Polyethylene oxide (PEO)-based solid polymer electrolyte membrane and preparation method thereof

A solid polymer, electrolyte membrane technology, used in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, circuits, etc., can solve the problems of poor thermal and electrical properties, and achieve good moldability, uniform texture, and excellent mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0041] Dissolve PEO (0.7g) in dichloromethane (40ml) and seal it and place it in an iodine bottle for 12h. Then take PMMA (0.3g) and dissolve it in dichloromethane (10ml). in methyl chloride solution. Stir well, heat until fully dissolved, then add lithium perchlorate (0.1g) and stir at room temperature until fully dissolved. Put the rotor into the iodine flask, seal it, and stir magnetically at 700rmp for 90min at 25°C.

[0042] Weigh the LCI / MMT hybrid material (0.004g) and dissolve it in a test tube by shaking with 2ml N-methylpyrrolidone. Add the LCI / MMT solution to the PEO / PMMA solution and mix and stir evenly. For scraping the film, the thickness of the scraper is set to 0.5 mm. The homogeneous film was automatically scraped off, and the prepared film was dried at 50°C for 2 hours in a blast drying oven, and then the substrate was peeled off with a blade. Then vacuum-dry at 45°C for 12 hours to completely remove the solvent.

[0043] The prepared solution was scraped...

example 2

[0047] The difference from Example 1 is that the added amount of LCI / MMT hybrid material is 0.007g.

[0048] The thickness of the obtained film was 0.033 mm.

example 3

[0050] The difference from Example 1 is that the added amount of the LCI / MMT hybrid material is 0.01 g.

[0051] The thickness of the obtained film was 0.031 mm.

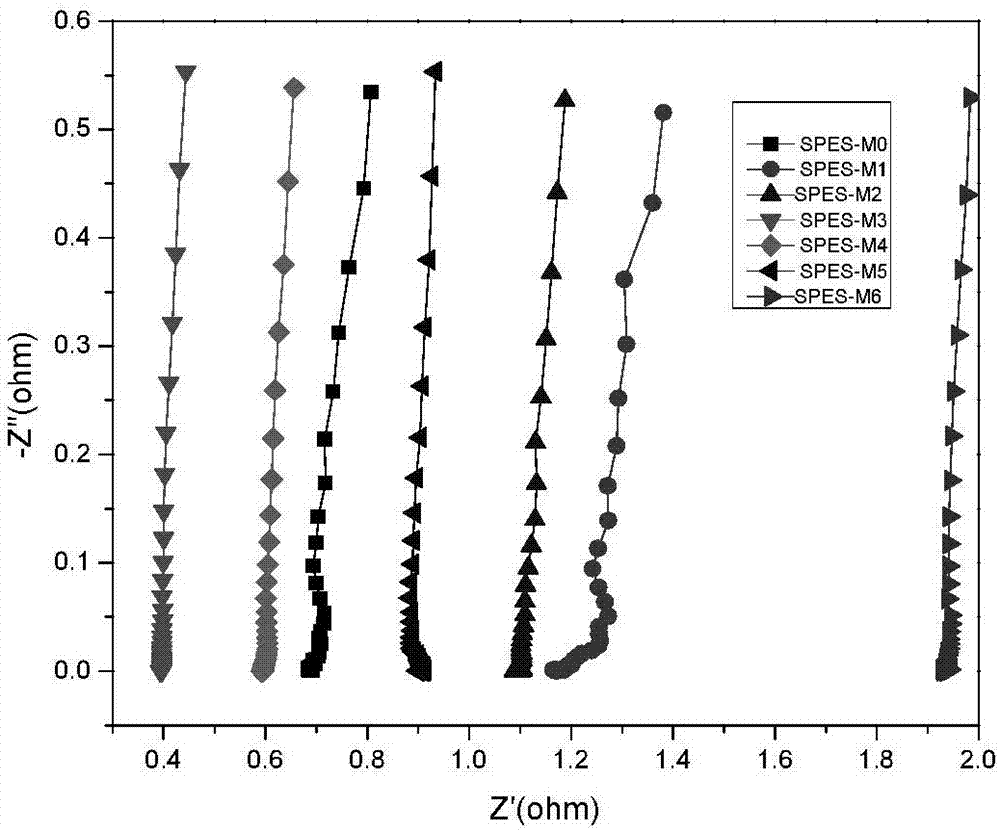

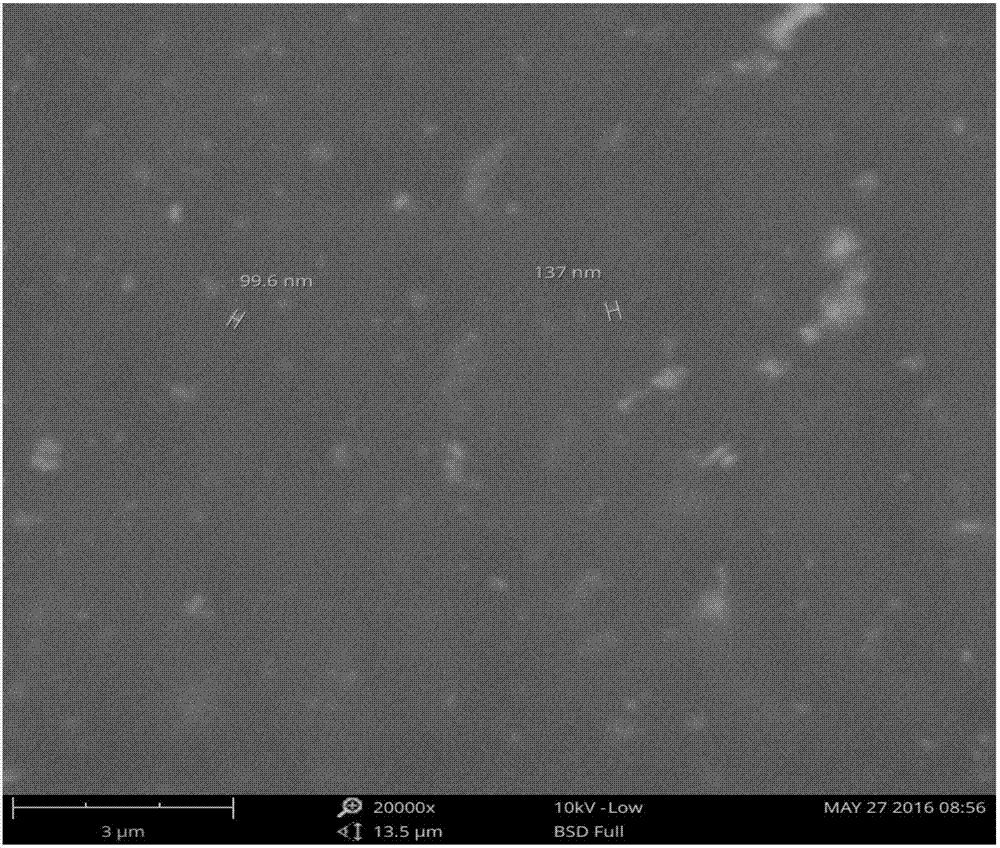

[0052] figure 1 It is the Nyquist curve of the AC impedance of the polymer electrolyte membrane. It can be seen that the intersection point between the low frequency region and the horizontal axis of Example 3 (SPEs-M3) is the smallest, Rb=24.62Ω, and the conductivity σ=4.00×10-3. figure 2 It is the scanning electron microscope picture of Example 3, it can be seen that the particle size of the hybrid material in the film is similar, and the dispersion is uniform.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com