Smart factory management platform system

A factory management and intelligent technology, applied in technical management, comprehensive factory control, comprehensive factory control, etc., can solve the problems of no equipment health status monitoring, production safety hazards, accelerated aging of equipment, etc., to improve the overall competitiveness of the market and reduce Operation and maintenance costs, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

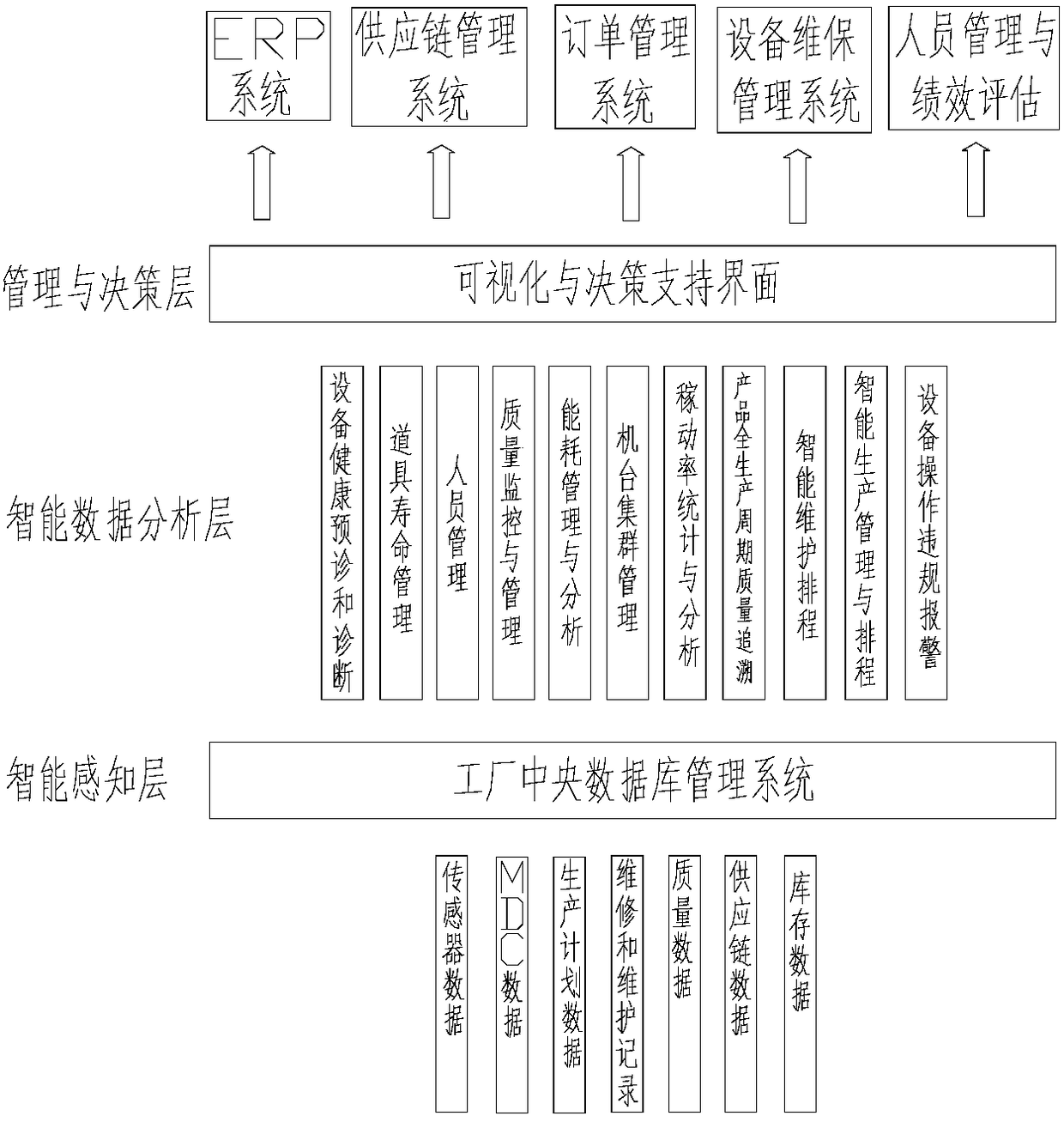

[0020] Such as figure 1 As shown, an intelligent factory management platform system provided by the present invention includes an intelligent perception layer, an intelligent data analysis layer, and a management and decision-making layer.

[0021] Among them, the intelligent perception layer is the central database management system of the factory, which is used to collect, summarize, organize and store data from various information sources in the production process. The data collected in the intelligent perception layer is mainly for the collection of production data, management data and monitoring data of key components of CNC machine tools. The key components of CNC machine tools are mainly shaft drive motors, tools, spindles, feed systems, coolant pumps, and lubrication systems, etc. Data collection for these key components is mainly divid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com