Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Improved piezoelectric response" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

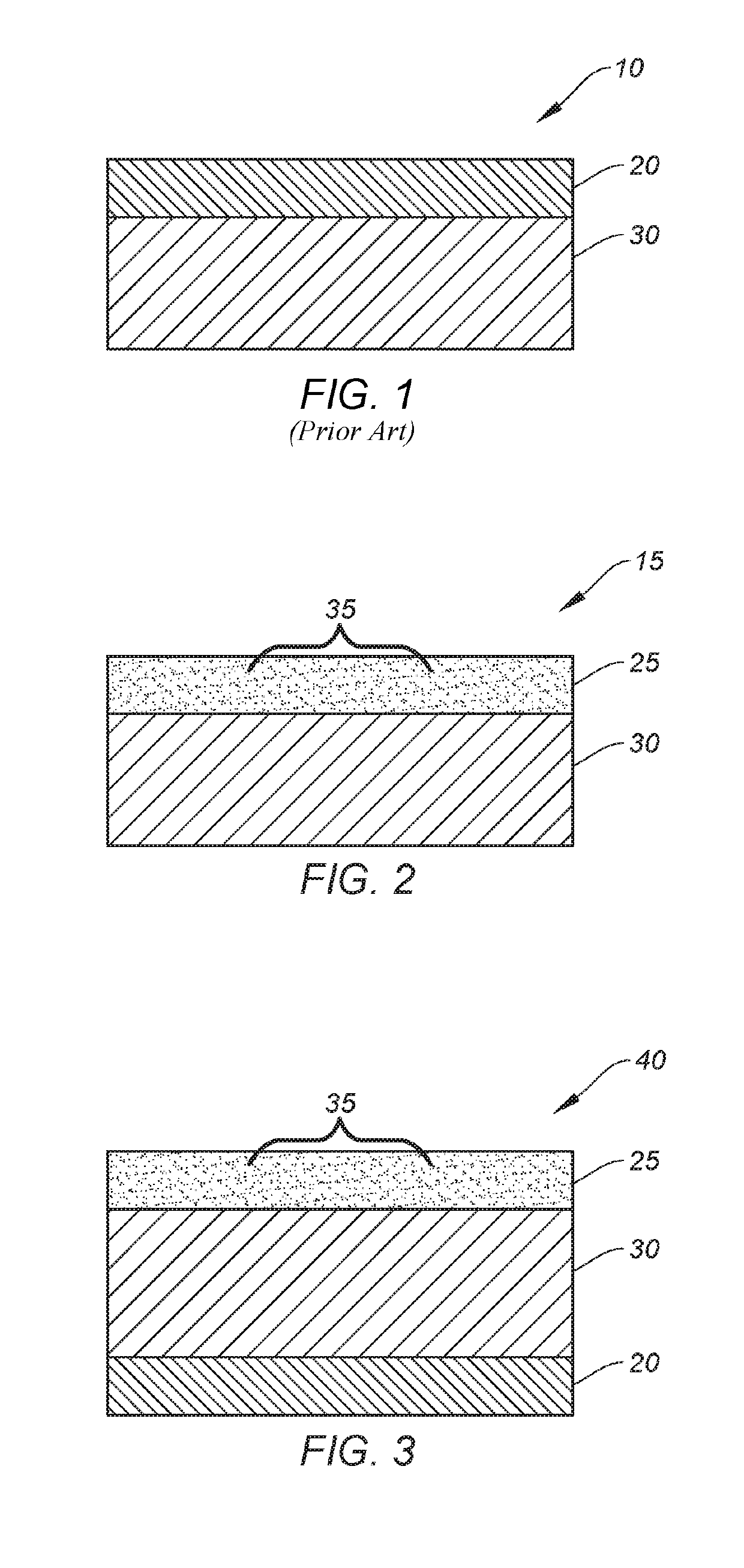

Electrostrictive and piezoelectric thin film assemblies and method of fabrication therefor

InactiveUS6447887B1Avoid misalignmentUniform propertyAnodisationMaterial nanotechnologyMolecular levelEngineering

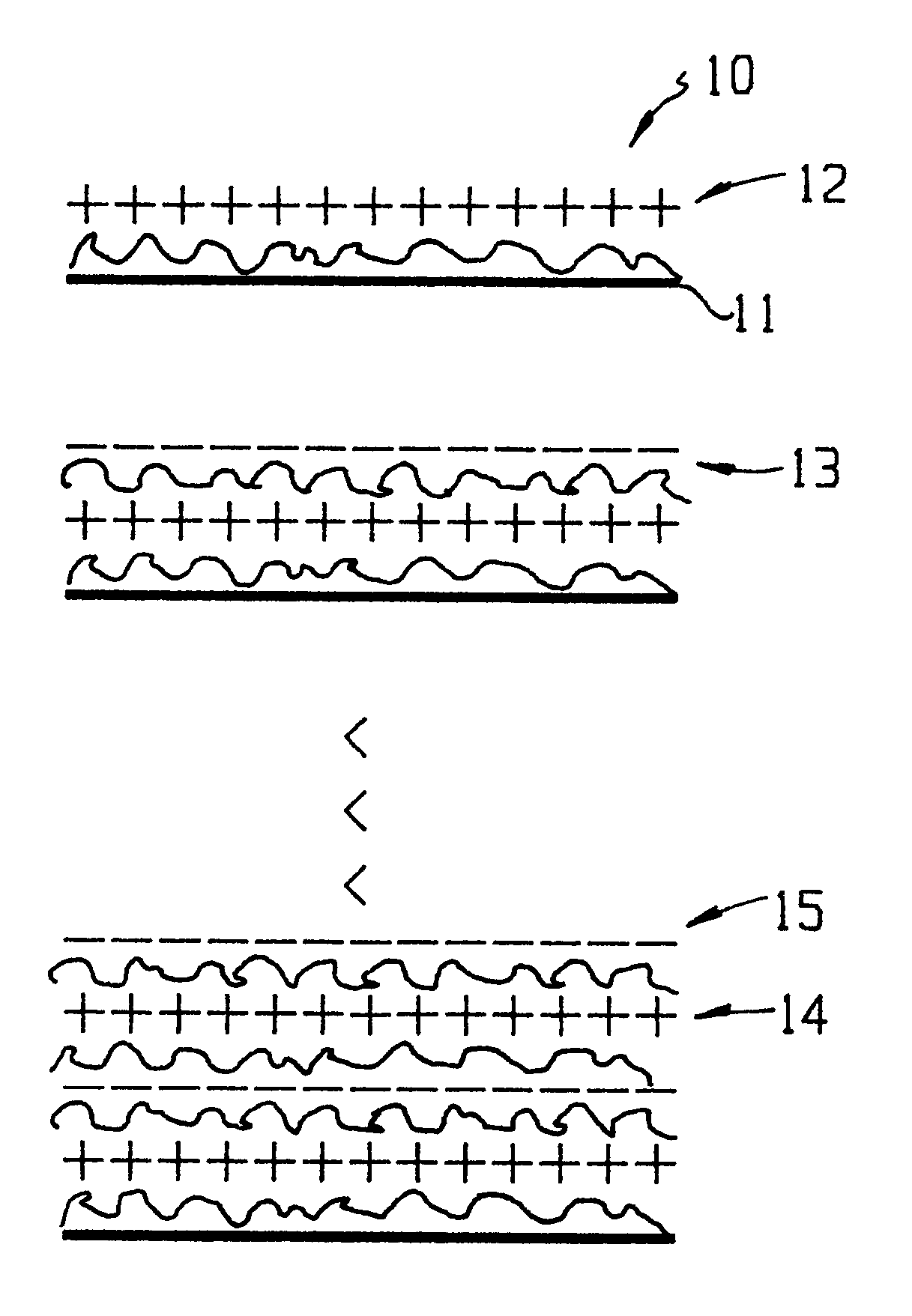

An electrostatic self-assembly method of fabricating electrostrictive and piezoelectric thin film assemblies not only provides a thinner film than is attainable by conventional methods, but provides excellent molecular-level uniformity and precise structural control, and thus large, effective piezoelectric coefficients. The method produces a thin film assembly including (a) a substrate, and (b) a film having one or a plurality of layers disposed upon the substrate, wherein at least one of the layers includes a dipolar material, and this layer of dipolar material has a uniform thickness of at most 500 nm.

Owner:VIRGINIA TECH INTPROP INC

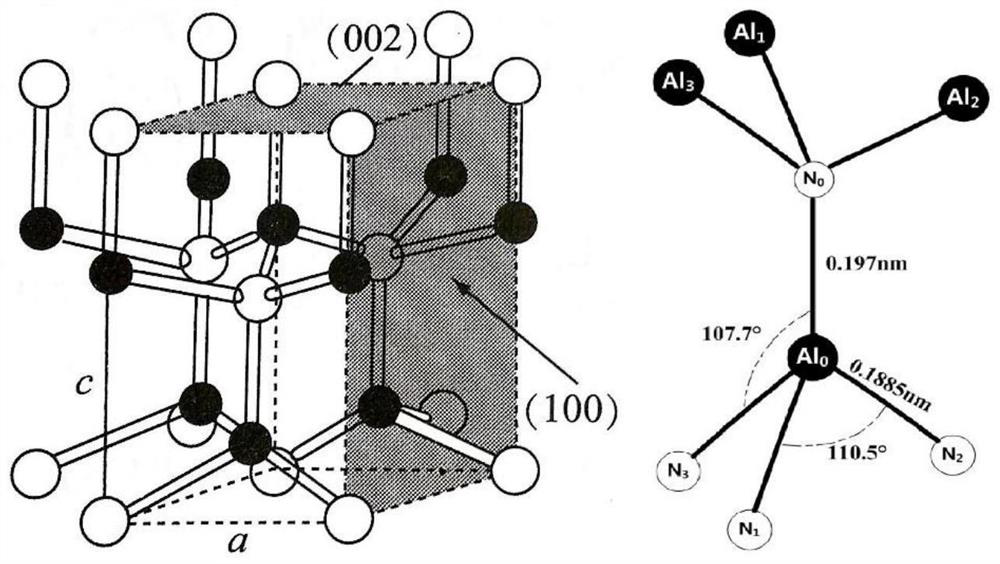

Piezoelectric thin film, piezoelectric material, and fabrication method of piezoelectric thin film and piezoelectric material, and piezoelectric resonator, actuator element, and physical sensor using piezoelectric thin film

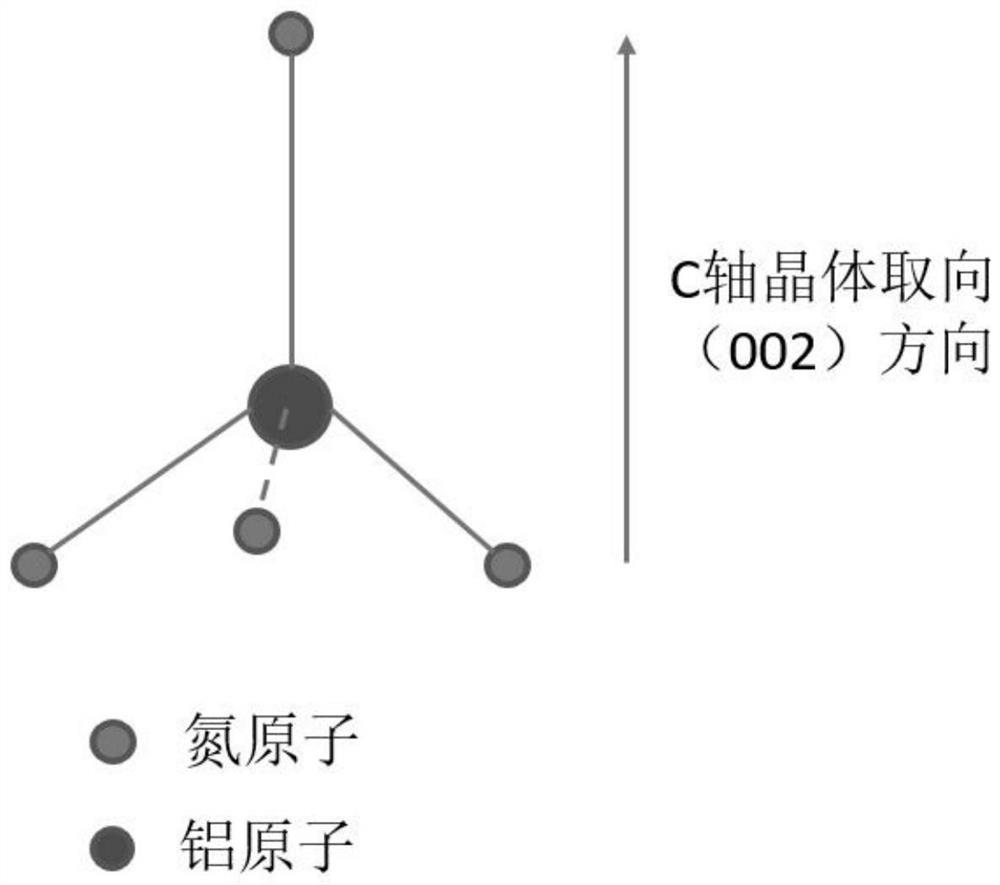

ActiveUS7758979B2Improved piezoelectric responsePiezoelectric response of the aluminum nitride thin film that contains scandium can be further improvedImpedence networksNatural mineral layered productsActuatorTemperature coefficient

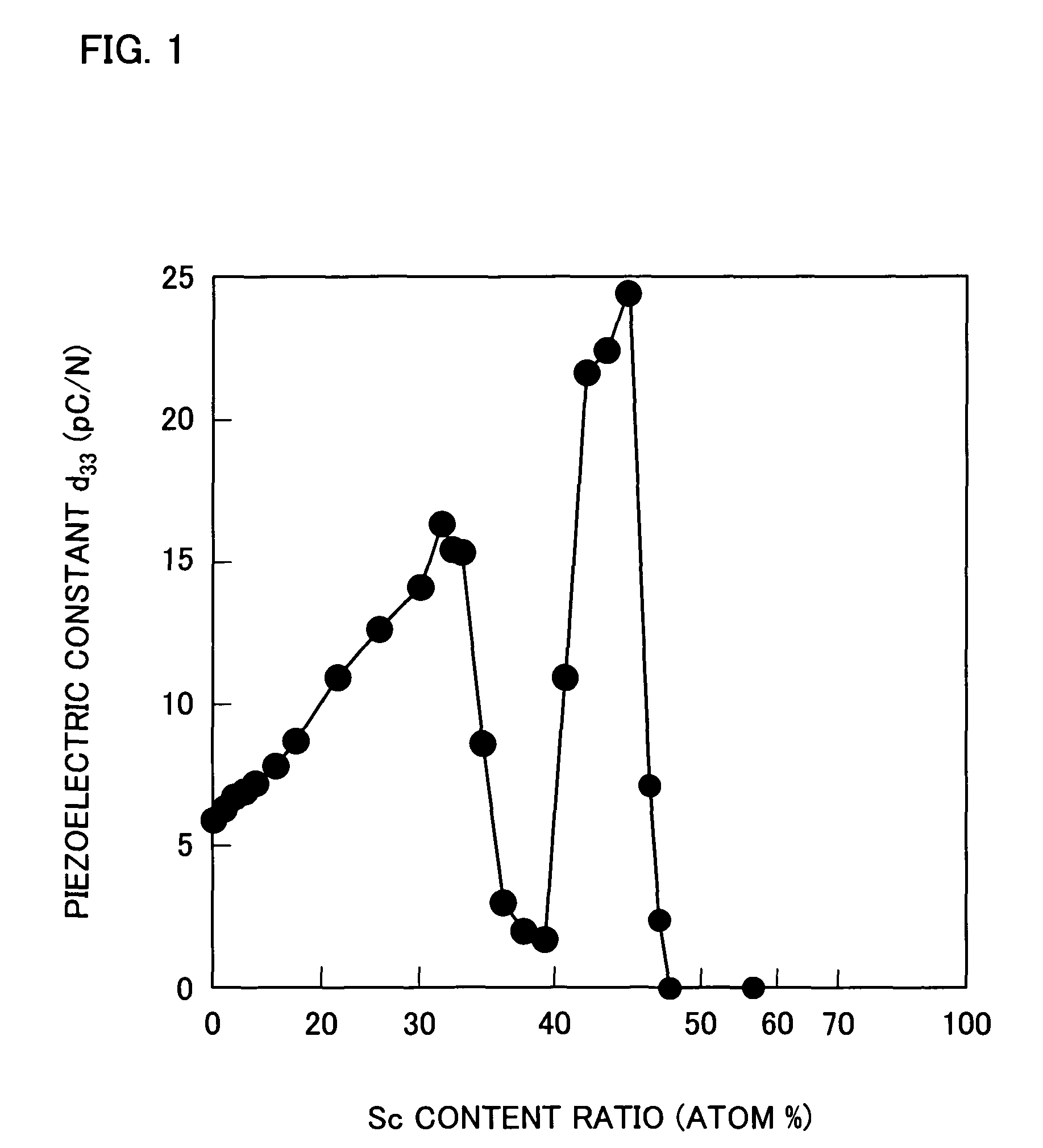

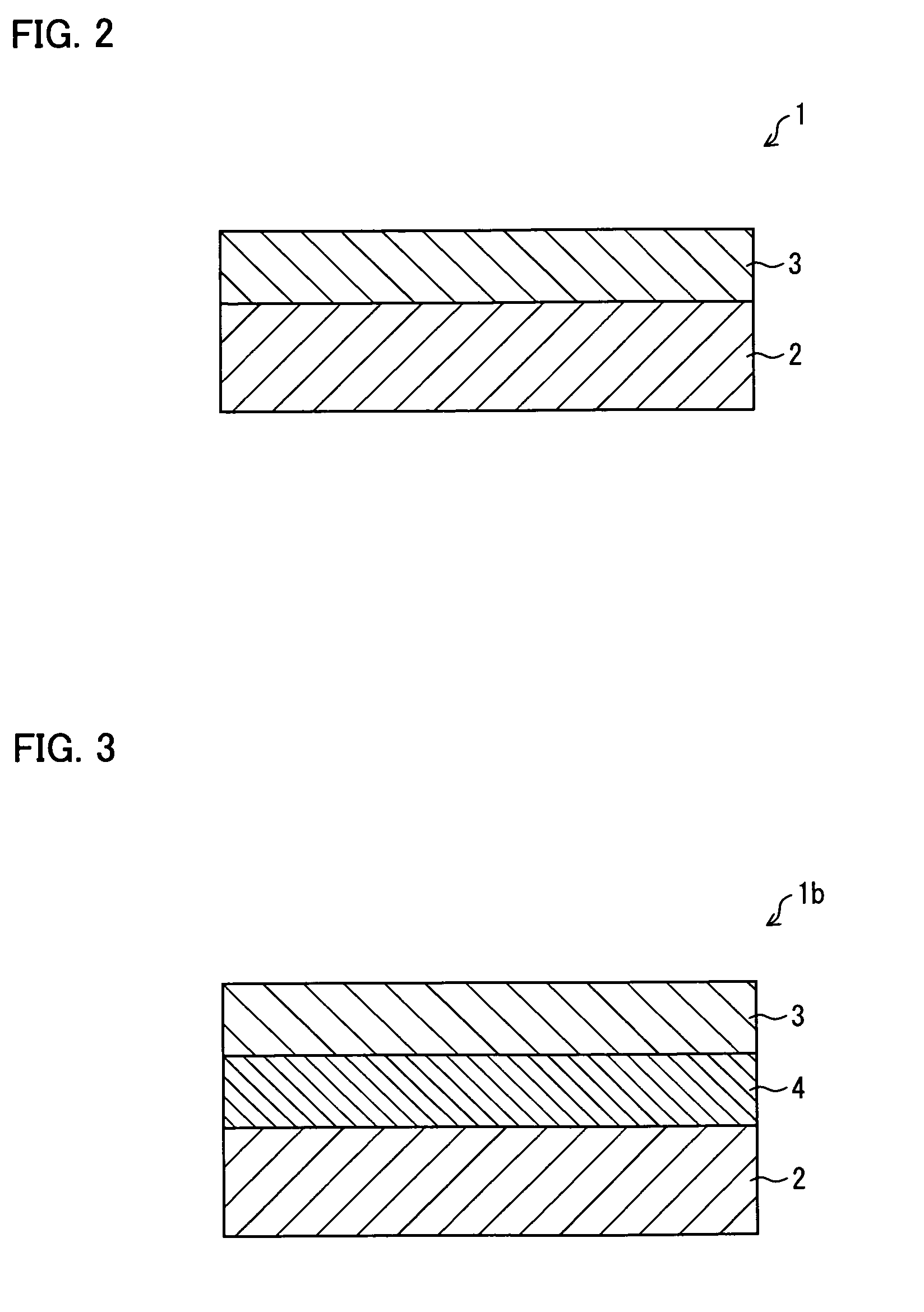

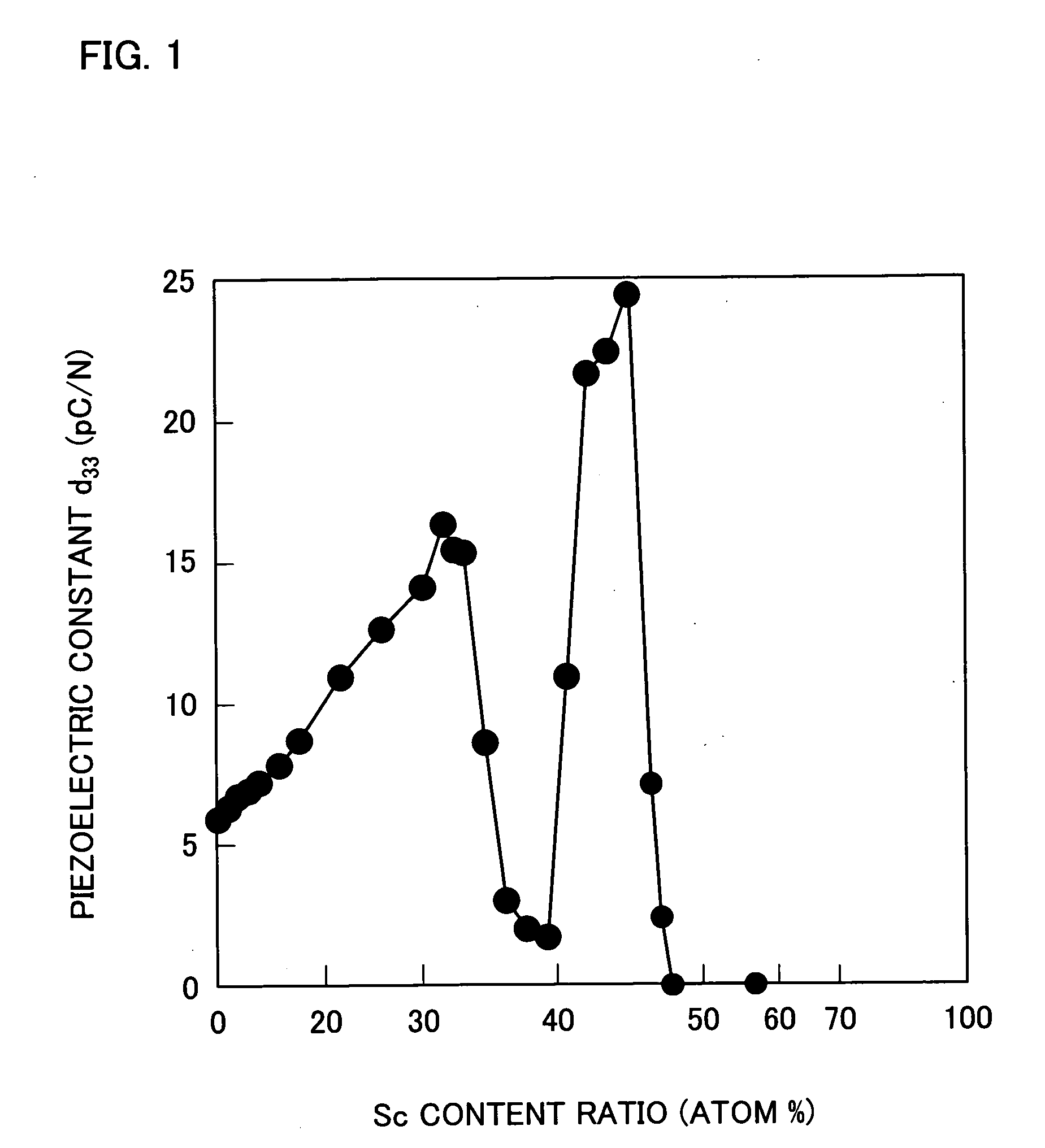

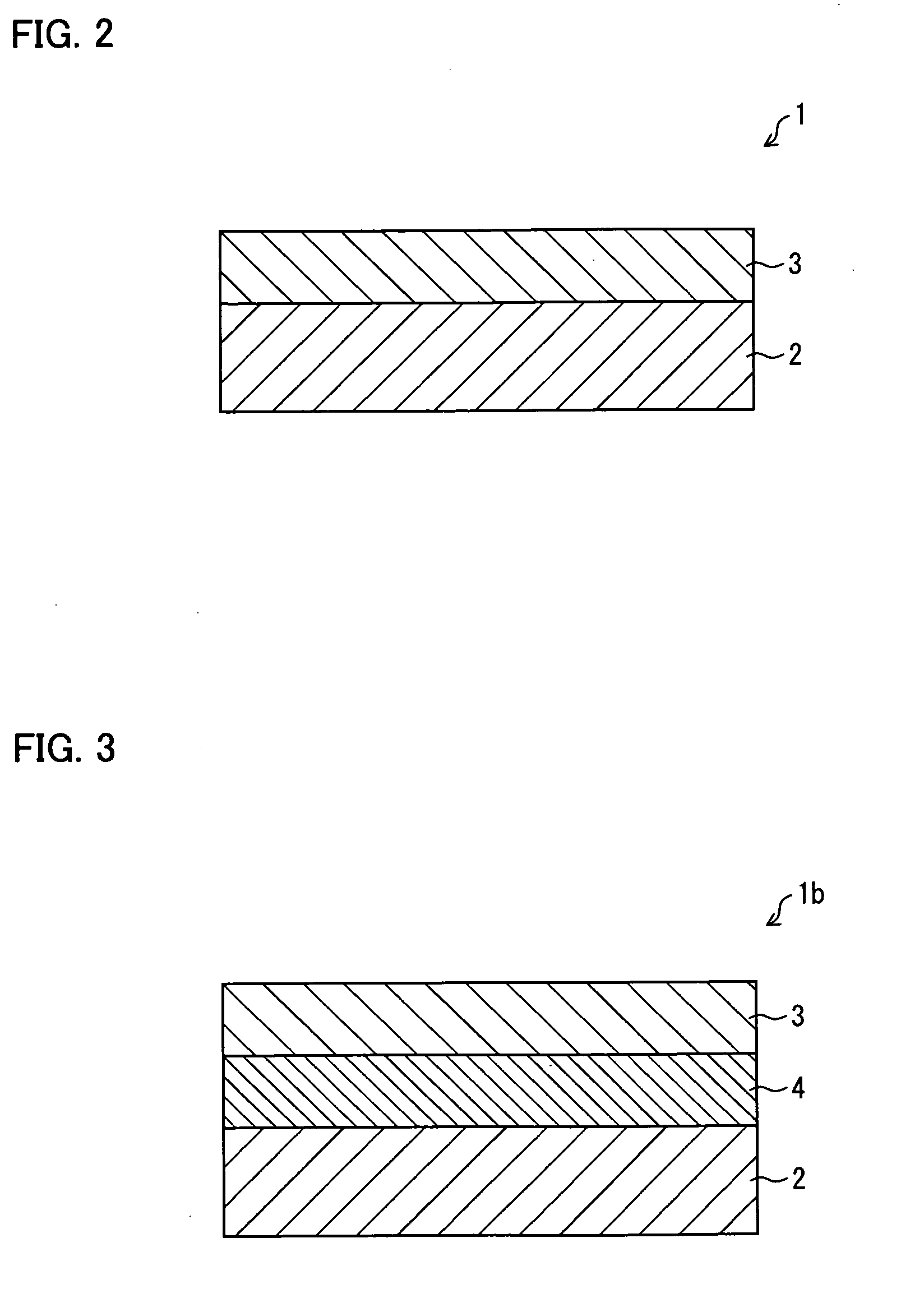

A piezoelectric thin film of the present invention includes an aluminum nitride thin film that contains scandium. A content ratio of scandium in the aluminum nitride thin film is 0.5 atom % to 50 atom % on the assumption that a total amount of the number of scandium atoms and the number of aluminum atoms is 100 atom %. According to this arrangement, the piezoelectric thin film of the present invention can improve a piezoelectric response while keeping characteristics of elastic wave propagation speed, Q value, and frequency-temperature coefficient that the aluminum nitride thin film has.

Owner:NAT INST OF ADVANCED IND SCI & TECH +1

Piezoelectric thin film, piezoelectric material, and fabrication method of piezoelectric thin film and piezoelectric material, and piezoelectric resonator, actuator element, and physical sensor using piezoelectric thin film

ActiveUS20080296529A1Improved piezoelectric responsePiezoelectric response of the aluminum nitride thin film that contains scandium can be further improvedImpedence networksPiezoelectric/electrostrictive device material selectionActuatorTemperature coefficient

A piezoelectric thin film of the present invention includes an aluminum nitride thin film that contains scandium. A content ratio of scandium in the aluminum nitride thin film is 0.5 atom % to 50 atom % on the assumption that a total amount of the number of scandium atoms and the number of aluminum atoms is 100 atom %. According to this arrangement, the piezoelectric thin film of the present invention can improve a piezoelectric response while keeping characteristics of elastic wave propagation speed, Q value, and frequency-temperature coefficient that the aluminum nitride thin film has.

