Water tank antirot material dissolvent characteristic detection test method

A technology of anti-corrosion materials and characteristics, applied in the field of water treatment, can solve problems such as the dissolution characteristics of anti-corrosion coatings that cannot be investigated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

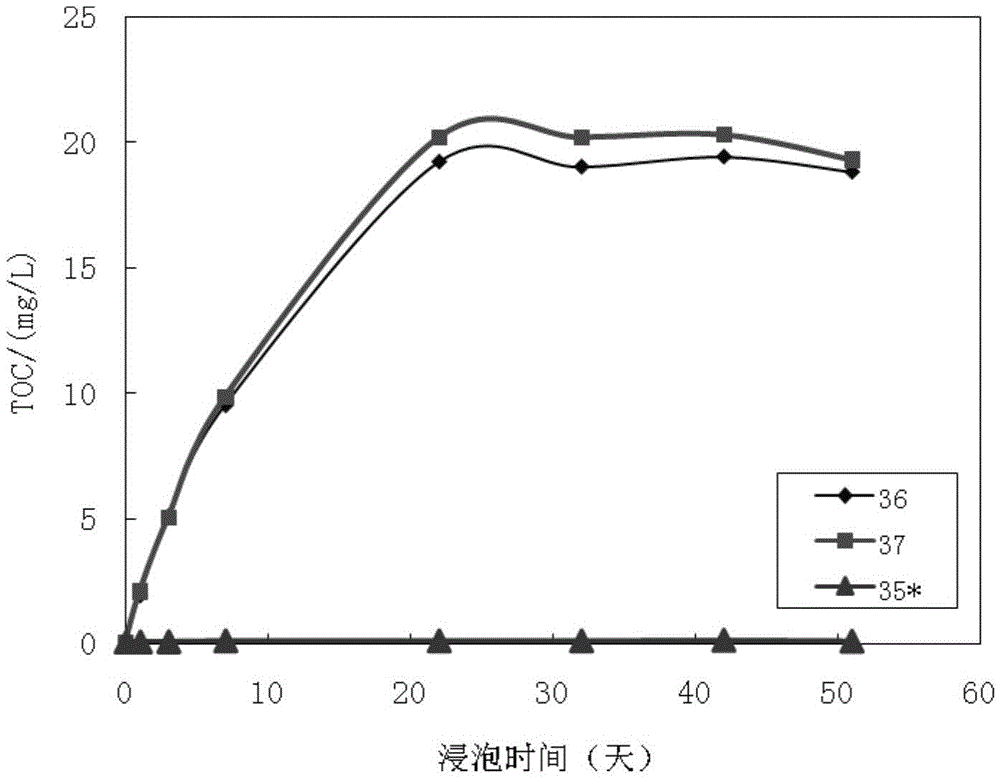

[0090] Analysis of TOC detection results of domestically produced polyurea samples in a power plant in Beijing

[0091] (1) Test conditions

[0092] Sample No. 36: Size (mm): 77.62×10.42×1.58, 77.65×10.42×1.53;

[0093] Mass (g): 2.6199, the volume of soaking liquid is 610mL, sealed.

[0094] Sample No. 37: Size (mm): 77.62×10.42×1.55, 77.62×10.43×1.56;

[0095] Mass (g): 2.7738. The soaking solution has a volume of 610mL and is sealed.

[0096] No. 38 is a blank sample with a volume of 610mL and sealed.

[0097] Test temperature: room temperature 21°C.

