Deep drawing forming composite die for shallow conical pieces with sunken side walls

A compound mold and deep-drawing forming technology, which is applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve problems such as difficult stretch forming of shallow conical parts, and achieve the effect of improving production efficiency and ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

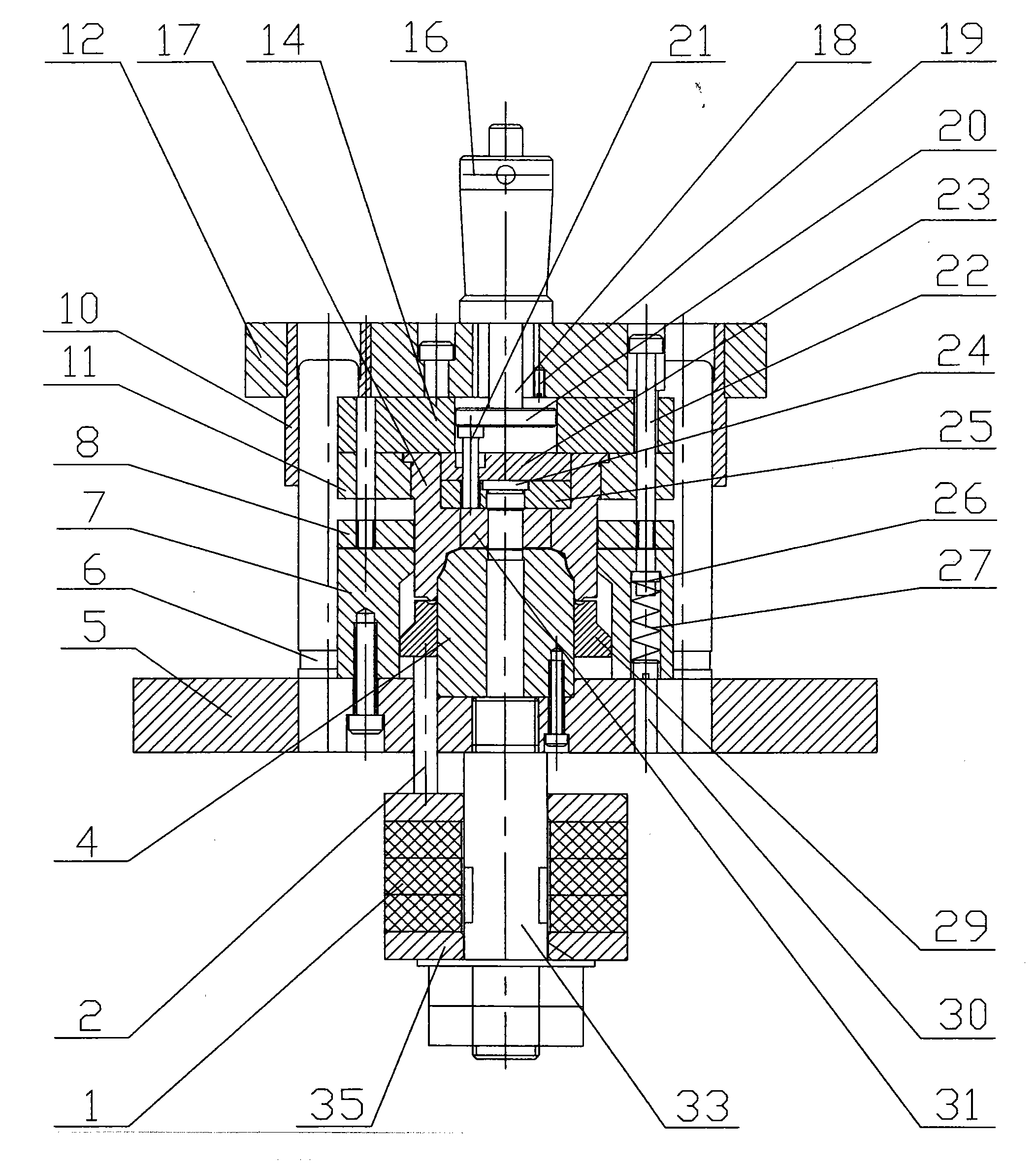

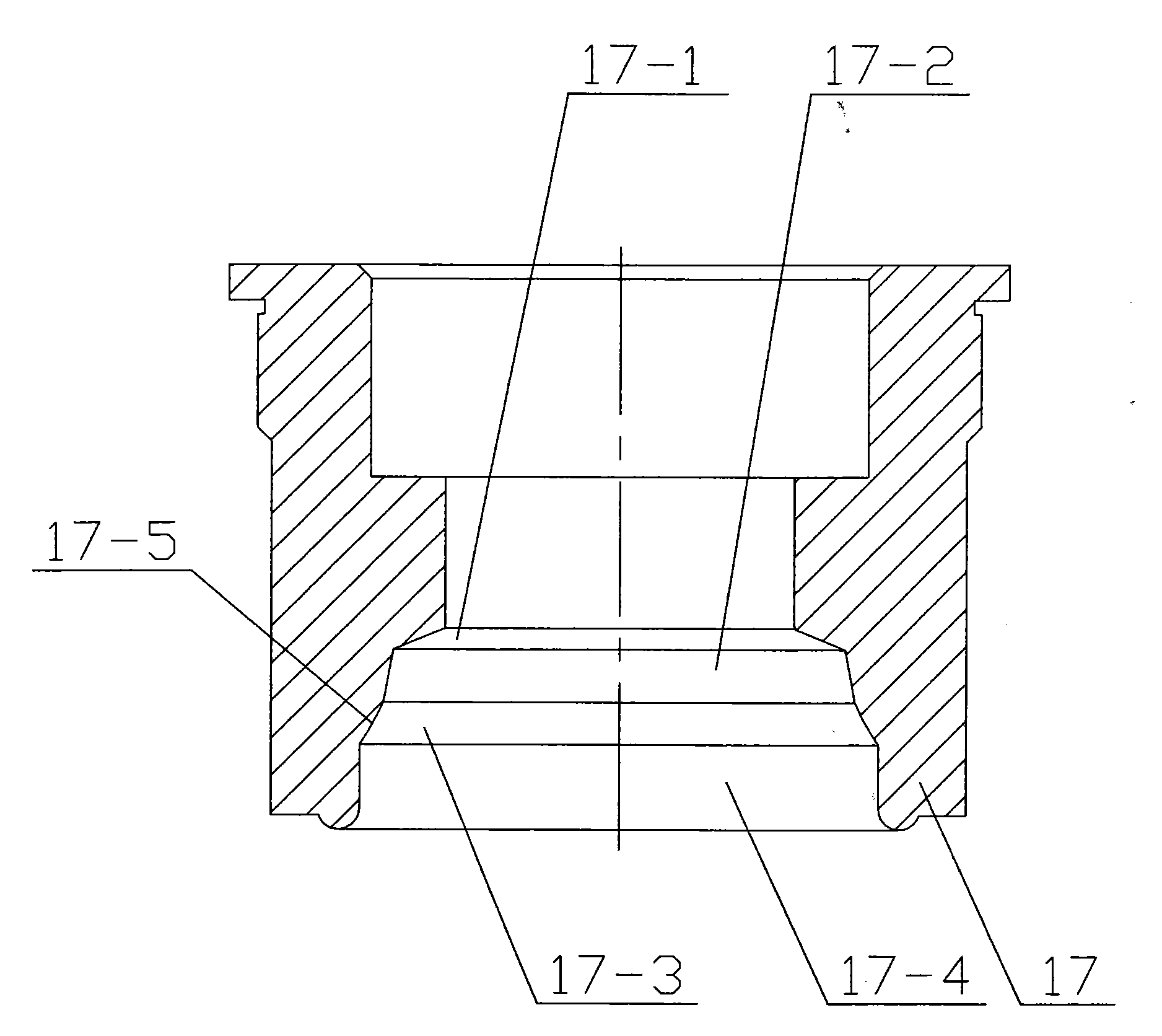

[0007] Specific implementation mode one: combine Figure 1-Figure 3 Illustrates that a composite die for deep-drawing of a shallow conical part with a concave side wall in this embodiment is composed of an upper die assembly and a lower die assembly; the upper die assembly includes a die handle 16, an upper die plate 12, two Guide sleeve 10, backing ring 14, fixed plate 11, punching rod 18, top plate 20, unloading connector 22, backing plate 23, punching punch 24, punching punch fixing plate 25, upper convex and concave die 17, return plate 31 and Threaded connector 21; lower mold assembly consists of support pin 2, lower template 5, two guide pillars 6, blanking die 7, discharge plate 8, lower convex die 4, retaining pin 26, blank holder ring 29, The spring 27, the support pin 2, the limit screw rod 30, the spiral tube 33, the supporting plate 35 and a group of edge-holding rubber pads 1 are composed; the lower end of the die handle 16 is detachably connected to the upper tem...