Owner:NAT INST OF ADVANCED IND SCI & TECH +1

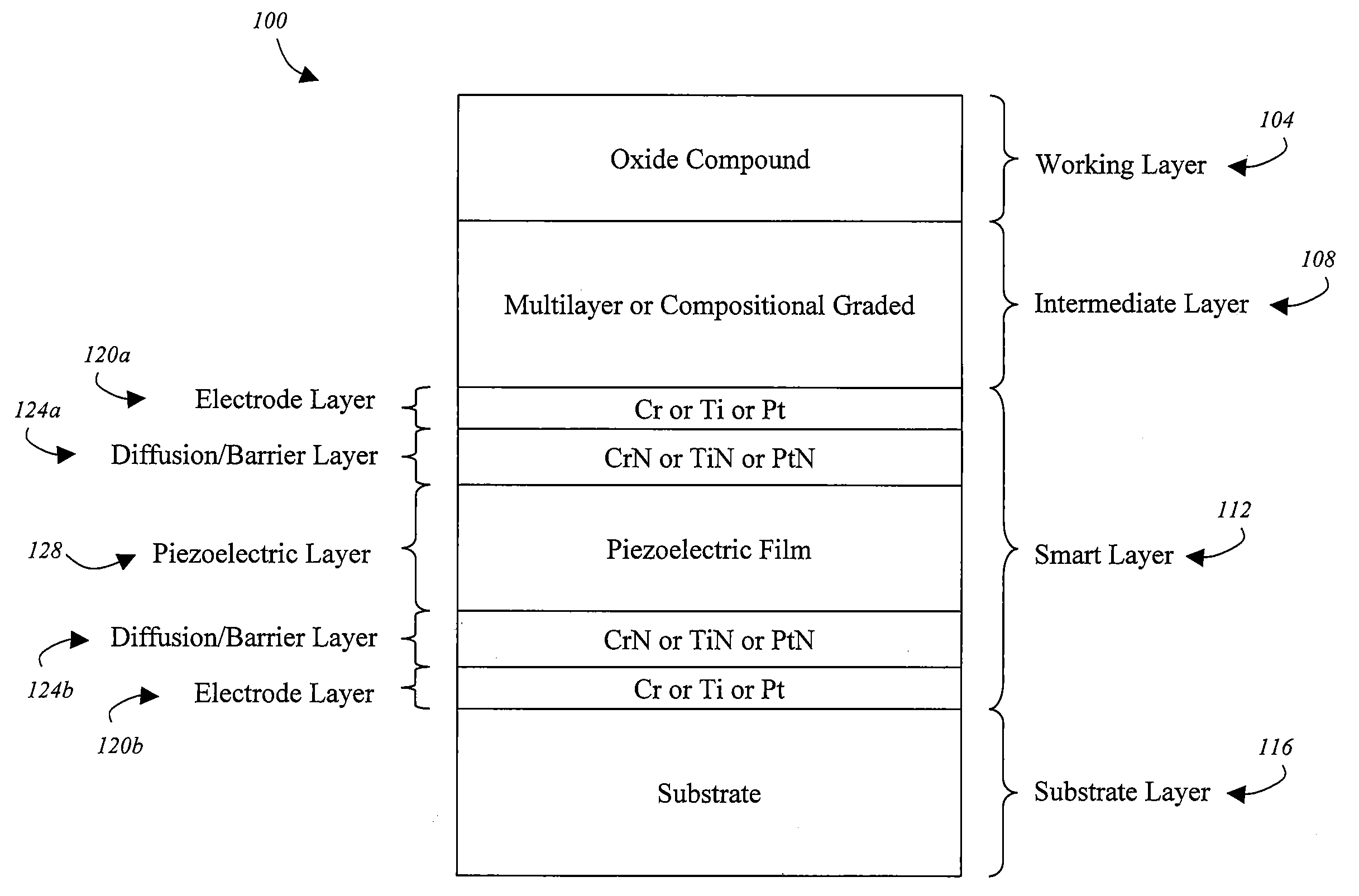

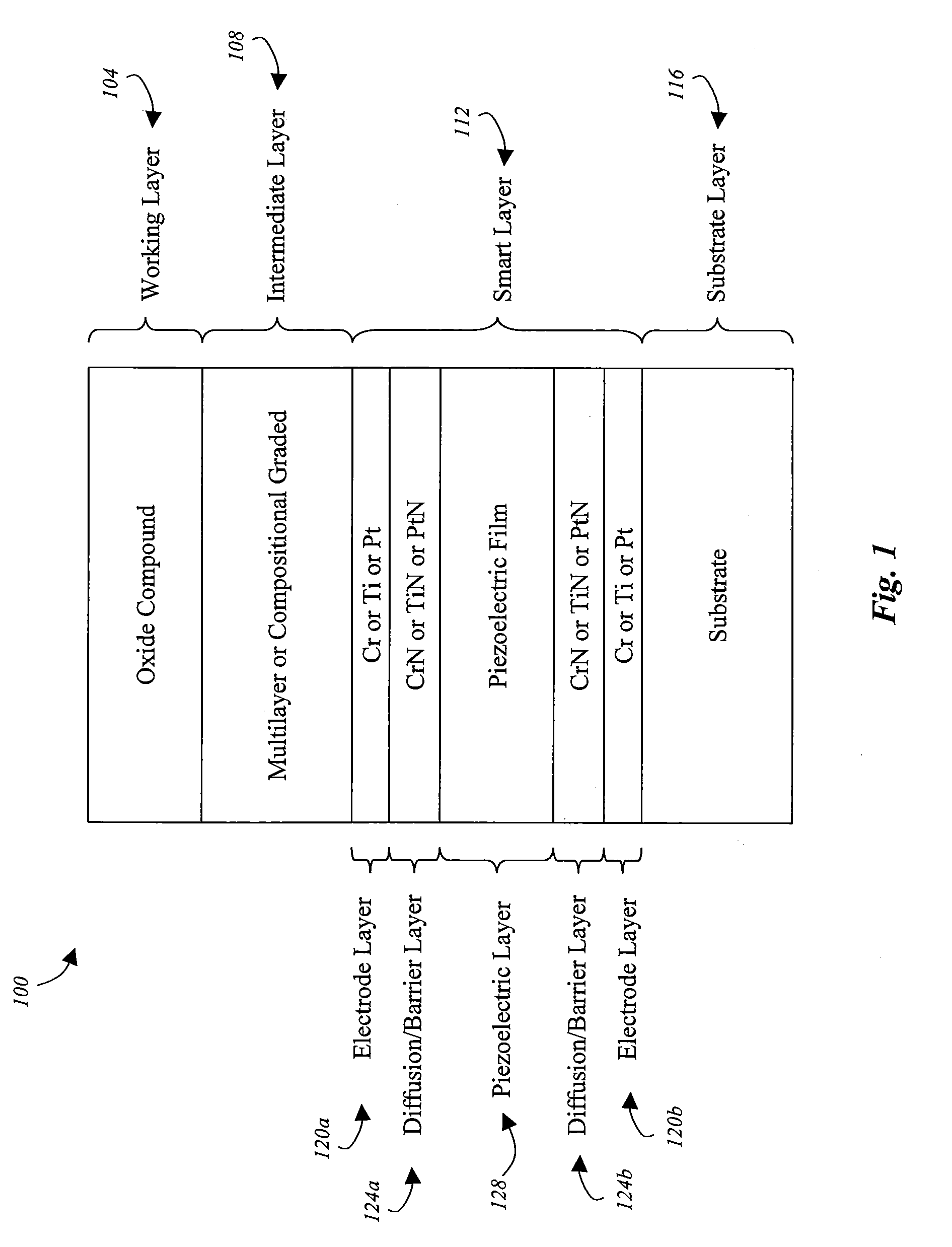

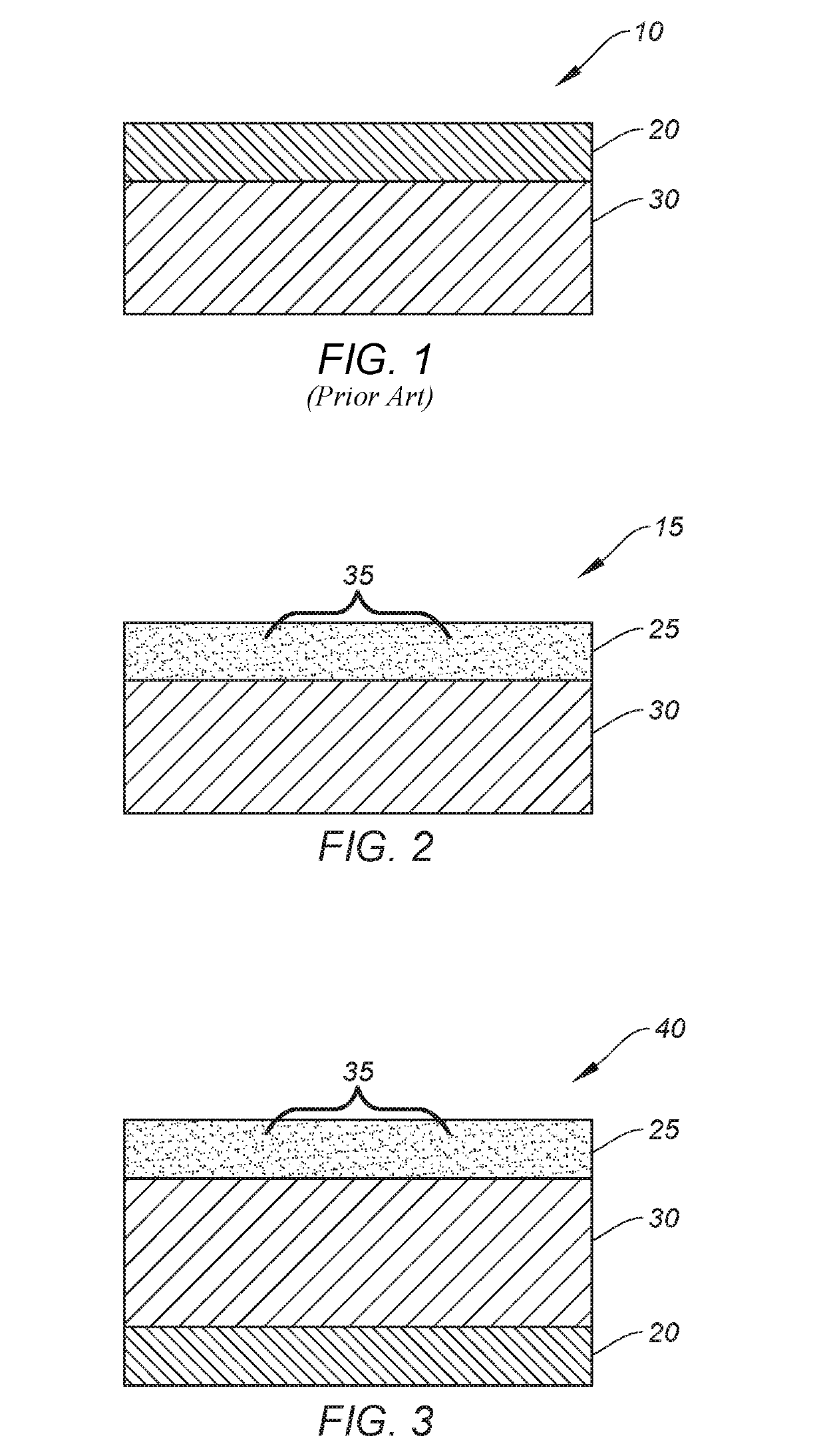

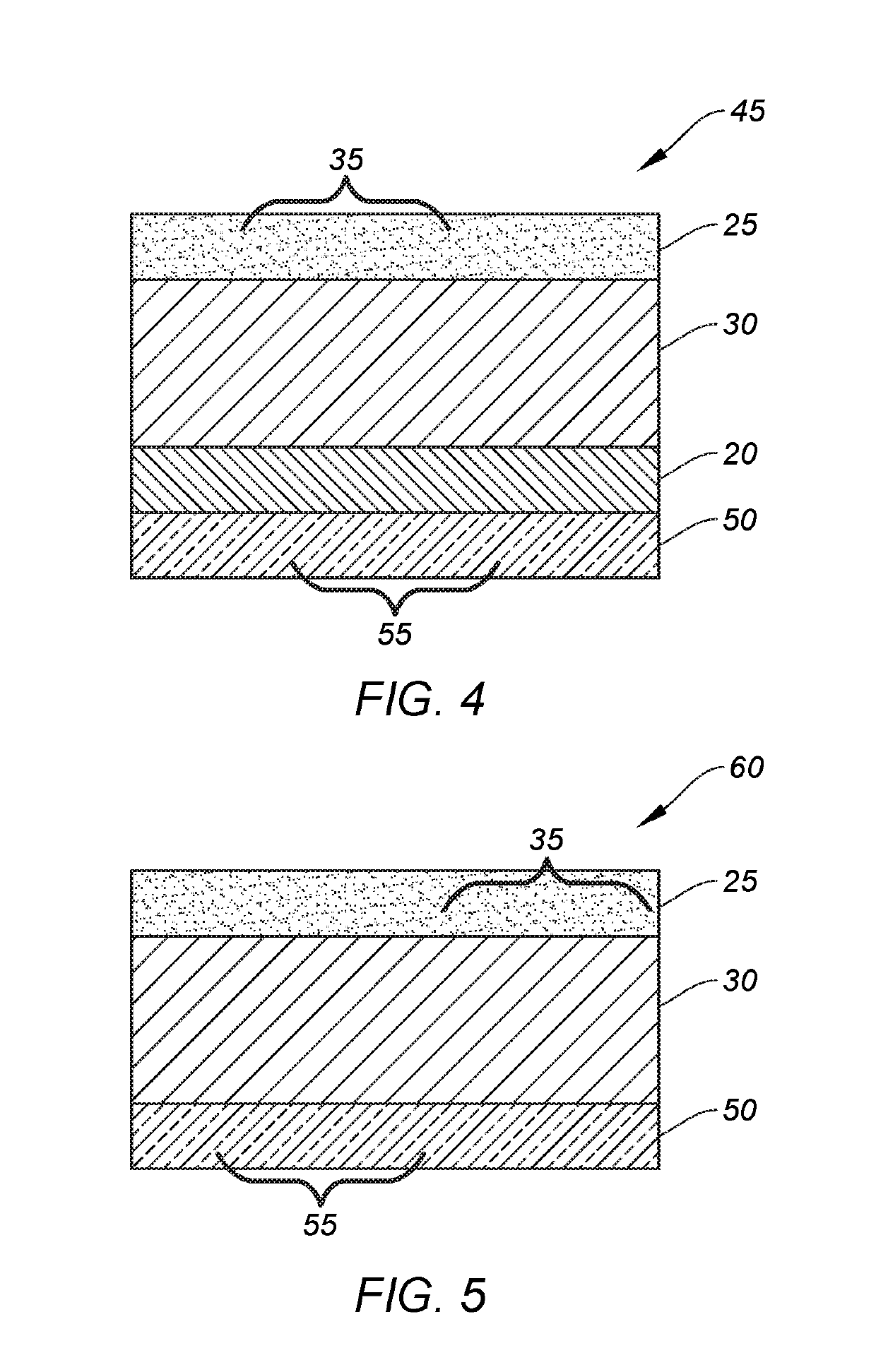

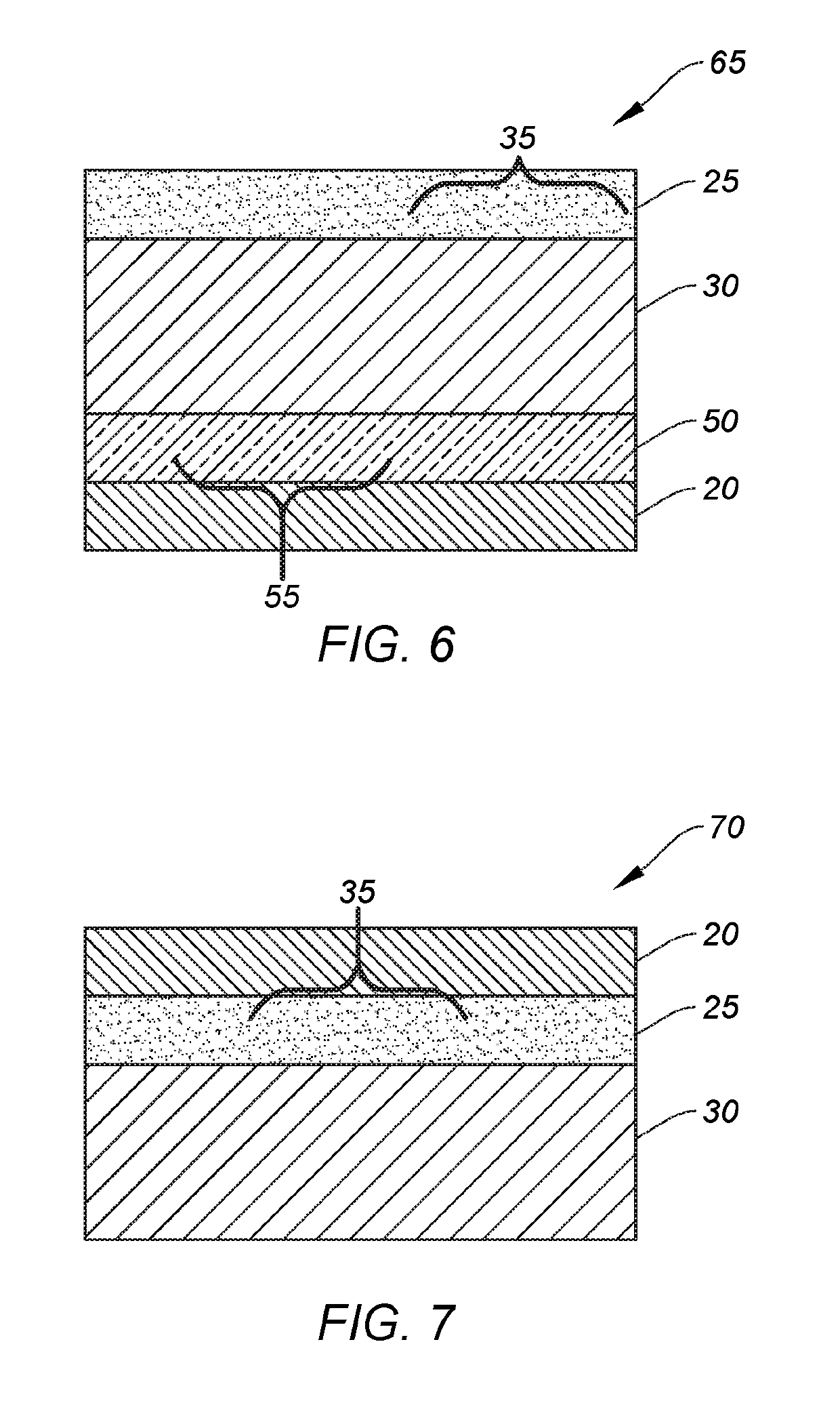

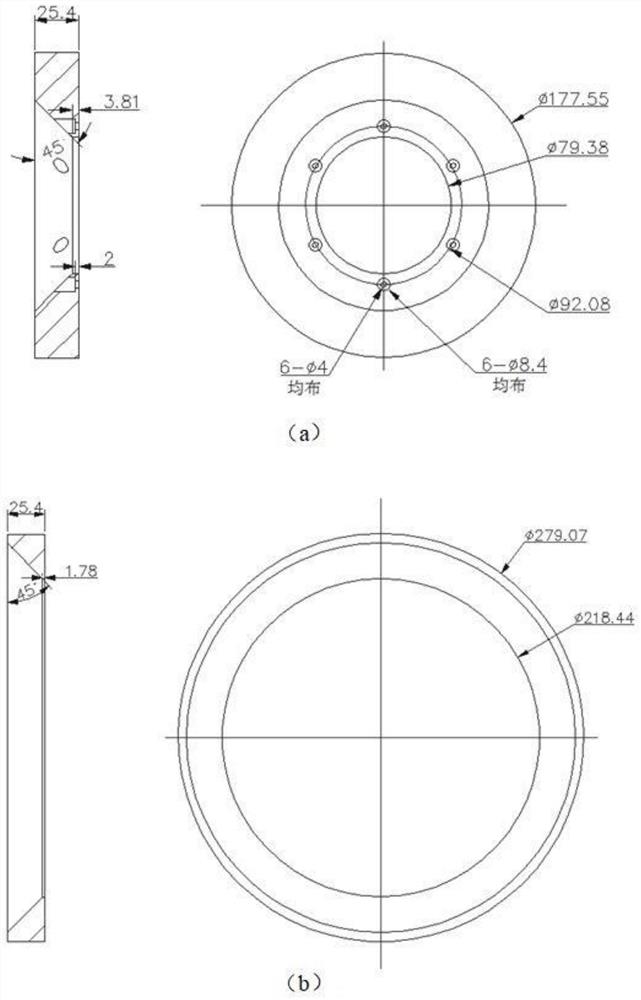

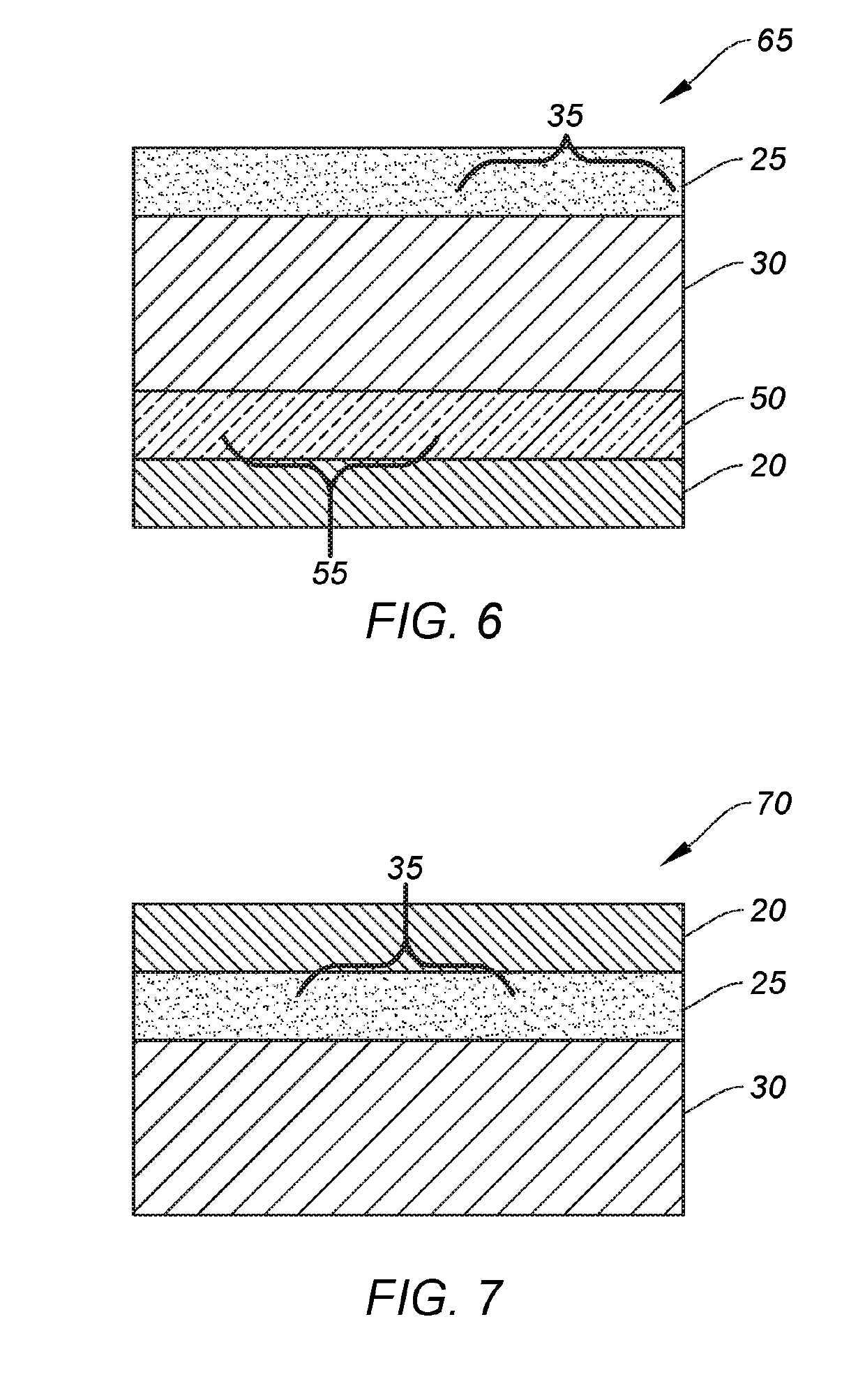

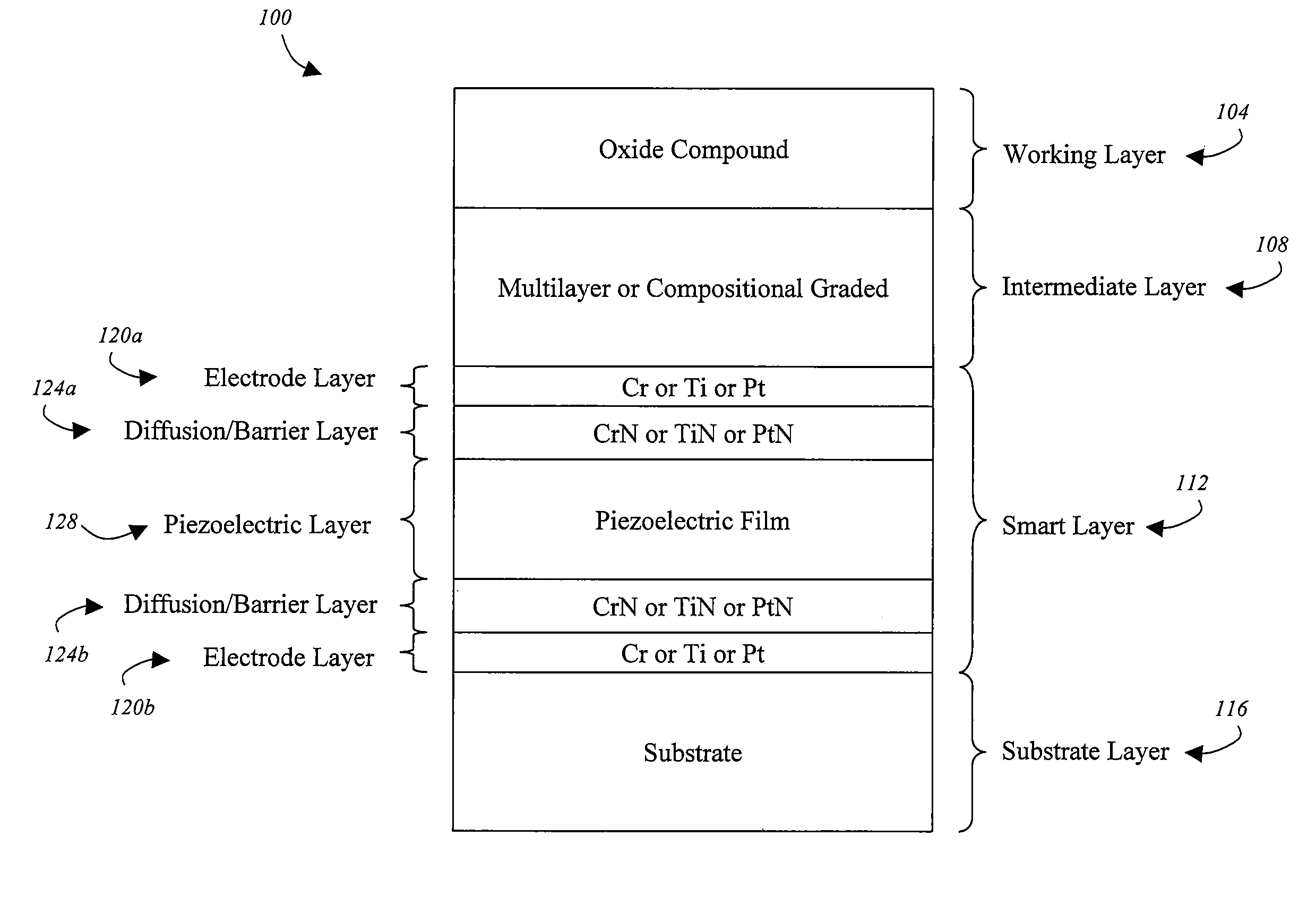

Piezoelectric sensor based smart-die structure for predicting the onset of failure during die casting operations

InactiveUS20080250863A1Strong anisotropyPiezoelectric propertyPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesDie castingCatastrophic failure

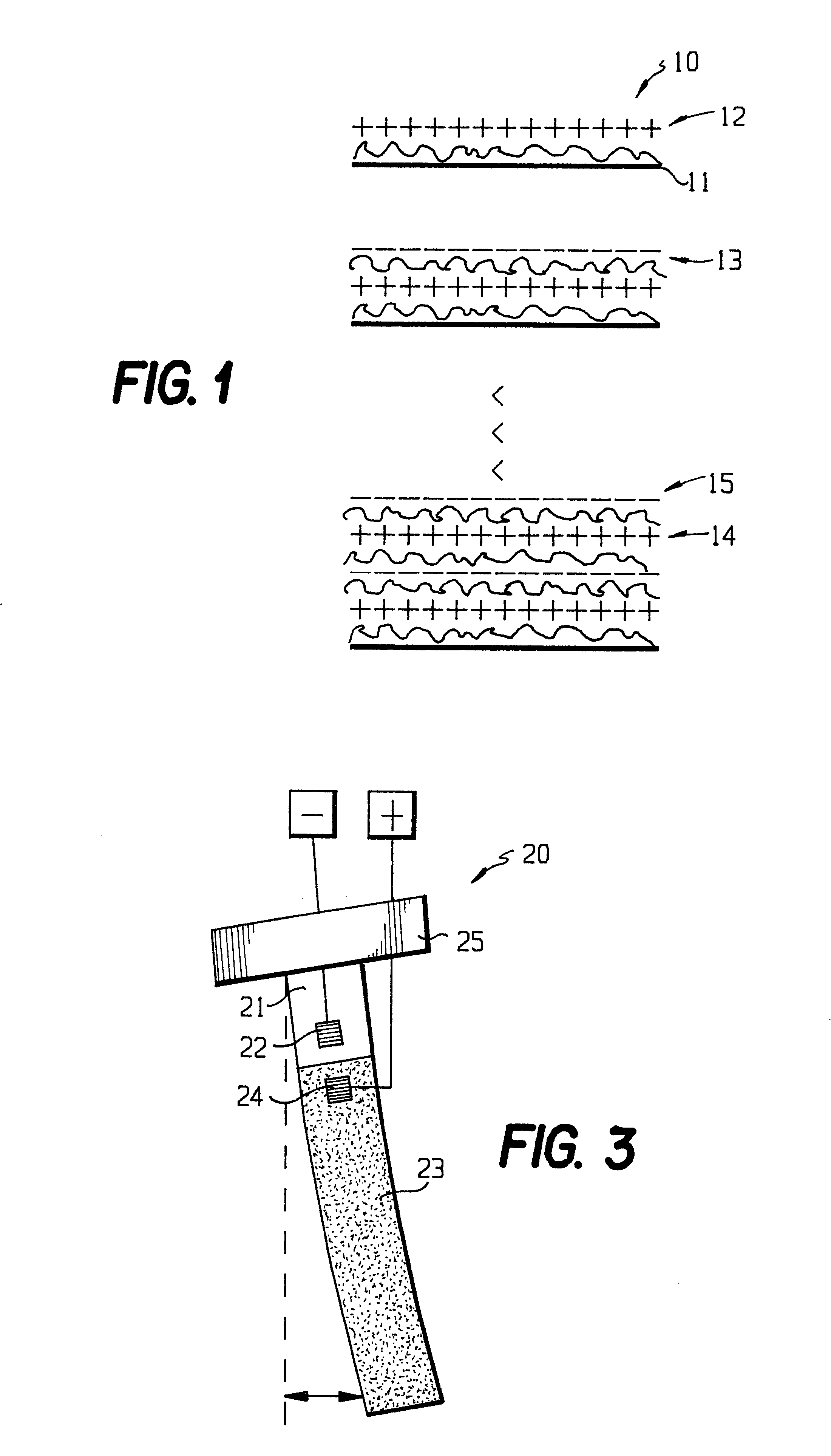

An in-situ apparatus is provided for monitoring the state of stress / strain and cracking in a die surface. The apparatus may also be used to facilitate the prudent removal of the die from the surface so that it may be repaired before catastrophic failure occurs. Accordingly, the yield of a process used to generate die cast structures may be greatly increased.

Owner:COLORADO SCHOOL OF MINES

Electrically-conductive compositions

ActiveUS10297741B1Improve performanceImprove the overall coefficientNon-conductive material with dispersed conductive materialCoatingsYoung's modulusConductive materials

An electrically-conductive composition can be used with piezoelectric materials to enhance the piezoelectric effects. This composition essentially has (a) an electrically-conductive material; (b) particles having a Young's modulus that is different from the Young's modulus of the (a) electrically-conductive material by at least 10%, and which (b) particles have a d50 of at least 500 nm and up to and including 500 μm and a polydispersity coefficient that is less than or equal to 3; and (c) a non-electrically-conductive binder material. The weight ratio of the (b) particles to the (a) electrically-conductive material is at least 0.01:1 and up to and including 10:1. When the composition is coated and dried on an insulating substrate, a resulting dried composition exhibits a resistivity of less than 10,000 ohm-cm.

