Automobile instrument automatic detection equipment based on machine vision

A technology of automatic detection and automotive instrumentation, applied in the direction of instruments, etc., can solve the problems of high labor intensity, large errors, and low test efficiency, and achieve the effects of improving production efficiency, overcoming various errors, and realizing traceability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following will be further described in detail in conjunction with the accompanying drawings and embodiments of the present invention, but it should not be understood that the scope of the subject matter of the present invention is limited to the following embodiments.

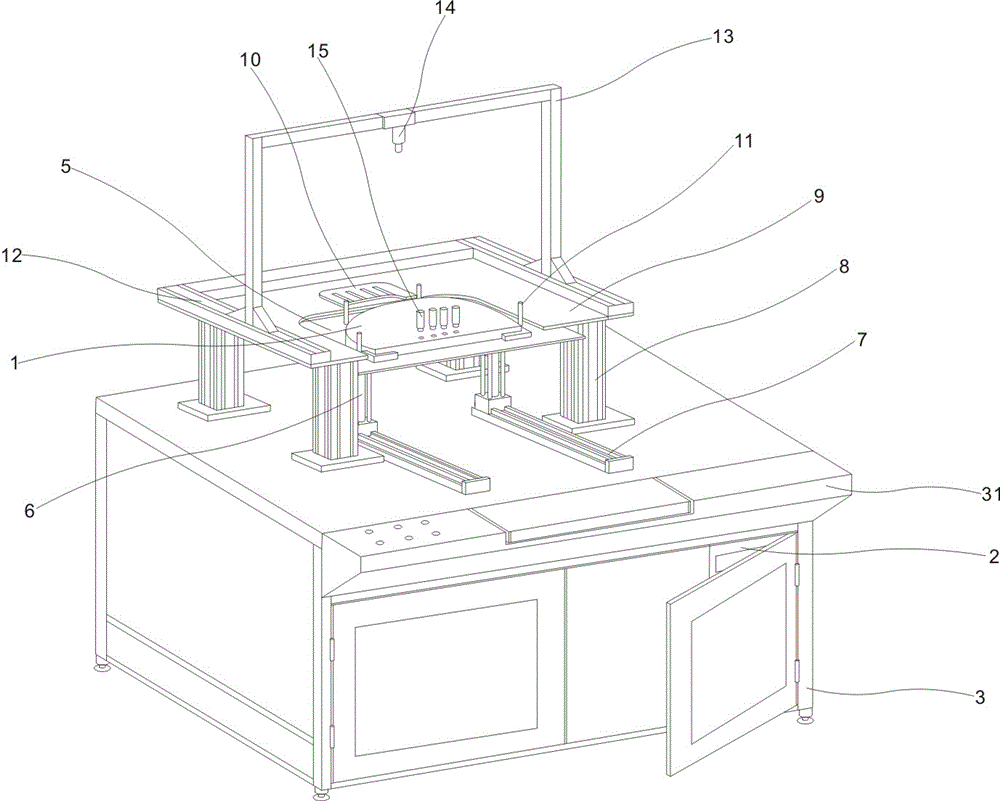

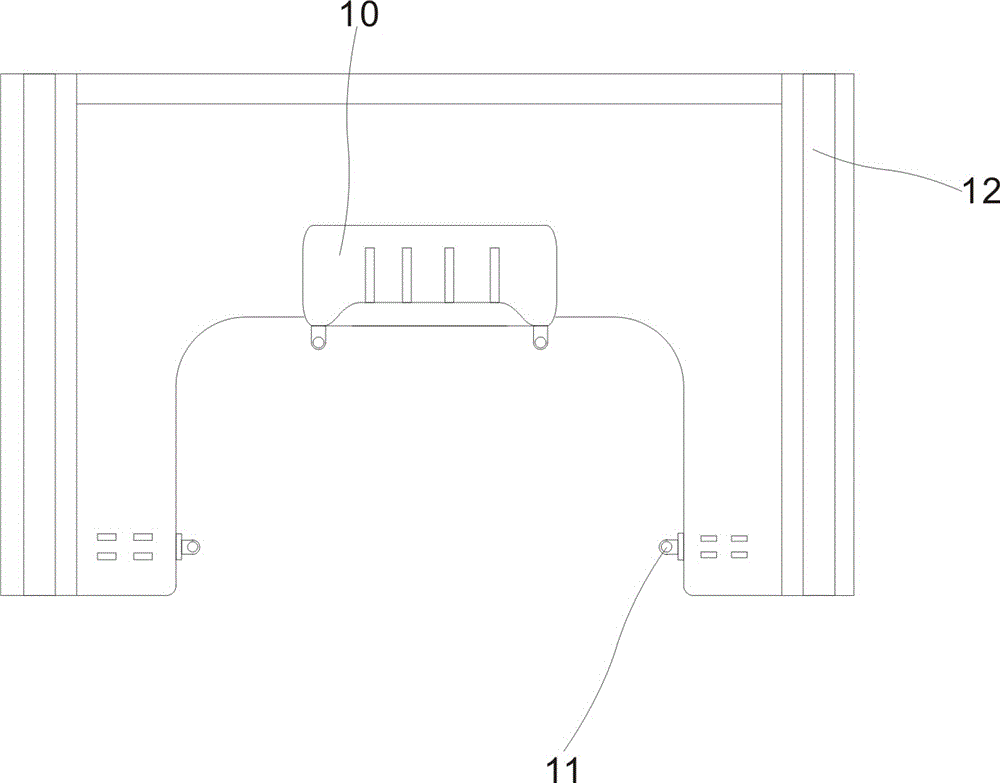

[0025] figure 1 It is a schematic structural diagram of a machine vision-based automatic detection device for automobile meters of the present invention, and the overall assembly structure of the device is as follows:

[0026] The industrial computer 2 is installed inside the control cabinet 3; the upper end of the front part of the control cabinet 3 is provided with a protruding console 31.

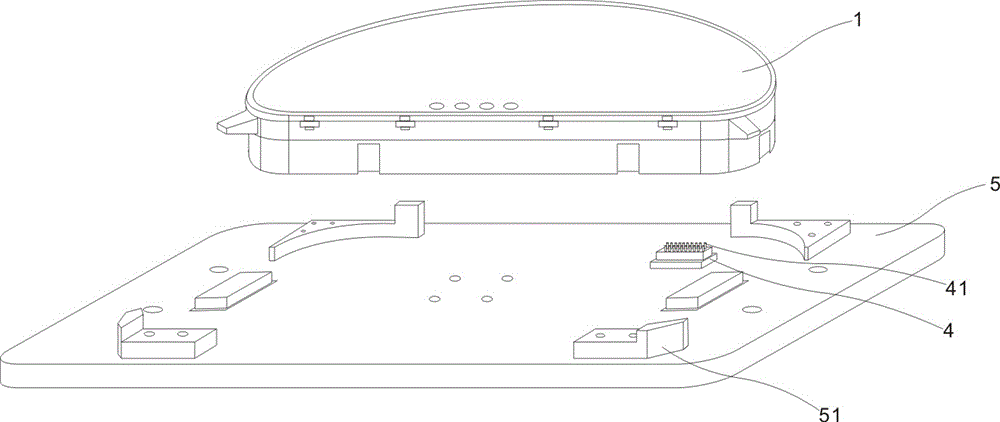

[0027] The test probe base 4 and the test base plate 5 used for the driving connection of the automobile instrument are assembled as a whole and installed on the locking cylinder 6 , and the test probe base 4 is equipped with a test probe 41 . Simultaneously, photoelectric sensors are installed on the test bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com