Automatic plug-in machine for plug-in production of specially-shaped electronic elements of electronic products

A technology of automatic plug-in machine and electronic components, applied in the direction of electrical components, electrical components, etc., can solve the problems of prone to errors, high product defect rate, low production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solution of the present invention will be further described below in conjunction with the drawings and specific embodiments.

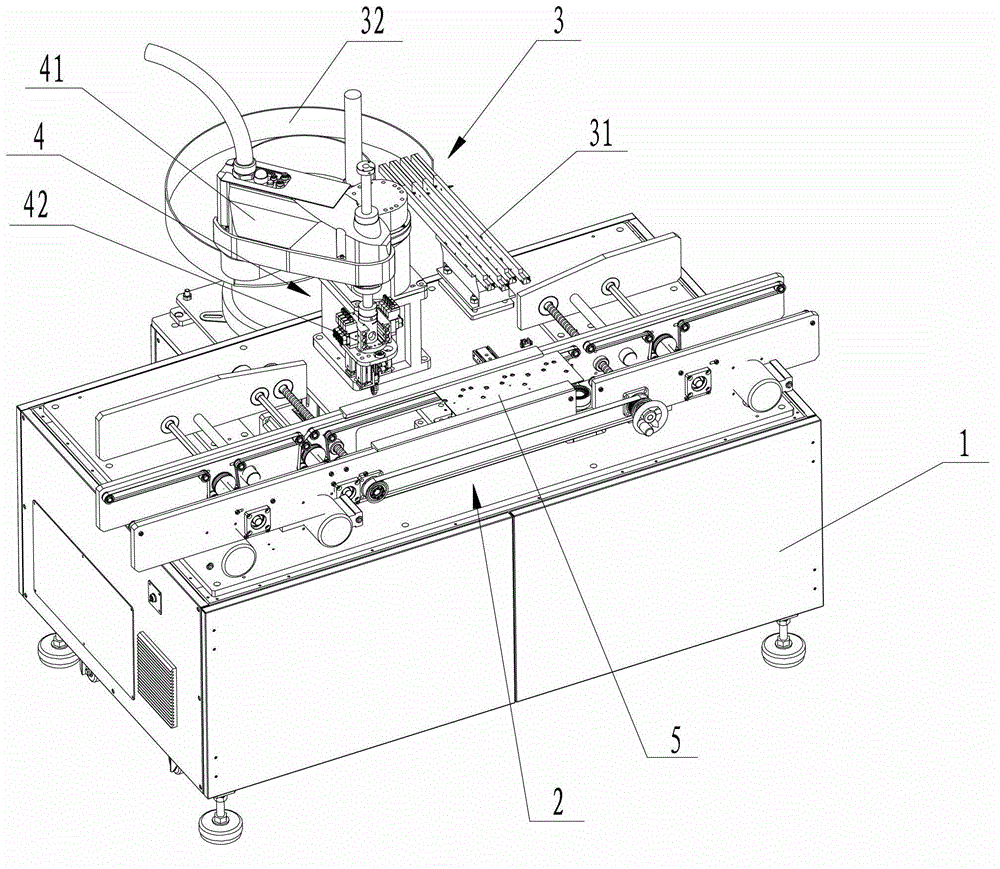

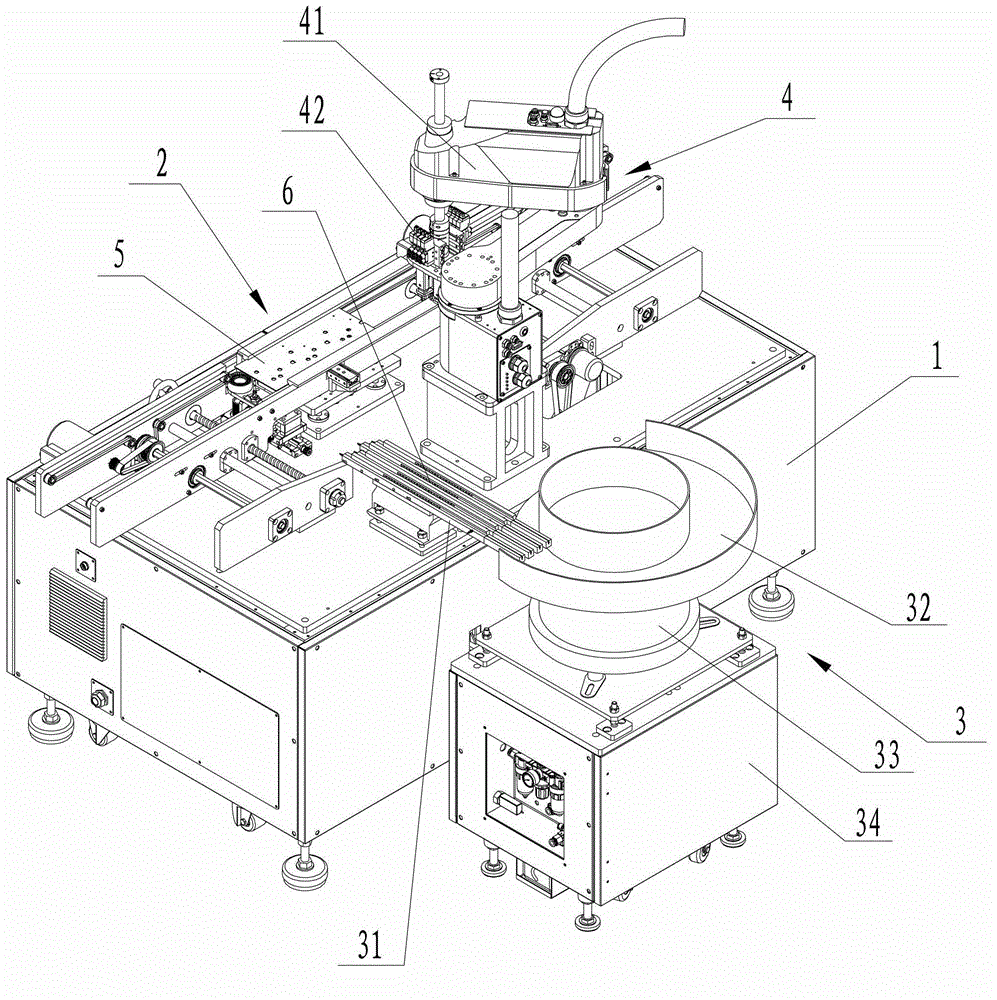

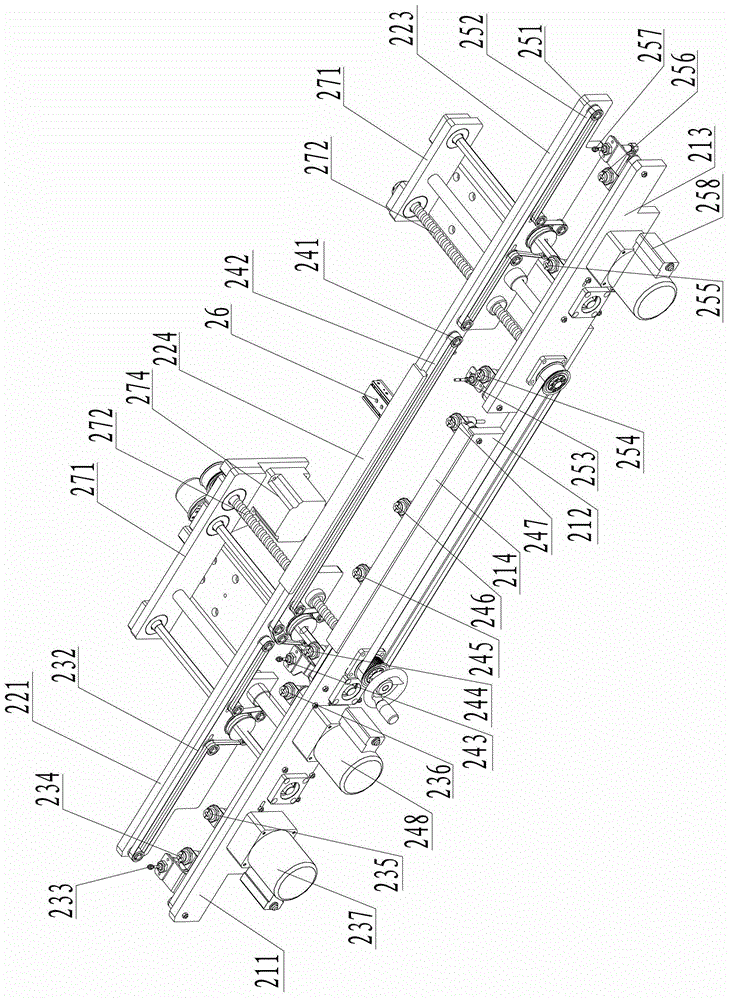

[0032] See Figure 1~2 Shown is an automatic plug-in machine for the production of special-shaped electronic components for electronic products. The electronic product to be produced includes a substrate 5 and a plurality of electronic components 6 inserted on the substrate 5. The electronic components 6 can be conventional electronic components. Components and special-shaped electronic components. The automatic plug-in machine includes a workbench 1, a substrate feeding device set on the workbench 1 for transferring a substrate 5, a component feeding device 3 for transporting electronic components 6 to be plugged in, and a device provided on the workbench 1. The component pickup device 4 for picking up the electronic components 6 from the component feeding device 3 and inserting the picked up electronic components 6 on the substrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com