Owner:EASTMAN KODAK CO

Piezoelectric ceramic material with high voltage electric response and high Curie temperature and preparation method thereof

ActiveCN109626988APrecise and controllable stoichiometric ratioShort preparation cycleAdhesiveSlurry

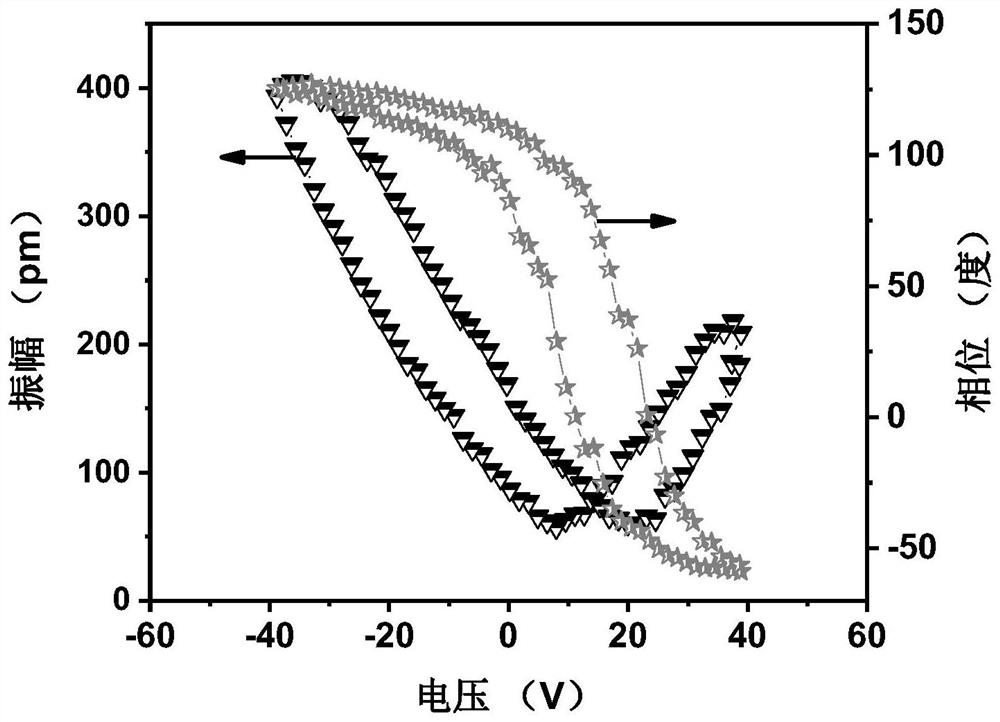

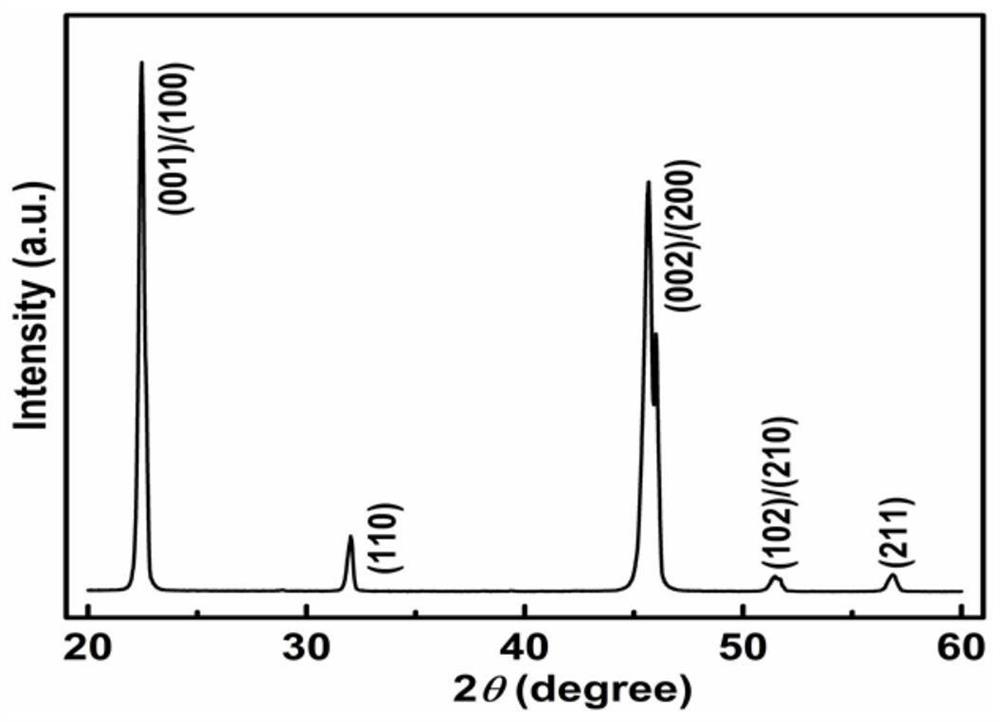

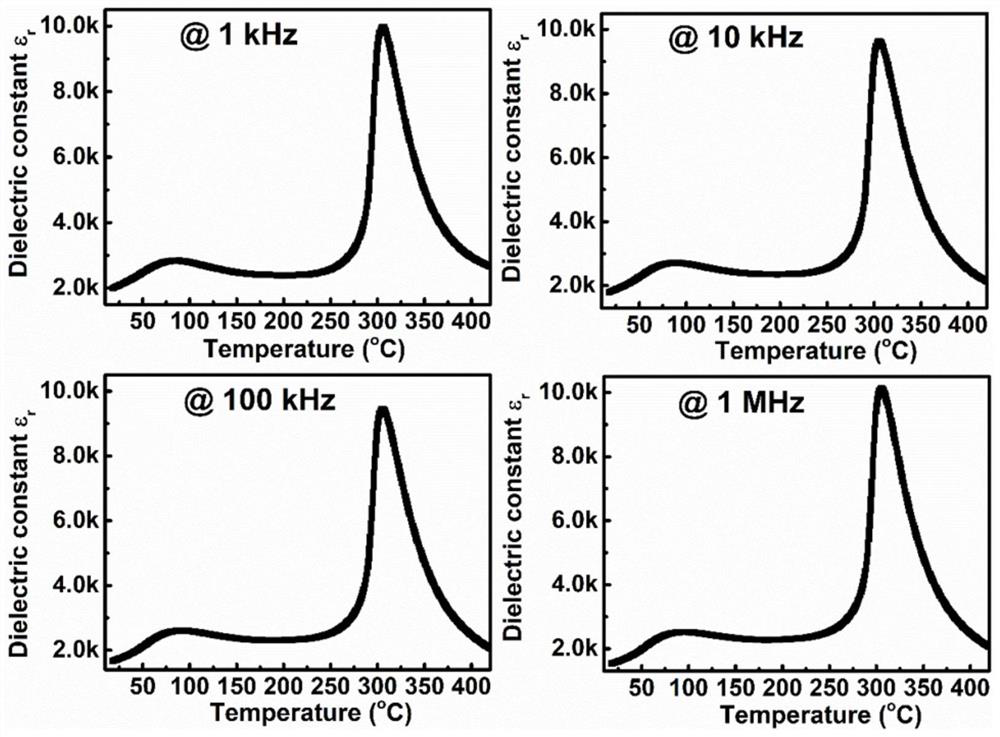

The invention relates to a piezoelectric ceramic material with high voltage electric response and a high Curie temperature and a preparation method thereof. A stoichiometric ratio accords with a chemical general formula (1-x)(K0.48Na0.52)(Nb1-ySby)O3-xBi0.5(Na0.8K0.2)0.5ZrO3; wherein x is more than or equal to 0.02 and less than or equal to 0.04, and y is more than or equal to 0.02 and less than or equal to 0.04. The preparation method comprises the following steps of: (1), preparing a base material according to the stoichiometric ratio and a sodium niobate (NaNbO3) sheet template for texturegrowth of crystal grains; (2), weighing the base material, the template and a MnO2 sintering aid according to the stoichiometric ratio, placing the weighed base material, template and MnO2 sintering aid in a nylon tank, adding a solvent, a dispersant and a binder, and uniformly stirring the mixture to obtain casting slurry with good fluidity; (3) casting the slurry to obtain a strip-shaped thick film, cutting the thick film after the thick film is dried, laminating and hot pressing the thick film into a ceramic blank body; (4) removing the blank body from the adhesive, and sintering the blankbody by using a two-step sintering process to obtain lead-free textured piezoelectric ceramic, wherein the lead-free textured piezoelectric ceramic has high piezoelectric performance and a high Curietemperature. The environment-friendly lead-free piezoelectric ceramic material has higher practical value in the fields of low and medium temperature sensors, transducers, drivers and the like.

