Automatic paper box positioning and processing method and device for implementing same

A technology of automatic positioning and processing methods, applied in packaging, papermaking, transportation and packaging, etc., can solve problems such as prone to defective products, excessive material waste, and high labor intensity, so as to ensure product quality, improve production efficiency, and reduce labor. The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

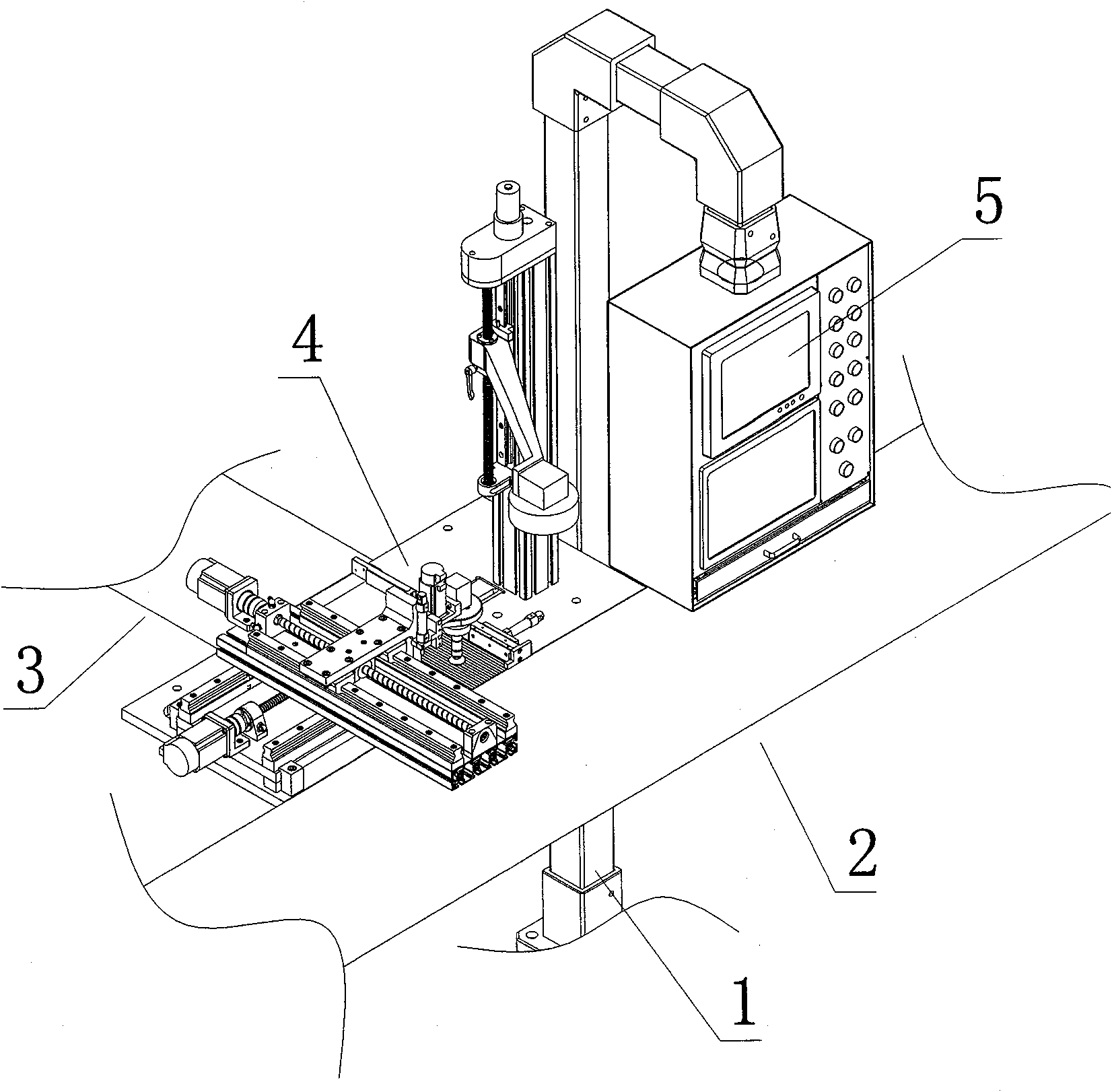

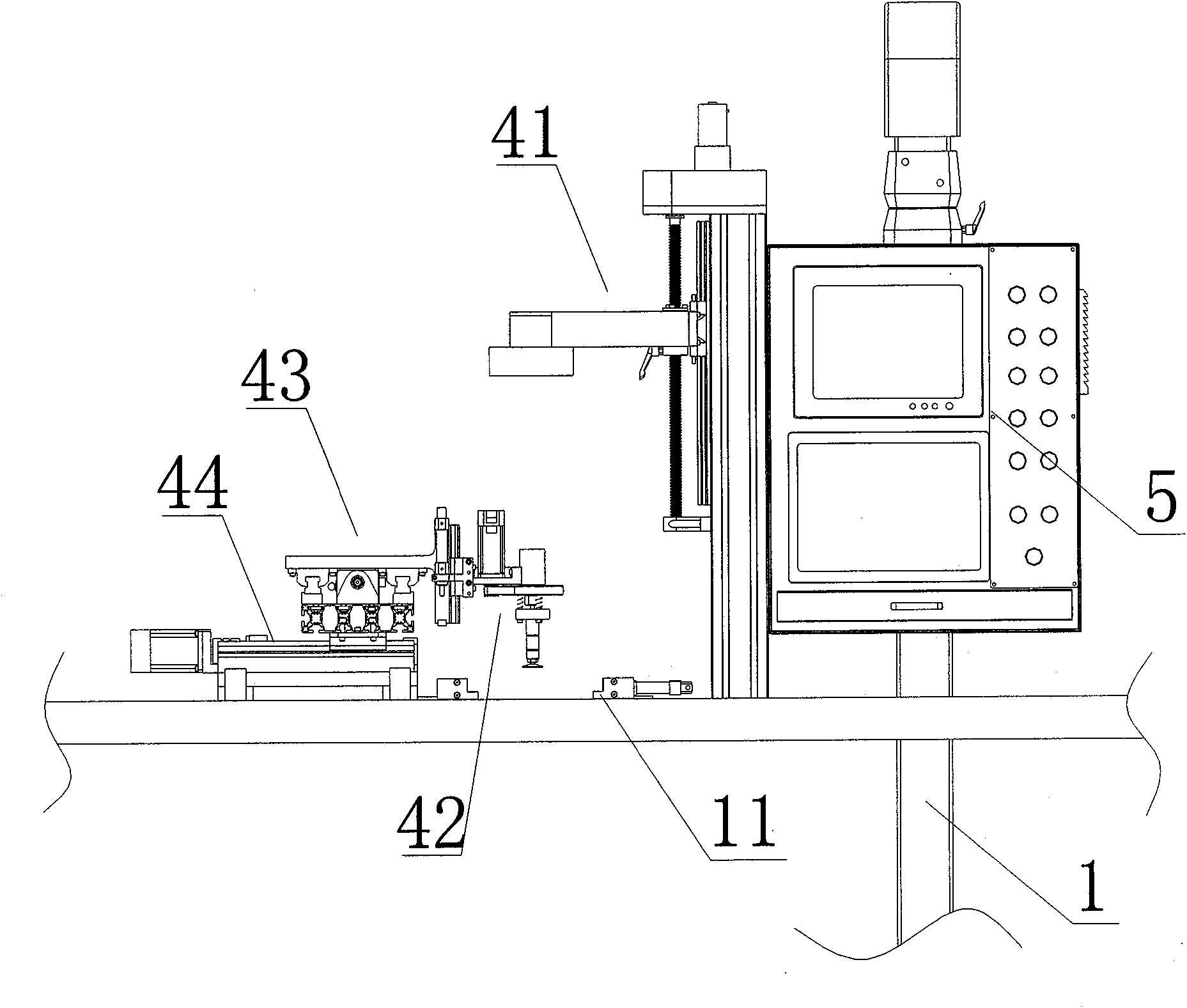

