Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

115results about How to "Free from defect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

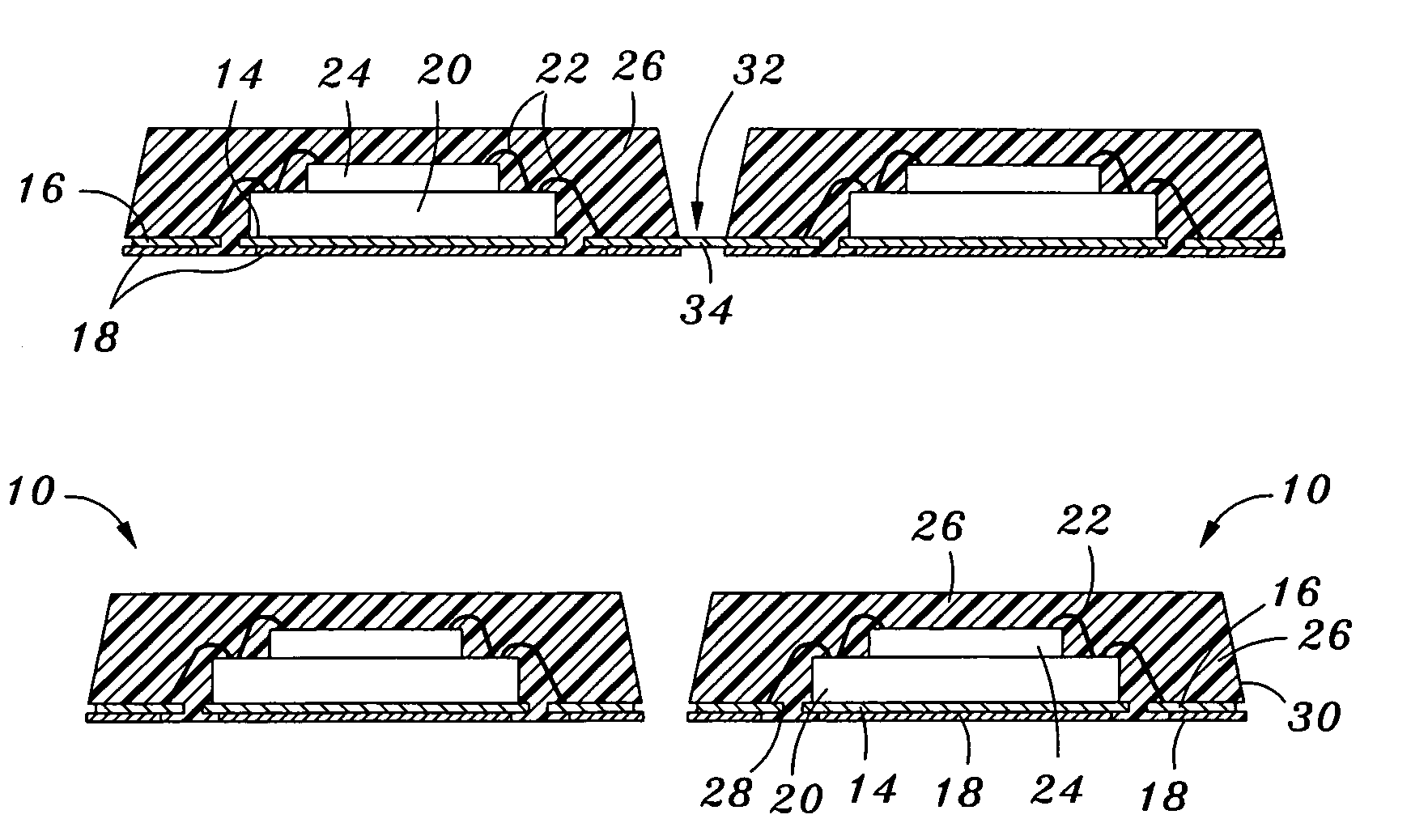

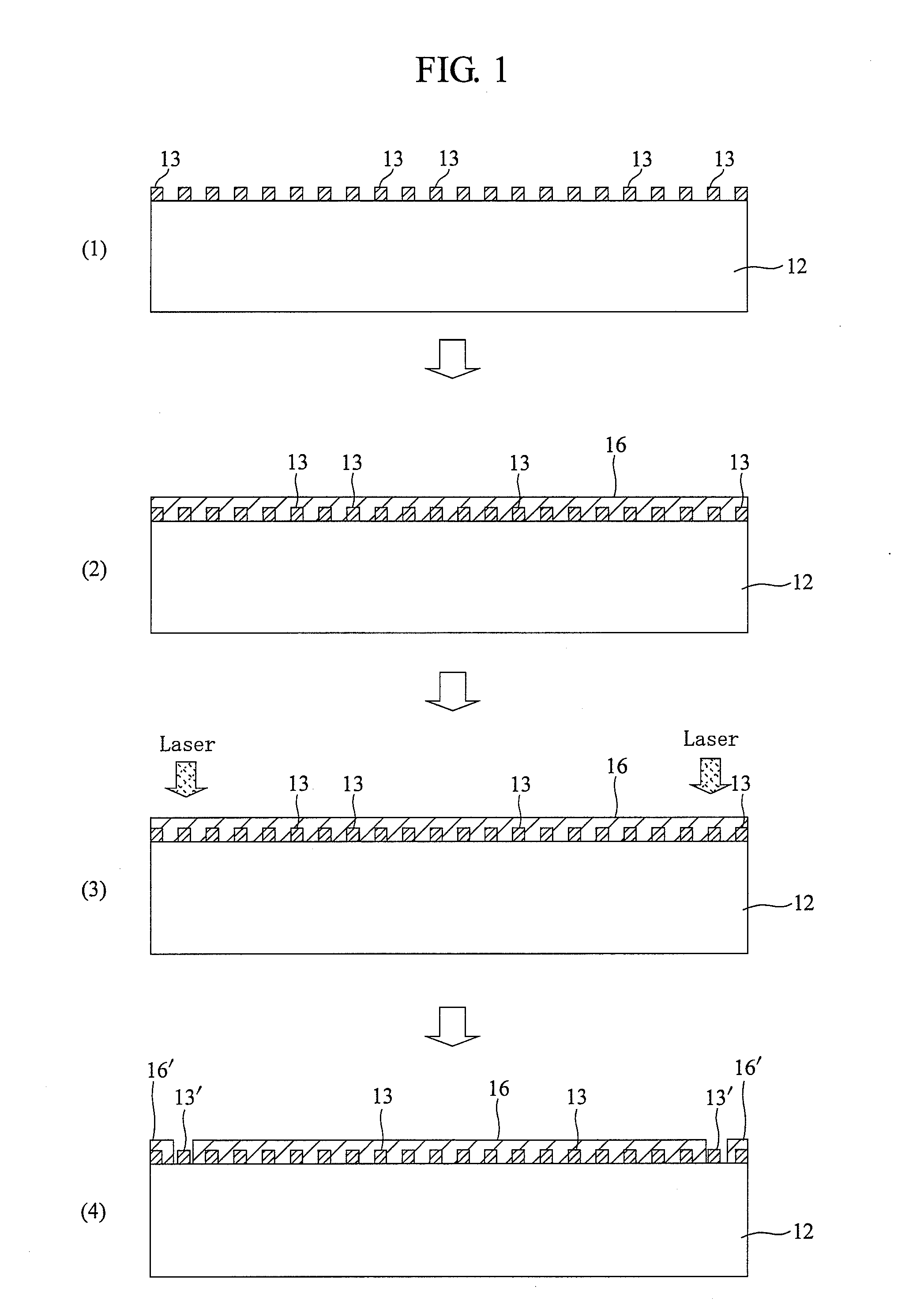

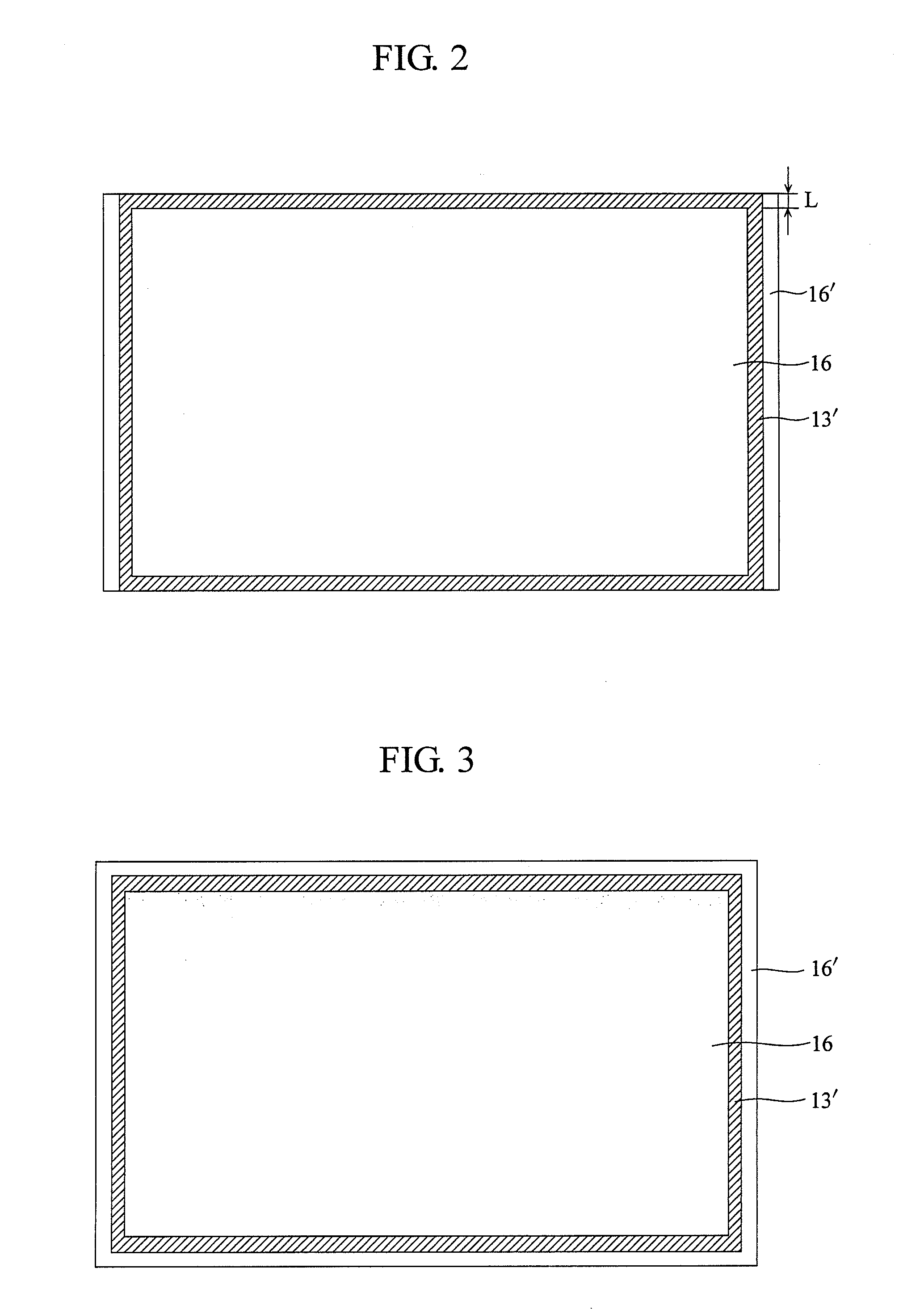

Composition and process for the sealing of microcups in roll-to-roll display manufacturing

InactiveUS7144942B2Improve adhesionQuality improvementLamination ancillary operationsLaminationCrystallographyElectrophoresis

Owner:E INK CALIFORNIA

Ink jet ink

An ink jet ink composition comprising from about 0.5% to about 30% by weight of a pigment, a carrier and a hydrophobically capped oligomeric acrylamide dispersant in a ratio of dispersant:pigment from about 0.1:1 to about 5:1.