specific Embodiment approach 2

[0008] Specific implementation mode two: combination figure 1 Note that the upper mold assembly in this embodiment also includes anti-rotation locking screws 19 ; Others are the same as in the first embodiment.

Embodiment

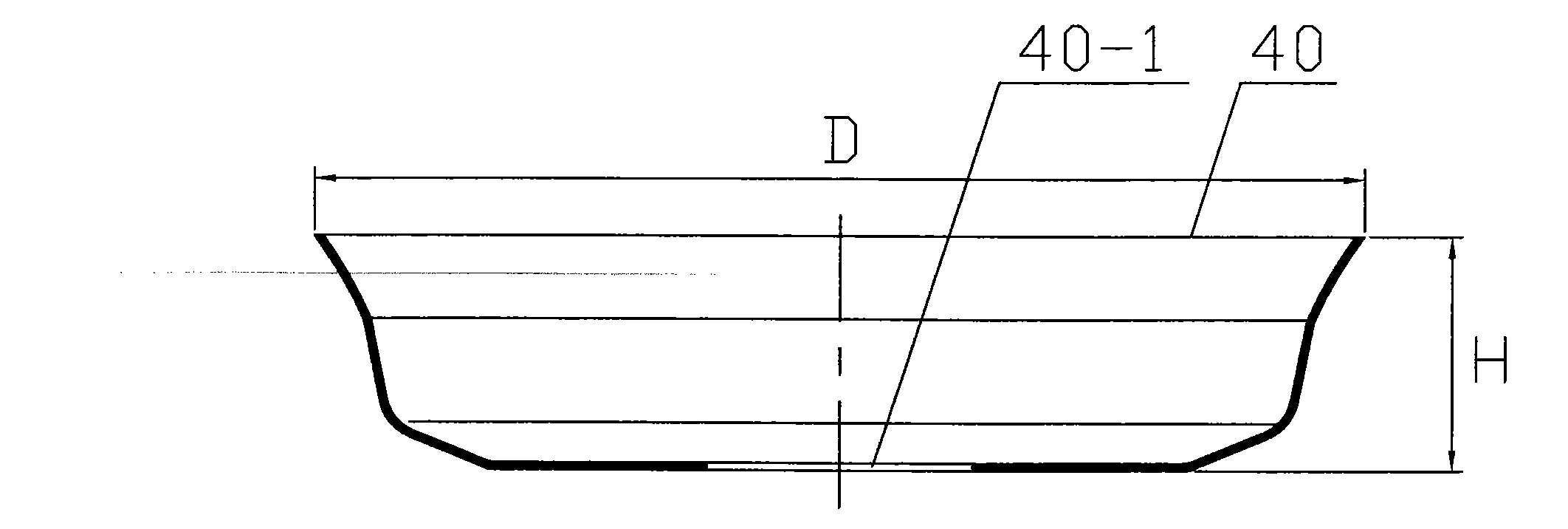

[0009] Embodiment: Utilize a shallow conical part with concave side wall of the present invention to draw and form a composite mold. After deep drawing, the outer diameter D at the port of the shallow conical part is 73.9 mm. The height H of the shape is 16.5mm.

[0010]The working principle is: according to the shape and size of the shallow conical part with the concave side wall that needs to be drawn, design the blanking die 7, the upper convex die 17, the lower convex die 4 and other auxiliary parts, and assemble them into a A complete composite mold. The composite mold is installed on the crank press, and the lower template 5 is fixed on the lower table of the crank press, and the upper mold assembly is fixed on the upper slide of the crank press (with the rotation of the crankshaft of the equipment, the same as the upper slide) The blocks move up and down together, and each reciprocating movement up and down once completes a working cycle. The downward movement is the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com