Method and system for treating construction waste

A technology of construction waste and treatment system, which is applied in the field of construction waste treatment methods and its systems, can solve problems such as difficulty in finely removing impurities in construction waste, high labor load intensity, and difficulty in meeting national standards for recycled aggregate products. Reduce the load of manual picking and the effect of system sorting and impurity removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

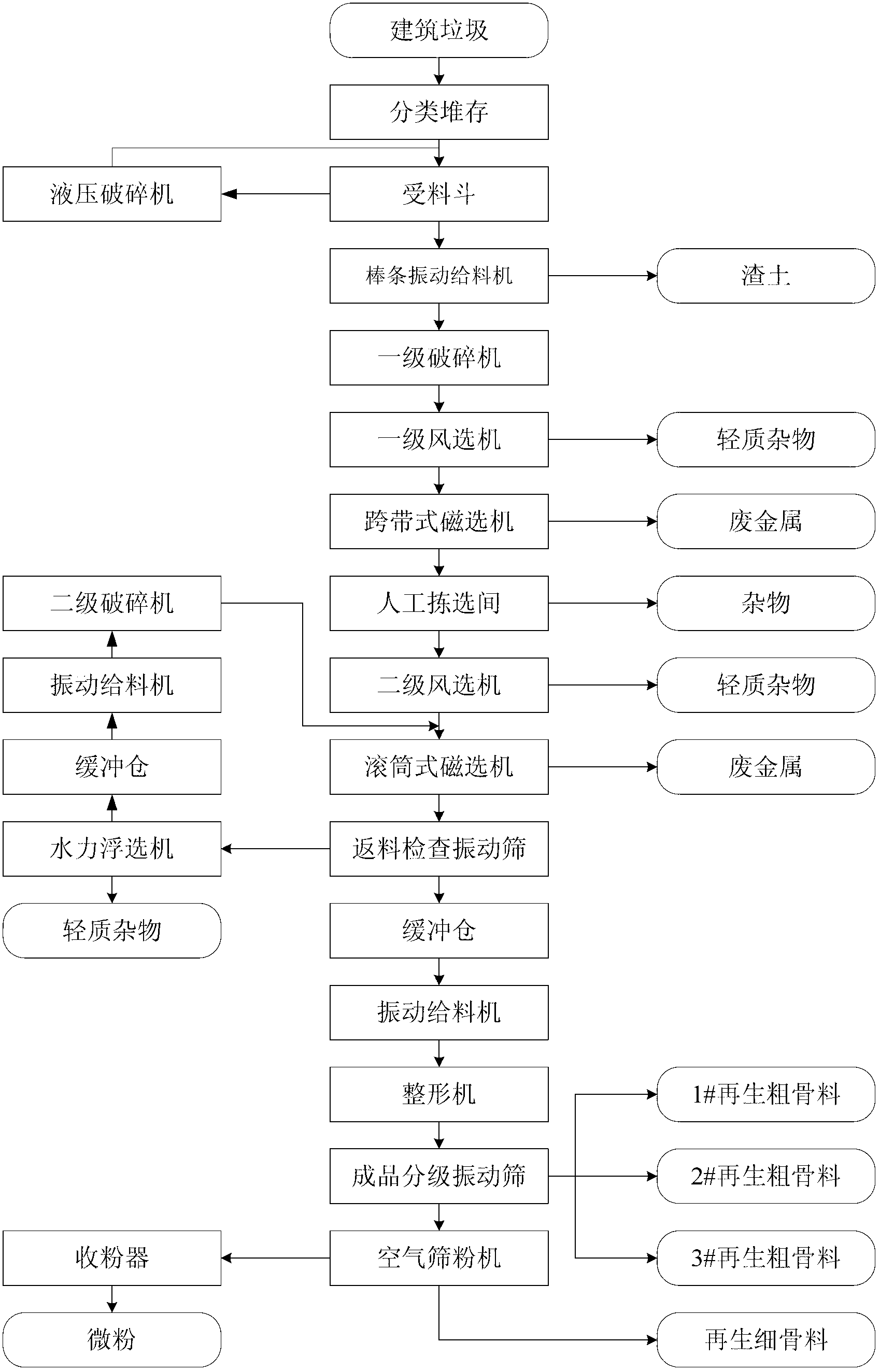

[0010] see figure 1 , a method for processing construction waste provided by an embodiment of the present invention, comprising sequentially:

[0011] The first step is to carry out feeding and pre-screening of dregs, and set up pre-screening of dregs after feeding to realize pre-separation of dregs and avoid its impact on product quality;

[0012] The second step is primary crushing to achieve primary crushing of large particle size materials;

[0013] The third step is to sort and remove impurities. The materials are subjected to primary air separation, primary magnetic separation, manual selection, secondary air separation, and secondary magnetic separation, and the waste plastics in the primary crushed materials can be targeted. , waste fabric, waste paper, waste wood, waste metal, etc. are effectively separated and removed, and the scientific sorting process setting can not only reasonably reduce the load of manual sorting, but also achieve the effect of refined impurity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com