Owner:EASTMAN KODAK CO

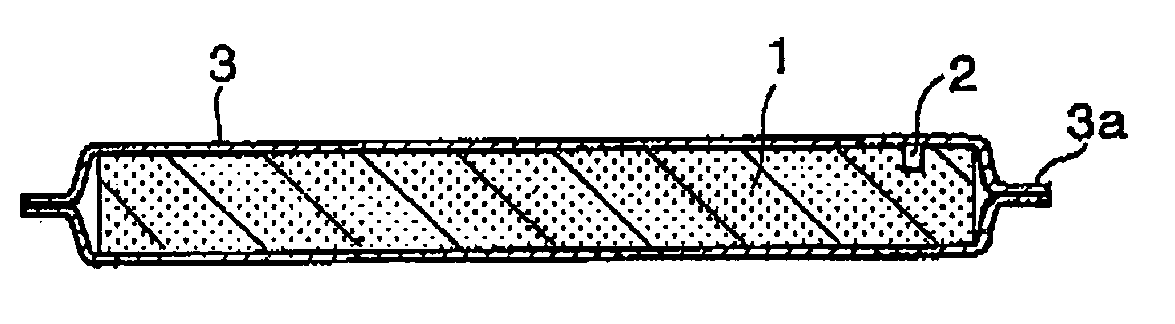

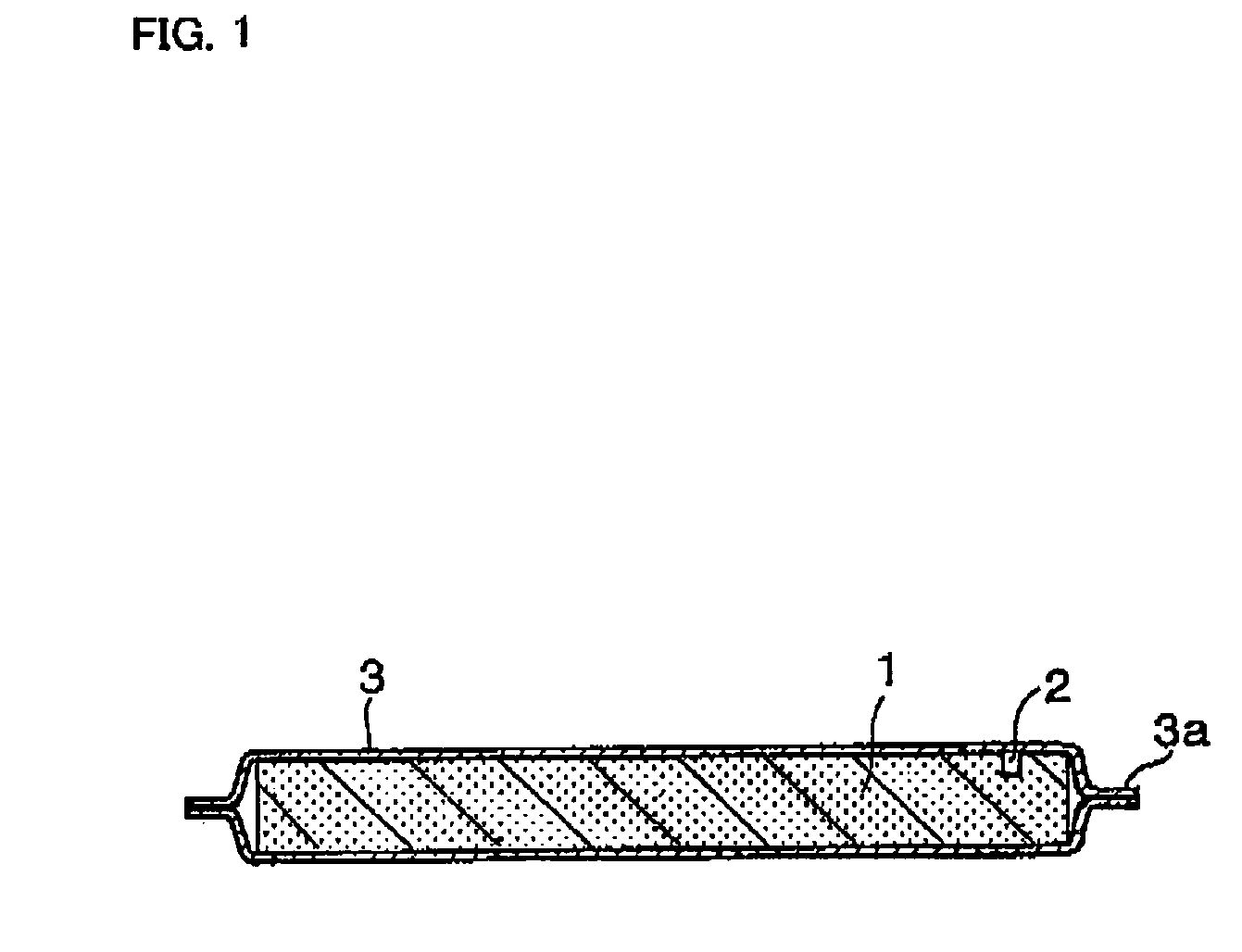

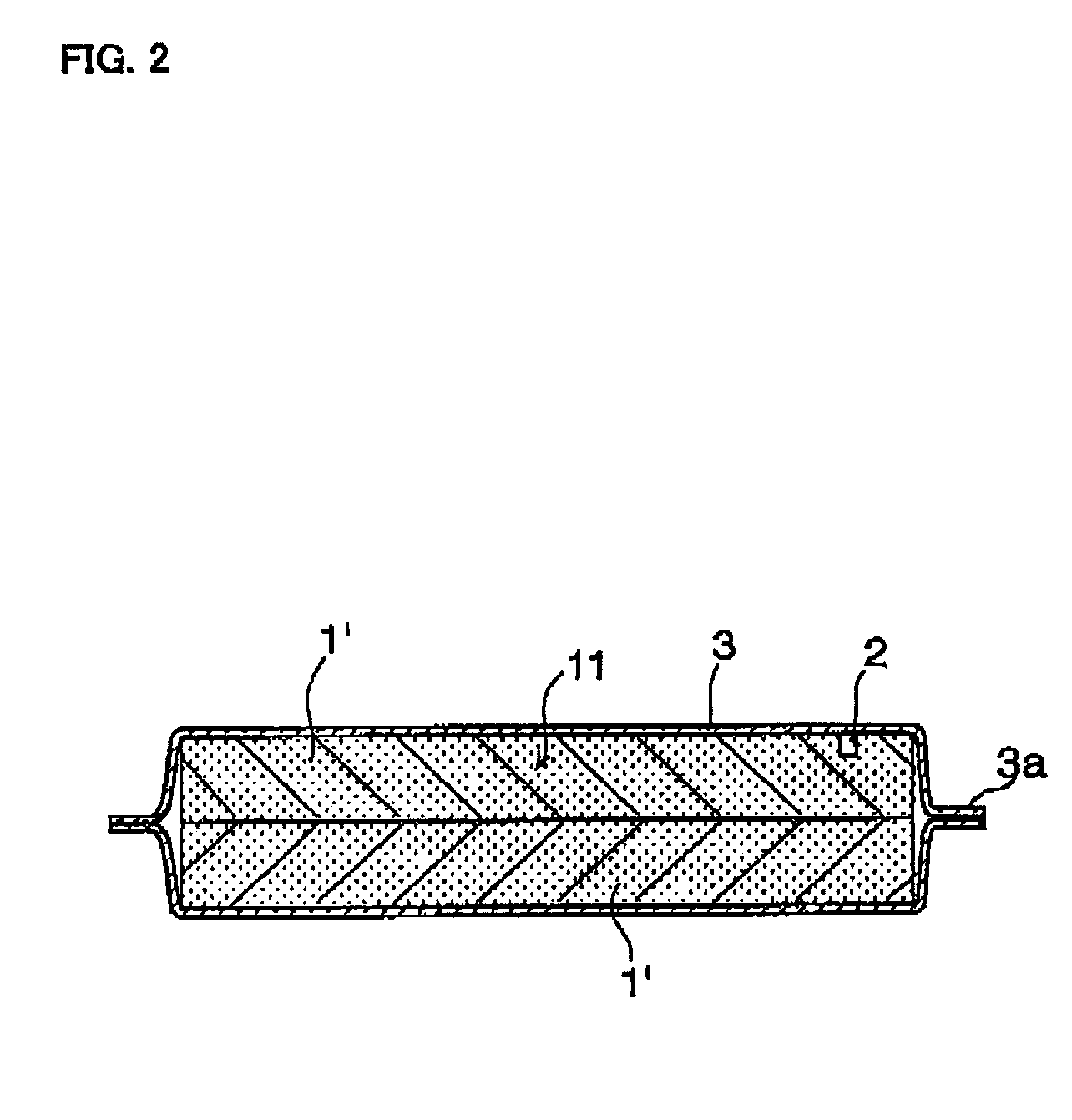

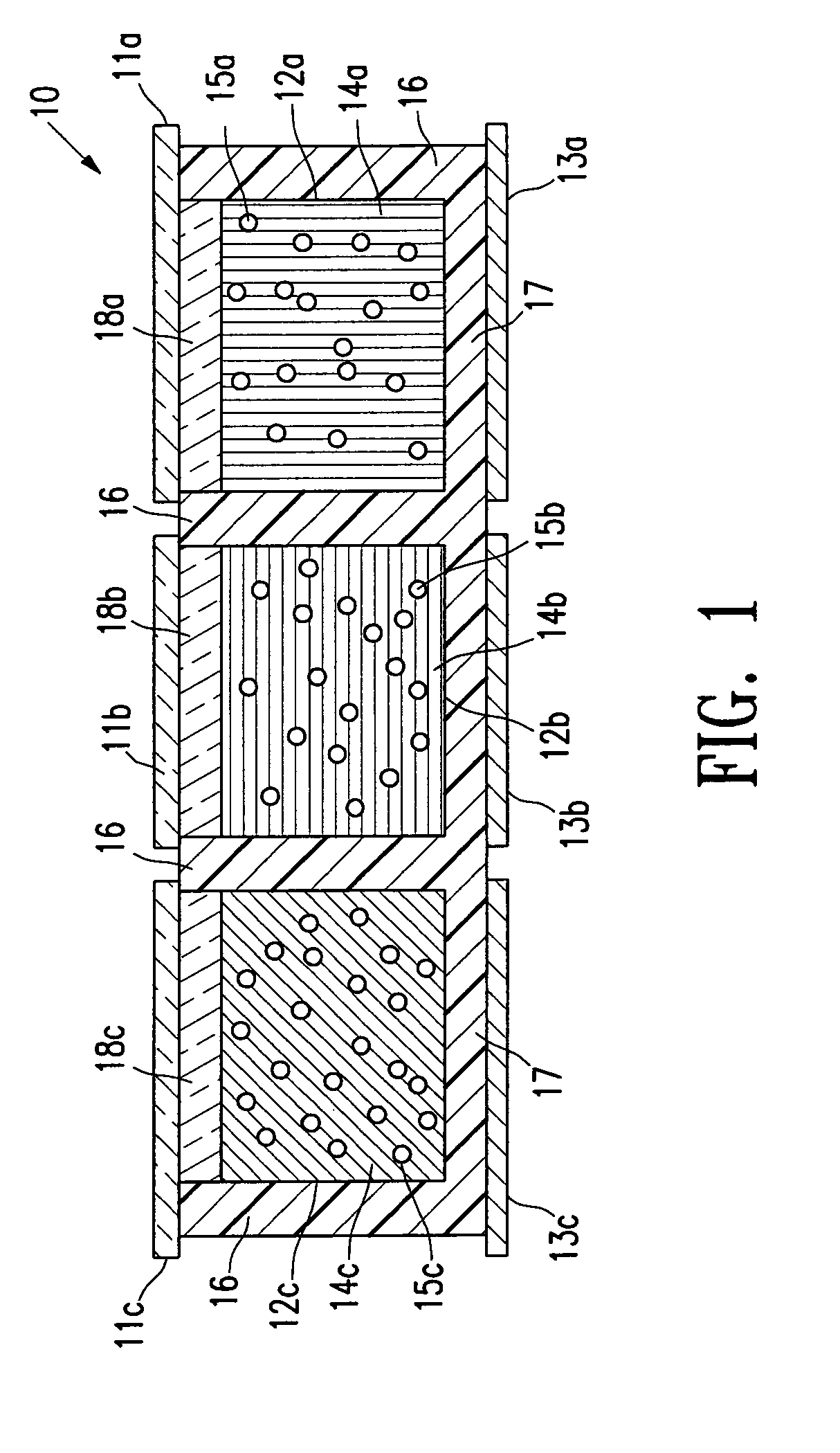

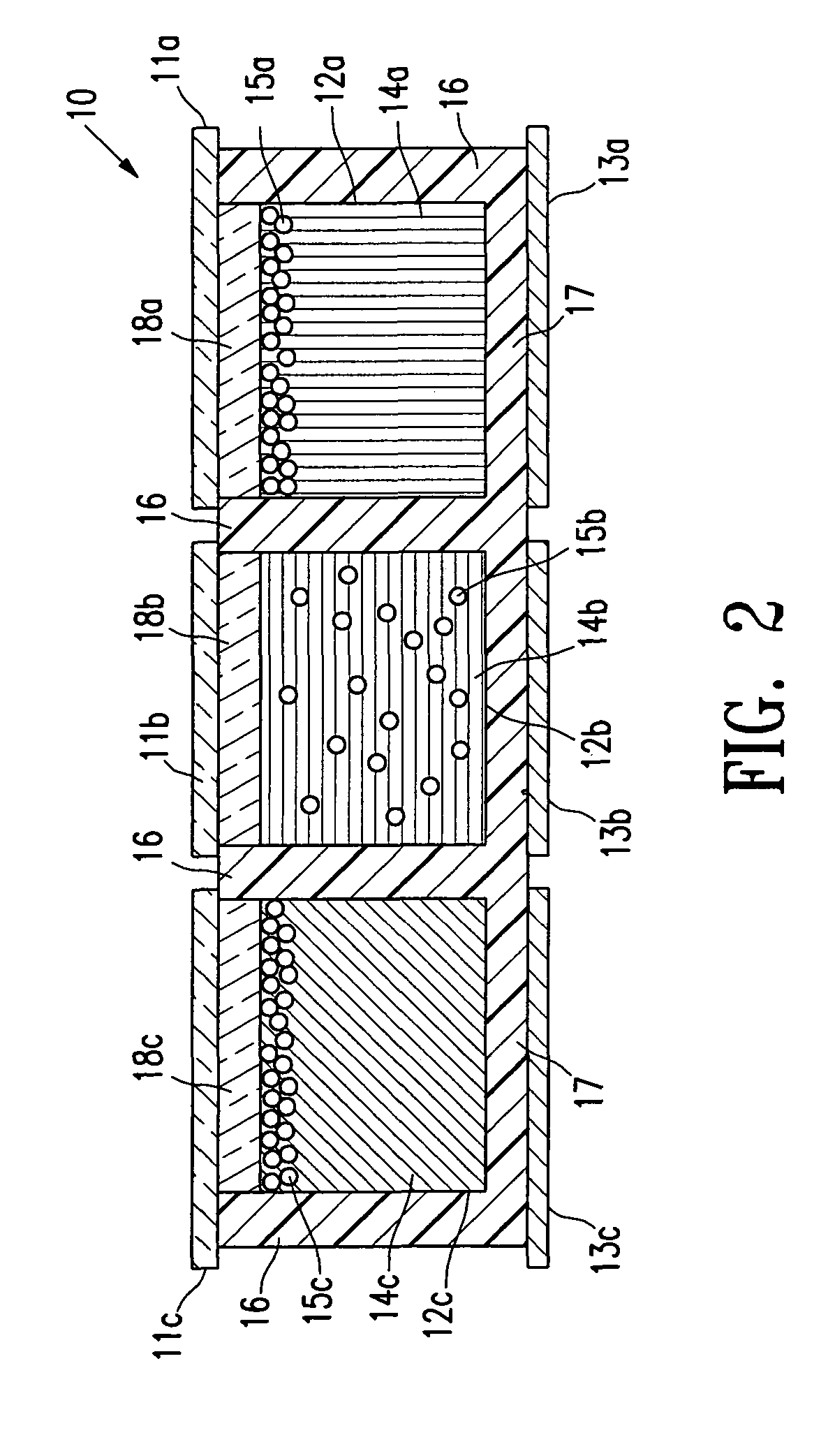

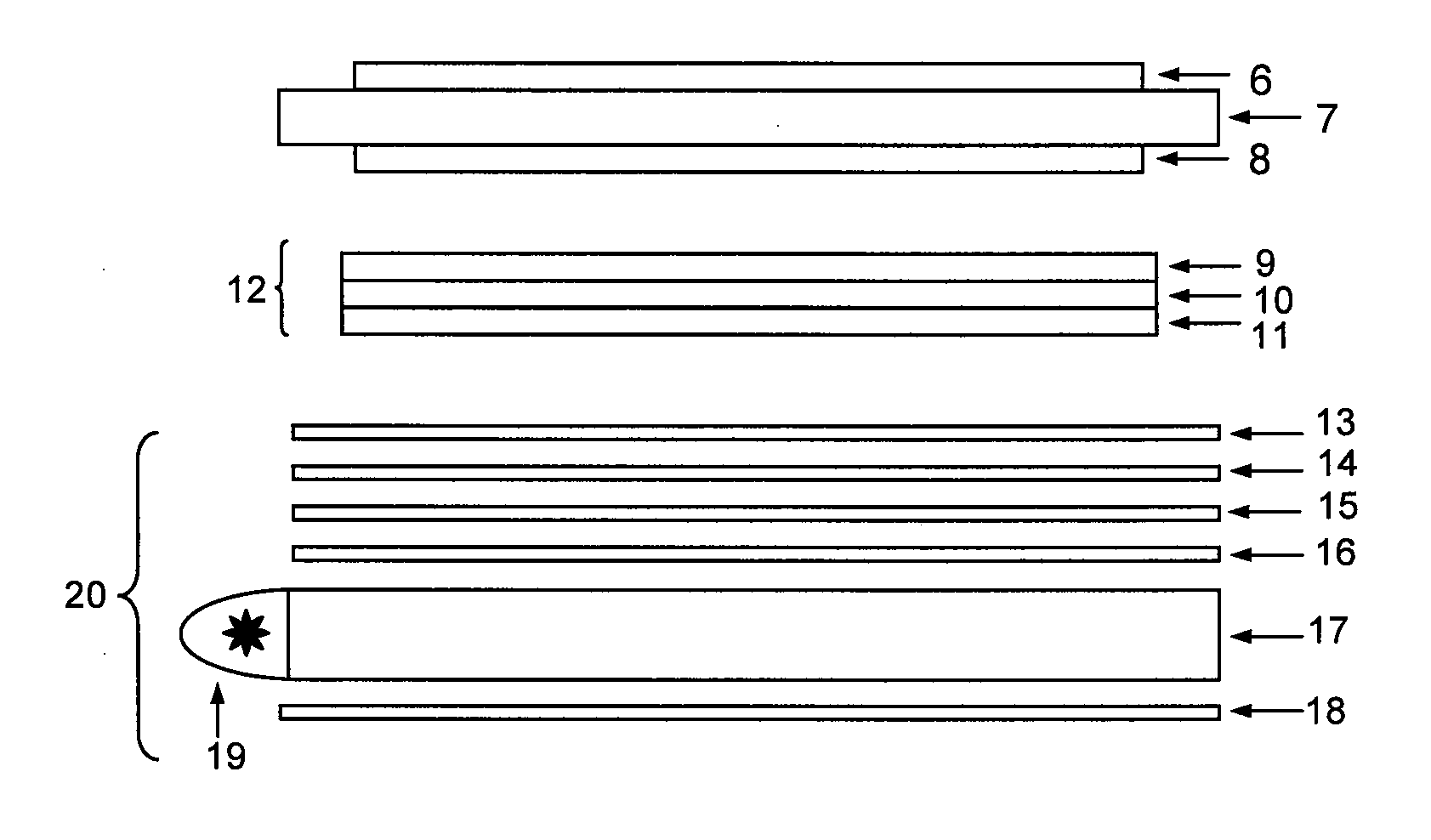

Vacuum heat insulating material and manufacturing method therefor

InactiveUS20040253406A1Improve performanceLow thermal conductivityThermal insulationDomestic cooling apparatusSorbentDecreased pressure

Provided is a vacuum heat insulating material, using inorganic fibers as a core material, high in heat insulating performance (low in thermal conductivity), capable of maintaining the heat insulating performance for a long period, free of defects such as projections and depressions on a large scale on a surface thereof, short in manufacturing time and advantageous in terms of cost; and a manufacturing method therefor. A vacuum heat insulating material of the present invention is of a construction in which a core material 1 and a gas adsorbent 2 are housed in a bag 3 made from a gas barrier film and the interior thereof is reduced in internal pressure thereof and air-tightly sealed, wherein the core material 1 is a molded product obtained by coating a binder B on inorganic fibers having an average fiber diameter in the range of from 3 to 5 mum at a coating amount in the range of from 0.5 to 1.5 wt % relative to the fibers and heat pressing the inorganic fibers, or a laminate fabricated by stacking two or more sheets of the molded product.

Owner:ASAHI FIBER GLASS CO LTD

Composition and process for the sealing of microcups in roll-to-roll display manufacturing

InactiveUS7005468B2Improve barrier propertiesImprove integrityAdhesivesNon-linear opticsCrystallographyElectrophoresis