Owner:TONGJI UNIV

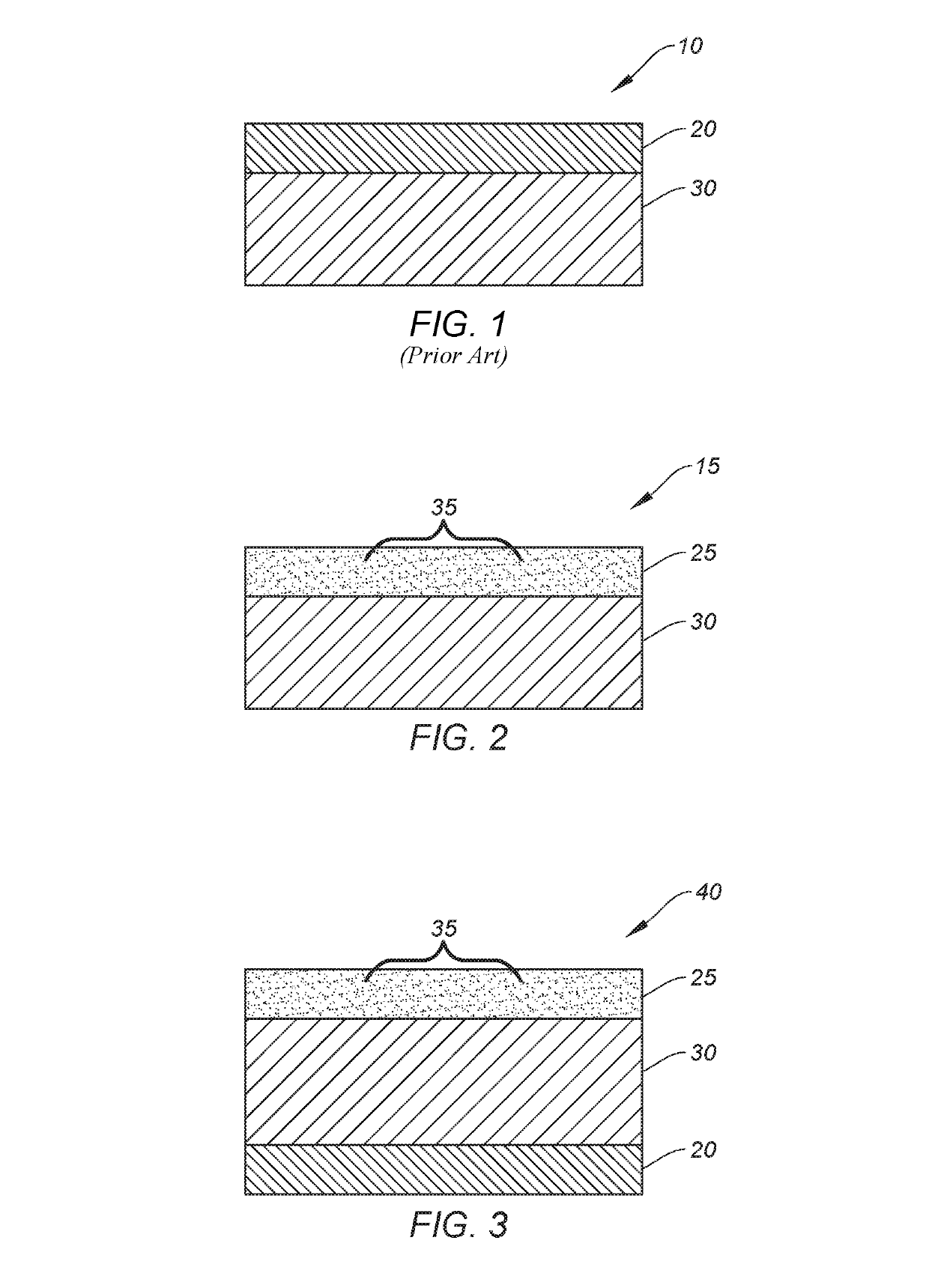

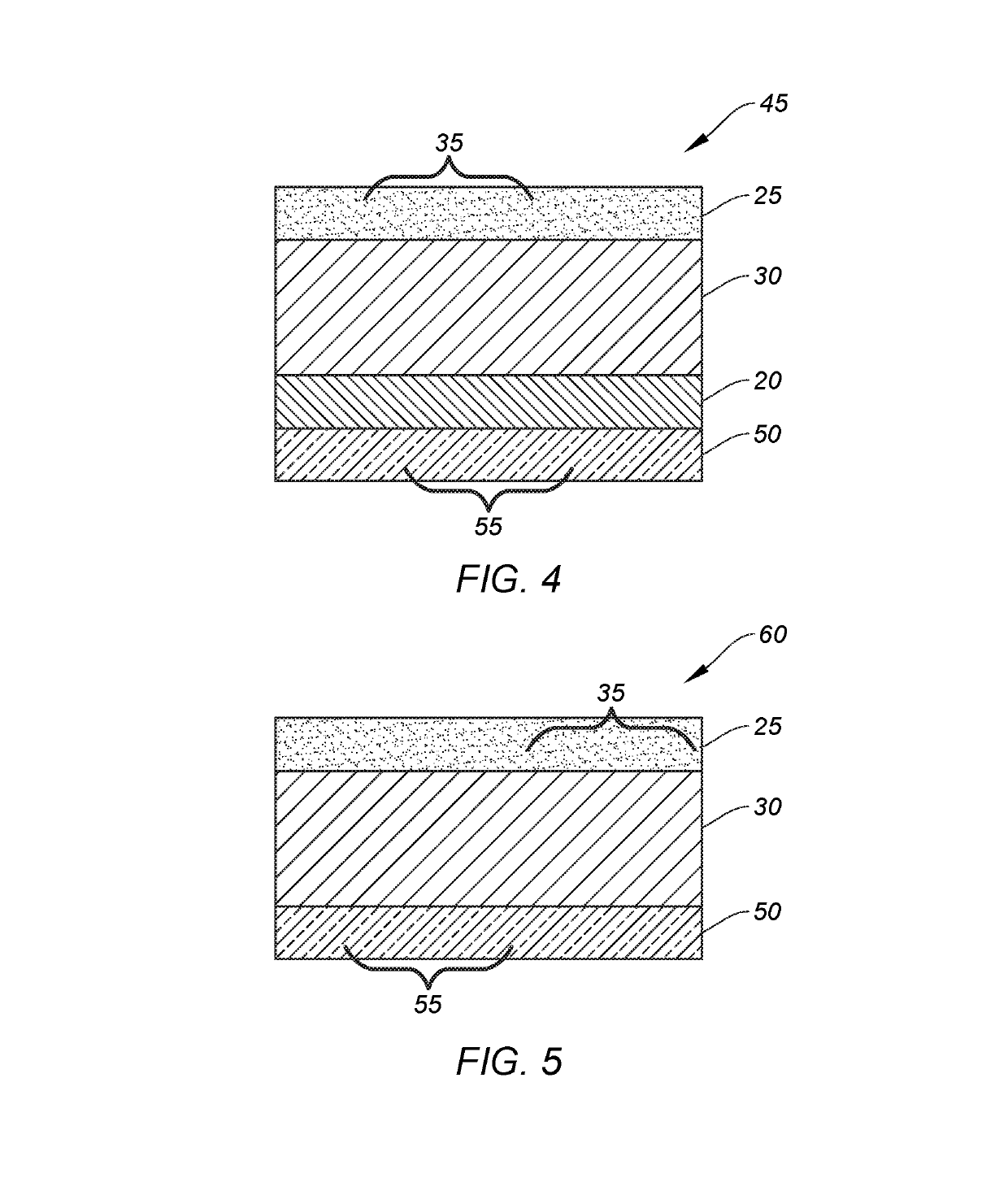

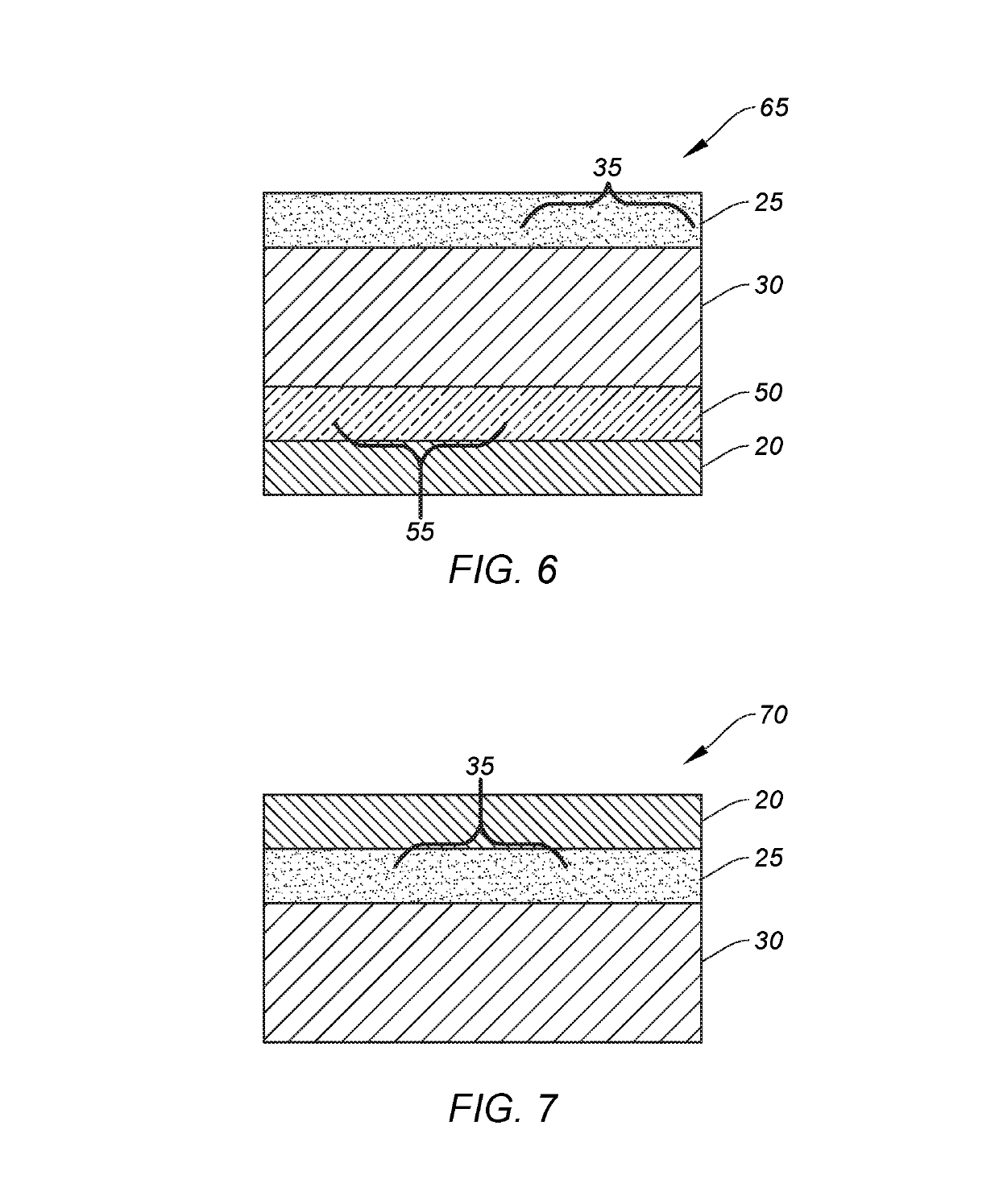

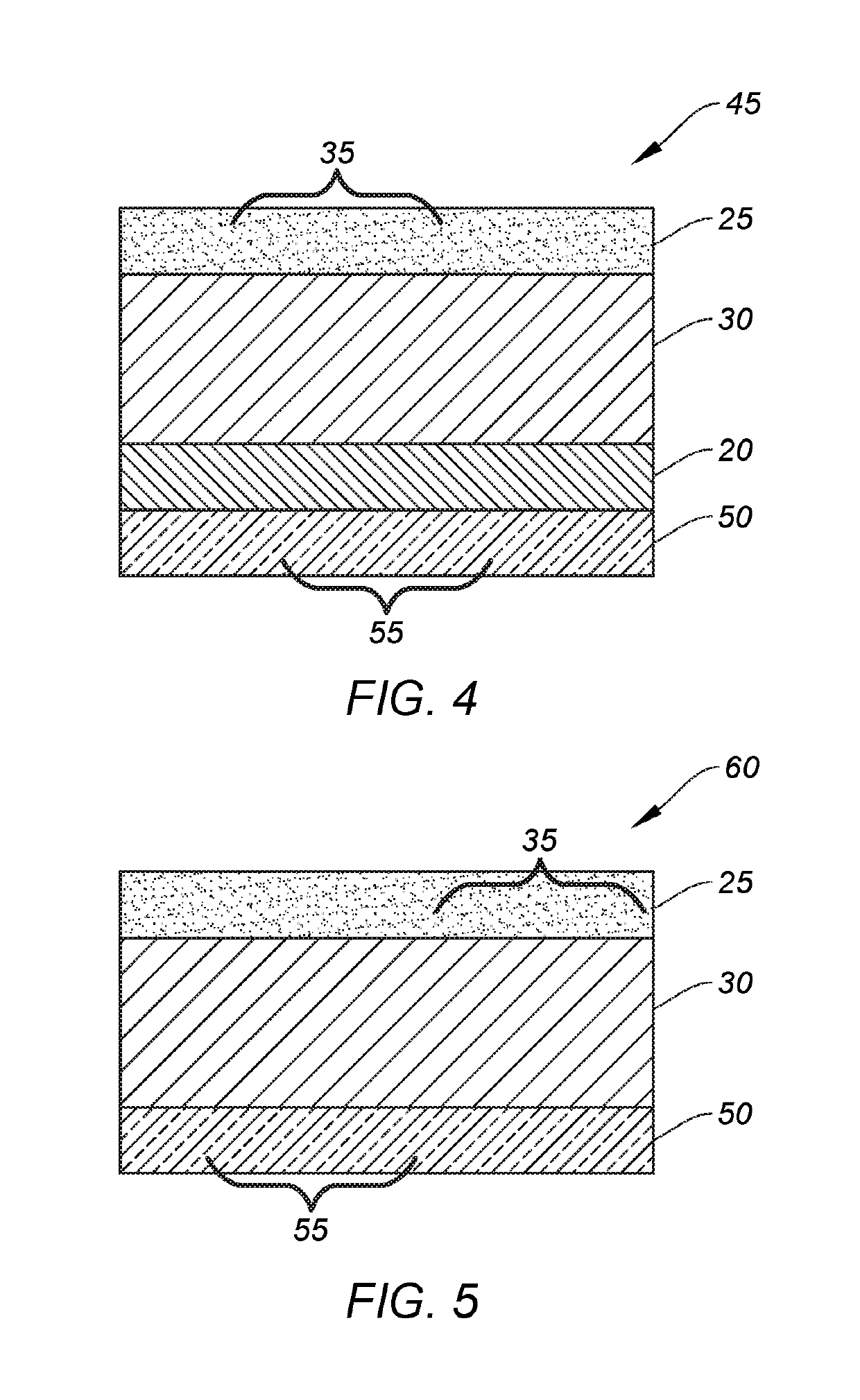

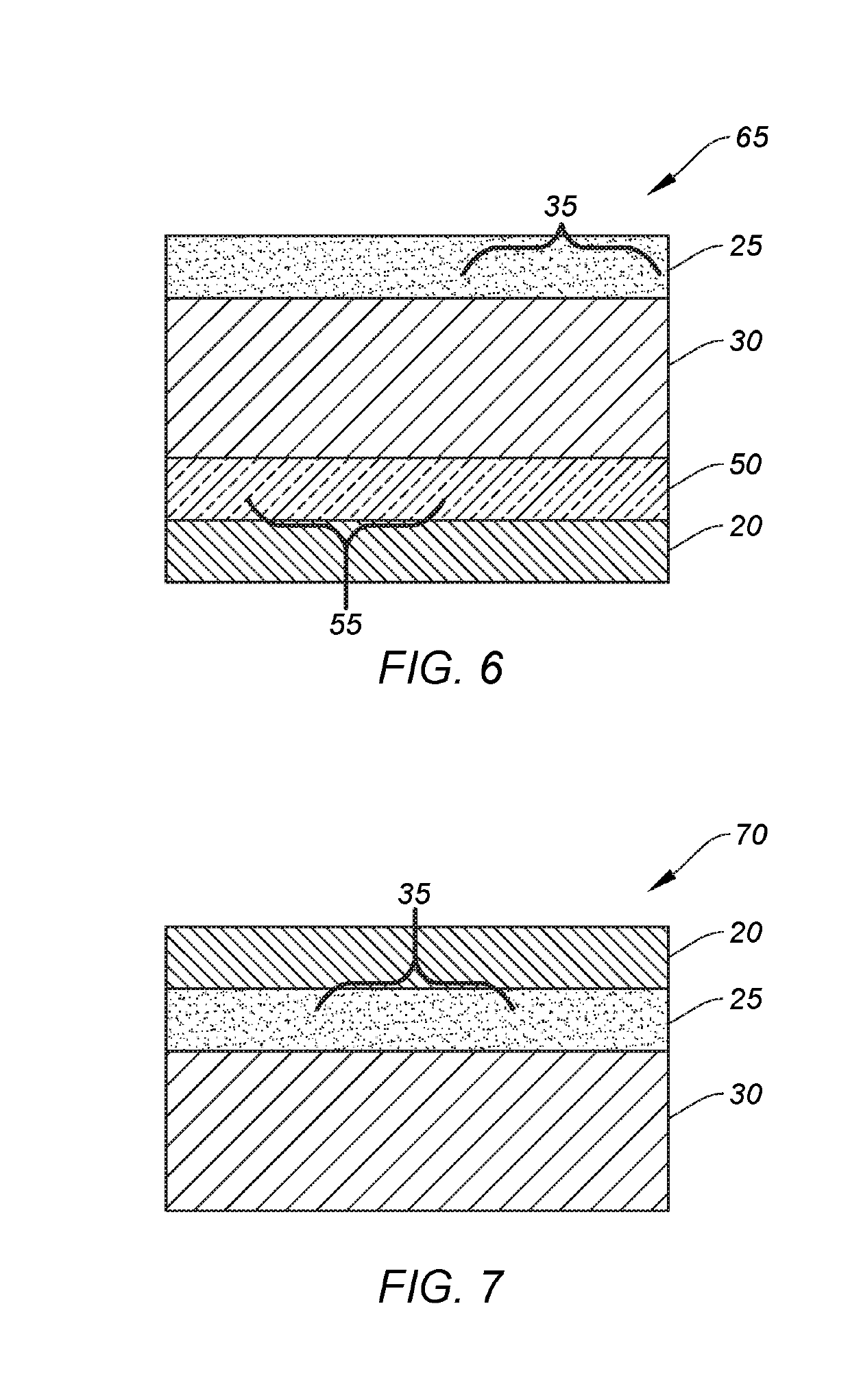

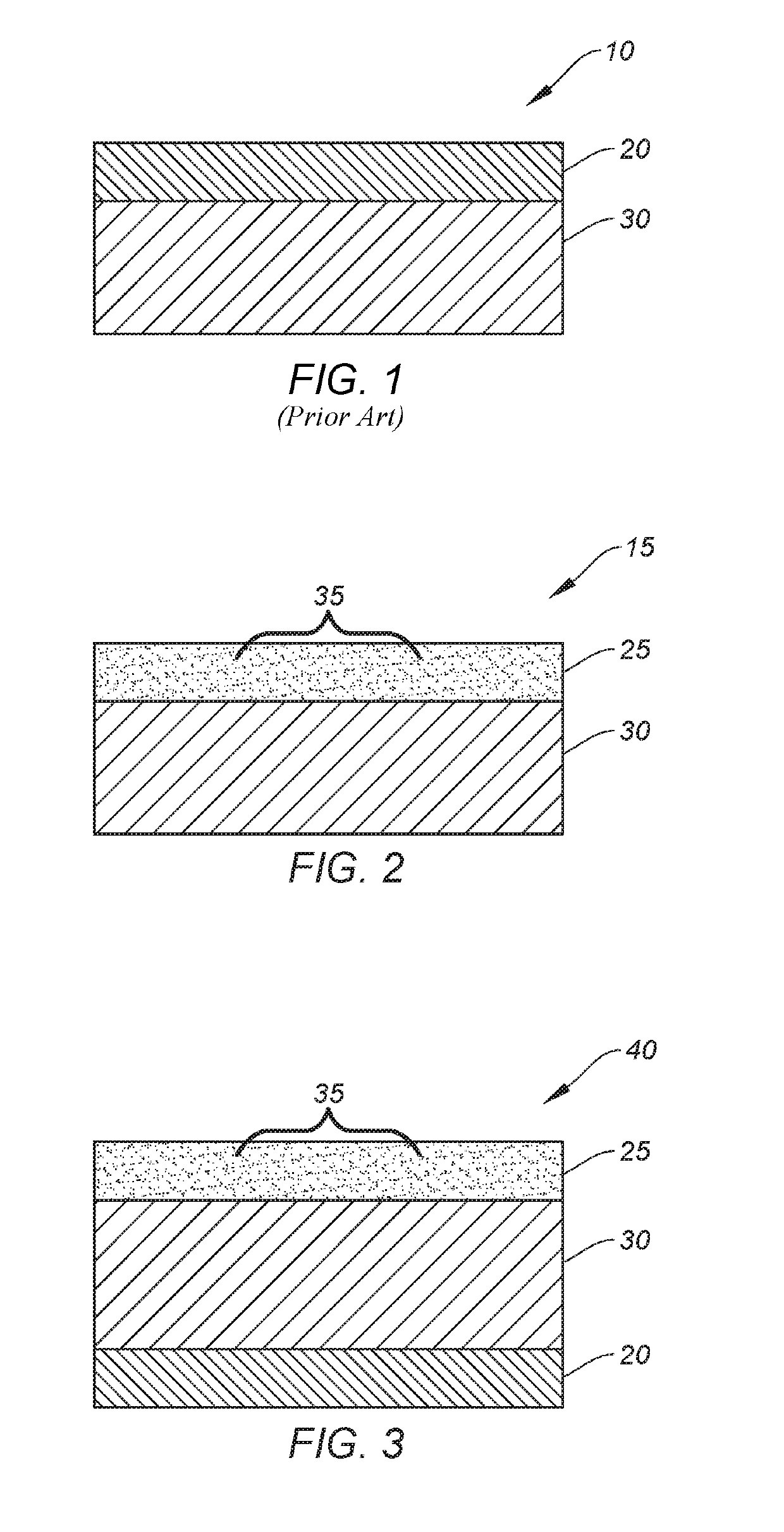

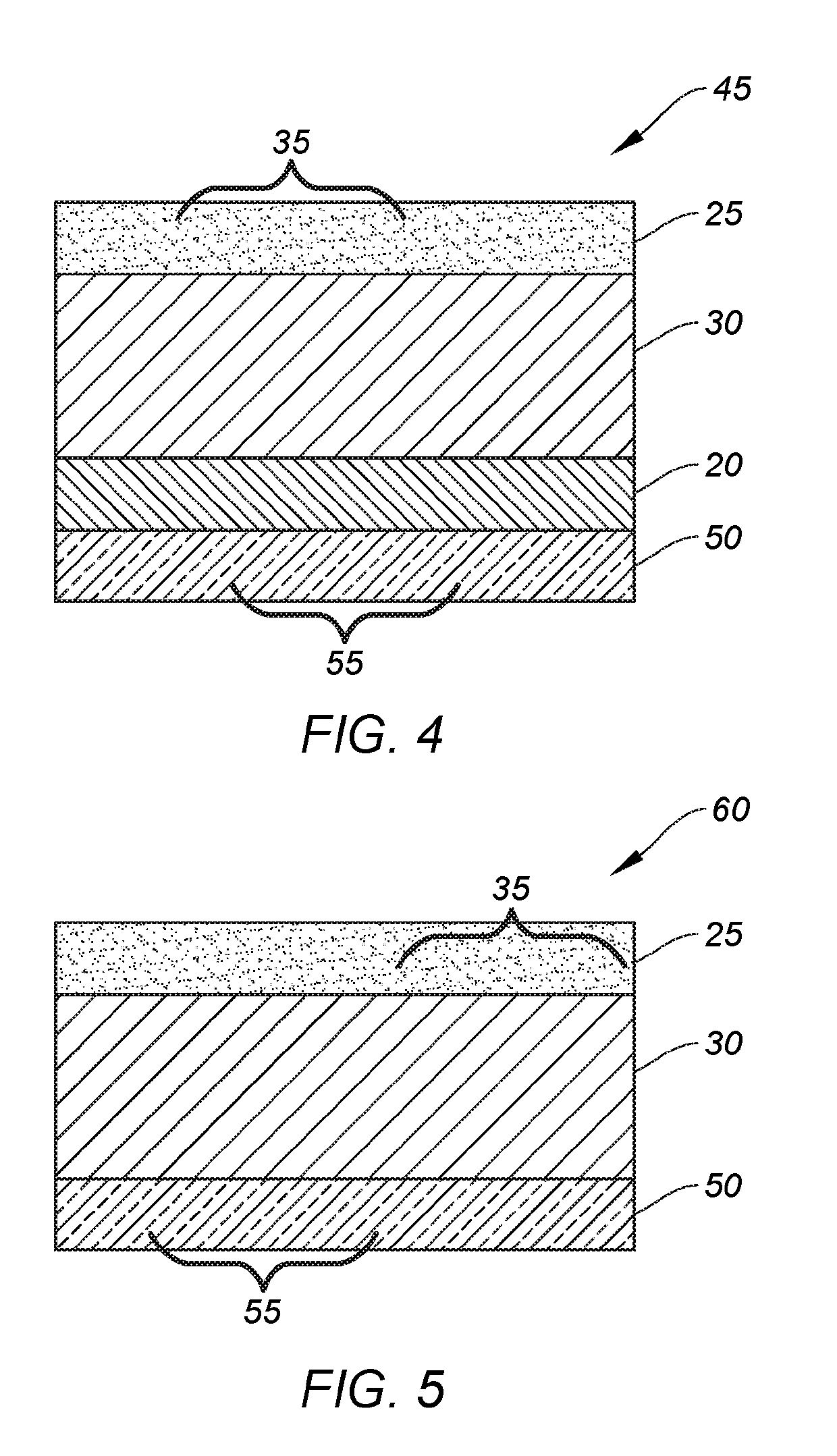

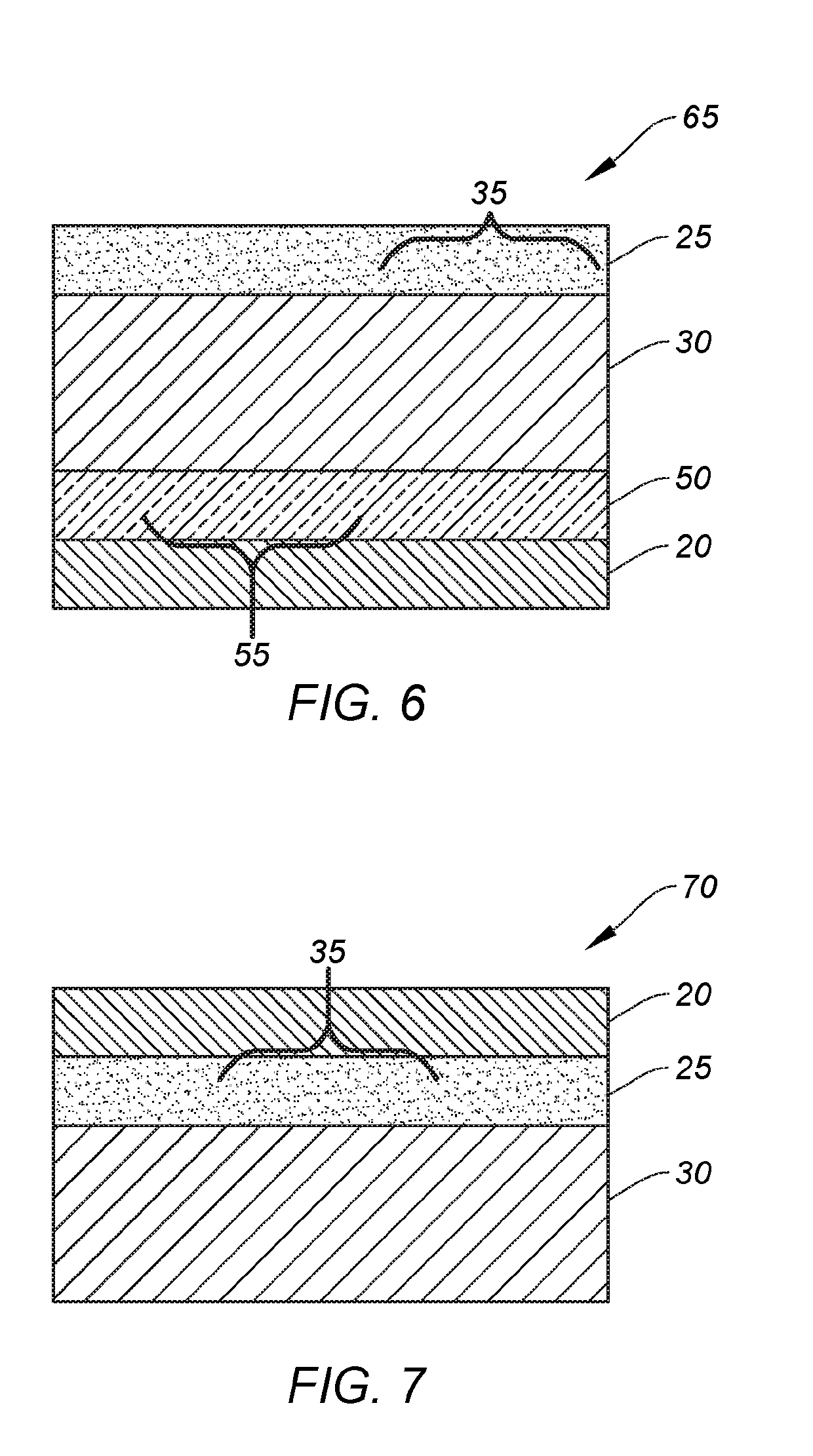

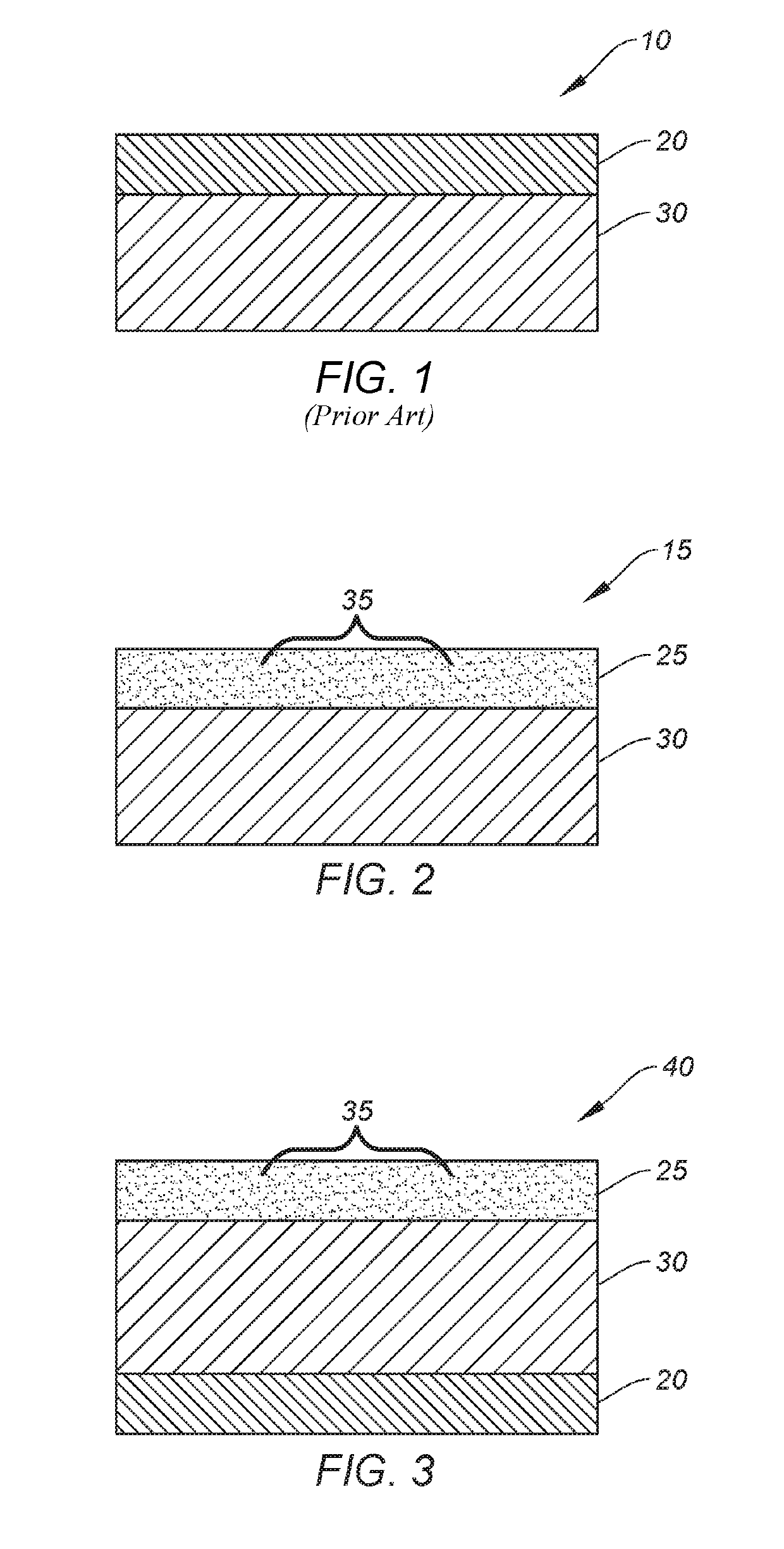

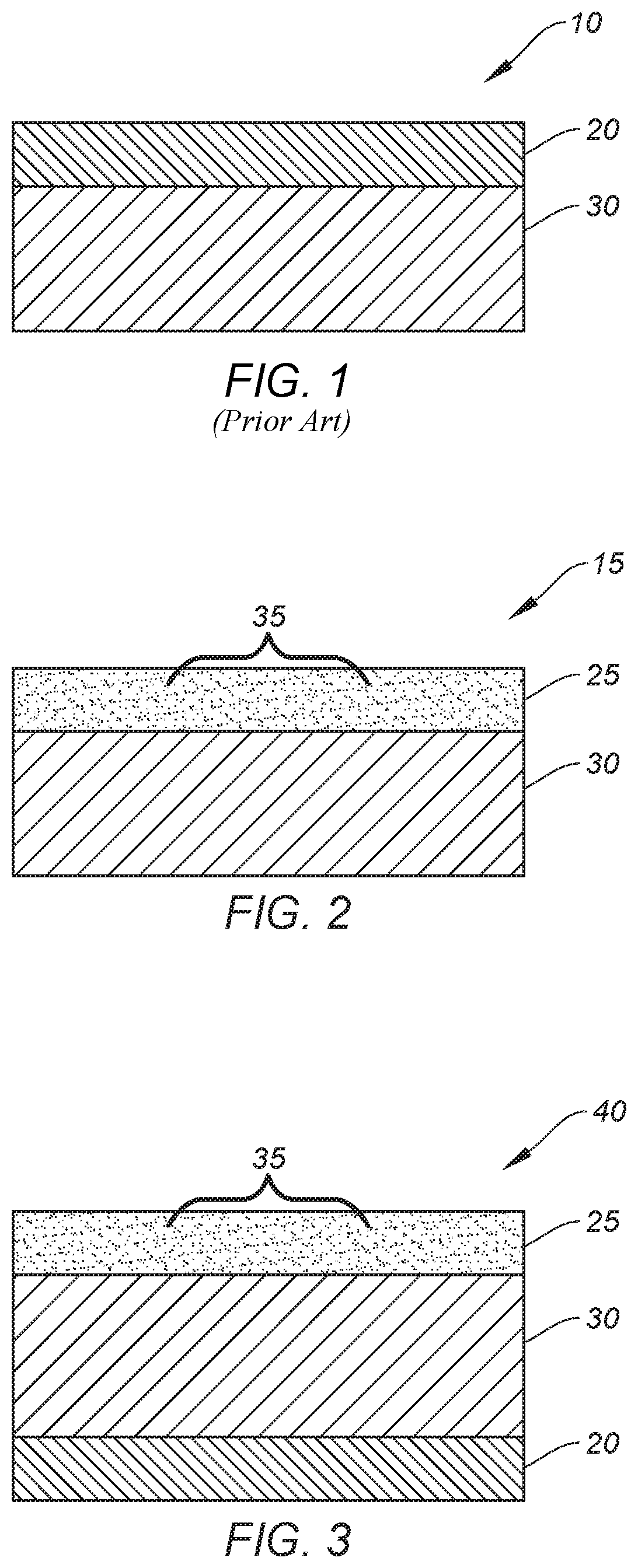

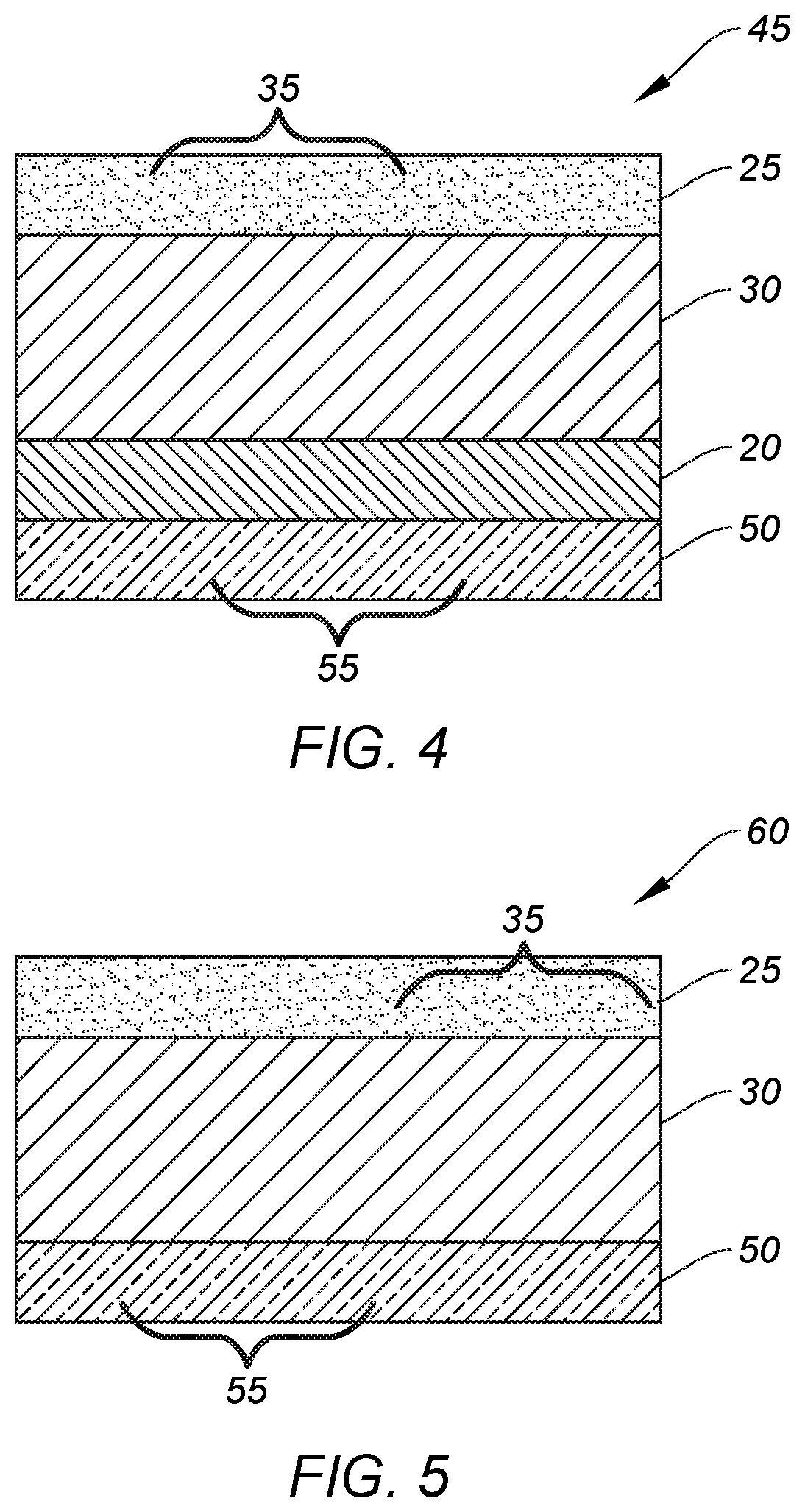

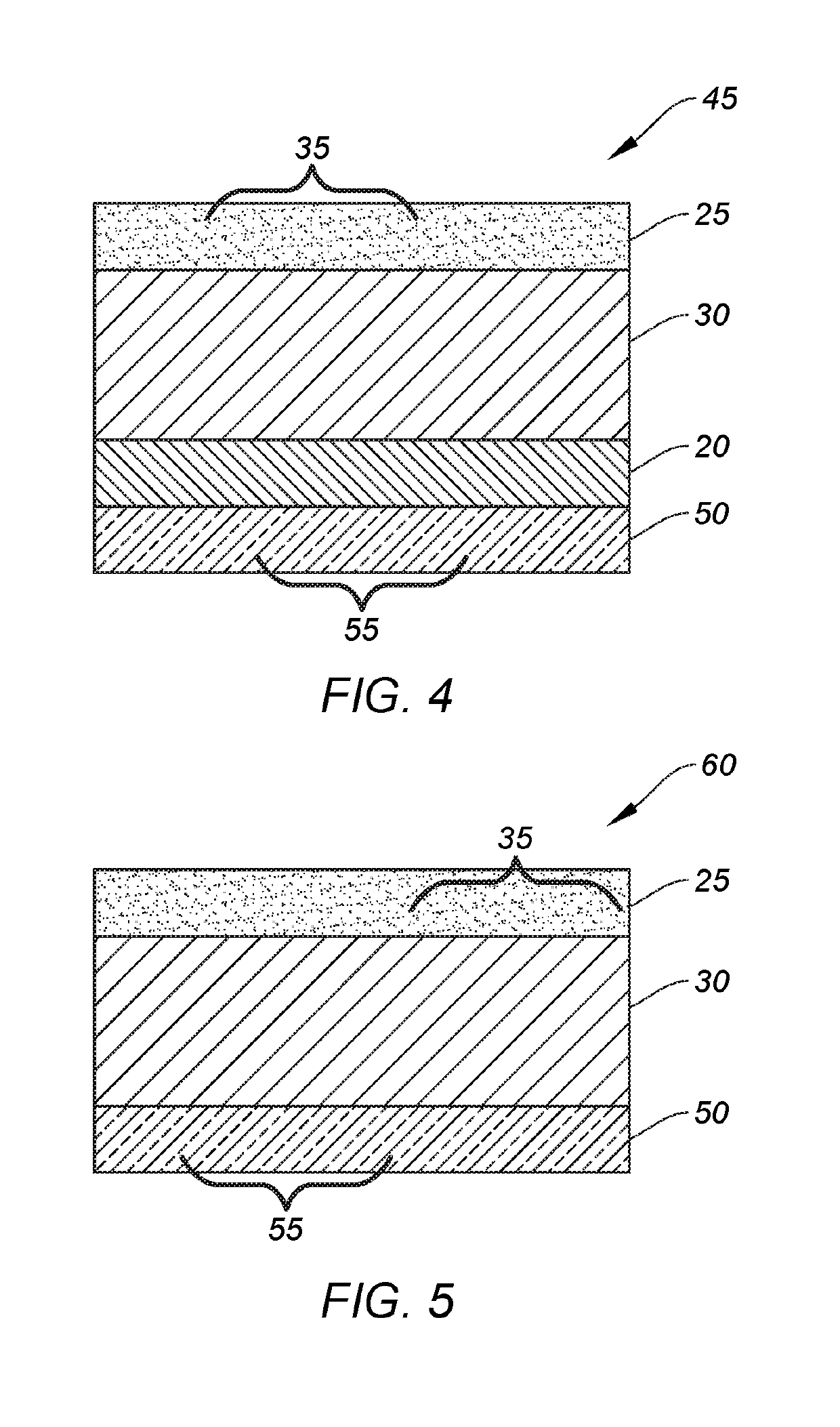

Piezoelectric article with dielectric layer and co-planar electrodes

ActiveUS20190189889A1Magnitude be affectChanges in coefficientPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive/magnetostrictive devicesPlanar electrodeYoung's modulus

A composite article has 1) a dry piezoelectric layer comprising a piezoelectric material, 2) a dry dielectric layer arranged contiguously with at least one of the opposing surfaces of the dry piezoelectric layer, and 3) a pair of non-electrically-connected co-planar patterned electrodes. The dry dielectric layer has essentially (a′) a dielectric material; and (b) particles having a Young's modulus that is different from the Young's modulus of the (a′) dielectric material by at least 10%.

Owner:EASTMAN KODAK CO

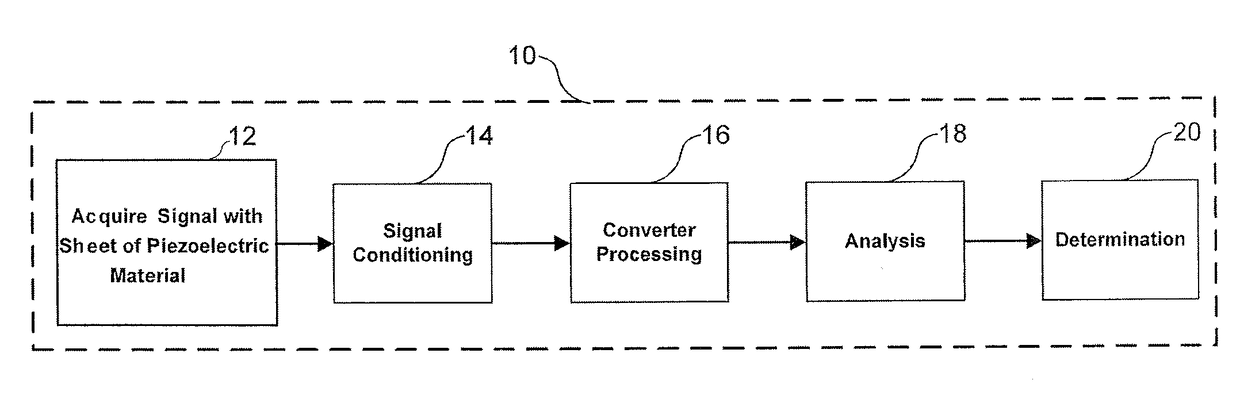

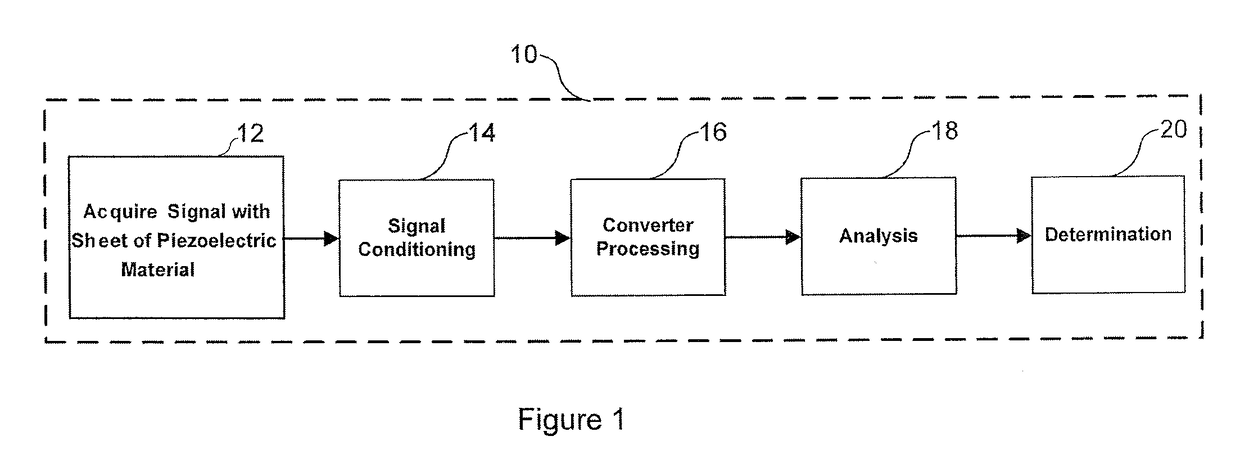

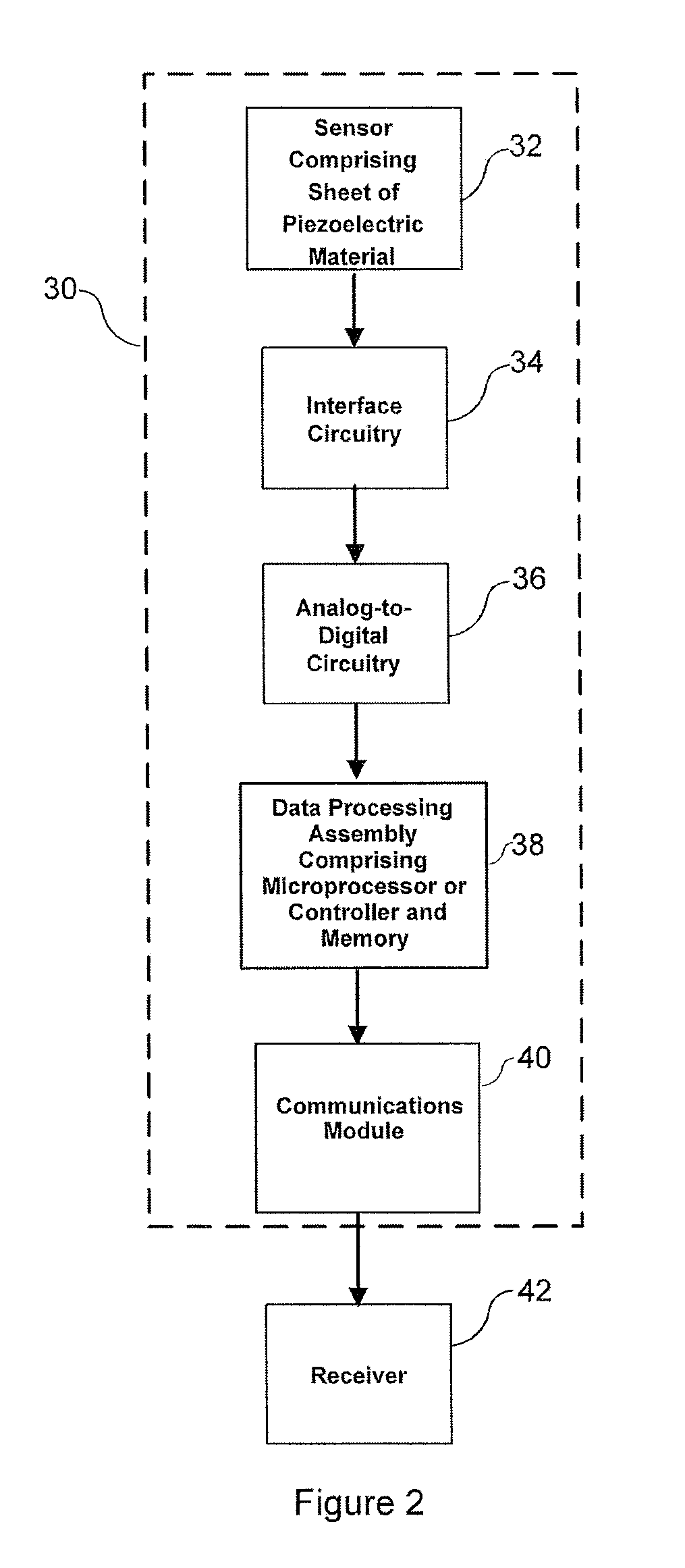

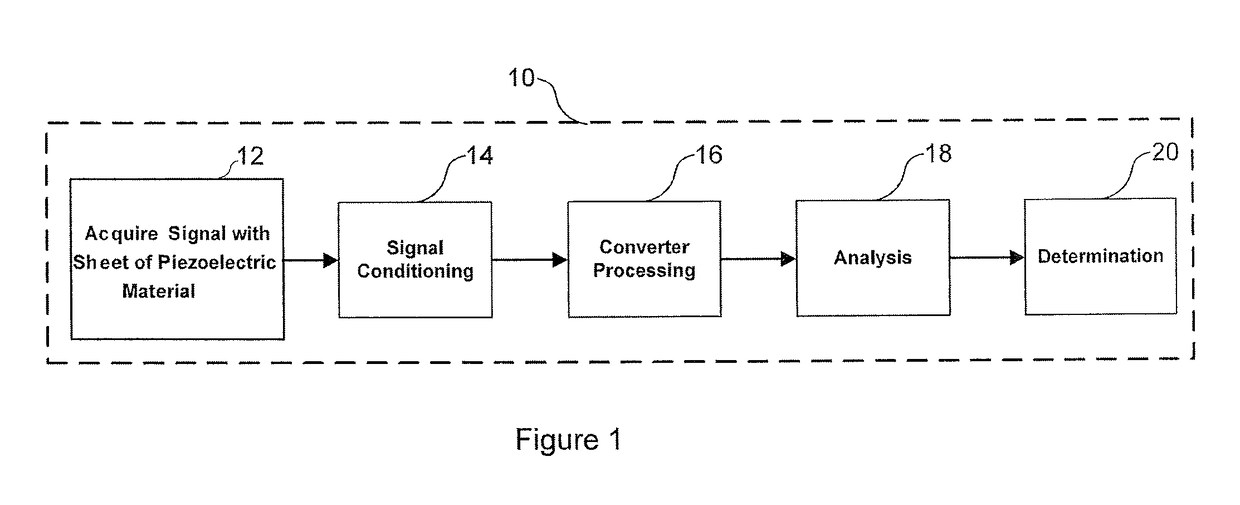

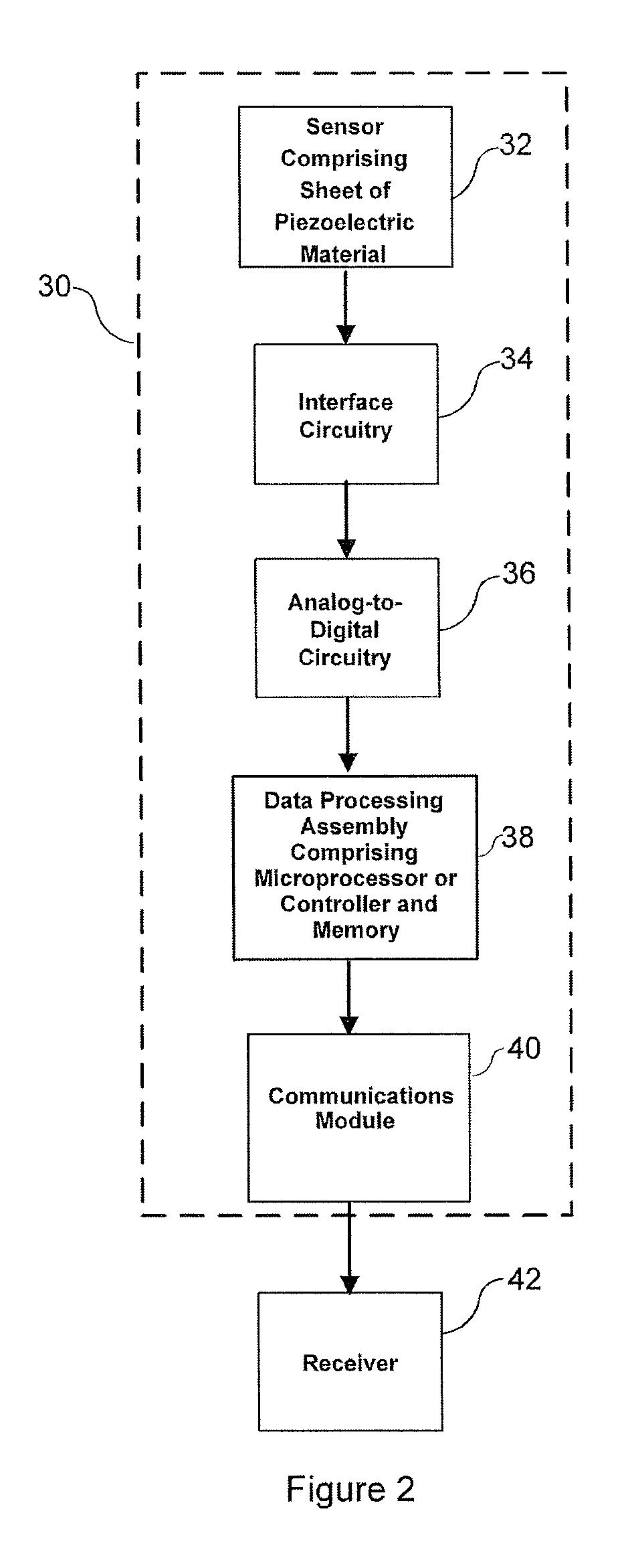

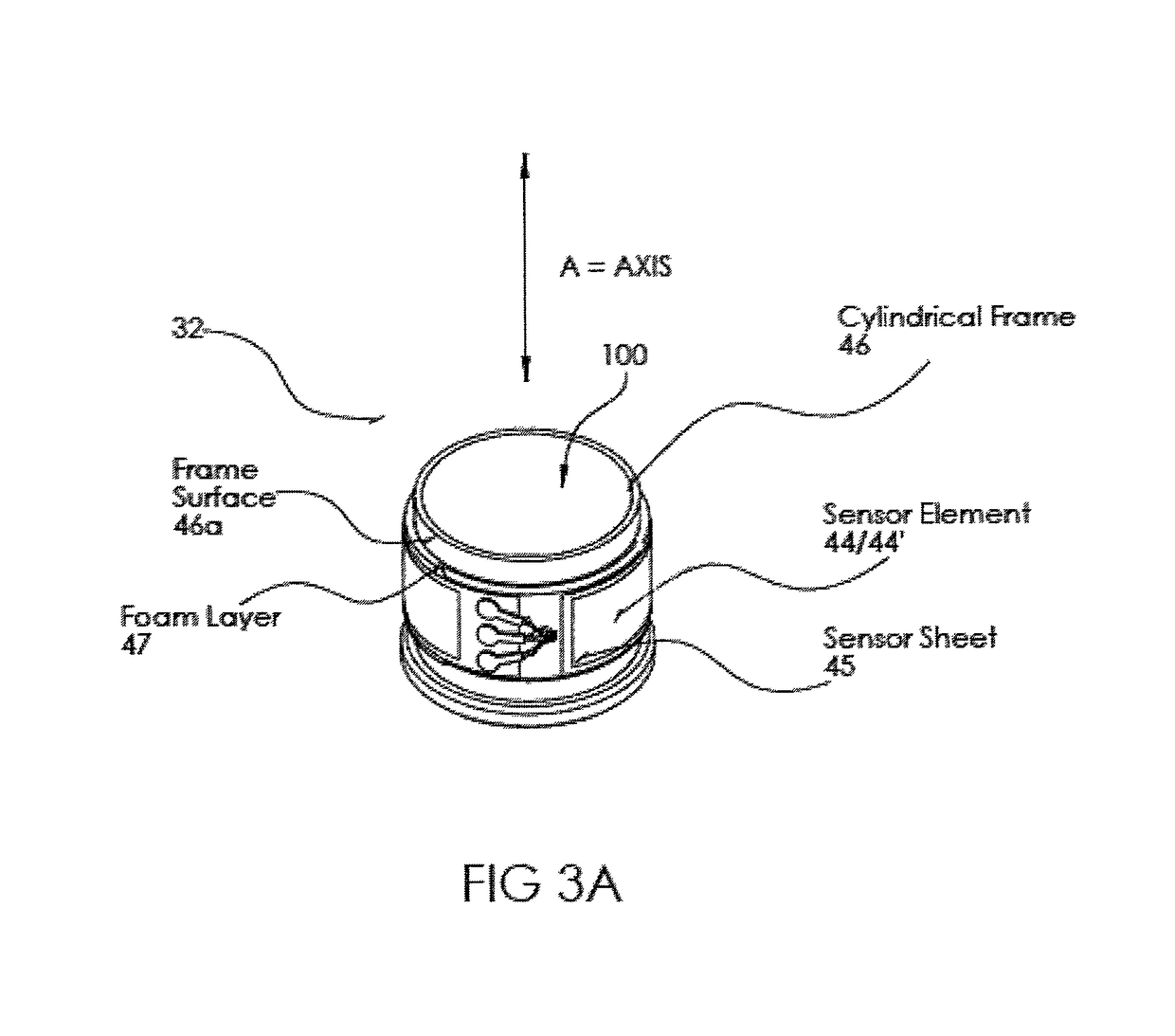

System and method for improved seismic acoustic sensor performance

ActiveUS20170146689A1Good signal responseImproved piezoelectric responseSeismic signal receiversSound producing devicesEngineeringSignal response

