Manufacturing method and structure of camber-shaped capacitance type touch-control plate

A capacitive touch, curved surface technology, applied in electrical digital data processing, data processing input/output process, instruments, etc., can solve the problems of weak stress strength, broken substrate, become waste, etc., to achieve easy shape control , The effect of reducing processing difficulty and product quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

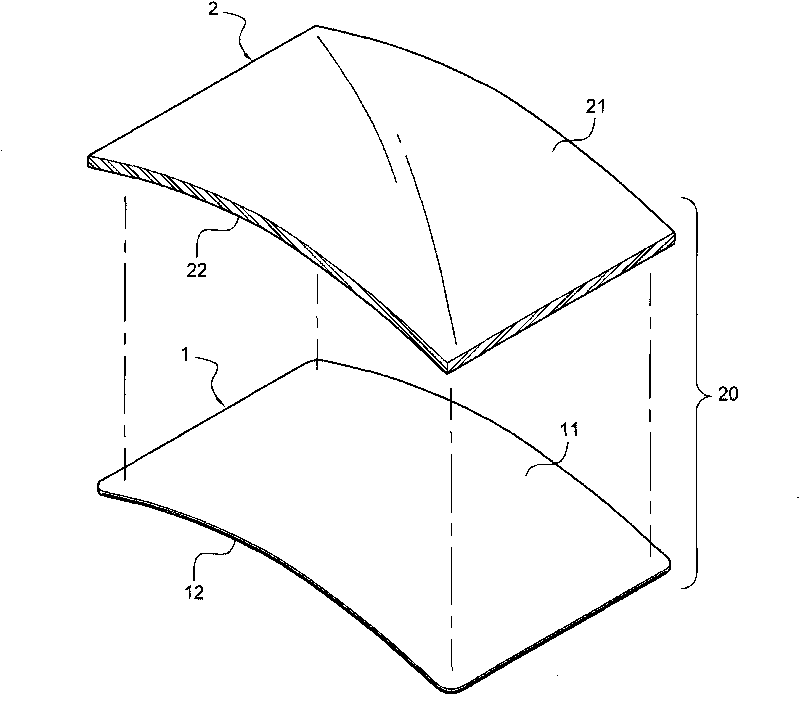

[0053] see figure 1 , revealing a three-dimensional exploded view of an embodiment of the present invention, and cooperate with Figure 2A to Figure 8 Illustrate the preparation method of the curved capacitive touch panel of the present invention, comprise the following steps:

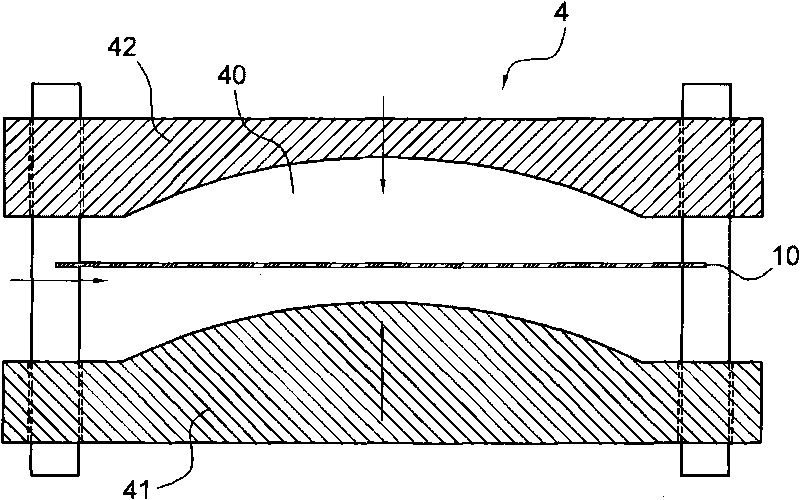

[0054] (1) Provide a planar flexible circuit board 10 with capacitive touch function (such as Figure 2A shown).

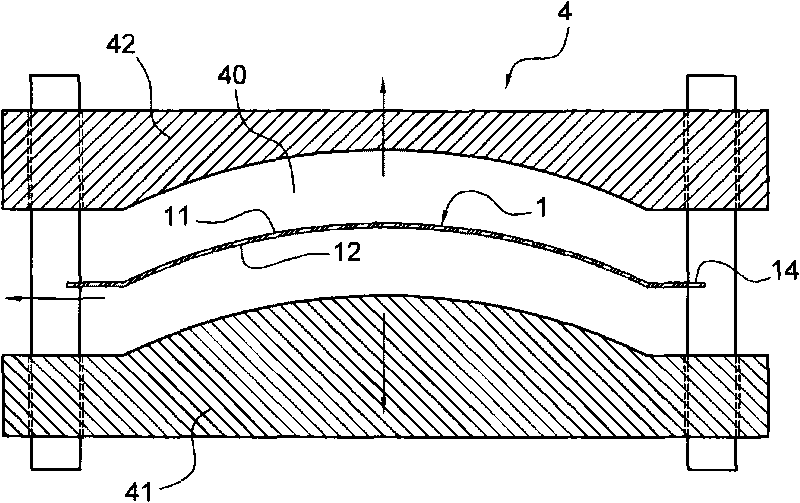

[0055] (2) Forming the flat flexible circuit board 10 with a curved surface by means of molding. In the mold cavity 40 between a male mold 41 of molding device 4 and a female mold 42 (as Figure 2A shown), the male mold 41 and the female mold 42 are preheated to a preset temperature (about 200 to 250 degrees Celsius), and the preset temperature can be used to thermally mold the planar flexible circuit board 10 Molding temperature; in this way, the flat flexible circuit board 10 can be clamped and hot-pressed by the male mold 41 and the female mold 42 to mold the flat flexible circuit b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com