Method for reducing metal and alloy hydroxide gel by hydrogen separated from electrochemistry cathode

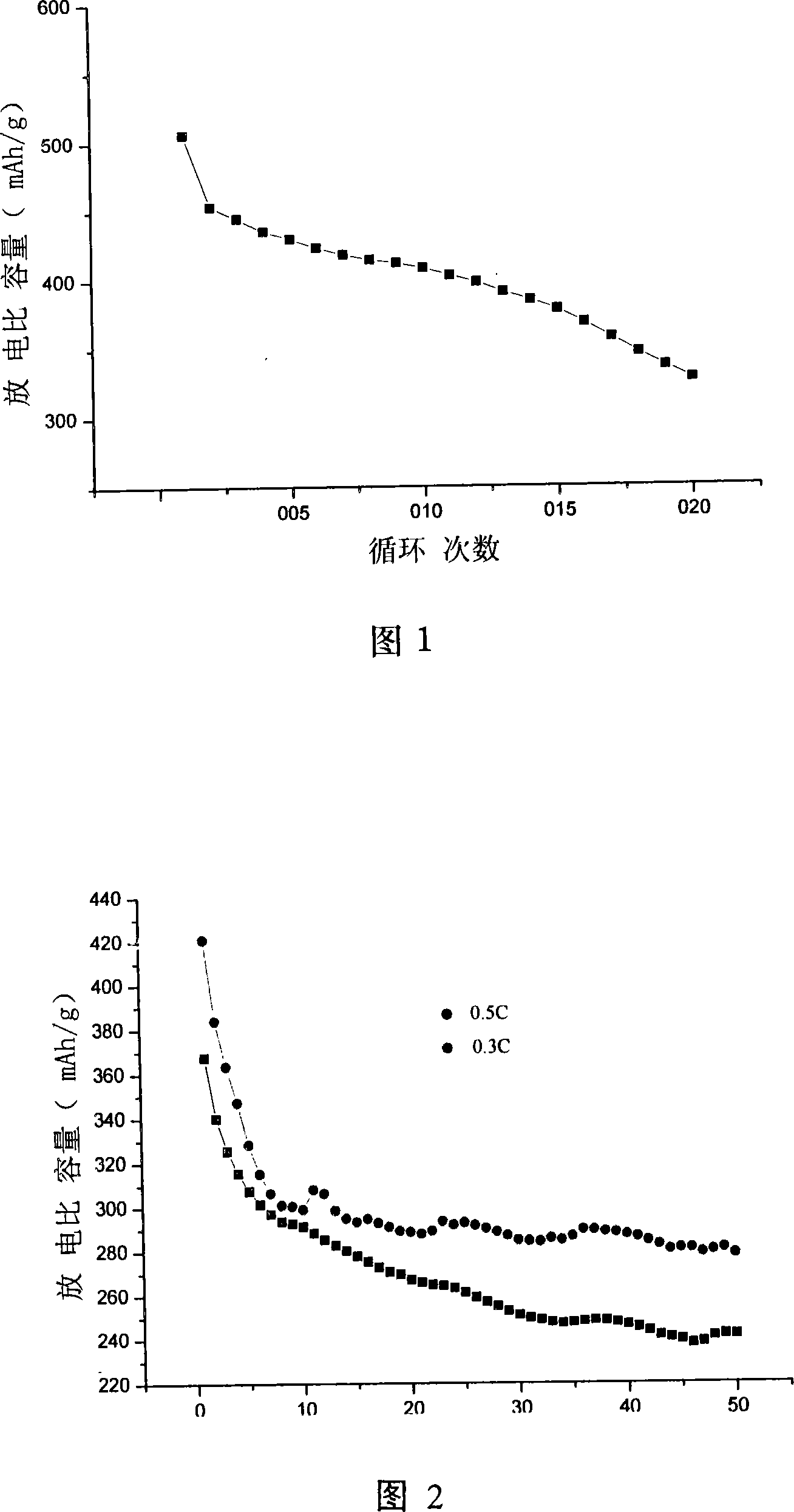

A hydroxide, electrochemical technology, applied in the direction of alkaline battery electrodes, electrolytic coatings, coatings, etc., can solve the problem of difficult to accurately control the content and distribution of carbon particles in the coating, affecting the reproducibility of electrode material performance, mechanical alloying In order to solve the problems of long preparation time and other problems, it achieves the effects of excellent cycle performance, controllable shape and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with examples.

[0039] The present invention is a method of preparing metal hydroxide gel, metal hydroxide-carbon gel, alloy hydroxide gel and alloy hydroxide-carbon gel by using fixed ratio chemical precipitation method, which can be directly reduced by subsequent cathode hydrogen evolution reduction. A method for preparing metal and metal-carbon and alloy and alloy-carbon electrode materials by one-step molding on a copper foil current collector. This method comprises the following steps:

[0040] The first step: prepare metal hydroxide gel or metal hydroxide-carbon gel or alloy hydroxide gel or alloy hydroxide-carbon gel by fixed ratio chemical precipitation method,

[0041] First prepare the solution to prepare the gel:

[0042] 1. The solvent is distilled water or deionized water, the solute is tin chloride or tin sulfate, the concentration is 0.01~5mol / L, mol means mole, L means lite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com