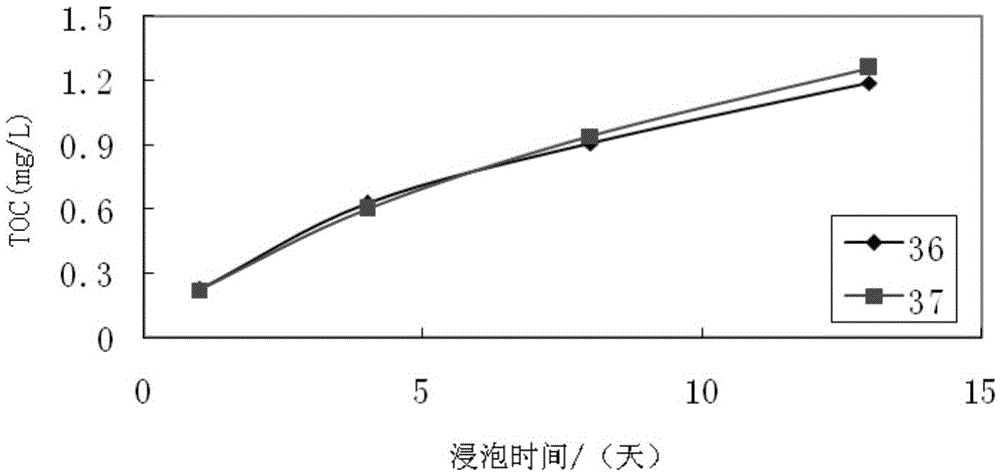

[0098] (2) Analysis of TOC detection results in the initial dissolution stage

[0099] See figure 1 shown.

[0100] From figure 1 It can be seen that the TOC measured values of the two groups of parallel samples No. 36 and No. 37 have the same changing law, and the correlation is very good, which verifies the reliability of the TOC measuring instrument and measuring method used in this experiment.

[0101] It can ...

Embodiment 2

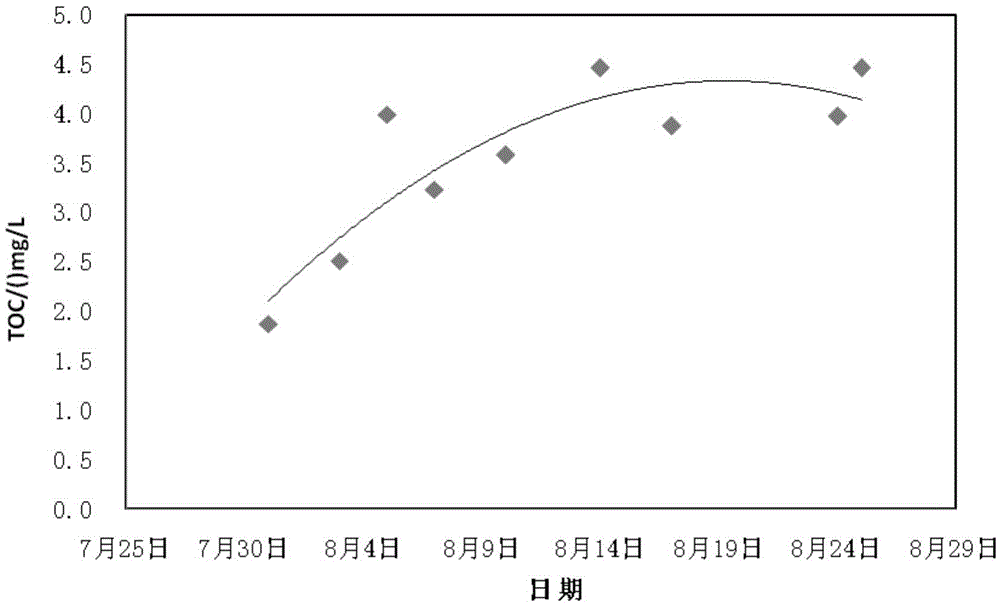

[0119] Example 2: Analysis of TOC detection results of polyurea samples from an imported polyurea sample

[0120] (1) Test conditions

[0121] Sample No. 1: Size (mm): 64.02×10.20×2.04, 64.02×10.08×2.06;

[0122] Mass (g): 2.3907, the volume of soaking liquid is 610mL, sealed.

[0123] Sample No. 3: Size (mm): 64.02×10.00×2.08, 64.02×10.26×2.06;

[0124] Mass (g): 2.4133. The soaking solution has a volume of 610mL and is sealed.

[0125] No. 2 is a blank sample with a volume of 610mL and sealed.

[0126] Test temperature: room temperature 21°C.

[0127] (2) Analysis of TOC detection results in the initial dissolution stage

[0128] For the measured value and changing law of TOC dissolution concentration in the initial dissolution stage of polyurea samples from an imported polyurea sample, see Figure 5 shown.

[0129] From Figure 5 It can be seen that the changes in the measured values of TOC of No. 1 and No. 3 groups of parallel samples are consistent, and the cor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Quality | aaaaa | aaaaa |

| Quality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com