Device for heating to generate uniform motlen pool

A molten pool and uniform technology, applied in metal processing equipment, instruments, manufacturing tools, etc., can solve the problems of low production process, material boiling vaporization, dents, etc., so as to reduce the overlap rate of weld bead and avoid vaporization splash. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The technical content of the present invention is described below through specific specific examples, and those skilled in the art can easily understand the advantages and effects of the present invention from the content disclosed in this specification. However, the present invention can also be practiced or applied in other different specific embodiments.

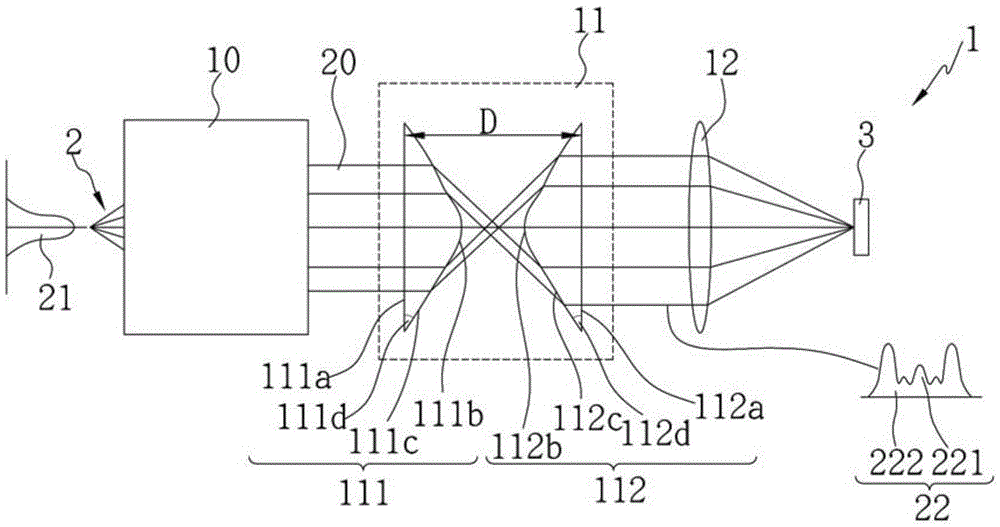

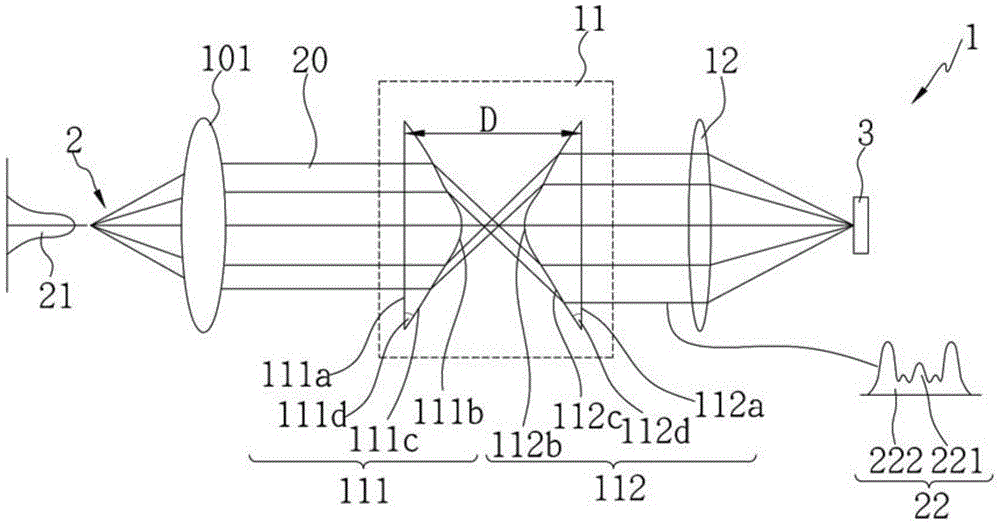

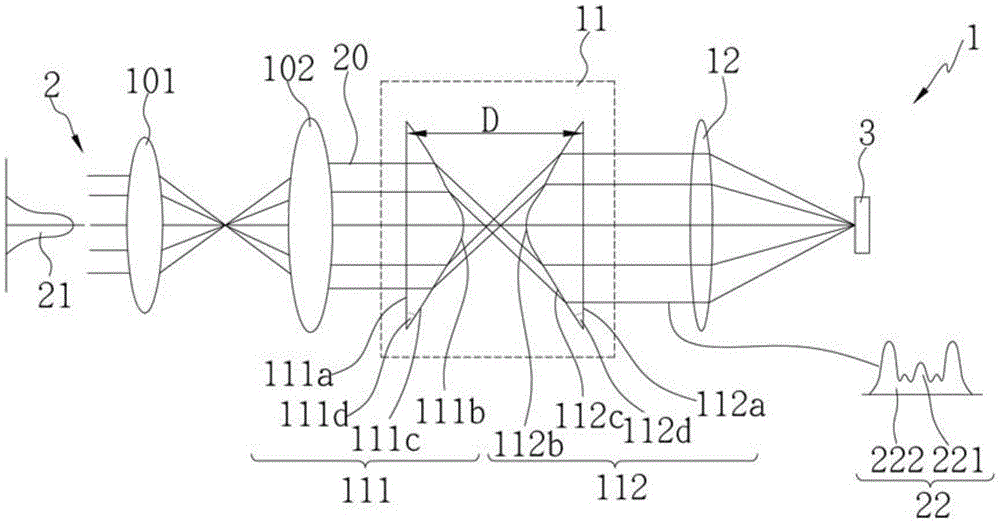

[0066] Please refer to Figure 1A , Figure 1B , Figure 1C-1 to Figure 1C-5 and Figure 1D-1 to Figure 1D-4 , is the energy path diagram of the device 1 for heating and generating a uniform molten pool in the present invention, wherein, Figure 1C-2 to Figure 1C-5 and Figure 1D-2 to Figure 1D-4 It is an enlarged explanatory diagram of the energy path from the source unit of the device for heating and generating a uniform molten pool in the present invention to the front of the incident flat-top conical lens group. The energy beam can be emitted from the source unit 2 or applied externally, and the pattern of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com