Owner:E INK CALIFORNIA

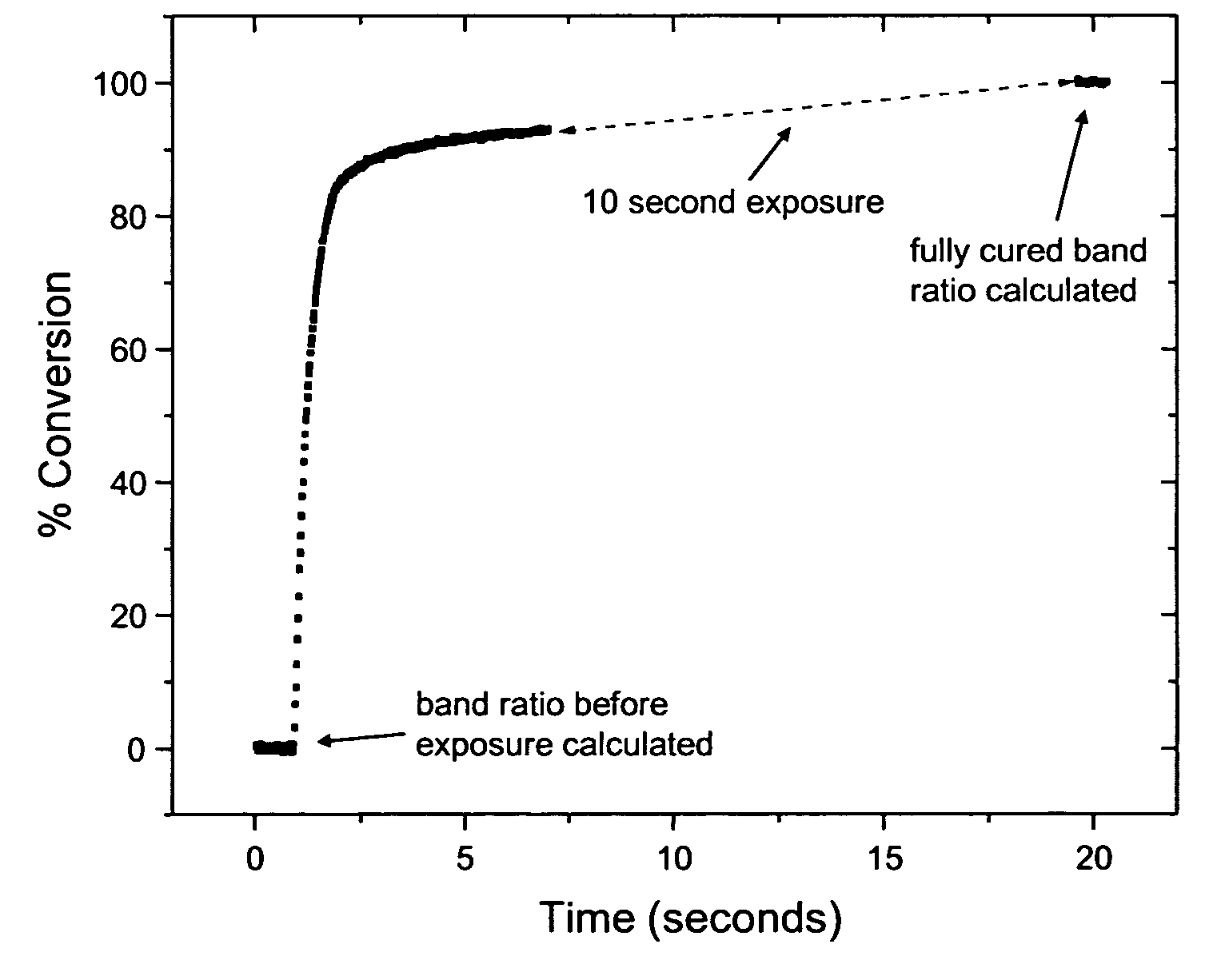

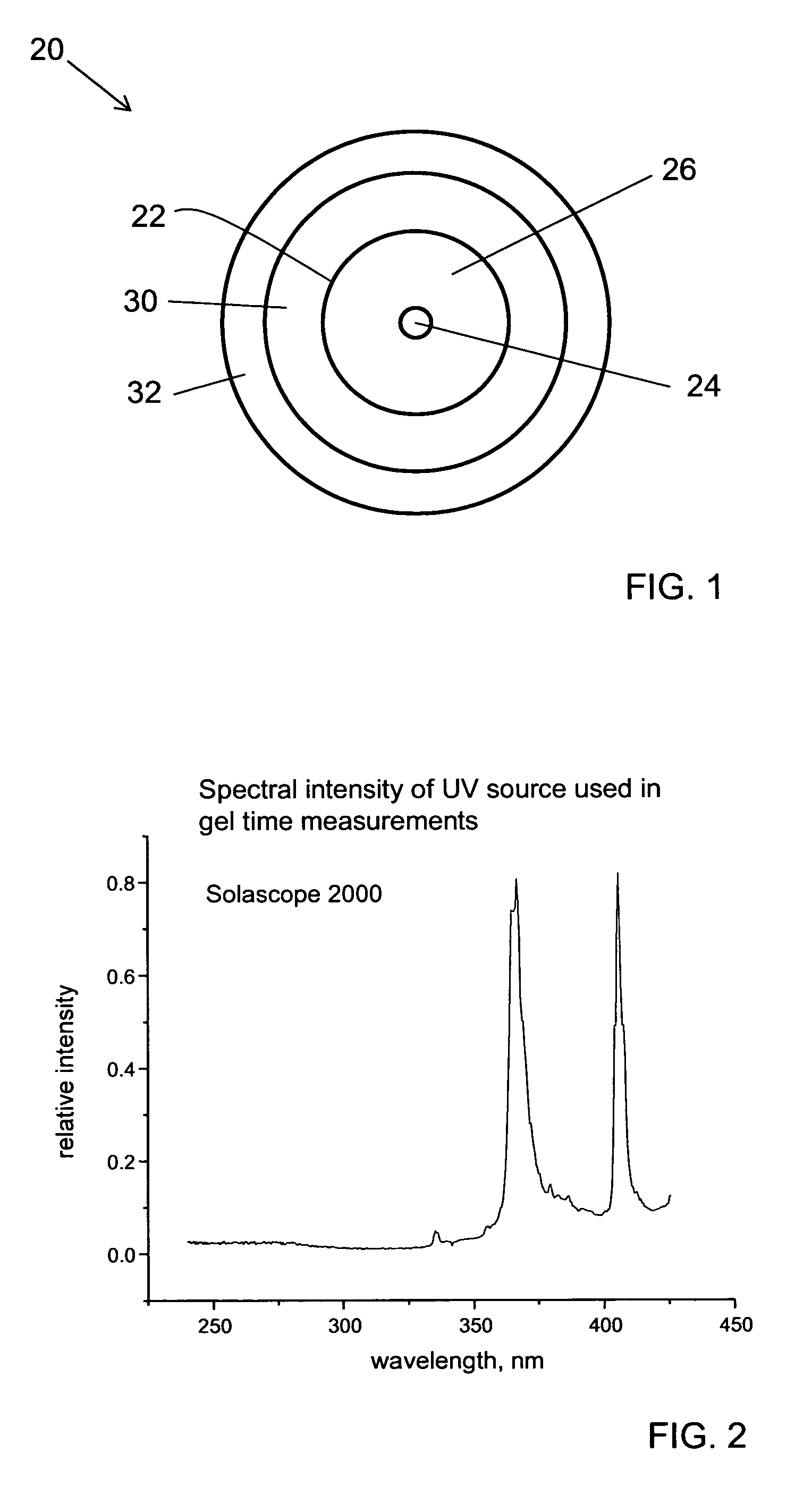

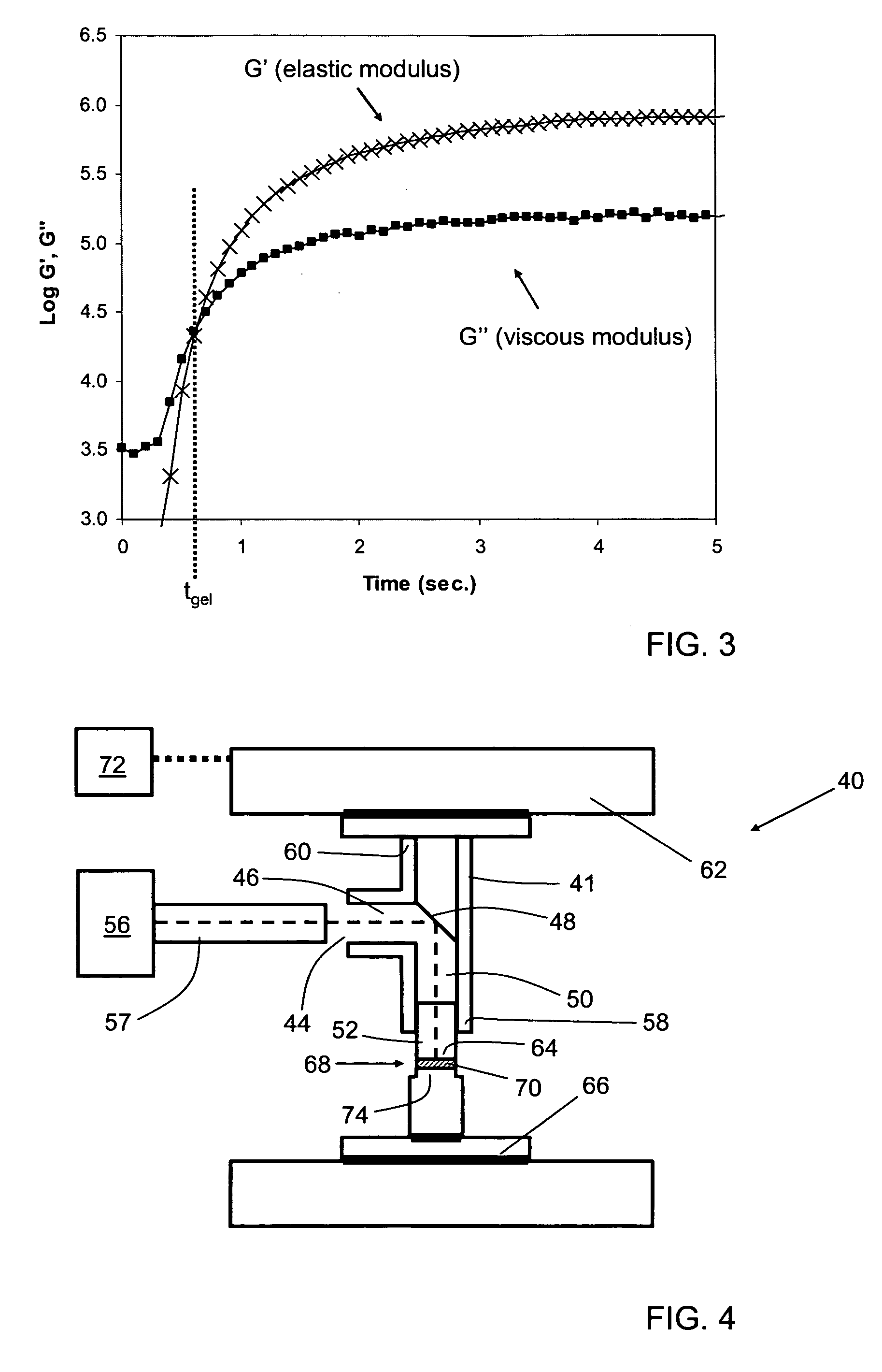

Coated optical fiber and optical fiber coating system including a fast-gelling primary coating

ActiveUS7010206B1Improve throughputHigh speedGlass optical fibreOptical