Production method of composite material automobile parts

A technology for auto parts and production methods, which is applied in the production field of composite auto parts, can solve the problems of large carbon dioxide exhaust emissions, aggravated environmental pollution, large fuel consumption, etc., and achieves low cost, high surface brightness, and reduced concentration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

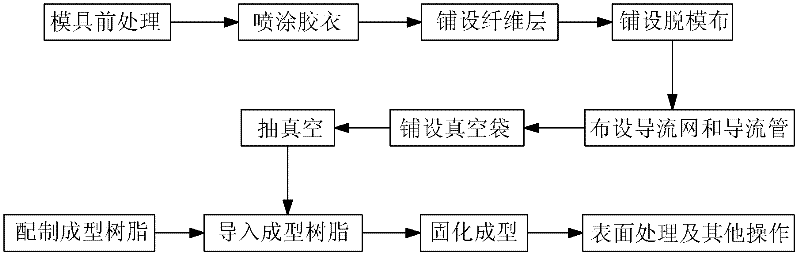

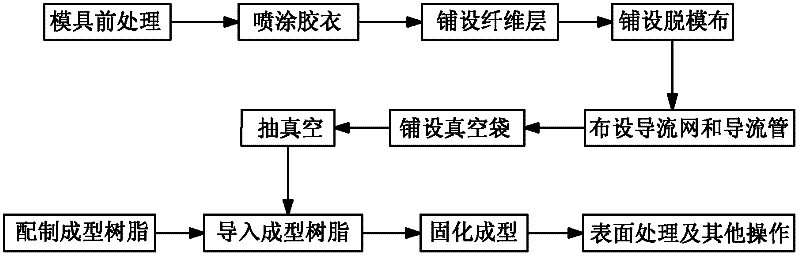

Method used

Image

Examples

example 1

[0020] Example 1: Preparation method of automobile fender

[0021] 1) Mold pre-treatment: first wipe the mold clean with acetone, then apply release wax twice on the surface of the mold, and dry for 3 minutes after each coating, before proceeding to the next operation.

[0022] 2) Gel coat: Mix and stir the curing agent and gel coat resin, the amount of curing agent is 4% of the total mixture mass, the total amount of gel coat and curing agent is 800g, and stir for 8 minutes. Apply the gel coat evenly on the surface of the mold with a brush and cure for 12 hours.

[0023] 3) Raw material resin: choose epoxy resin as the raw material resin, mix epoxy resin and curing agent according to the ratio of 100:15, and the ratio of epoxy resin to fiber is 2:3, after mixing the three, stir for 20 minutes and set aside .

[0024] 4) Laying fiber cloth: first cut the fiber cloth according to the size of the fender to be processed, then bake it at 50°C for 120 minutes, and lay five layers...

example 2

[0028] Example 2: Preparation method of automobile roof cover

[0029] 1) Mold pre-treatment: Wipe the mold clean with acetone first, then apply release wax on the surface of the mold 4 times, dry for 10 minutes after each coating, and then proceed to the next operation.

[0030] 2) Gel coat: Mix and stir the curing agent and gel coat resin, the amount of curing agent is 3.5% of the total mixture mass, the total amount of gel coat and curing agent is 1000g, and stir for 10 minutes. Spray the gel coat on the surface of the mold by spraying, the spraying air source pressure is 0.8Mpa, the distance between the nozzle and the mold surface is 40cm when spraying, and it is cured for 24 hours.

[0031] 3) Raw material resin: choose epoxy resin as the raw material resin, mix epoxy resin and curing agent according to the ratio of 100:25, and the ratio of epoxy resin to fiber is 1:1, after mixing the three, stir for 25 minutes and set aside .

[0032] 4) Laying fiber cloth: first cut ...

example 3

[0036] Example 3: Preparation method of car door outer panel

[0037] 1) Mold pre-treatment: Wipe the mold clean with acetone first, then apply release wax on the surface of the mold 3 times, dry for 6 minutes after each coating, and then proceed to the next operation. .

[0038] 2) Gel coat: Mix and stir the curing agent and gel coat resin, the amount of curing agent is 3% of the total mixture mass, the total amount of gel coat and curing agent is 80g, and stir for 8 minutes. Apply the gel coat evenly on the surface of the mold with a brush and cure for 12 hours.

[0039] 3) Raw material resin: choose epoxy resin as the raw material resin, mix epoxy resin and curing agent according to the ratio of 100:35, and the ratio of epoxy resin to fiber is 3:2, after mixing the three, stir for 20 minutes and set aside .

[0040] 4) Laying fiber cloth: first cut the fiber cloth according to the size of the fender to be processed, then bake it at 50°C for 120 minutes, and lay 2 layers ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com