Flexible ironing groove structure of groove type ironing machine

An ironing machine and trough type technology, applied in the direction of ironing machine, washing device, textile and paper making, etc., can solve the problems of hindering popularization, unable to meet the ironing process, and the price of flexible trough type ironing machine remains high. Achieve the effect of reducing manufacturing difficulty and realizing machine flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with accompanying drawing.

[0043] Figure 6~7 Among them, the ironing machine includes a horizontally arranged cylindrical drum 1 and an ironing tank 2 arranged below the drum 1, and both ends of the ironing tank 2 are open ends.

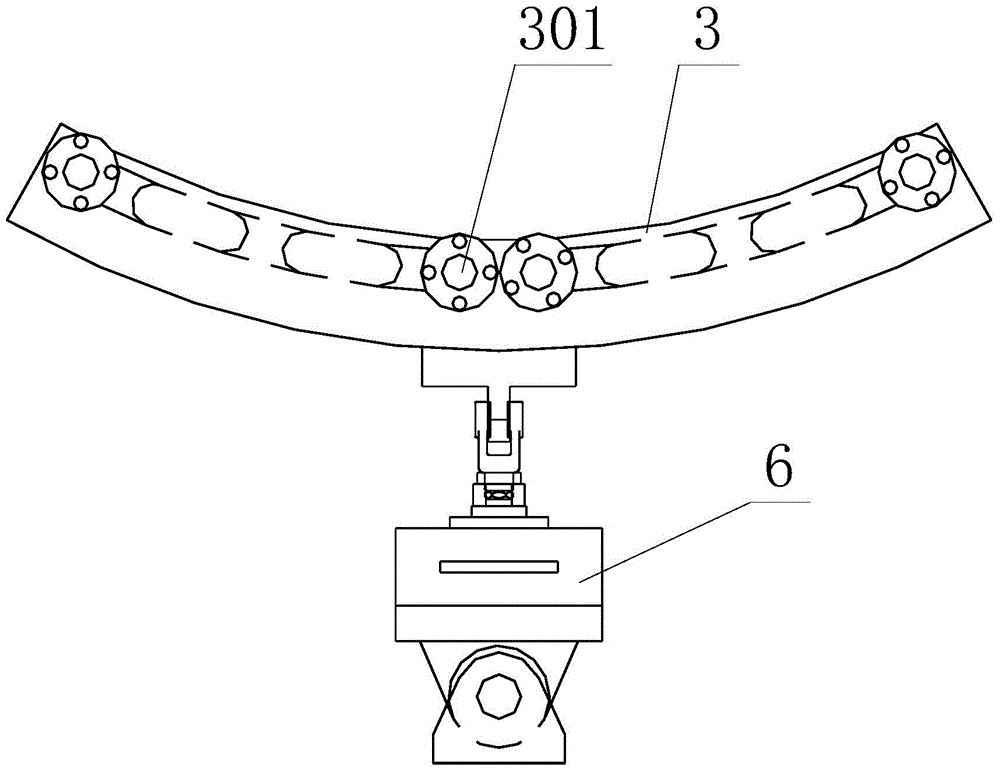

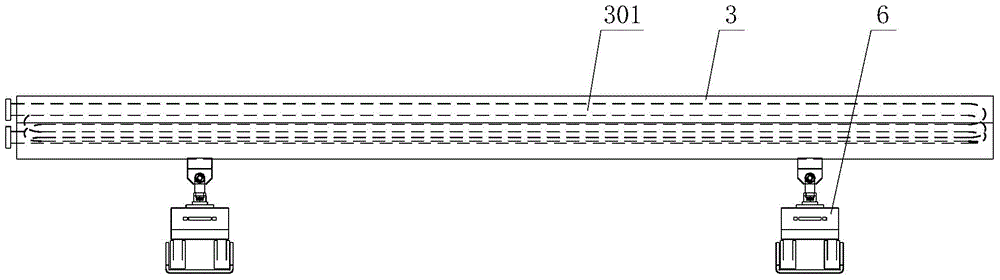

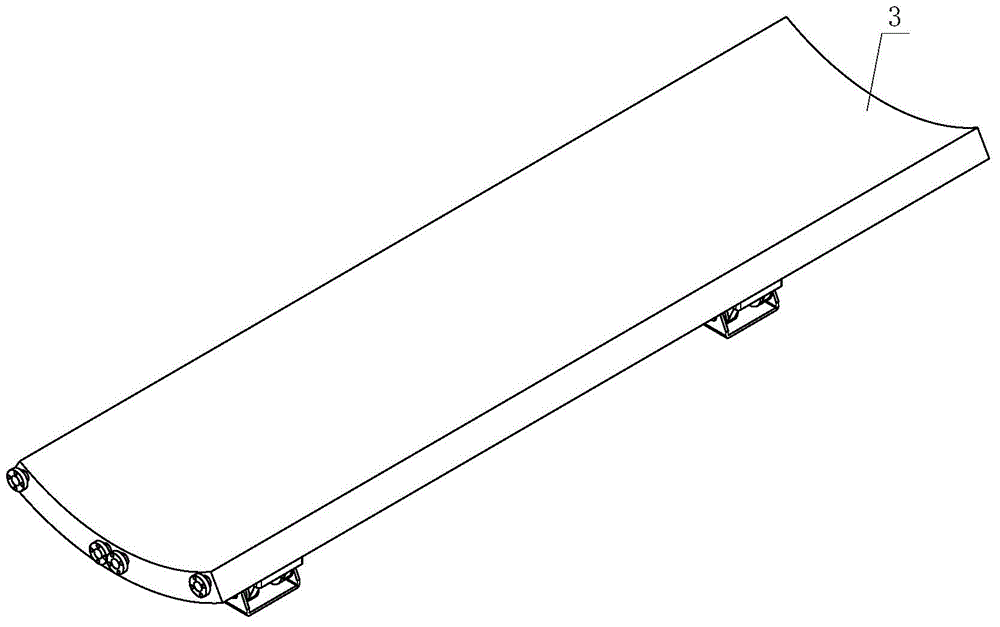

[0044] like Figure 4~5 As shown, the ironing tank 2 is divided into two segments along the axial direction, and each segment is divided into three tile-shaped heating blocks 3 along the circumferential direction to form a semicircular cavity. Arrange upwards into an orthogonal grid-like array.

[0045] like Figure 1~2 As shown, the heating block 3 is provided with a heating device 301 and equipped with a temperature sensor.

[0046] like Figure 6~4 As shown, the concave surface of the ironing tank 2 is covered with a balanced heat conduction metal sheet 4, and the balanced heat conduction metal sheet 4 with a semicircular opening facing upwards is divided into two ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com