Mineral slurry flux on-line detecting device and multi-parameter on-line detecting integrated system

A detection device and measurement device technology, which is applied in the direction of measurement device, liquid/fluid solid measurement, flow rate measurement/mass flow rate, etc., can solve problems such as low measurement accuracy, lower product quality, and inability to carry out online, so as to achieve accurate measurement results, Improve production efficiency and meet production requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

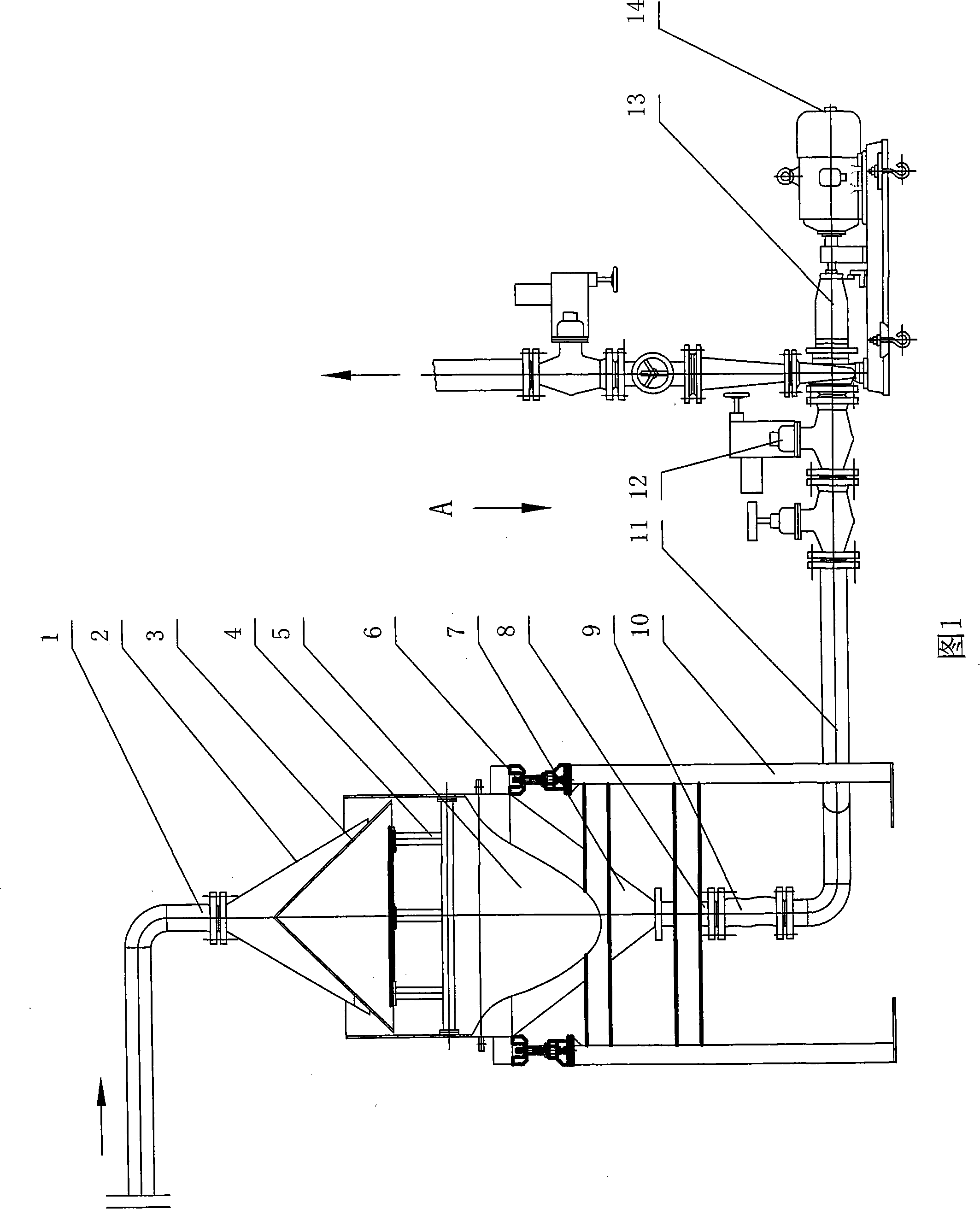

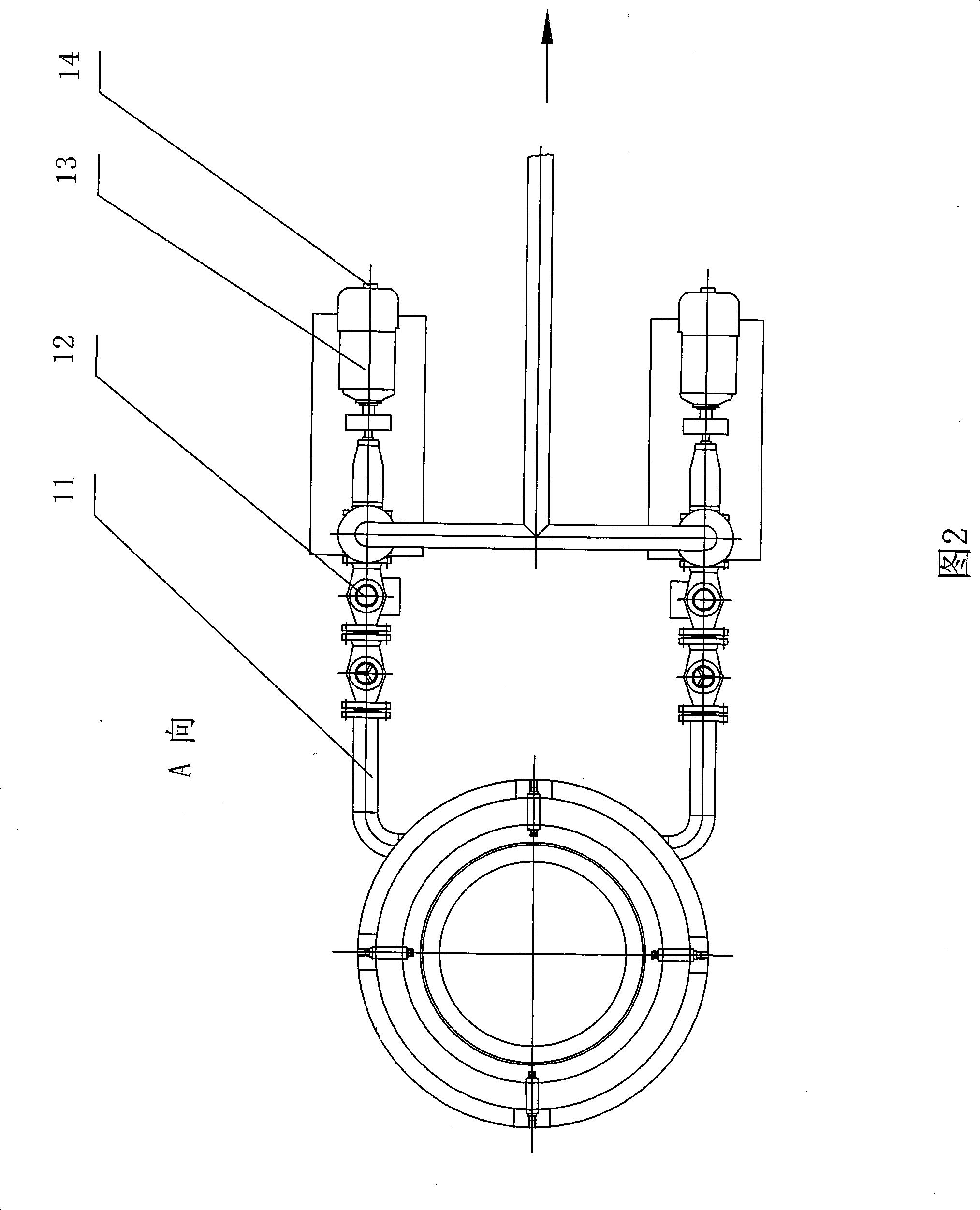

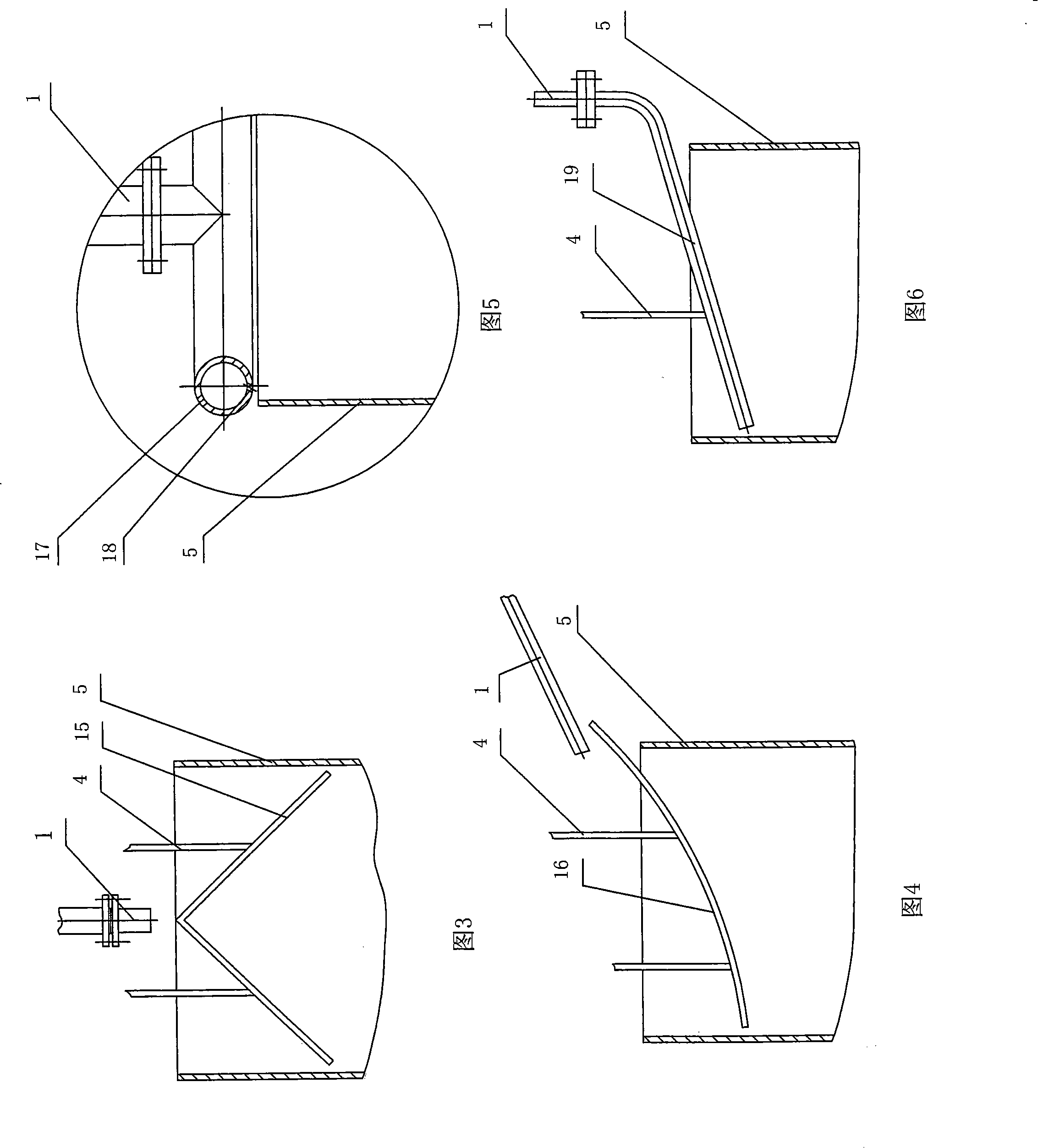

[0053] The present invention will be further described below in conjunction with the accompanying drawings, but the content of the present invention is not limited thereto.

[0054] In the on-line detection device for pulp flow provided by the present invention, the outlet end of the pulp feeding pipe 1 is equipped with a conical shielding cover 2, and below the shielding cover 2 is a distributor 3, which is a cone with the top of the cone upwards, and The support frame 4 is fixed on the inner wall of the pulp container 5, so that a pulp flow gap is formed between the bottom end of the cone of the distributor 3 and the inner wall of the pulp container 5, so that after the pulp flows out from the feeding pipe 1, it passes through the cone surface of the distributor 3 and The gap flows into the pulp container 5, and the shielding cover 2 is used to prevent the pulp from splashing out. The upper part of the pulp container 5 is a cylinder, and the lower part is a cone 7. The discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com