A sensing system responsive to a wavefield of acoustic or seismic signals. In one embodiment, the system includes a frame having a surface of tubular shape about which a layer of piezoelectric material can be positioned to extend along a first direction. A piezoelectric element is positioned under tension to apply a force against the frame, which tension increases signal response of the element.

Owner:QUANTUM TECHNOLGY SCI INC

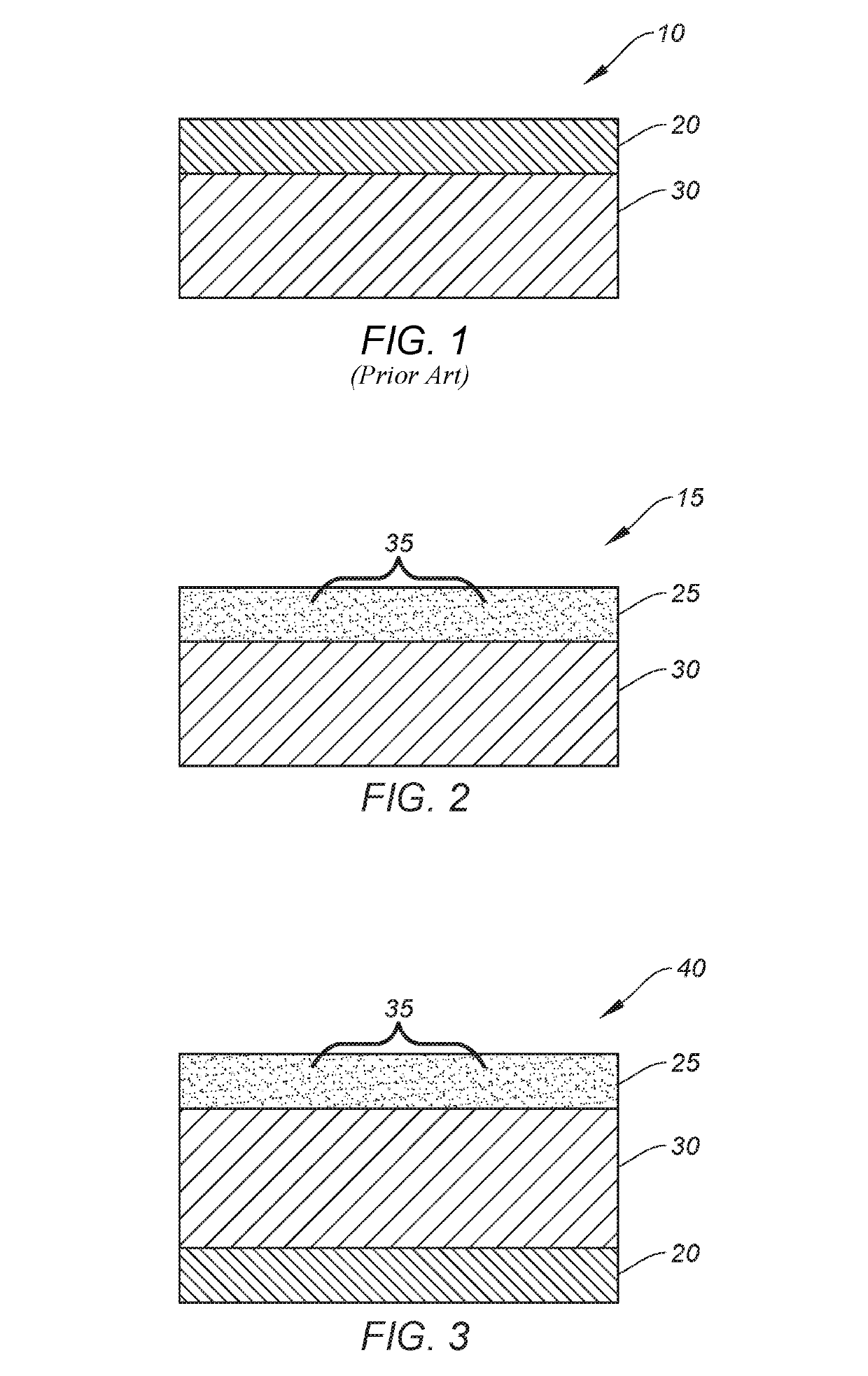

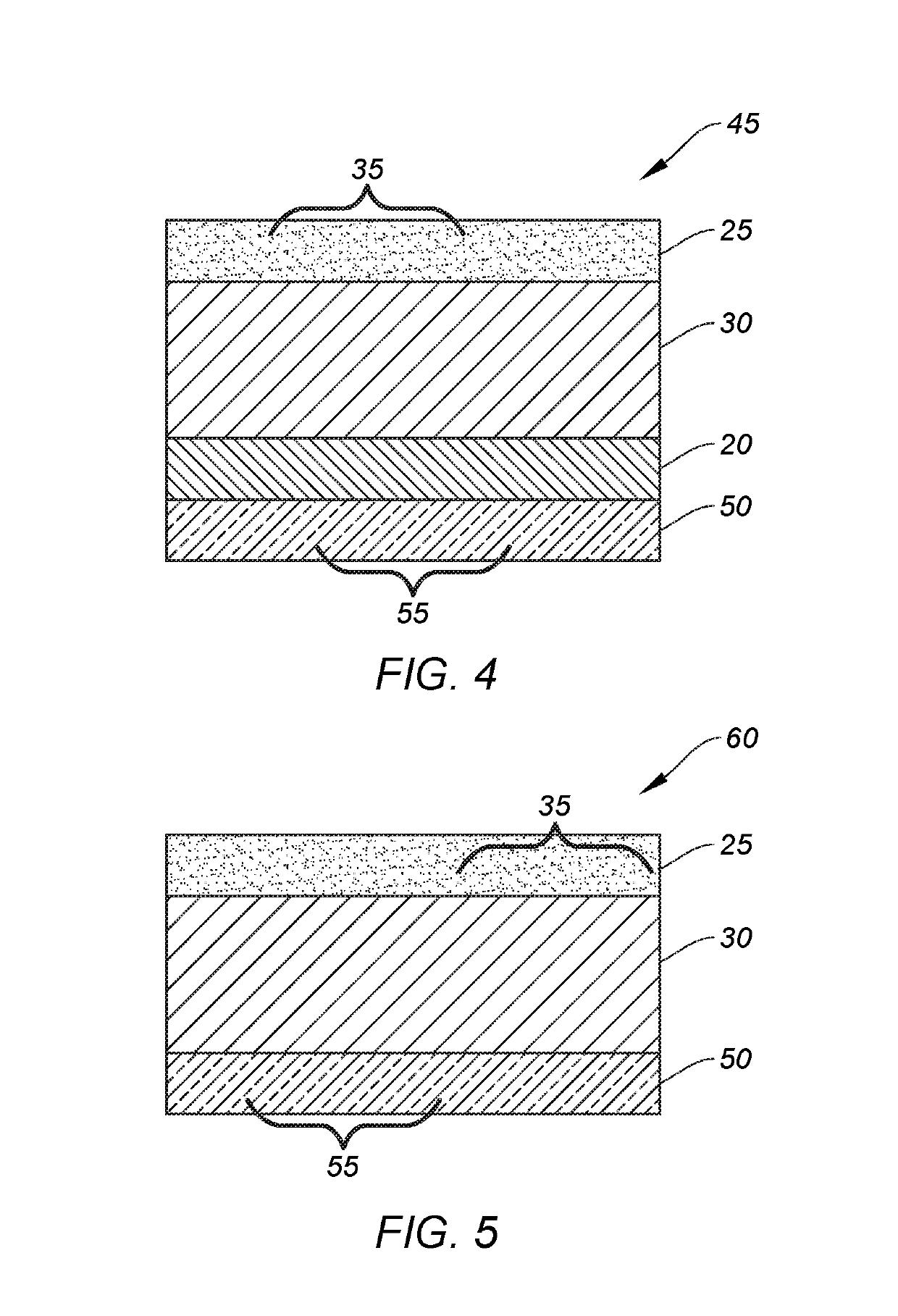

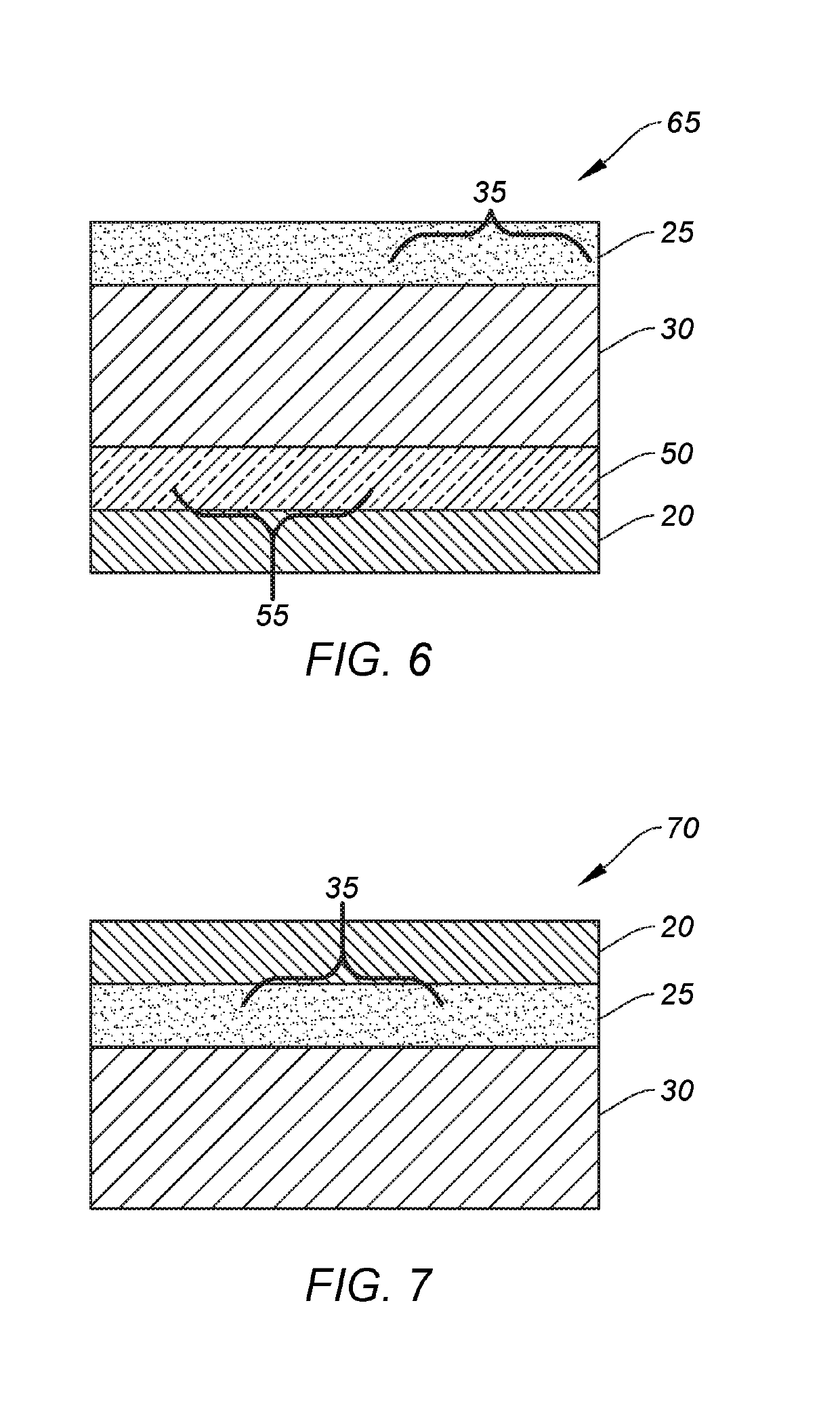

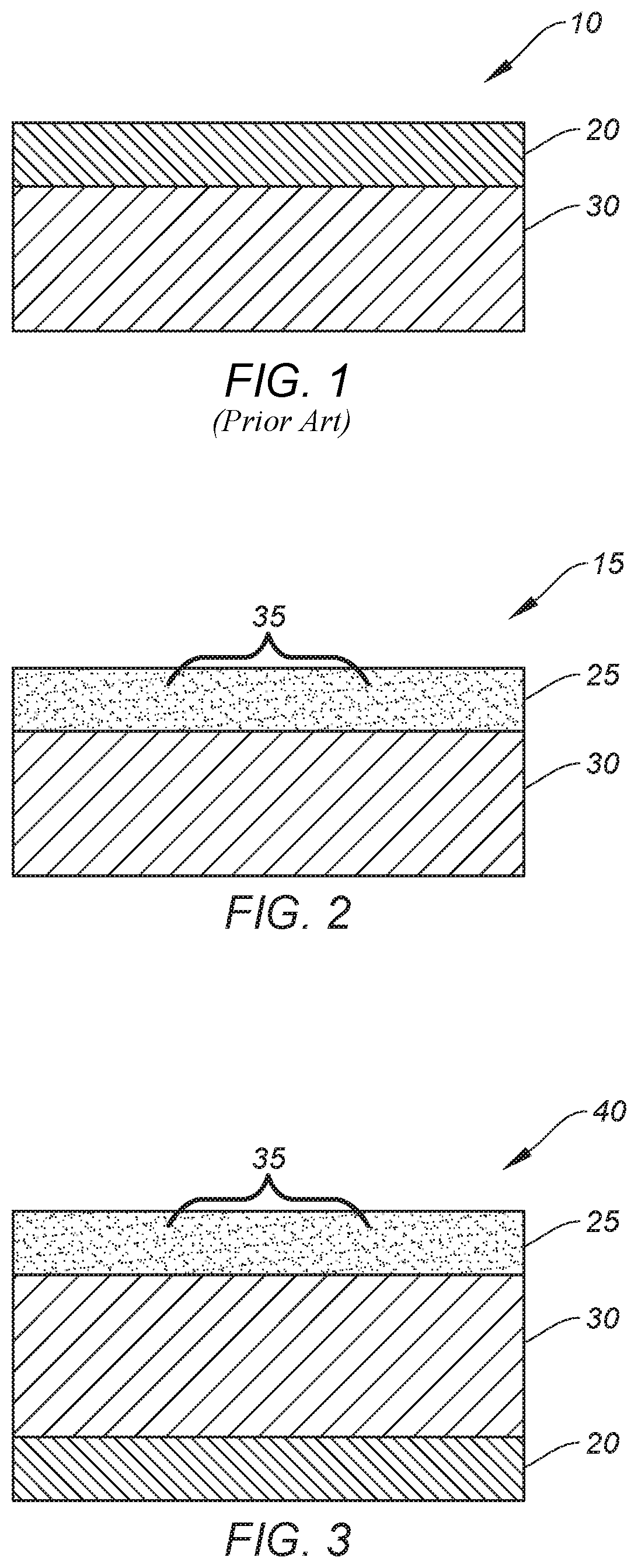

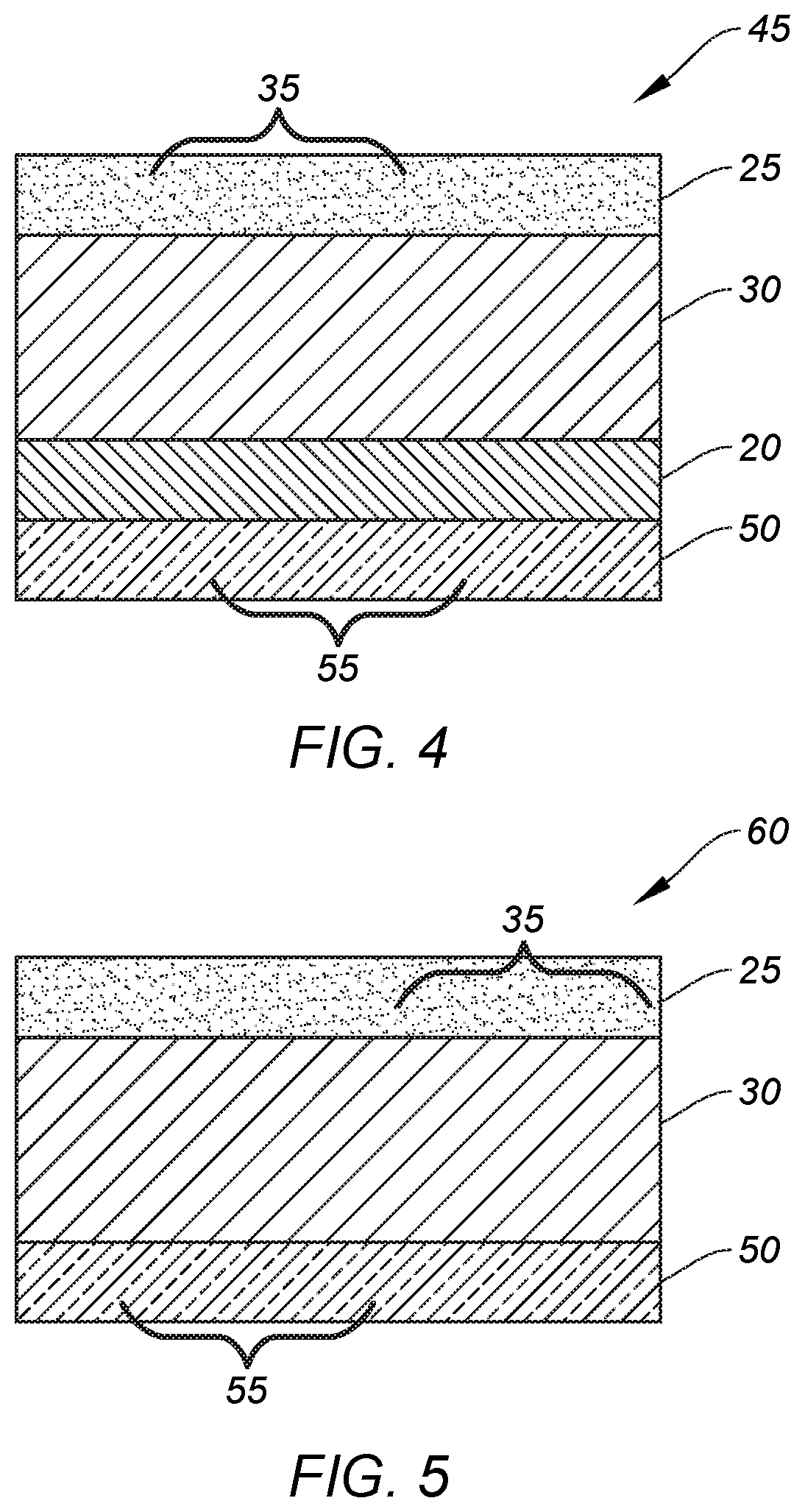

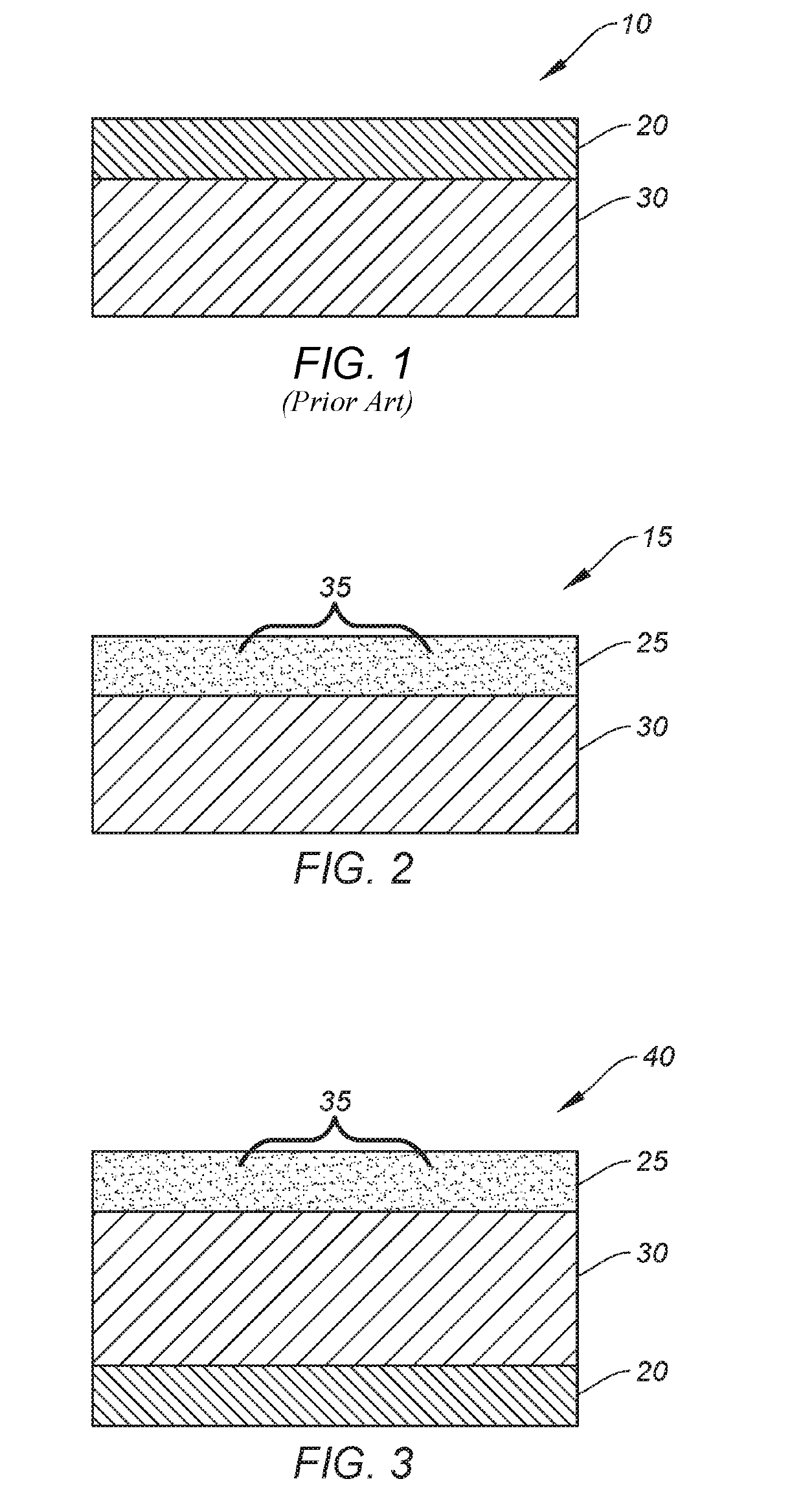

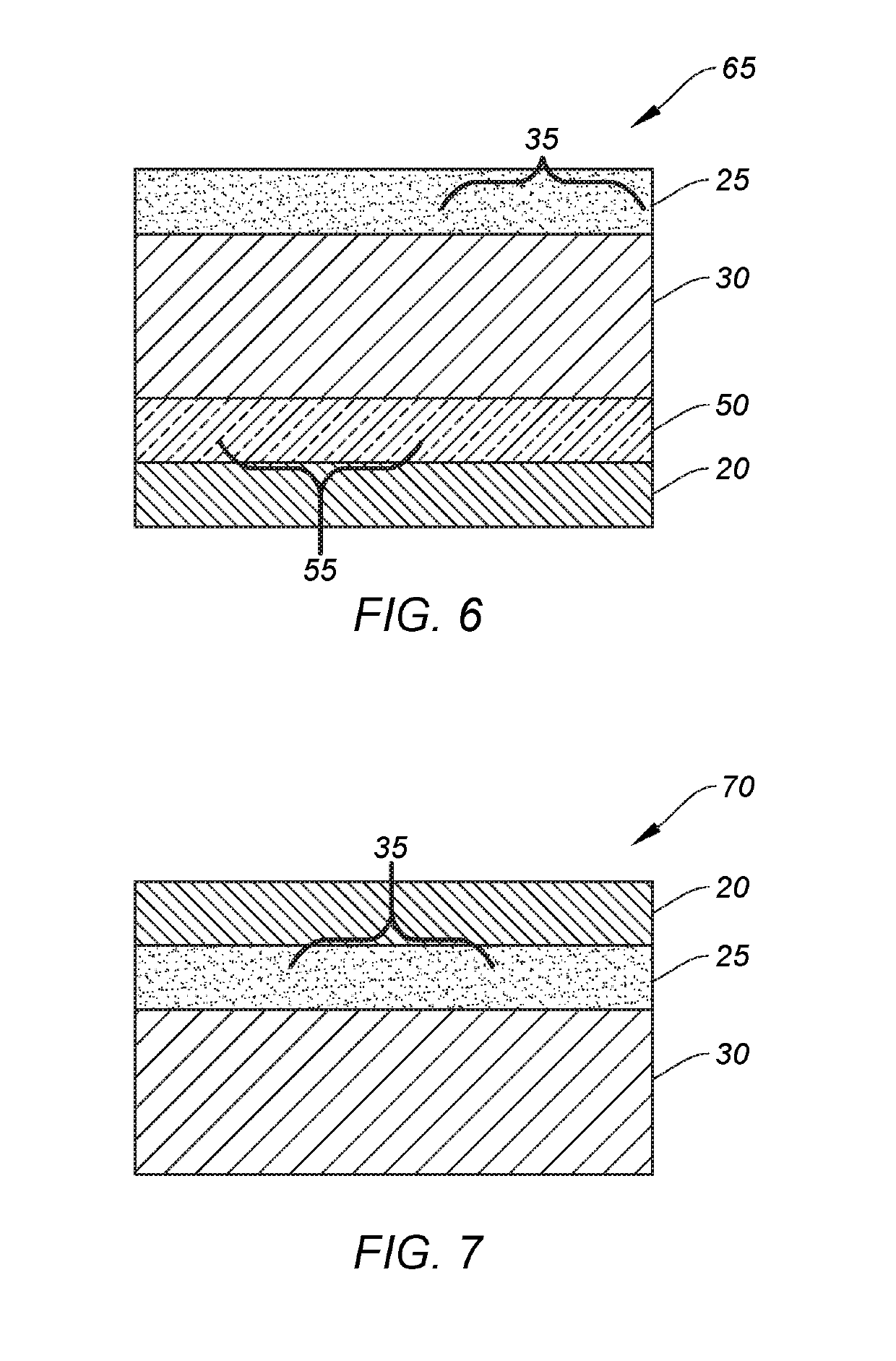

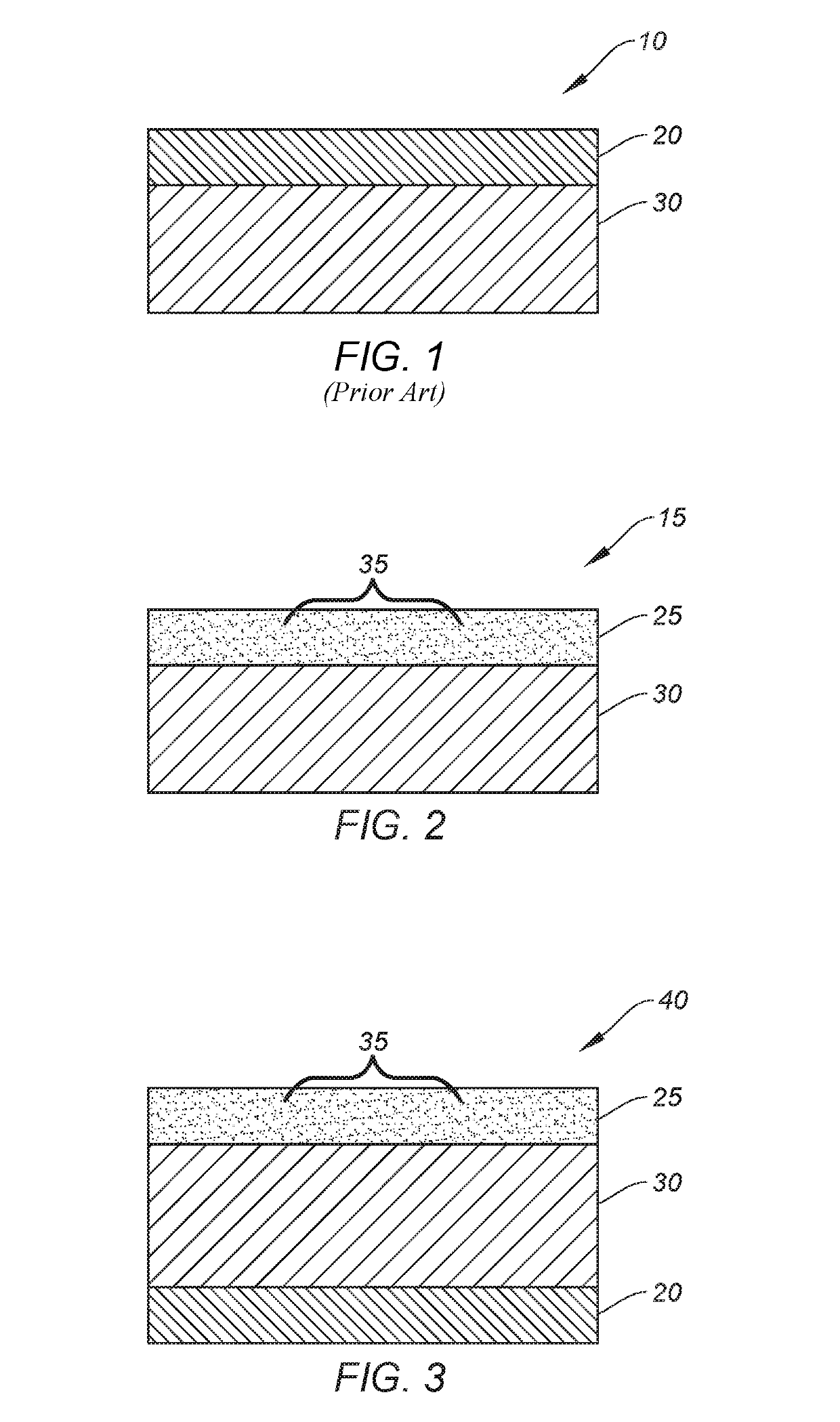

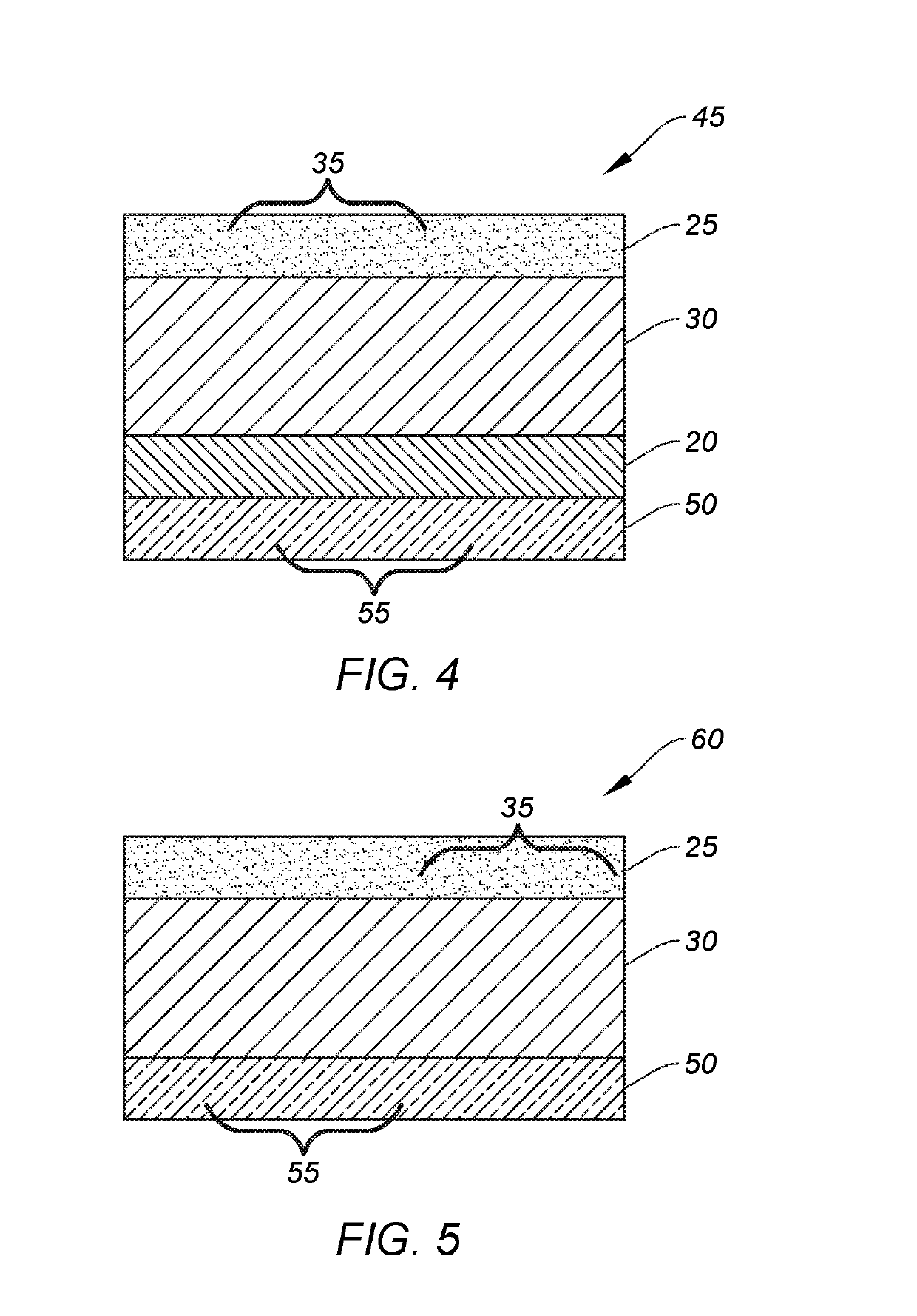

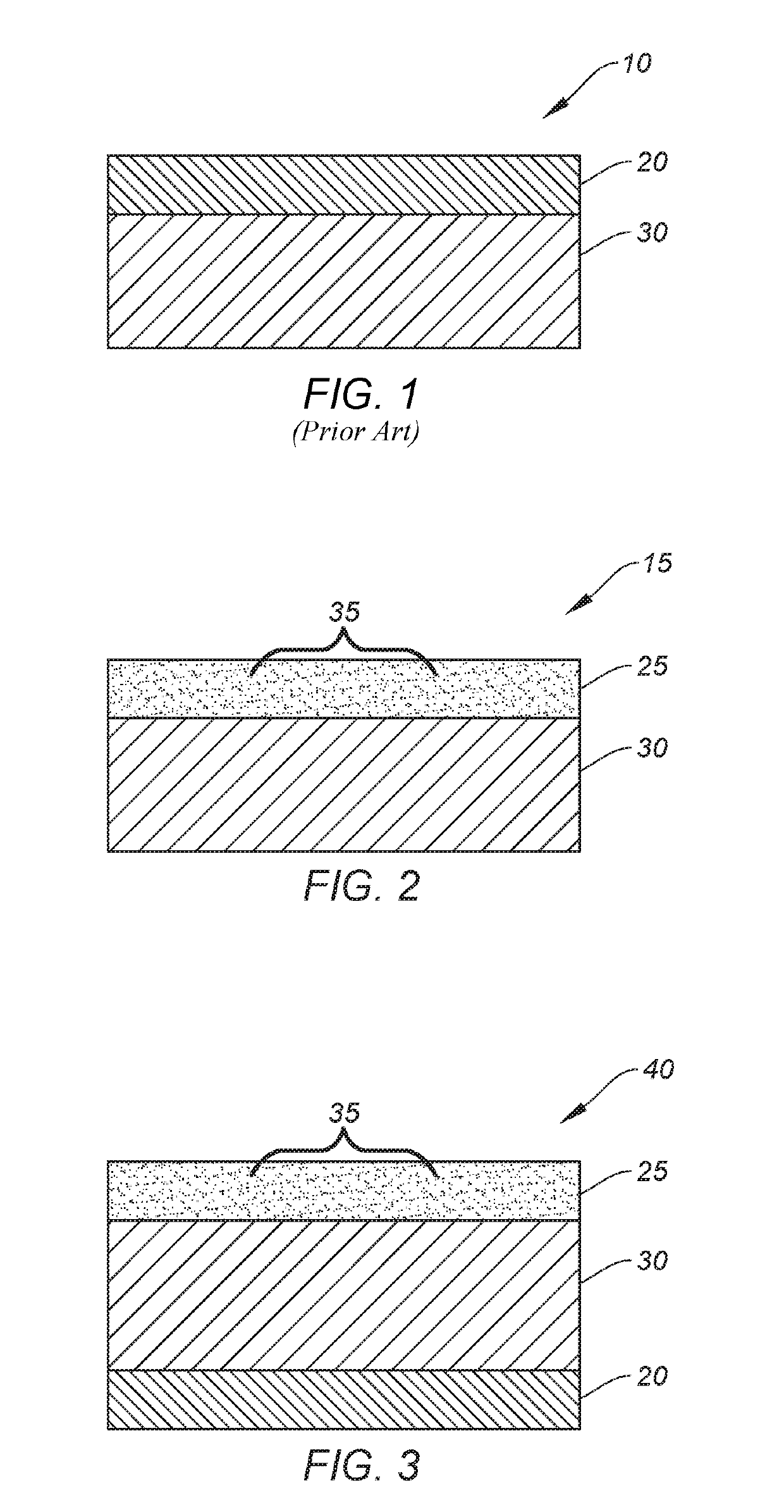

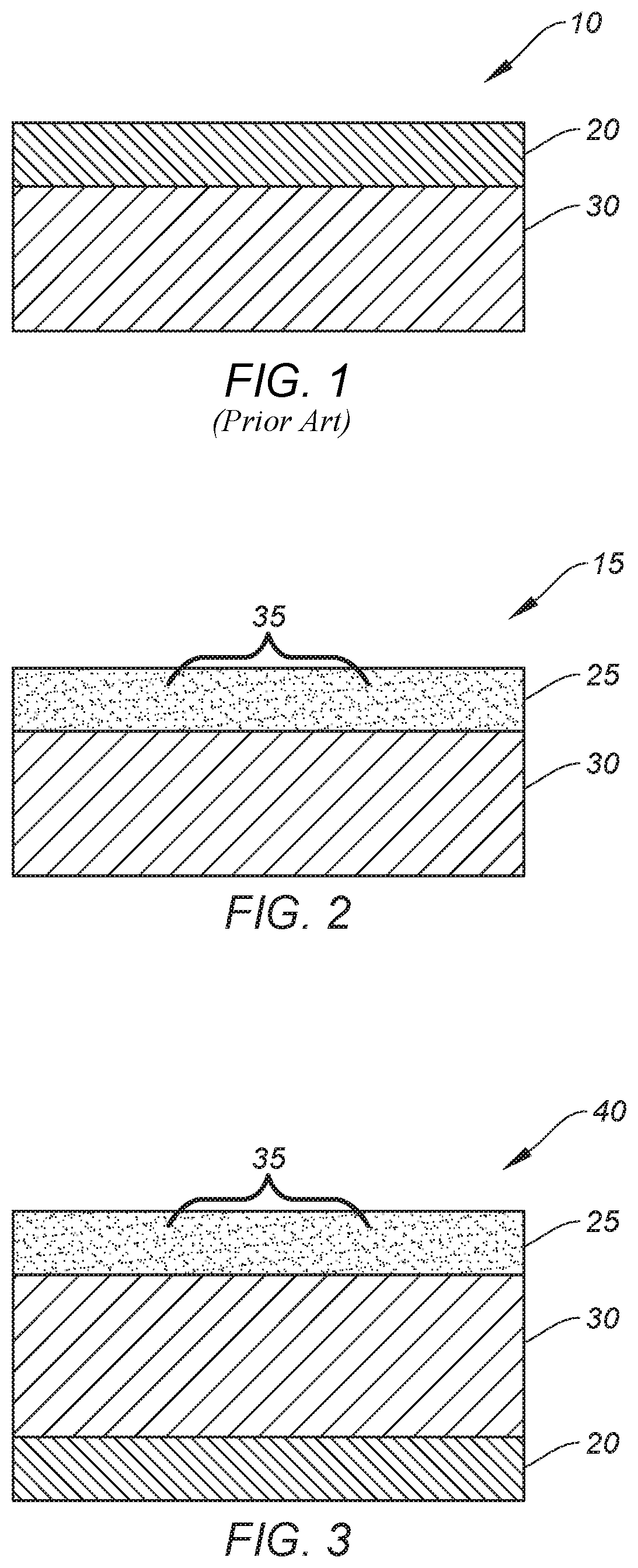

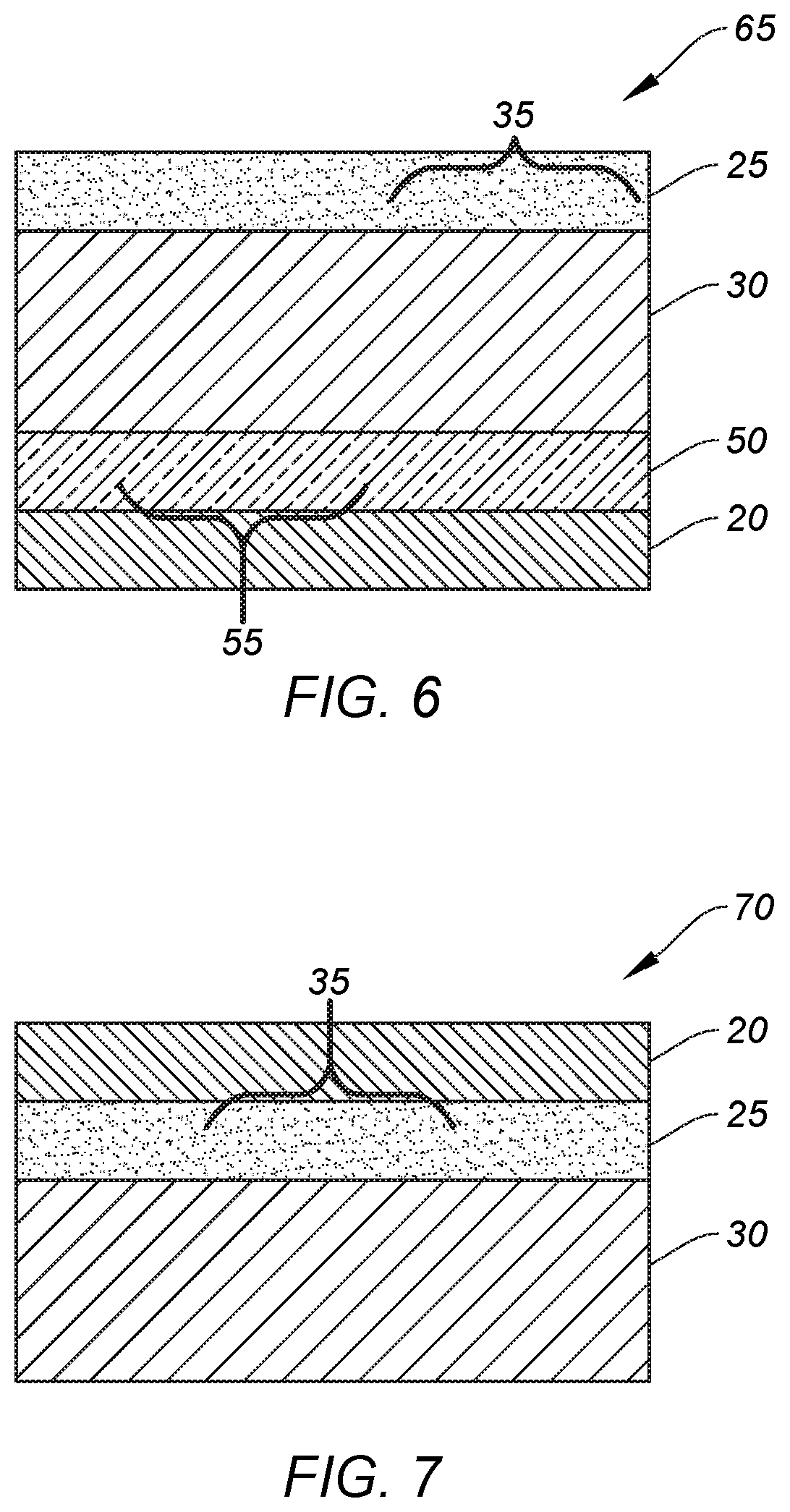

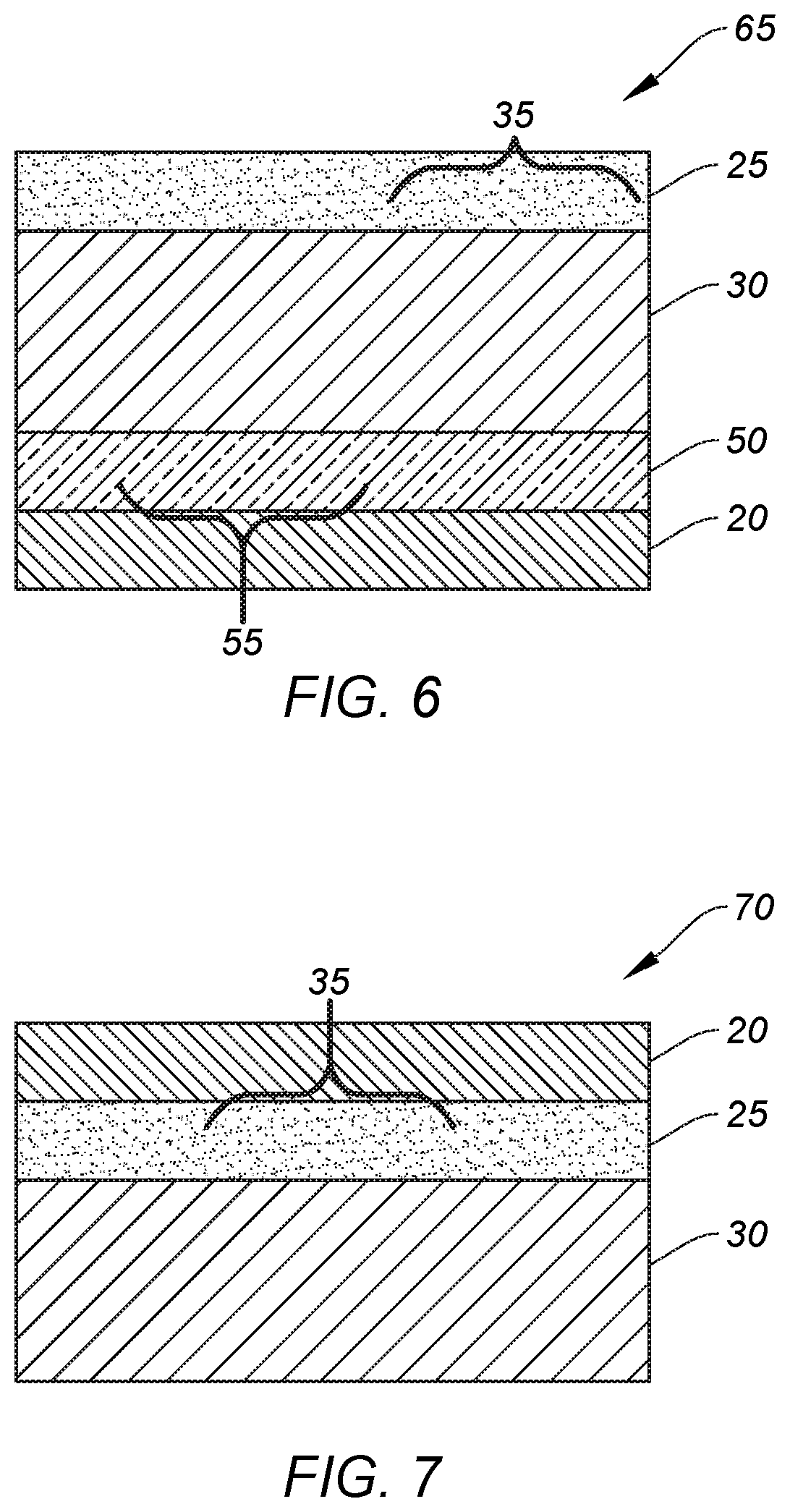

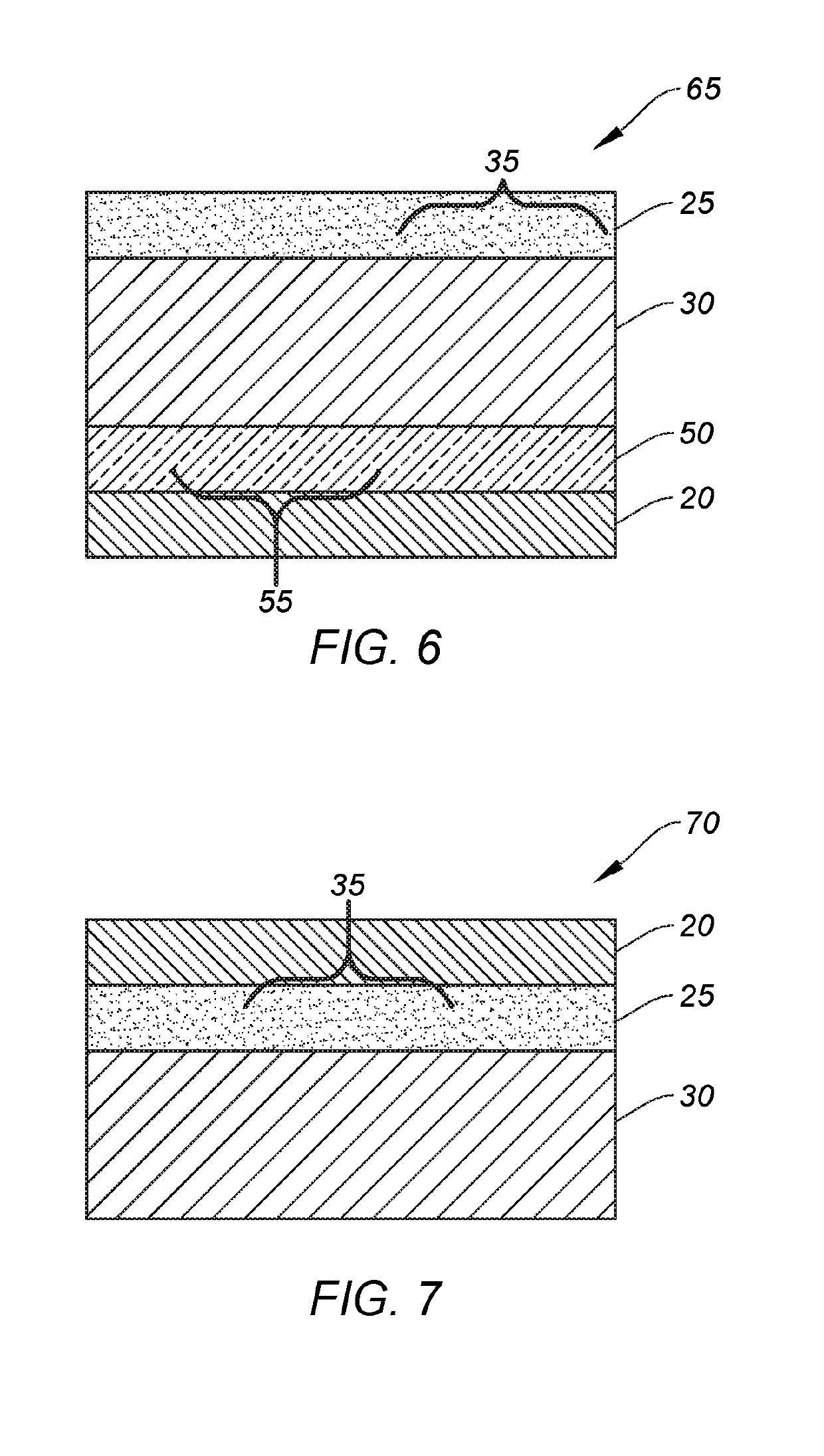

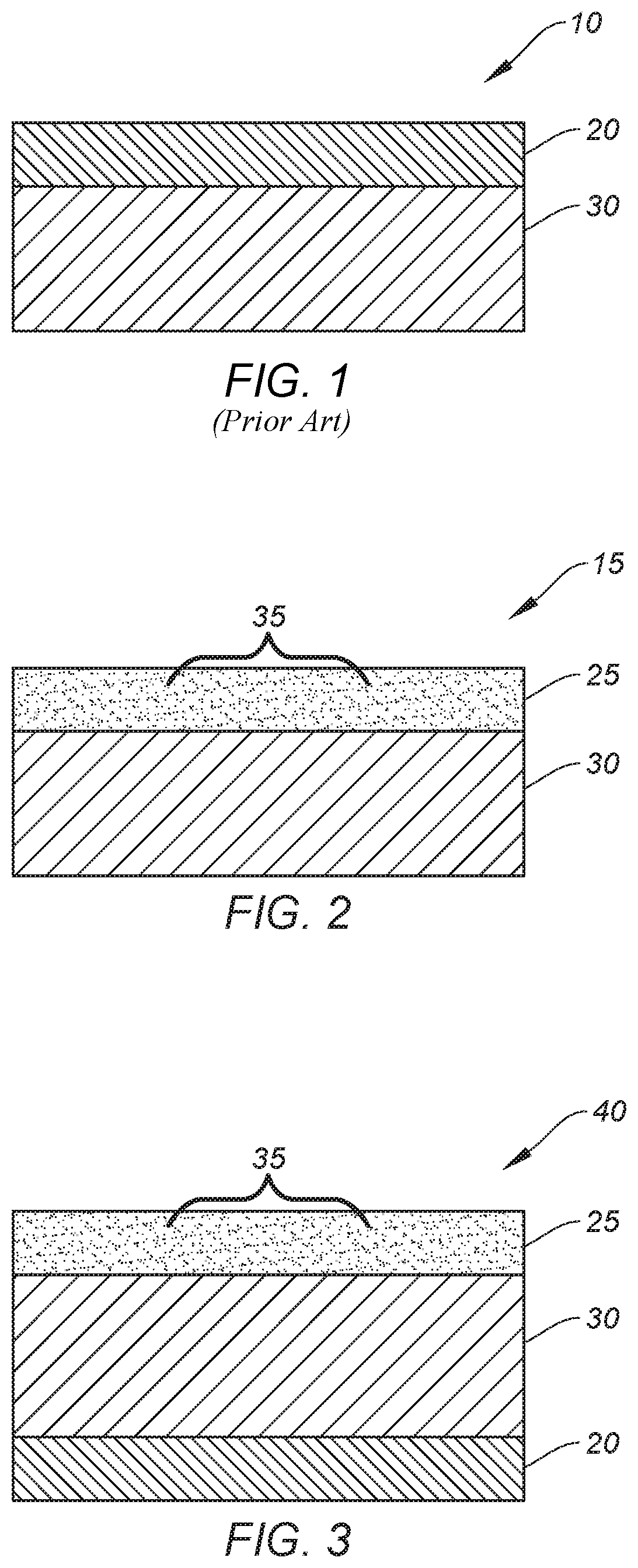

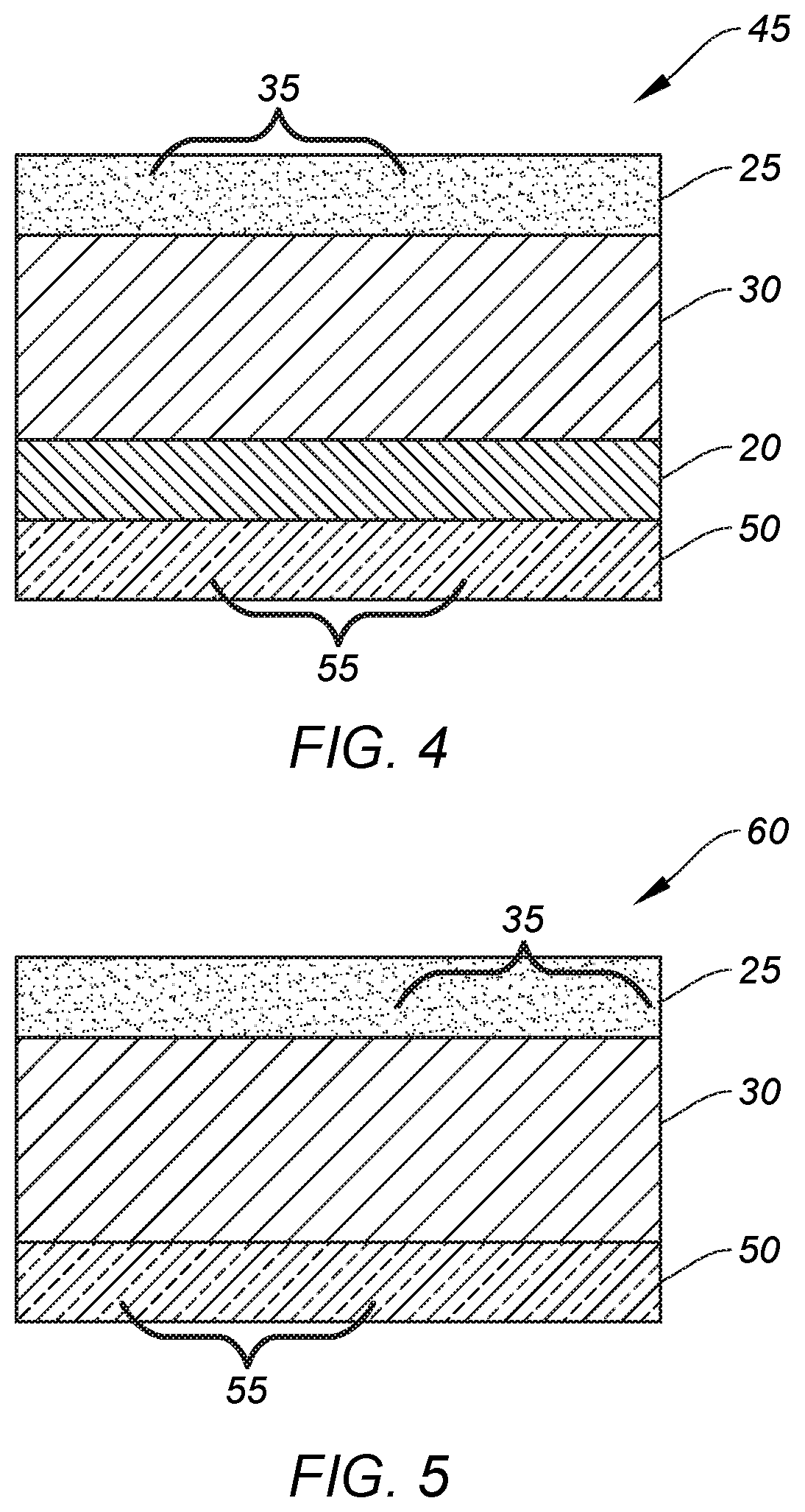

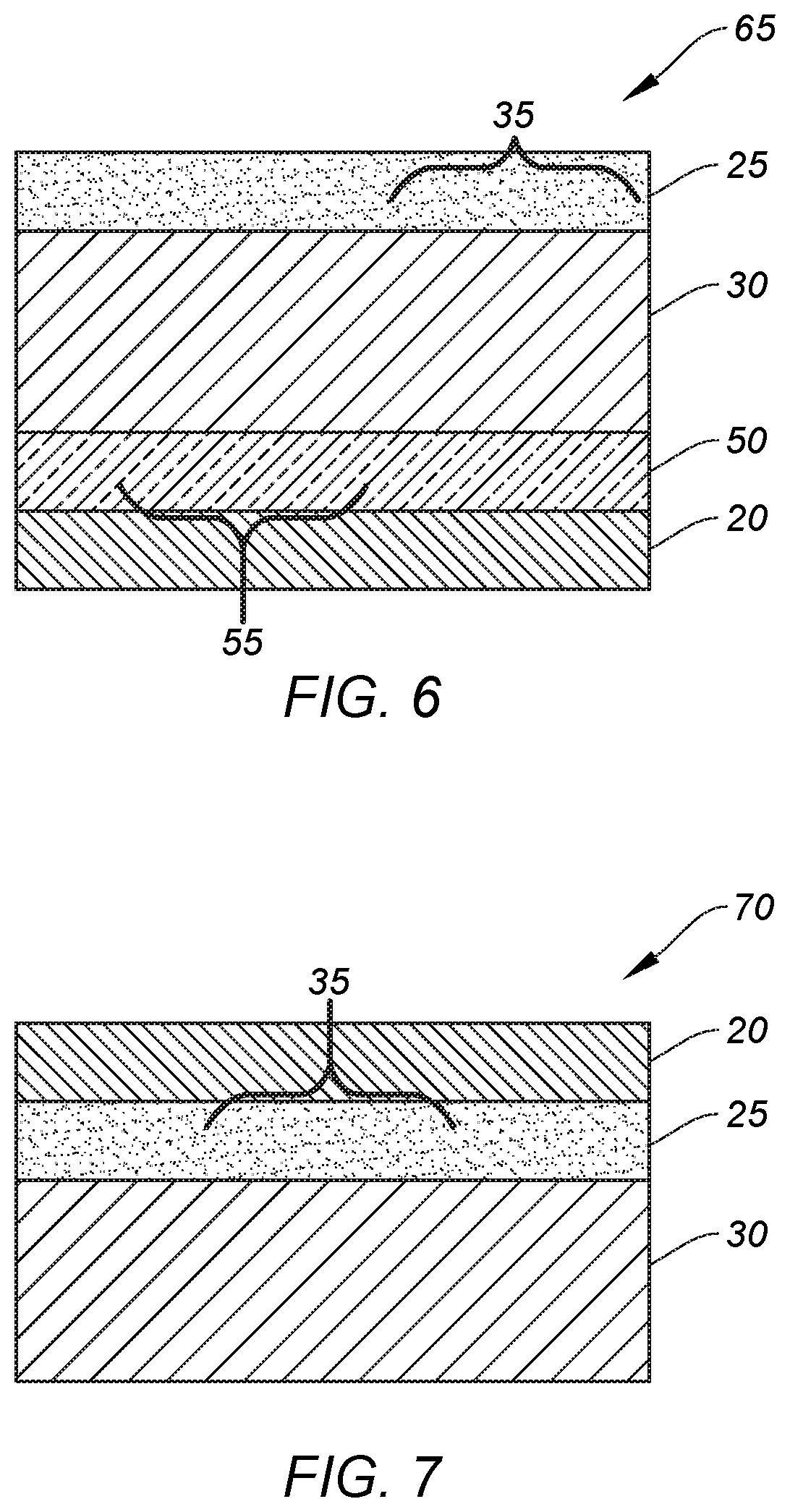

Method for providing piezoelectric devices

InactiveUS20190189904A1Improved piezoelectric responseAffects distributionPiezoelectric/electrostrictive device material selectionPhysical chemistryConductive materials

A piezoelectric device can be provided by: A) providing a first dry piezoelectric layer (first dry PL) comprising a dielectric material and having first and second opposing surfaces; and B) providing a first dry electrically-conductive layer (first dry ECL-P) that is arranged contiguously with the first opposing surface of the first dry PL. The first dry ECL-P has (a) an electrically-conductive material; and (b) particles distributed within the (a) electrically-conductive material, the (b) particles having a Young's modulus that is different from the Young's modulus of the (a) electrically-conductive material by at least 10%, and which (b) particles have a d50 of at least 500 nm and up to and including 500 μm and a polydispersity coefficient that is less than 3. The weight ratio of the (b) particles to the (a) electrically-conductive material is at least 0.01:1 and up to and including 10:1.

