect of improving particle strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment prepares Fe / C composite porous structure material according to the following steps:

[0028] (1) crushing low-grade sedimentary siderite ore with an iron grade of 47.3% and passing through a 0.1mm sieve to obtain sedimentary siderite powder; crushing rapeseed straw and passing through a 1mm sieve to obtain straw powder;

[0029] (2) Weigh the deposited siderite powder and the straw powder according to the mass ratio of 1:3 and mix them evenly to obtain the mixture;

[0030] (3) above-mentioned mixture is added in the hopper of screw extruder molding machine, extruded and formed into the rod-shaped particle of diameter 5mm;

[0031] (4) Roast the formed rod-shaped particles in a tube furnace at 750°C for 30 minutes in a hydrogen atmosphere, and then naturally cool to room temperature in an oxygen-free atmosphere to obtain Fe / C composite porous structure material.

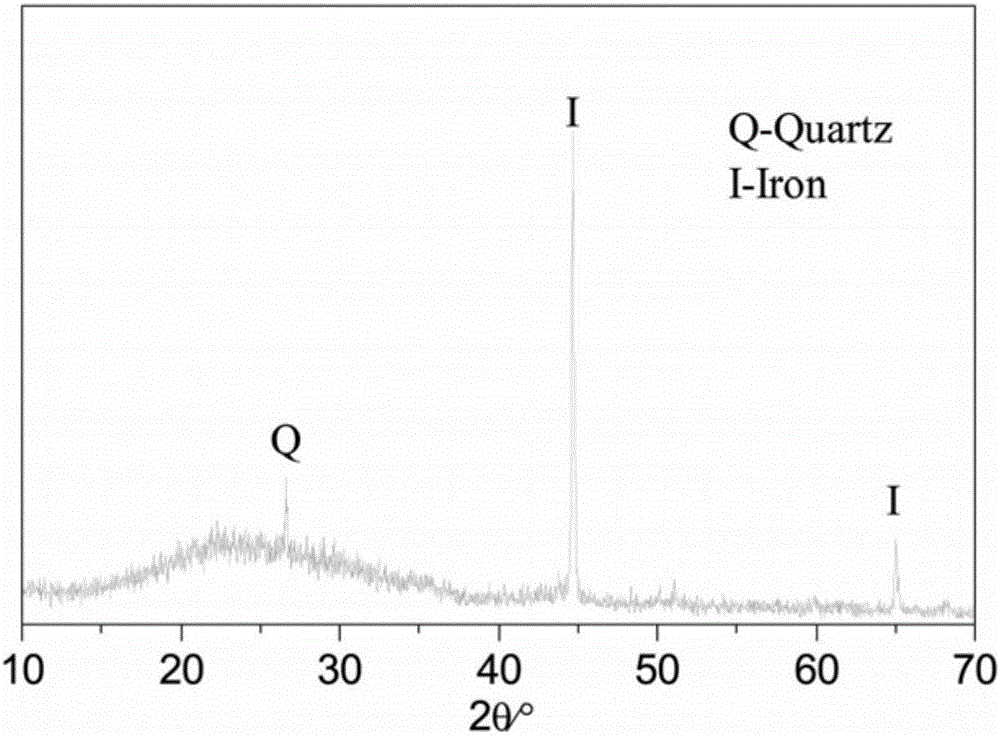

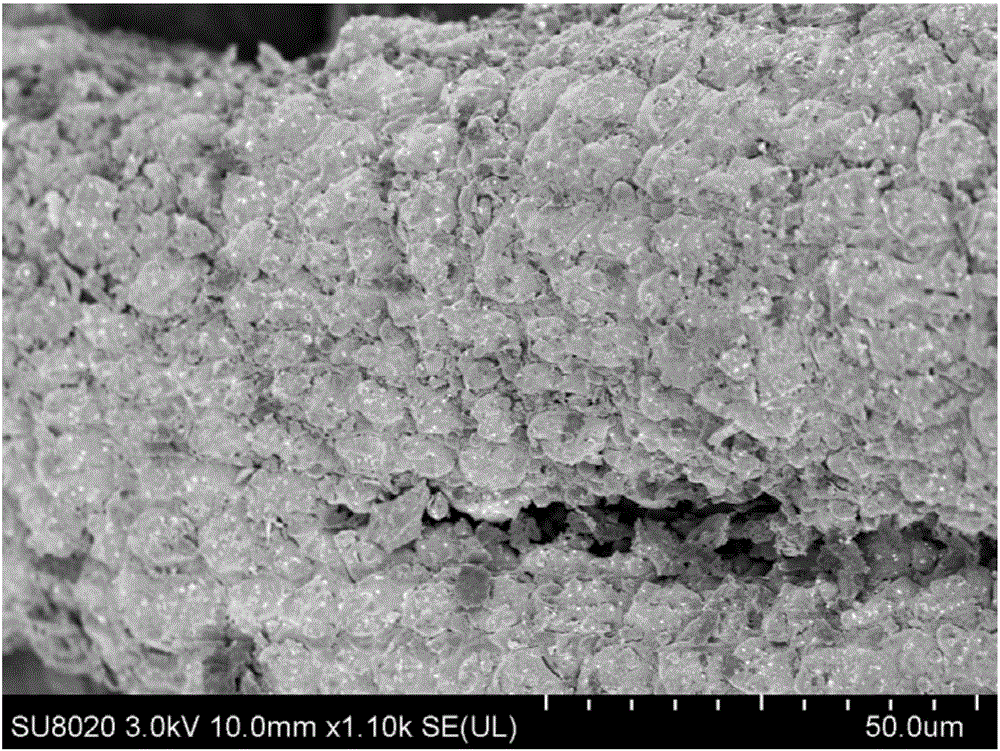

[0032] figure 1 The X-ray diffraction pattern of the Fe / C composite porous structure ma...

Embodiment 2

[0035] This embodiment prepares Fe / C composite porous structure material according to the following steps:

[0036] (1) Crushing the low-grade sedimentary siderite ore with an iron grade of 47.3% and passing through a 0.1mm sieve to obtain a sedimentary siderite powder; crushing sawdust from wood processing and passing through a 1mm sieve to obtain a biomass powder;

[0037] (2) Weigh the deposited siderite powder and the biomass powder according to the mass ratio of 1:5 and mix them evenly to obtain the mixture;

[0038] (3) above-mentioned mixture is added in the hopper of screw extruder molding machine, extruded and formed into the rod-shaped particle of diameter 5mm;

[0039] (4) Roast the formed rod-shaped particles in a tube furnace at 850°C for 25 minutes in a hydrogen atmosphere, and then naturally cool to room temperature in an oxygen-free atmosphere to obtain Fe / C composite porous structure material.

[0040] After XRD analysis, the results showed that the impurit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com