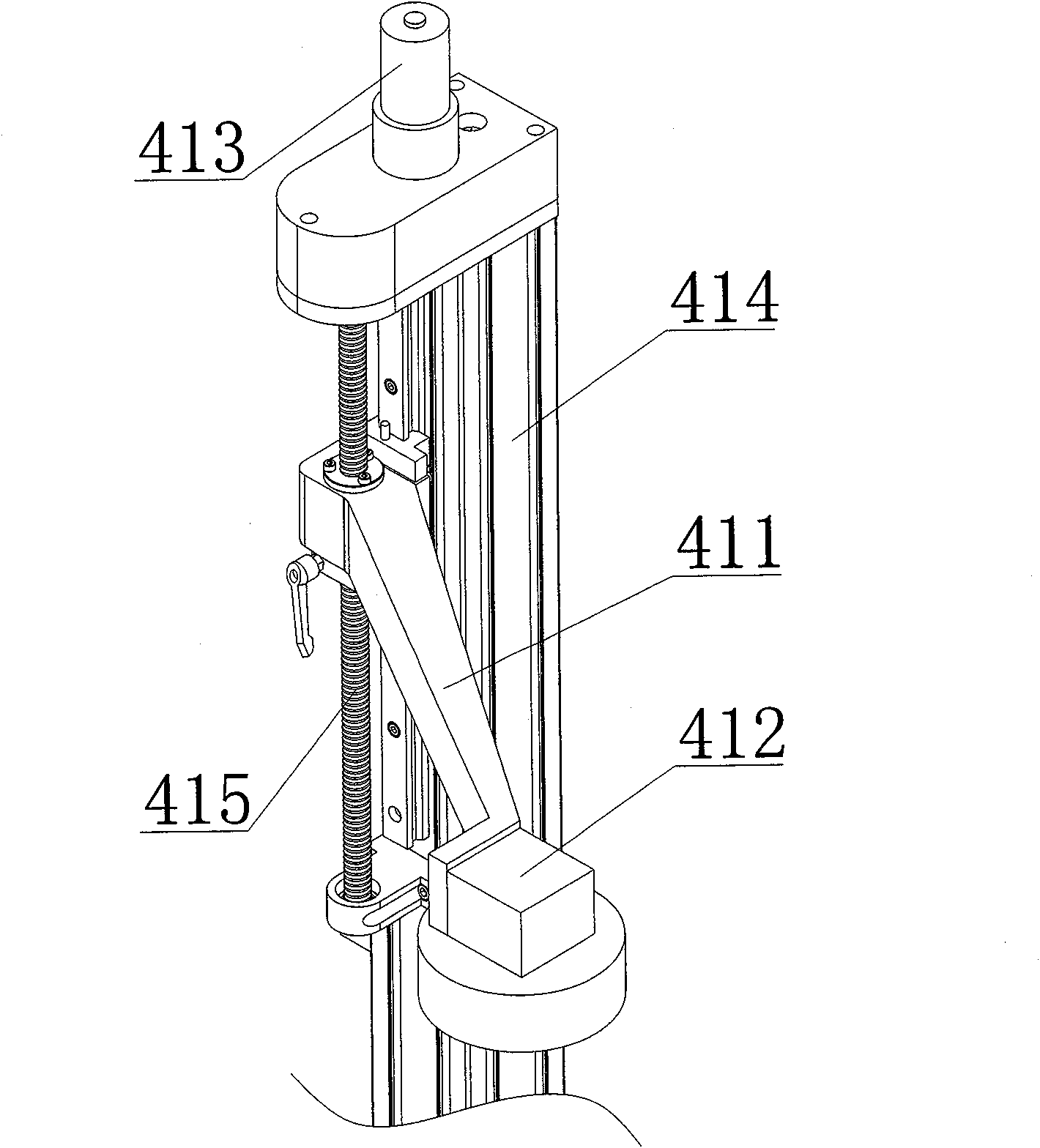

[0045] Example: see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 , a carton automatic positioning processing method provided by an embodiment of the present invention, which includes a carton to be wrapped and a glued cover paper that is compatible with the carton to be wrapped, and includes the following steps:

[0046] (1) A carton conveying device 2 is set, and by controlling the work of the carton conveying device 2, the carton conveying belt is driven to convey the carton to be wrapped forward;

[0047] (2) One face paper conveying device 3 is set, and by controlling the work of the face paper conveying device 3, to realize driving the face paper conveying belt to convey the glued cover paper forward;

[0048] (3) an automatic positioning system 4 is set, and by controlling the automatic positioning system 4 to work, to realize that the carton to be wrapped is accurately attached to the glued cover paper;

[0049] (4) An automatic control sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com