Owner:EASTMAN KODAK CO

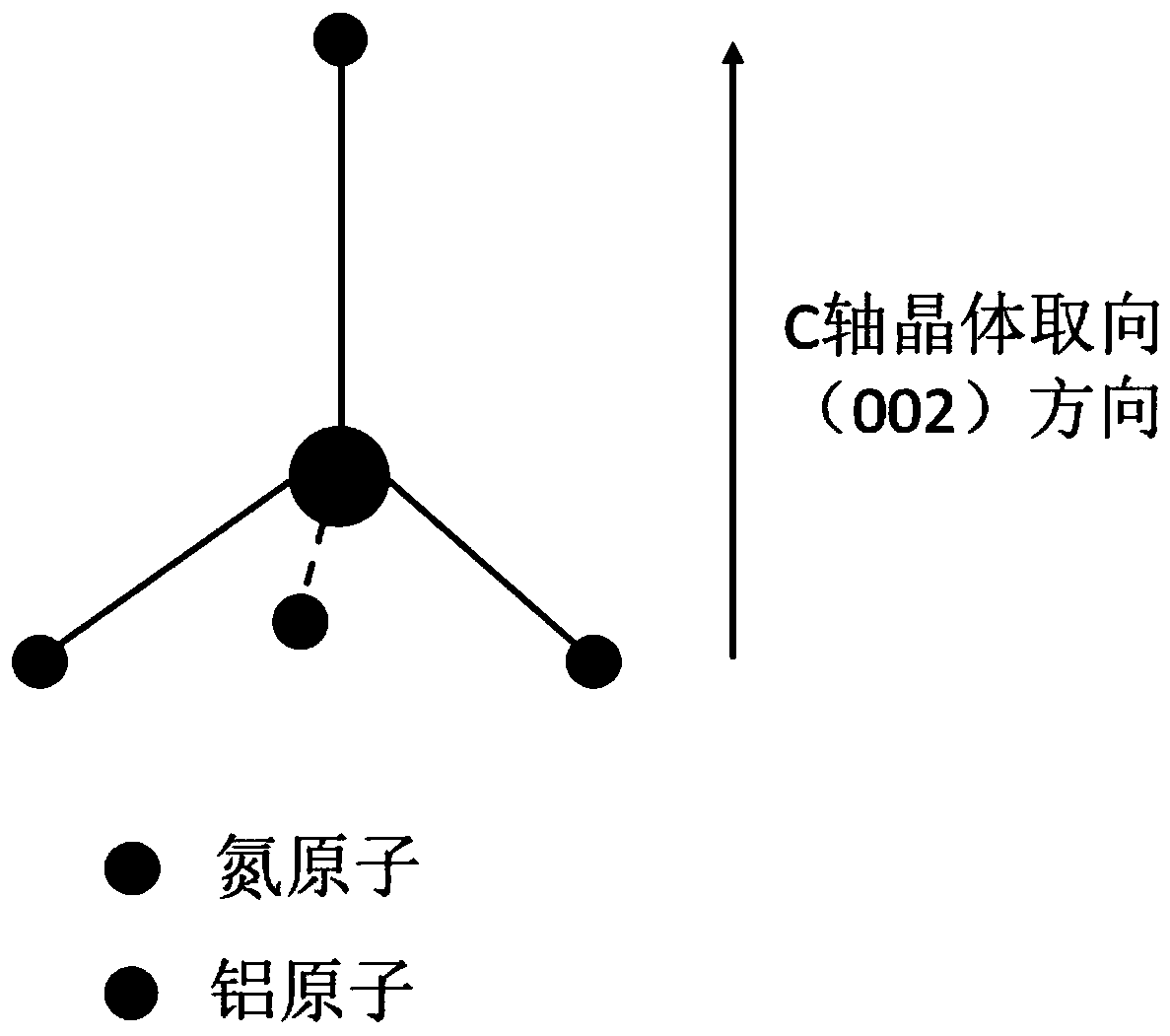

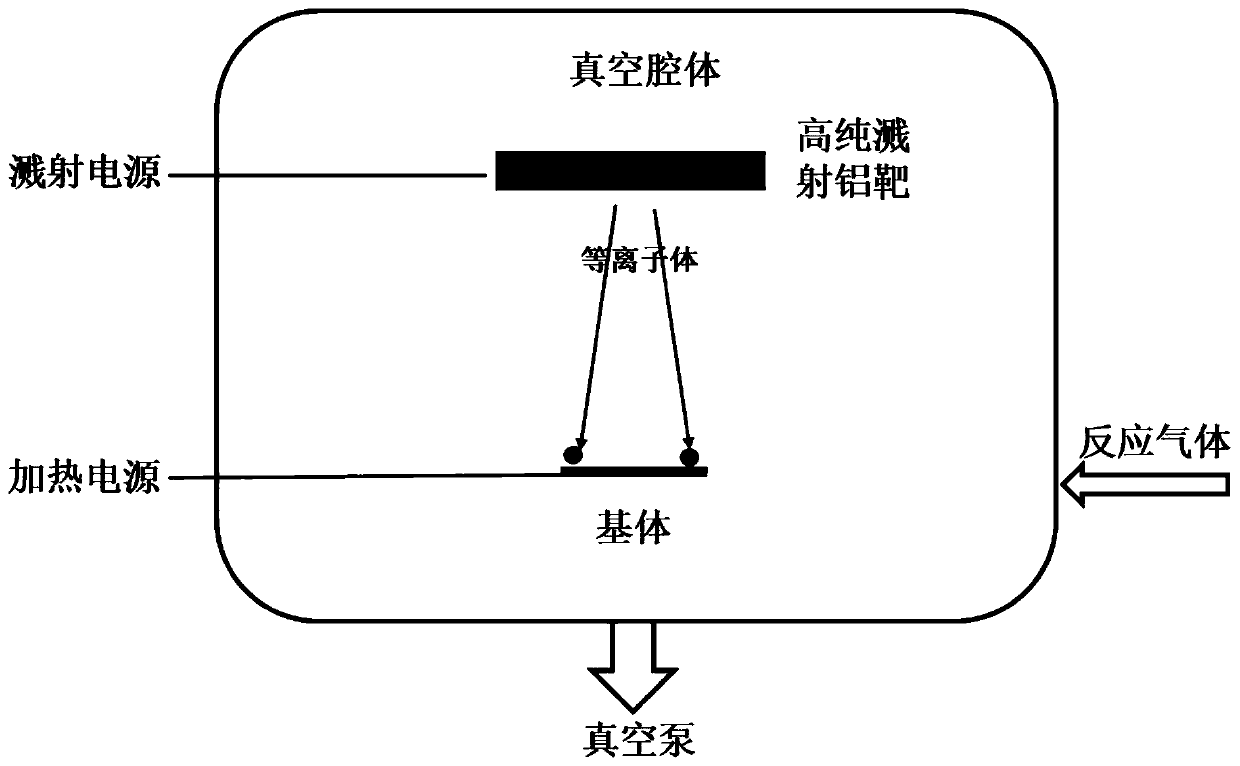

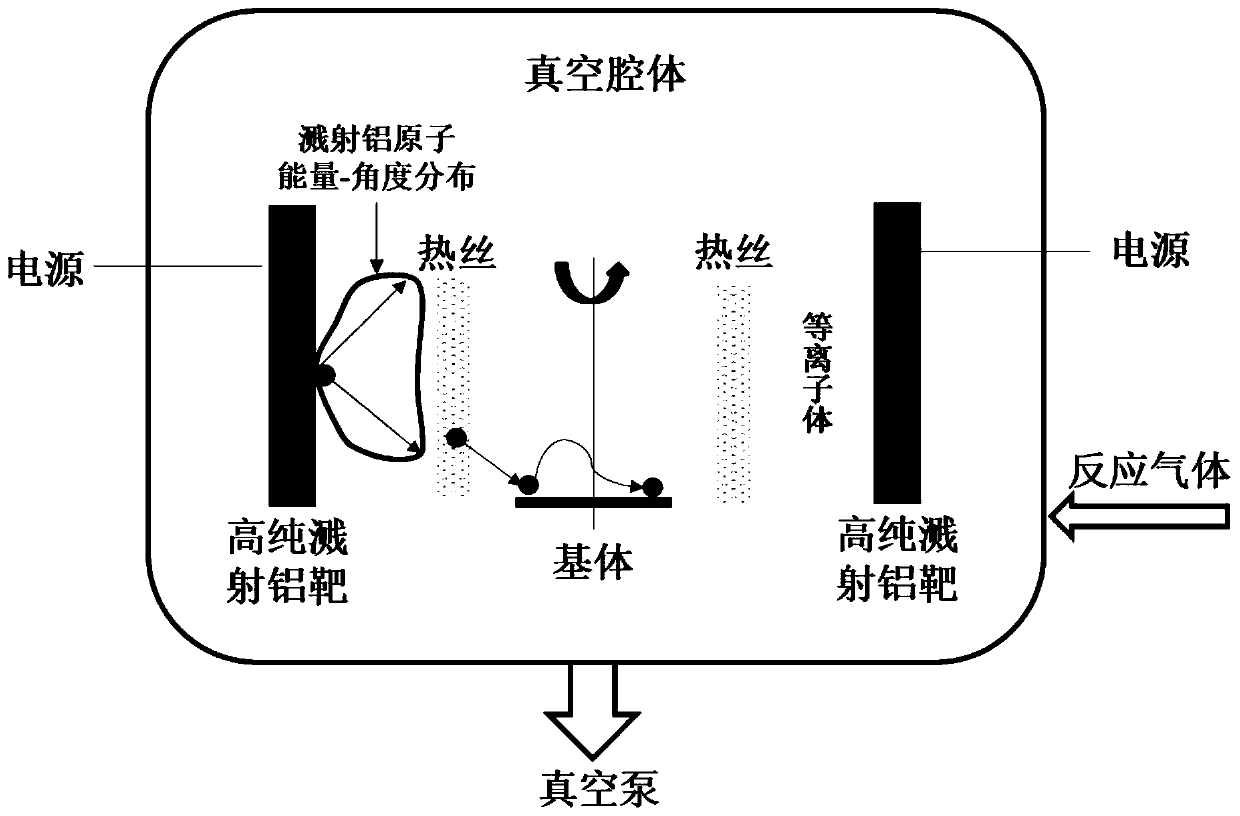

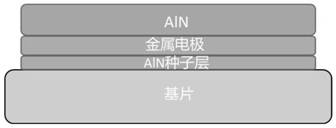

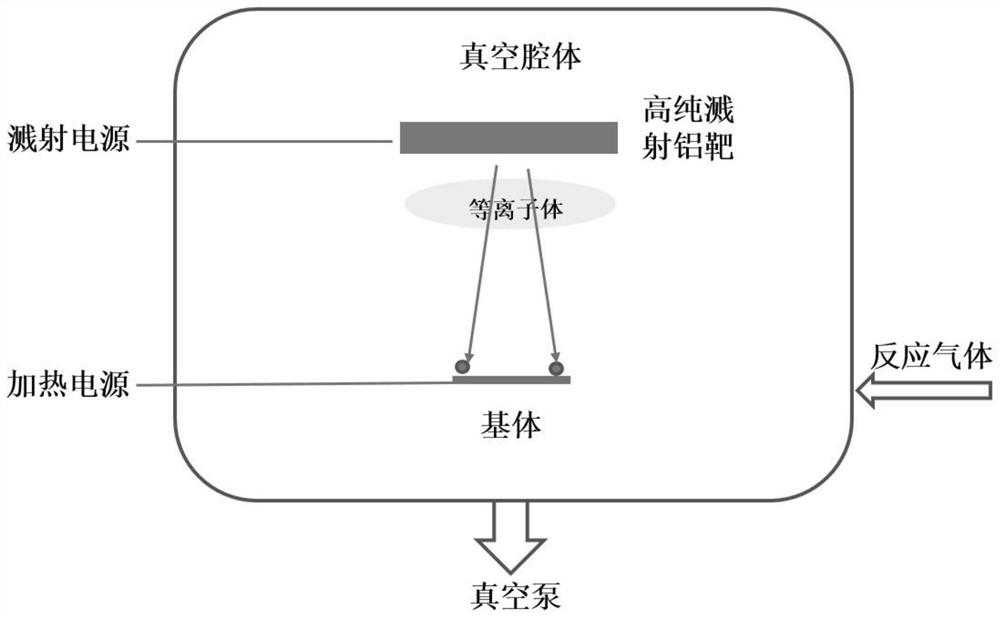

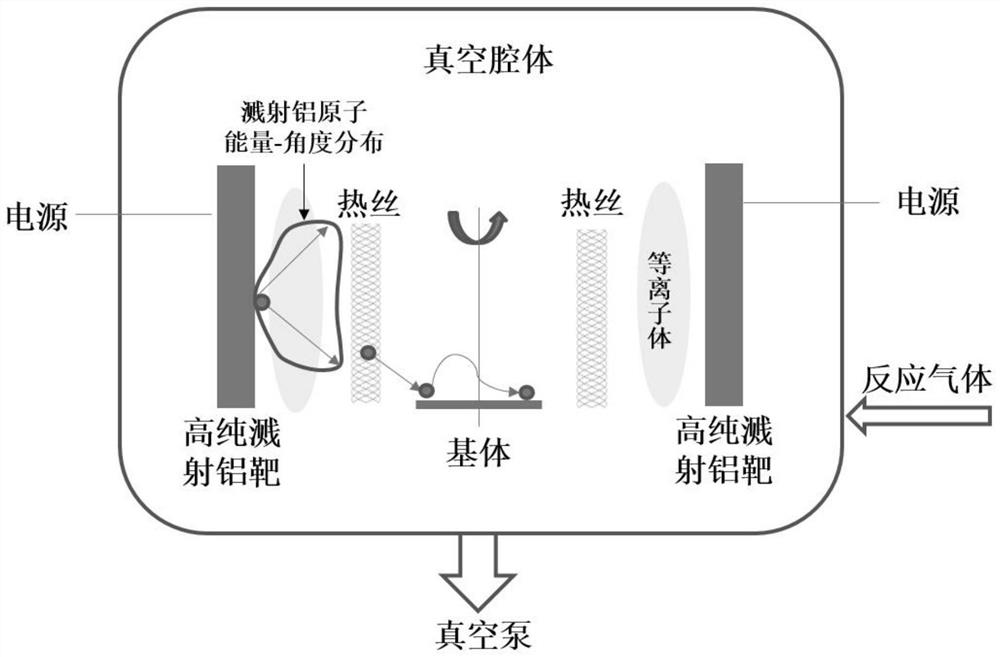

Method for preparing C-axis preferred orientation aluminum nitride polycrystalline film through magnetron sputtering and aluminum nitride polycrystalline film

ActiveCN111270214AImproved piezoelectric responseHigh degree of crystallinityPolycrystalline material growthVacuum evaporation coatingSputteringSemiconductor materials

The invention provides a method for preparing a C-axis preferred orientation aluminum nitride polycrystalline film through magnetron sputtering and the aluminum nitride polycrystalline film, and relates to the technical field of film material preparation. According to the method, the semiconductor material substrate and the high-purity sputtering aluminum target are relatively vertically arranged,so that the energy of migration movement of sputtering aluminum atomic groups parallel to the surface of the substrate after reaching the substrate can be greatly improved, the C-axis preferred orientation growth of the aluminum nitride film is convenient, and the piezoelectric response and electromechanical coupling coefficient of the film are improved; according to the method, the heating wireis arranged near the semiconductor material substrate, and high-temperature radiation generated by the heating wire performs rapid heat treatment on the aluminum nitride film, so that the crystallization degree of the film can be improved. Therefore, according to the method, the C-axis preferred orientation aluminum nitride thin film can be grown by utilizing the magnetron sputtering technology ata lower temperature, and the obtained aluminum nitride thin film is high in crystallinity, has a higher piezoelectric response coefficient and an electromechanical coupling coefficient, and can be used as a chip material to be applied to a surface acoustic wave device or a bulk acoustic wave device.

Owner:河南科之诚第三代半导体碳基芯片有限公司 +1

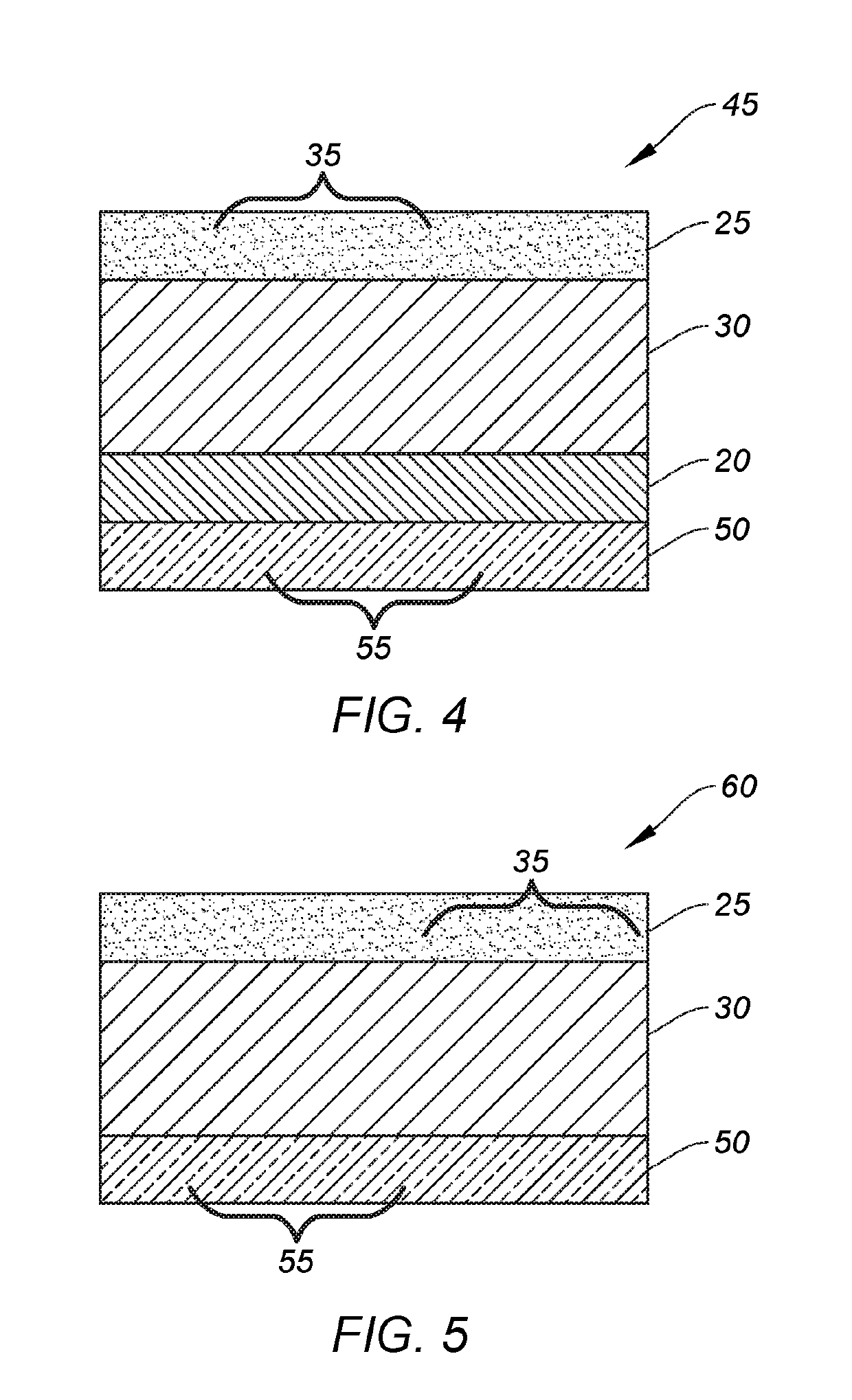

Composite articles with dielectric layer

ActiveUS20190189903A1Improve performanceImprove the overall coefficientPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive device material selectionYoung's modulusDielectric layer

A composite article useful in various electronic devices has 1) a dry piezoelectric layer (first dry PL) comprising a piezoelectric material, and 2) one or more dry dielectric layers arranged contiguously with opposing surfaces of the first dry PL. The dry dielectric layer has essentially: (a′) a dielectric material; and (b) particles having a Young's modulus that is different from the Young's modulus of the (a′) dielectric material by at least 10%. The (b) particles have a d50 of at least 500 nm and up to and including 500 m and a polydispersity coefficient that is less than or equal to 3, provided that the weight ratio of the (b) particles to the (a′) dielectric material is at least 0.01:1 and up to and including 10:1.

Owner:EASTMAN KODAK CO

Silver-containing electrically-conductive compositions

ActiveUS20190189905A1Improve performanceImprove the overall coefficientPolyurea/polyurethane coatingsPiezoelectric/electrostrictive/magnetostrictive devicesYoung's modulusPolymer chemistry

Owner:EASTMAN KODAK CO

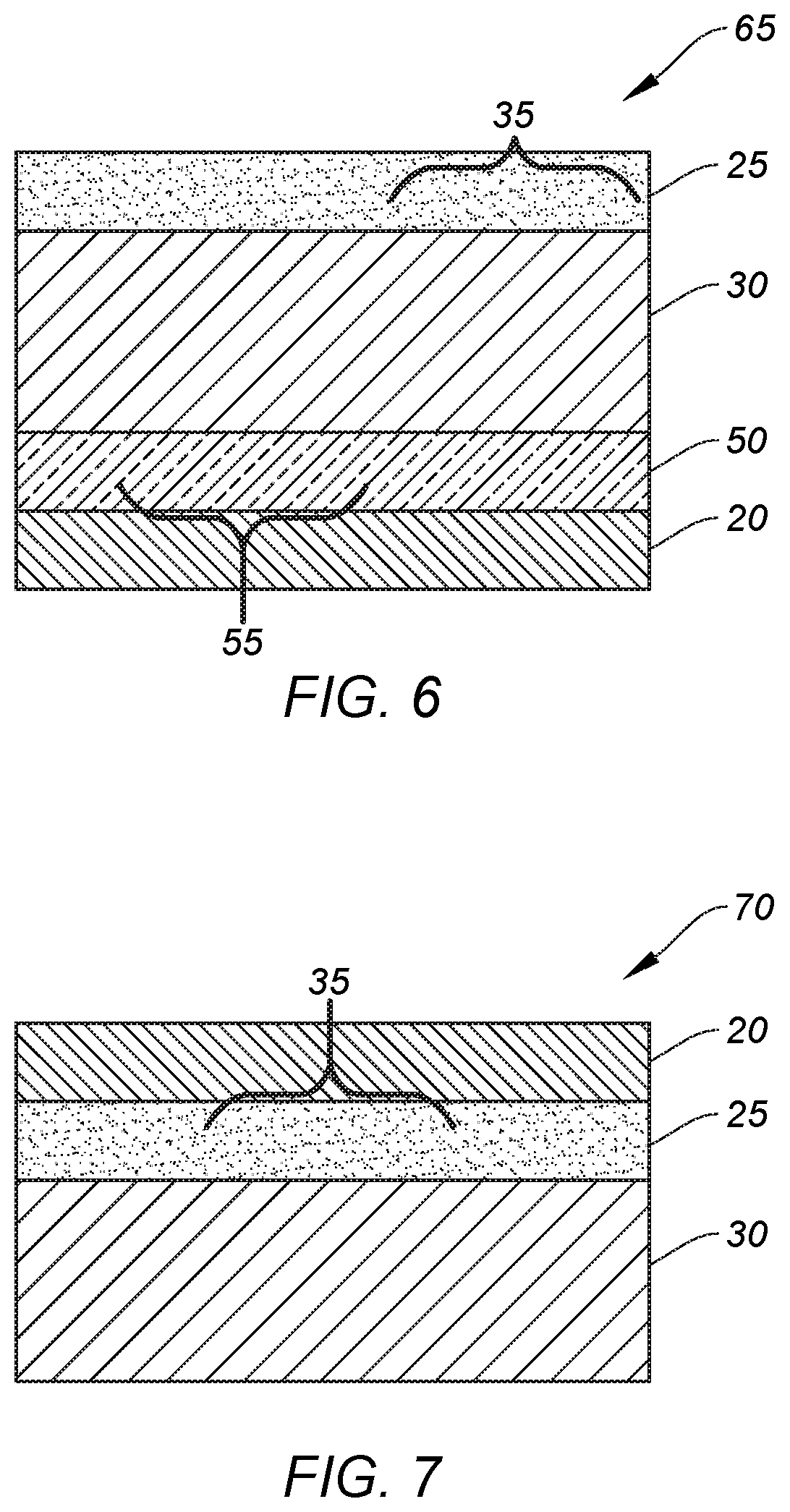

Inertial piezoelectric device

ActiveUS10818835B2Improve performanceImprove the overall coefficientMaterial nanotechnologyPiezoelectric/electrostriction/magnetostriction machinesEngineeringConductive materials

An inertial piezoelectric device has: A) piezoelectric capacitor having a substrate; 2) a dry piezoelectric layer comprising a piezoelectric material; 3) a first electrode arranged contiguously with one opposing surface of the dry PL; and 4) a second electrode arranged contiguously with a second opposing surface of the first dry PL. The first dry electrically-conductive layer consists essentially of: (a) an electrically-conductive material; and (b) particles having a Young's modulus that is different from the Young's modulus of the (a) electrically-conductive material by at least 10%. The device also has B) signal processing electronics in electrical communication with the piezoelectric capacitor; C) a means for converting all or a portion of an applied force to an inertial force that is transmitted to the first dry PL; and optionally D) a proof mass that is contiguous with at least one external surface of the piezoelectric capacitor.

Owner:EASTMAN KODAK CO

C-axis vertical preferred orientation AlN piezoelectric film and preparation method thereof

PendingCN112382718AReduce manufacturing costHigh crystallinityPiezoelectric/electrostrictive device manufacture/assemblyVacuum evaporation coatingElectromechanical coupling coefficientThin membrane

The invention relates to the technical field of thin film material preparation, in particular to a C-axis vertical preferred orientation AlN piezoelectric thin film and a preparation method thereof, and the preparation method comprises the step: a self-buffer layer AlN thin film, a metal electrode layer and an AlN piezoelectric thin film are sequentially prepared on a sapphire or YAG crystal. Andthe self-buffer layer AlN film induces the orientation of the metal electrode layer, so that the highly C-axis preferred orientation AlN film is prepared on the electrode layer. The sapphire or YAG crystal and the high-purity sputtering target form an angle of 45 degrees, so that the energy of migration motion parallel to the surface of the substrate after sputtering atomic groups reach the substrate is effectively regulated and controlled, the growth of a buffer layer and the C-axis preferred orientation growth of the AlN piezoelectric film are facilitated, and the piezoelectric response andelectromechanical coupling coefficient of the film are improved. According to the method disclosed by the invention, the C-axis preferred orientation AlN film can be grown by utilizing a magnetron sputtering technology at a relatively low temperature, and the obtained AlN film is high in crystallinity and has a relatively high piezoelectric response coefficient and a relatively high electromechanical coupling coefficient.

