3D printing light-cured ceramic particle and preparation method thereof

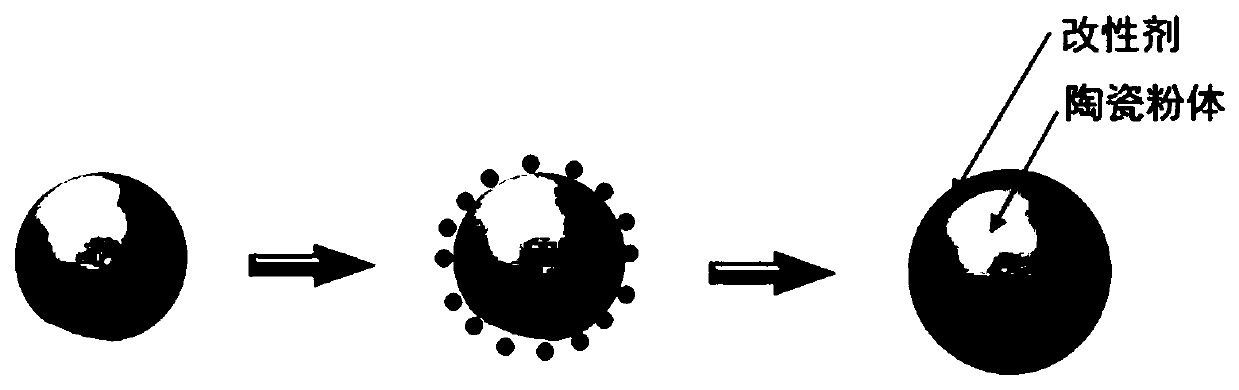

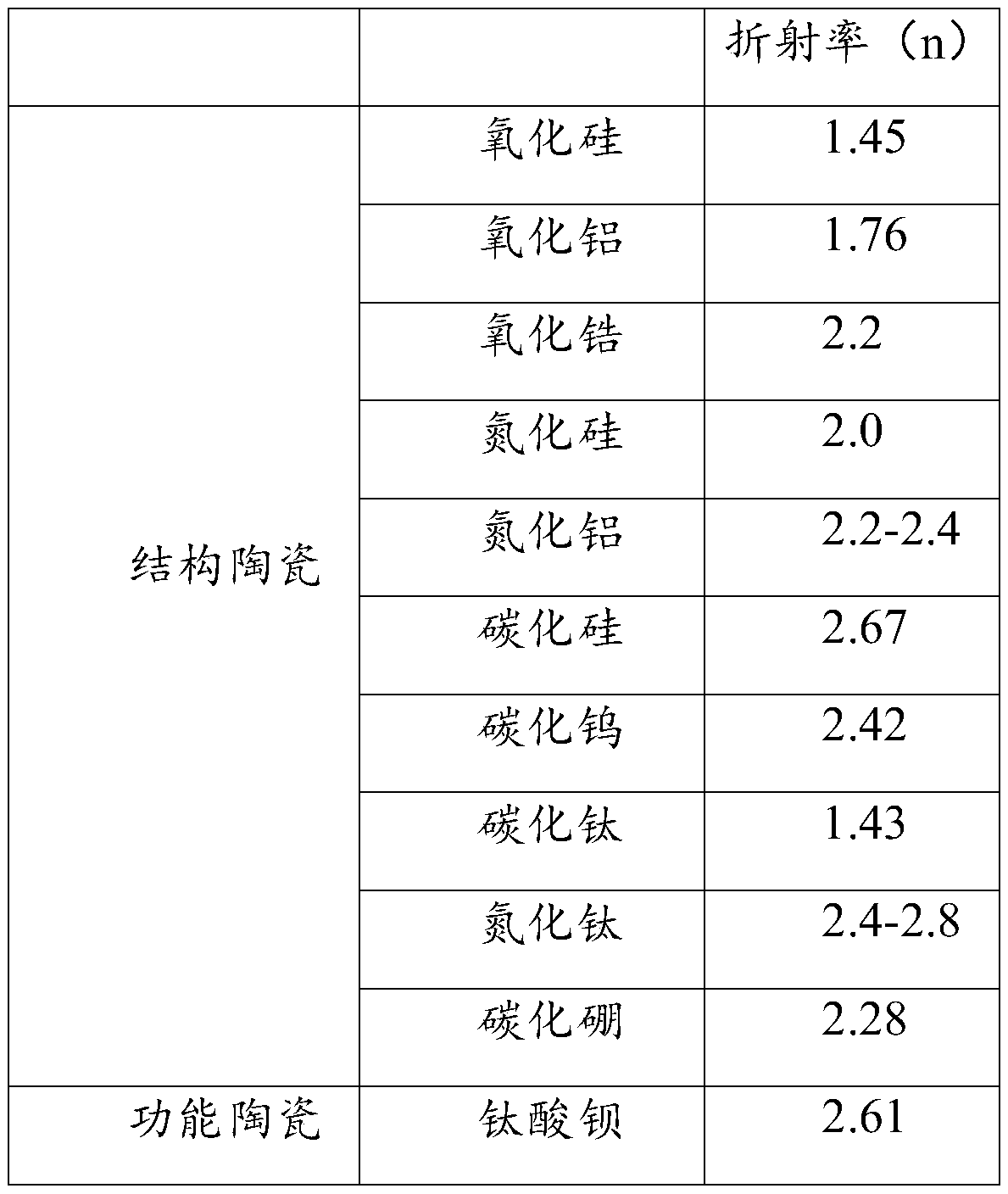

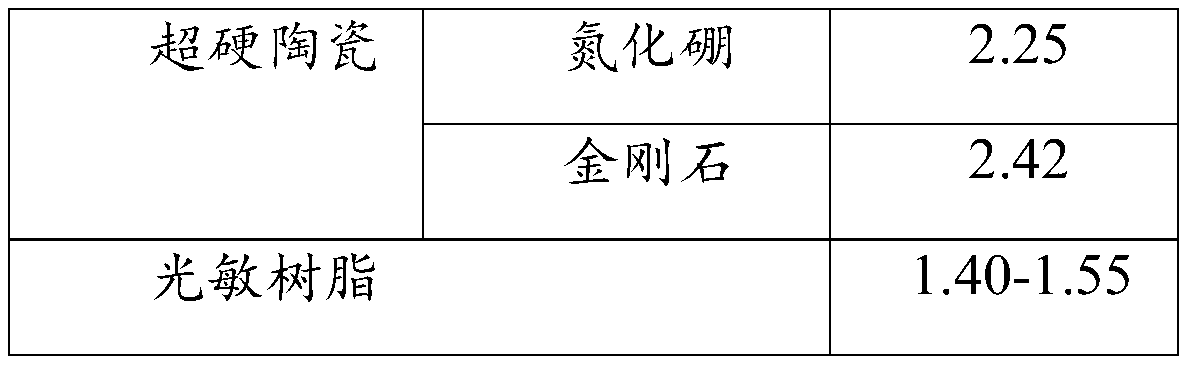

A ceramic particle, 3D printing technology, applied in the field of ceramic 3D printing, can solve the problems of reducing the curing depth of the slurry, reducing the curing depth, and reducing the printing efficiency, so as to reduce the curing width, increase the curing depth, and improve the printing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] 1. Prepare raw materials

[0054] The ceramic powder raw material is selected as zirconia, the coated sintering aid is selected as alumina, the solvent is selected as ethanol, the dispersant is polyethylene glycol (PEG), and the precipitating agent is urea.

[0055] 2. Preparation of ceramic particles wrapped with sintering aid layer

[0056] Dissolve aluminum chloride / aluminum nitrate in ethanol, then add zirconia powder and dispersant PEG to the above solvent, and then add precipitant urea dropwise to the above solution, so that the aluminum hydroxide is evenly coated on the The zirconia surface is finally filtered, dried and calcined to obtain alumina-coated zirconia ceramic powder, wherein the thickness of the coating layer is 2nm.

Embodiment 2

[0058] 1. Prepare raw materials

[0059] The ceramic powder raw material is silicon nitride, the coating sintering aid is yttrium oxide and aluminum oxide, the solvent is ethanol, the dispersant is ammonium citrate, and the precipitant is urea.

