High energy beam area-selecting fusing method and device capable of controlling temperature gradient in shaping area

A selective melting, high-energy beam technology, applied in additive processing and other directions, can solve the problems of high-performance directional solidification metal components and single-crystal metal components with high efficiency and near-net shape, and achieve high-efficiency forming, high precision, and reduced manufacturing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The first preferred high-energy beam selective melting equipment with controllable temperature gradient in the forming area disclosed in the present invention includes a forming component, a control system, a high-energy beam output module, an atmosphere control module and a powder supply and recovery module.

[0045] Such as figure 1 As shown, the forming assembly is composed of a forming cylinder 1, a substrate 2, a temperature measurement module 3, a temperature control module 4 and a substrate lifting drive system 5. Among them, the substrate 2 is located inside the forming cylinder 1; the temperature measurement module 3 includes a temperature measurement sub-module 6 1 ~6 n (n≧2): powder bed temperature measurement sub-module 6 1 Located at any position above the forming cylinder 1 that does not affect the normal operation of the high-energy beam output module 8, it contains a number of infrared thermometers or laser thermometers inside to measure the temperatur...

Embodiment 2

[0066] When the size of the metal component to be formed is small, or the single crystal / directional solidification structure of the metal component to be formed has a strong tendency to form, the following second preferred high-energy beam selective melting equipment with adjustable temperature gradient in the forming area can also be selected , and then take into account the quality and processing cost of directional solidification / single crystal metal products.

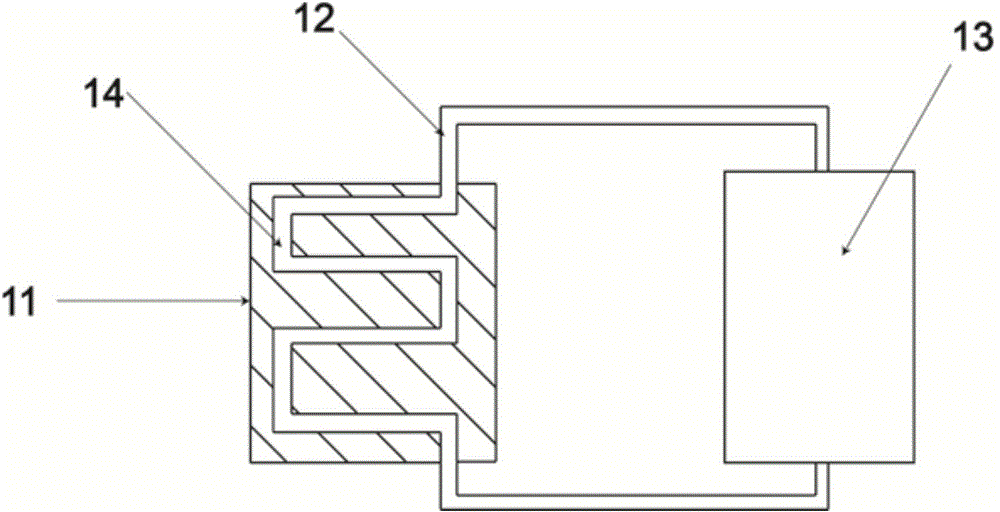

[0067] The second preferred high-energy beam selective melting equipment with controllable temperature gradient in the forming area involved in the present invention still includes a forming component, a control system, a high-energy beam output module, an atmosphere control module and a powder supply and recovery module. Among them, the structures and functions of the control system, the high-energy beam output module, the atmosphere control module and the powder supply and recovery module are still the same as tho...

Embodiment 3

[0084] The invention can not only make the temperature gradient in the forming area always meet the directional solidification conditions, and then realize the directional solidification of metal components or the efficient forming of single crystal parts, but also flexibly change the temperature gradient distribution in each stage of the forming process according to the actual processing needs , and then produce various types of functional / structural gradient components. To achieve this purpose, Embodiment 3 discloses a third preferred high-energy beam selective melting device with controllable temperature gradient in the forming area.

[0085] The overall structure of the equipment can still be consistent with the equipment disclosed in Embodiment 1, the difference is that the temperature control sub-module 7 included in the high-energy beam selective melting equipment in this embodiment 1 ~7 n The internal structure and function of the machine have been greatly improved. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com