Owner:CHINA ELECTRONICS TECH GRP NO 26 RES INST

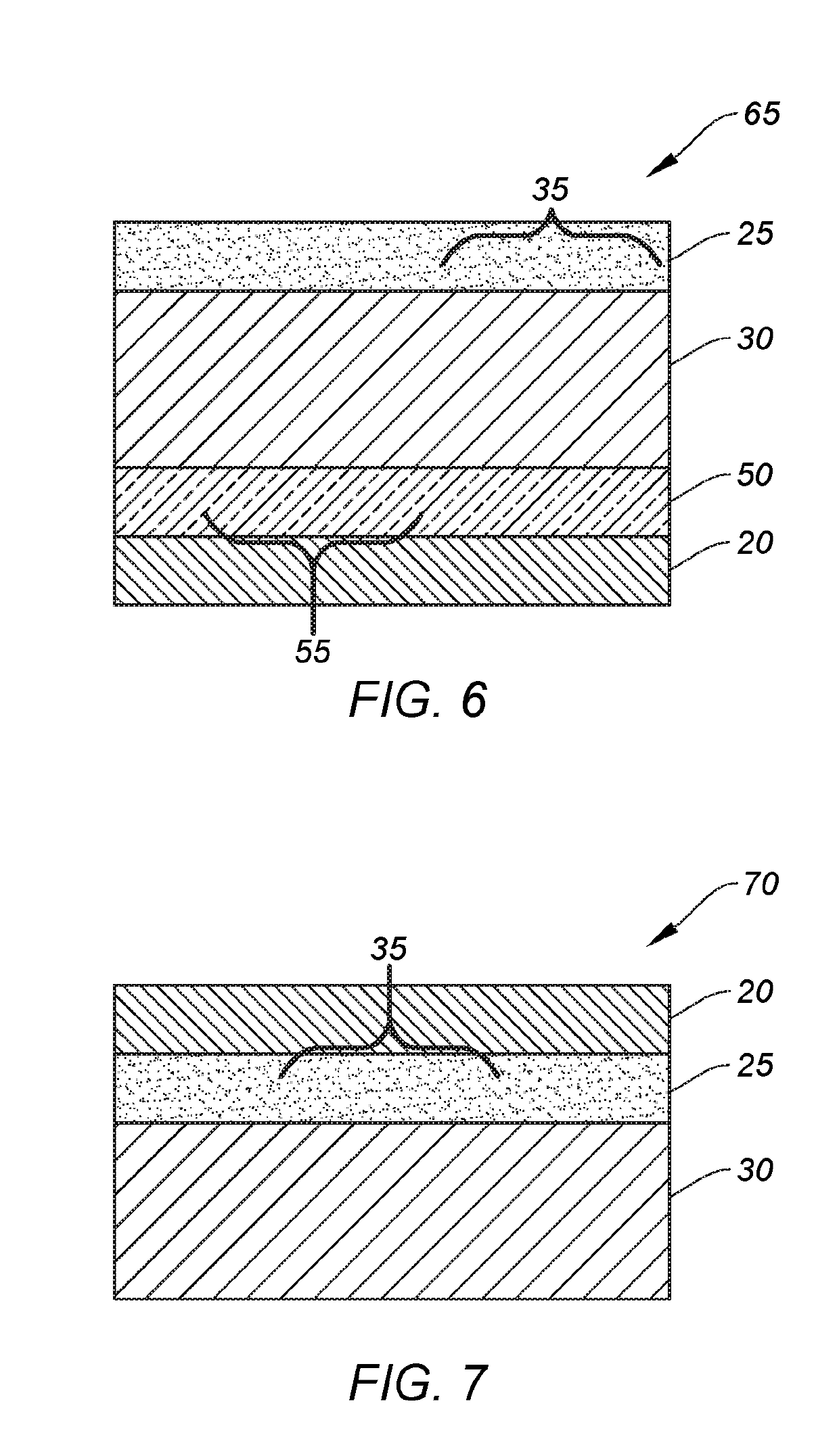

Kinetic piezoelectric capacitor with co-planar patterned electrodes

InactiveUS20190189898A1Improved piezoelectric responseAffects distributionPiezoelectric/electrostrictive device material selectionElectrically conductiveElectricity

A kinetic piezoelectric device is designed with: A) piezoelectric capacitor that has: 1) a substrate; 2) a first dry piezoelectric layer (first dry PL) comprising a piezoelectric material and having first and second opposing surfaces; and 3) a first pair of non-electrically-connected co-planar patterned electrodes that are arranged contiguously with at least one of the first and second opposing surfaces of the first dry PL. At least one of the first pair of non-electrically-connected co-planar patterned electrodes consists essentially of: (a) an electrically-conductive material; and (b) particles having a Young's modulus that is different from the Young's modulus of the (a) electrically-conductive material by at least 10%. The device also has B) signal processing electronics in electrical communication with the piezoelectric capacitor; and C) a means for transmitting all or a portion of an applied force directly to the first dry PL.

Owner:EASTMAN KODAK CO

Piezoelectric capacitor with co-planar patterned electrodes

InactiveUS20190189890A1Improve performanceImprove the overall coefficientPiezoelectric/electrostrictive device material selectionPiezoelectric actuatorsYoung's modulus

A piezoelectric capacitor is designed with A) a composite article that has: 1) a first dry piezoelectric layer; and 2) a first pair of non-electrically-connected co-planar patterned electrodes that are arranged contiguously with at least one opposing surface of the dry piezoelectric layer. At least one of the non-electrically-connected co-planar patterned electrodes has (a) an electrically-conductive material; and (b) particles having a Young's modulus that is different from the Young's modulus of the (a) electrically-conductive material by at least 10%. The piezoelectric capacitor also has B) electrical communication means attached to each of the first pair of non-electrically-connected co-planar patterned electrodes for electrical communication of the composite article with an external circuit.

Owner:EASTMAN KODAK CO

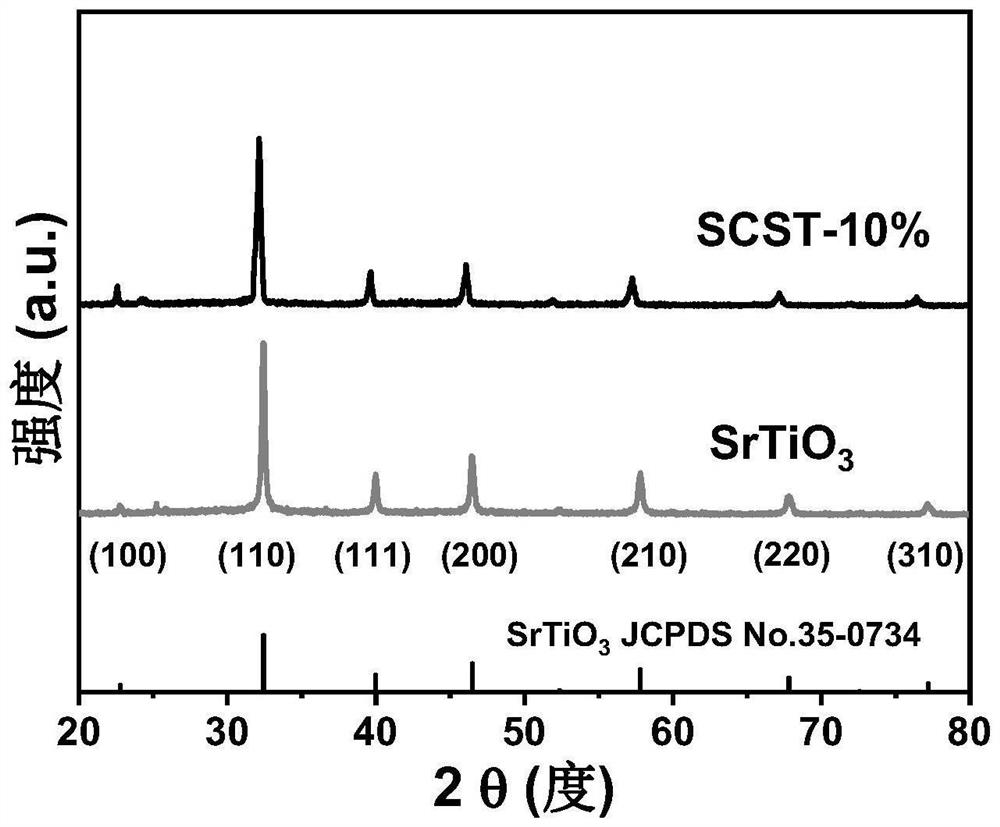

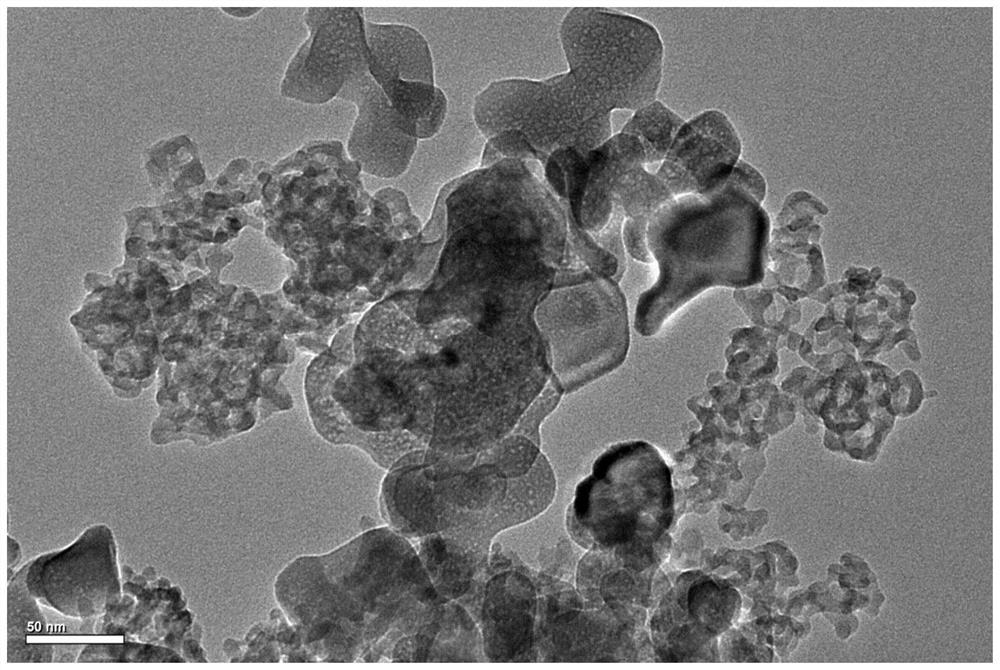

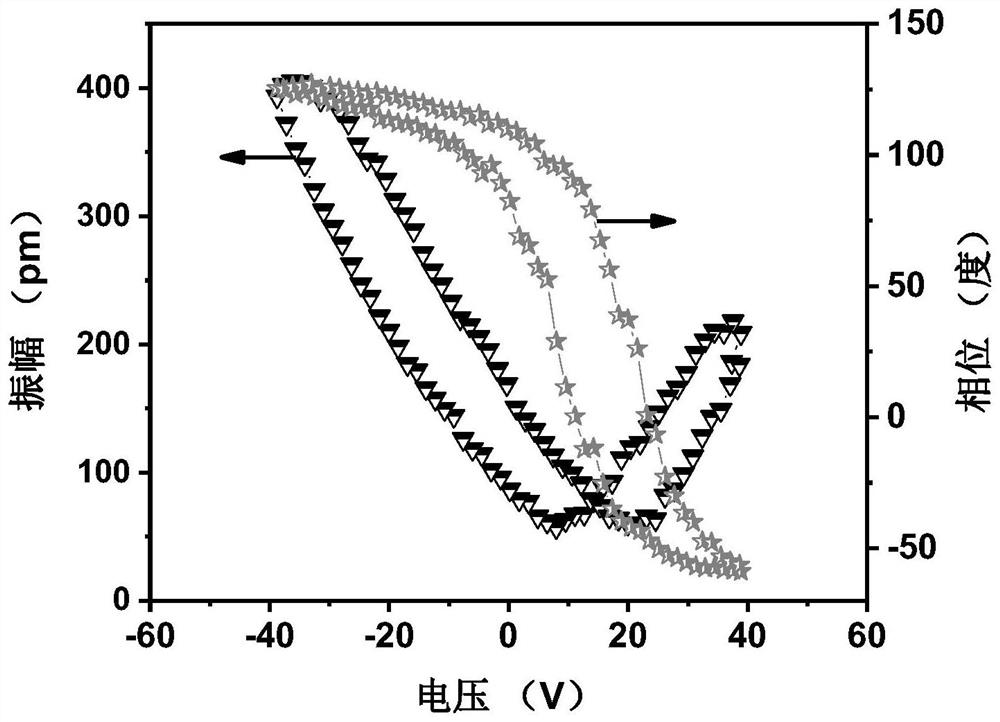

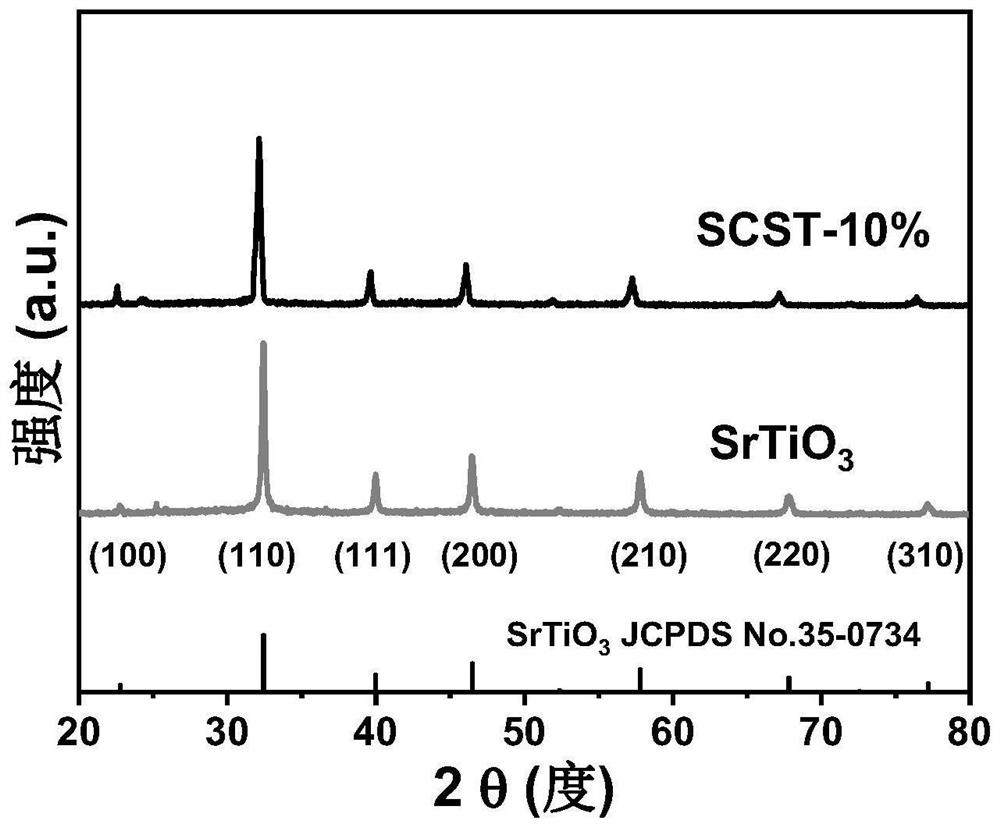

Tin and cerium-strontium titanate solid solution piezoelectric hydrogen production catalyst as well as preparation method and application thereof

ActiveCN113893846AImproved piezoelectric responseHigh crystal phase purityWater contaminantsWater/sewage treatment with mechanical oscillationsPtru catalystPhysical chemistry

The invention relates to the technical field of piezoelectric catalytic hydrogen production materials, and provides a tin and cerium-strontium titanate solid solution piezoelectric hydrogen production catalyst as well as a preparation method and application thereof. The chemical general formula of the material prepared according to the invention is SnxCeySr(1-x-y)TiO3 (x is more than 0 and less than or equal to 0.15, and y is more than 0 and less than or equal to 0.15). A Sr source, a Ce source, a Sn source and a Ti source are mixed with water and ethylene glycol, a coprecipitation method is adopted, a precursor of the tin and cerium-strontium titanate solid solution piezoelectric hydrogen production catalyst is prepared, and finally the solid solution piezoelectric hydrogen production catalyst is formed through high-temperature calcination. The result of the embodiment shows that the piezoelectric hydrogen production performance of SrTiO3 is greatly improved due to the introduction of Sn and Ce. Moreover, when x is equal to 0.1 and y is equal to 0.1, the hydrogen production efficiency is the best, reaches 411 [mu]mol / g and is far higher than 53.45 [mu]mol / g of SrTiO3.

Owner:广东粤绿环境工程有限公司

Piezoelectric sensor based smart-die structure for predicting the onset of failure during die casting operations

InactiveUS8833174B2Strong anisotropyPiezoelectric propertyForce measurementUsing electrical meansDie castingCatastrophic failure

An in-situ apparatus is provided for monitoring the state of stress / strain and cracking in a die surface. The apparatus may also be used to facilitate the prudent removal of the die from the surface so that it may be repaired before catastrophic failure occurs. Accordingly, the yield of a process used to generate die cast structures may be greatly increased.

Owner:COLORADO SCHOOL OF MINES

Inertial piezoelectric capacitor with co-planar patterned electrodes

InactiveUS20190189894A1Magnitude be affectChanges in coefficientCoatingsPiezoelectric/electrostrictive/magnetostrictive devicesPhysicsElectrically conductive

An inertial piezoelectric device has: A) piezoelectric capacitor having: 1) a substrate; 2) a dry piezoelectric layer; and 3) a first pair of non-electrically-connected co-planar patterned electrodes that are arranged contiguously with an opposing surface of the first dry PL. The non-electrically-connected co-planar patterned electrodes consist essentially of: (a) an electrically-conductive material; and (b) particles having a Young's modulus that is different from the Young's modulus of the (a) electrically-conductive material by at least 10%. The device also has B) signal processing electronics in electrical communication with the piezoelectric capacitor; C) a means for converting all or a portion of an applied force to an inertial force that is transmitted to the first dry PL; and optionally D) a proof mass that is contiguous with at least one external surface of the piezoelectric capacitor.

Owner:EASTMAN KODAK CO

A method for preparing c-axis preferred orientation aluminum nitride polycrystalline film by magnetron sputtering and aluminum nitride polycrystalline film

ActiveCN111270214BImproved piezoelectric responseHigh degree of crystallinityPolycrystalline material growthVacuum evaporation coatingSemiconductor materialsElectromechanical coupling coefficient

The invention provides a method for preparing a C-axis preferred orientation aluminum nitride polycrystalline film by magnetron sputtering and the aluminum nitride polycrystalline film, and relates to the technical field of film material preparation. In the present invention, the semiconductor material substrate and the high-purity sputtering aluminum target are relatively vertically placed, which can greatly increase the energy of migrating and moving parallel to the surface of the substrate after the sputtered aluminum atomic group reaches the substrate, and is conducive to the growth of the C-axis preferred orientation of the aluminum nitride film. Improve the piezoelectric response and electromechanical coupling coefficient of the film; the invention arranges a hot wire near the semiconductor material substrate, and the high-temperature radiation generated by the hot wire performs rapid heat treatment on the aluminum nitride film, which can improve the crystallization degree of the film. Therefore, the method provided by the present invention can realize the growth of C-axis preferred orientation aluminum nitride film by using magnetron sputtering technology at a lower temperature, and the obtained aluminum nitride film has high crystallinity, high piezoelectric response coefficient and electromechanical coupling The coefficient can be used as a chip material in surface acoustic wave devices or bulk acoustic wave devices.

Owner:河南科之诚第三代半导体碳基芯片有限公司 +1

A tin, cerium-strontium titanate solid solution piezoelectric hydrogen production catalyst and its preparation method and application

ActiveCN113893846BImproved piezoelectric responseHigh crystal phase purityWater/sewage treatment with mechanical oscillationsWater contaminantsStrontium titanatePtru catalyst

The invention relates to the technical field of piezoelectric catalytic hydrogen production materials, and provides a tin, cerium-strontium titanate solid solution piezoelectric hydrogen production catalyst and a preparation method and application thereof. According to the material prepared by the present invention, its general chemical formula is Sn x Ce y Sr (1‑x‑y) TiO 3 (0<x≤0.15, 0<y≤0.15). In the present invention, Sr source, Ce source, Sn source and Ti source are mixed with water and ethylene glycol, and a co-precipitation method is used to prepare a precursor of a tin, cerium-strontium titanate solid solution piezoelectric hydrogen production catalyst, and finally calcined at high temperature A solid solution piezoelectric hydrogen production catalyst is formed. The results of the examples show that the introduction of Sn and Ce makes SrTiO 3 The piezoelectric hydrogen production performance has been greatly improved. And, when x=0.1, y=0.1, it has the best hydrogen production efficiency, reaching 411 μmol / g, much higher than SrTiO 3 of 53.45 μmol / g.

Owner:广东粤绿环境工程有限公司

Piezoelectric ceramic material with high piezoelectric response and high Curie temperature and preparation method thereof

ActiveCN109626988BPrecise and controllable stoichiometric ratioShort preparation cycleSlurrySodium niobate

The invention relates to a piezoelectric ceramic material with high piezoelectric response and high Curie temperature and a preparation method thereof, the stoichiometric ratio conforms to the general chemical formula (1-x)(K 0.48 Na 0.52 )(Nb 1‑y Sb y )O 3 ‑xBi 0.5 (Na 0.8 K 0.2 ) 0.5 ZrO 3 ; Wherein, 0.02≤x≤0.04, 0.02≤y≤0.04, its preparation method is: (1) prepare the base material that meets above-mentioned stoichiometric ratio and the sodium niobate (NaNbO 3 ) sheet template; (2) base material, template and MnO 2 The sintering aid is weighed according to the stoichiometric ratio and placed in a nylon tank, and the solvent, dispersant and binder are added and stirred evenly to obtain a casting slurry with good fluidity; (3) the slurry is cast to obtain a long strip Thick film, after the thick film is dried, it is cut, laminated and hot-pressed into a ceramic green body; (4) The green body is debonded, and then the lead-free textured piezoelectric ceramic obtained by sintering with a two-step sintering process has High piezoelectric properties and high Curie temperature. The environment-friendly lead-free piezoelectric ceramic material has high practical value in the fields of low and medium temperature sensors, transducers and drivers.

Owner:TONGJI UNIV

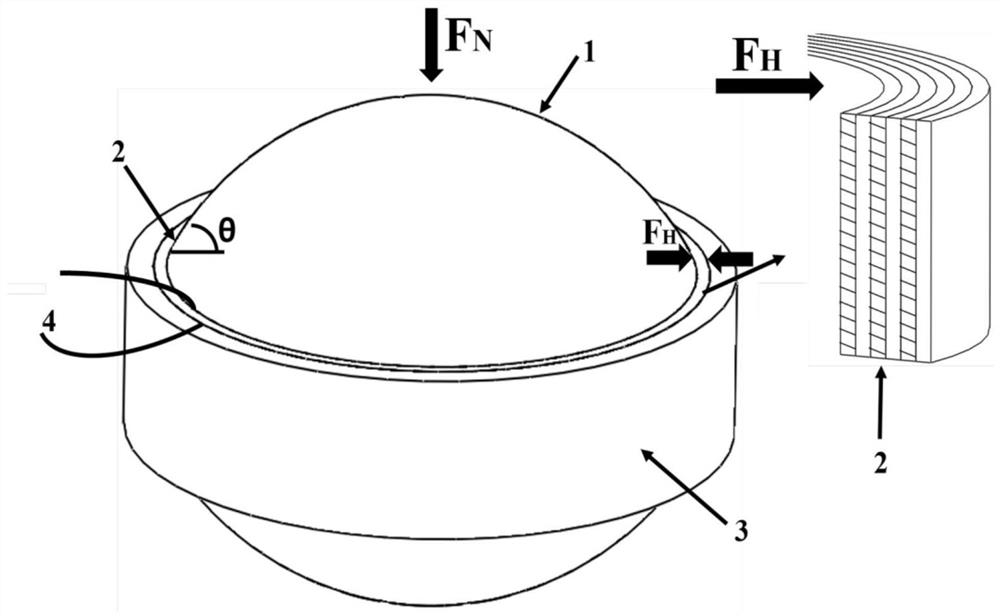

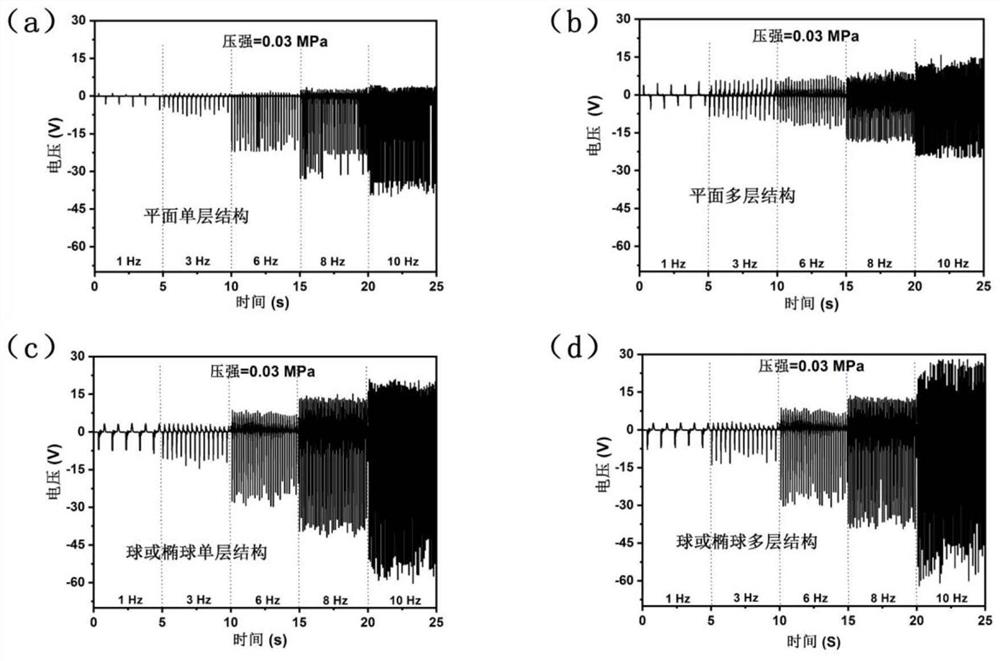

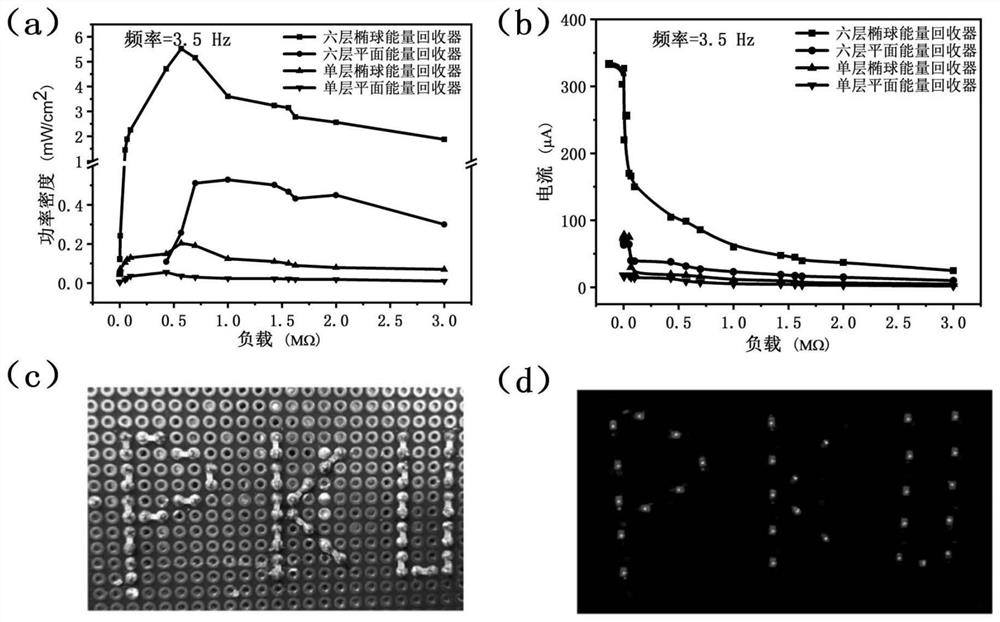

A flexible piezoelectric polymer micromechanical energy harvester and its preparation method

ActiveCN112216786BIncrease capacitanceLower internal impedanceFinal product manufacturePiezoelectric/electrostrictive/magnetostrictive devicesThin membraneCapacitance

The invention discloses a flexible piezoelectric polymer micromechanical energy collector and a preparation method thereof. In the invention, the parallel multi-layer piezoelectric films are wound on the side wall of the polymer elastic body along the length direction, and the parallel electrodes are led out by wires; Due to the curvature of the upper and lower surfaces, the force along the axial direction is amplified and transformed into a stress along the radial direction through the flexural tension mechanism, which is applied to the multilayer piezoelectric film to increase the stress applied to the piezoelectric film; The film converts the stress into electrical energy through the piezoelectric effect; the invention adopts the parallel structure of the multilayer piezoelectric film, so that the capacitance is increased, the internal impedance is reduced, and the effective piezoelectric response is enhanced, thereby increasing the output current and Power density; the invention has a good application prospect in the field of micro-energy.

Owner:PEKING UNIV +1

Nanometer carbon black/nanometer lead zirconate titanate/cement piezoelectric composite material and preparation method thereof

InactiveCN101531489BImprove conductivityImprove polarization efficiencyConverting sensor output electrically/magneticallyLead zirconate titanateResponsivity

The invention relates to a nanometer carbon black / nanometer lead zirconate titanate / cement piezoelectric composite material and a preparation method thereof. The piezoelectric composite material consists of the nanometer lead zirconate titanate, the nanometer carbon black and the cement. The preparation method of the composite materials comprises the following steps: evenly mixing nanometer lead zirconate titanate powder, nanometer carbon black powder, cement powder and water; pressing the mixture into a wafer shape; and hydrating and drying the mixture. The material can be used for preparinga civil engineering sensor after polarizing and aging. The piezoelectric composite material has excellent piezoelectric responsivity.

Owner:SHANDONG UNIV

Piezoelectric capacitor

ActiveUS11251359B2Improve performanceImprove the overall coefficientPiezoelectric/electrostrictive device material selectionCoatingsHemt circuitsConductive materials

A piezoelectric capacitor includes A) a composite article that has 1) a dry piezoelectric layer (dry PL); 2) a first dry electrode comprising a dry electrically-conductive layer arranged contiguously with a first opposing surface of the dry PL; and 3) a second dry electrode arranged contiguously with a second opposing surface of the dry PL. The dry electrically-conductive layer has essentially (a) an electrically-conductive material; and (b) particles having a Young's modulus that is different from the Young's modulus of the (a) electrically-conductive material by at least 10%. The capacitor also has B) electrical communication means attached to both electrodes for electrical communication of the composite article with an external electrical circuit.

Owner:EASTMAN KODAK CO

Carbon nano tube/lead zirconate titanate/cement piezoelectric composite material and preparation method thereof

InactiveCN101531490BImprove conductivityImproved piezoelectric responseConverting sensor output electrically/magneticallyLead zirconate titanateResponsivity

The invention relates to a carbon nano tube / lead zirconate titanate / cement piezoelectric composite material for a civil engineering sensor and a preparation method thereof. The piezoelectric composite material consists of the carbon nano tube, the lead zirconate titanate and cement. The preparation method comprises the following steps: evenly mixing the carbon nano tube, lead zirconate titanate powder and cement powder; shaping the mixture with water; and hydrating and drying the mixture. The material can be used for preparing the civil engineering sensor after polarizing and aging. The piezoelectric composite material has excellent piezoelectric responsivity.

Owner:SHANDONG UNIV

System and method for improved seismic acoustic sensor performance

ActiveUS10185054B2Improved piezoelectric responseReduce mechanical couplingSeismic signal receiversSound producing devicesSignal responseWave field

A sensing system responsive to a wavefield of acoustic or seismic signals. In one embodiment, the system includes a frame having a surface of tubular shape about which a layer of piezoelectric material can be positioned to extend along a first direction. A piezoelectric element is positioned under tension to apply a force against the frame, which tension increases signal response of the element.

Owner:QUANTUM TECHNOLOGY SCIENCES INC

Composite articles with dielectric layer

ActiveUS10763424B2Improve performanceImprove the overall coefficientPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive device material selectionPolymer scienceYoung's modulus

Owner:EASTMAN KODAK CO

Piezoelectric capacitor

ActiveUS20190189893A1Improved piezoelectric responseAffects distributionCoatingsPiezoelectric/electrostrictive/magnetostrictive devicesElectrically conductiveConductive polymer

A piezoelectric capacitor includes A) a composite article that has 1) a dry piezoelectric layer (dry PL); 2) a first dry electrode comprising a dry electrically-conductive layer arranged contiguously with a first opposing surface of the dry PL; and 3) a second dry electrode arranged contiguously with a second opposing surface of the dry PL. The dry electrically-conductive layer has essentially (a) an electrically-conductive material; and (b) particles having a Young's modulus that is different from the Young's modulus of the (a) electrically-conductive material by at least 10%. The capacitor also has B) electrical communication means attached to both electrodes for electrical communication of the composite article with an external electrical circuit.

Owner:EASTMAN KODAK CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com