[0060] 2. Preparation of ceramic particles wrapped with sintering aid layer

[0061] Dissolve yttrium nitrate and aluminum nitrate in solvent ethanol, then add silicon nitride powder and dispersant ammonium citrate to the above solution, and then add precipitant urea dropwise to the above solution, so that the hydroxide of yttrium and aluminum Evenly coated on the surface of silicon nitride, finally filtered, dried and calcined to obtain silicon nitride ceramic powder coated with yttrium oxide and aluminum oxide, wherein the thickness of the coating layer is 5nm.

Embodiment 3

[0063] 1. Prepare raw materials

[0064] The ceramic powder raw material is silicon nitride, the coated sintering aid is yttrium oxide and magnesium oxide, the solvent is ethanol, the dispersant is hyperdispersant, and the precipitant is triethanolamine.

[0065] 2. Preparation of ceramic particles wrapped with sintering aid layer

[0066] Dissolve yttrium nitrate and magnesium nitrate in solvent ethanol, then add silicon nitride powder and dispersant hyperdispersant to the above solvent, and then add the precipitant triethanolamine dropwise to the above solution to make the hydroxide of yttrium and aluminum The material is uniformly coated on the surface of silicon nitride, and finally filtered, dried, and calcined to obtain silicon nitride ceramic powder coated with yttrium oxide and magnesium oxide. The thickness of the coating layer is 8nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com