fibre with multilayer core/claddingCoating systemYoung's modulus

The present invention provides optical fiber coating systems and coated optical fibers. According to one embodiment of the invention, a coated optical fiber includes an optical fiber having a core and a cladding; and a primary coating encapsulating the optical fiber, the primary coating having a Young's modulus of about 5 MPa or less, the primary coating being the cured reaction product of a primary curable composition having a gel time less than about 1.4 seconds at a UV intensity of 3.4 mW / cm2.

Owner:CORNING INC

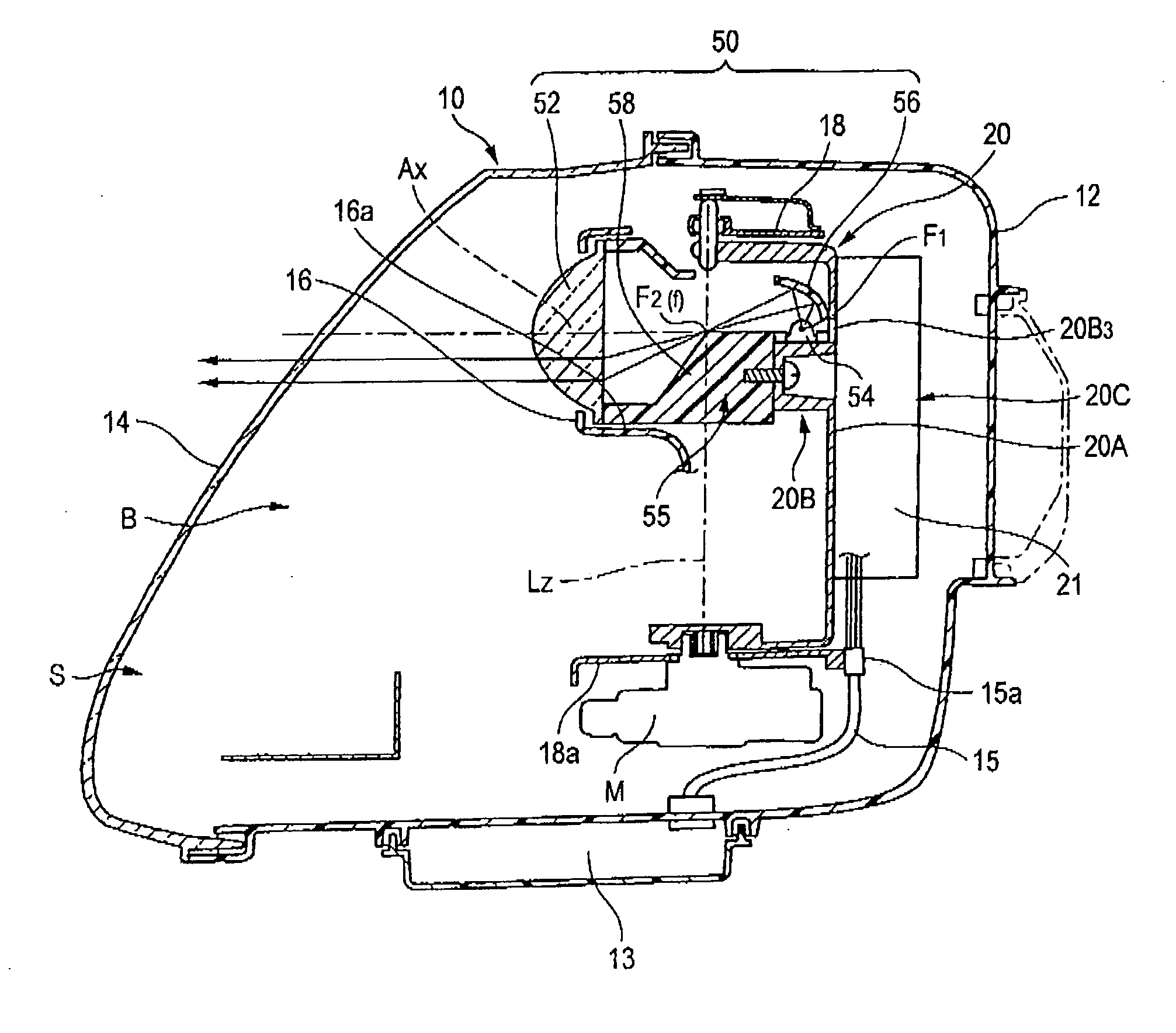

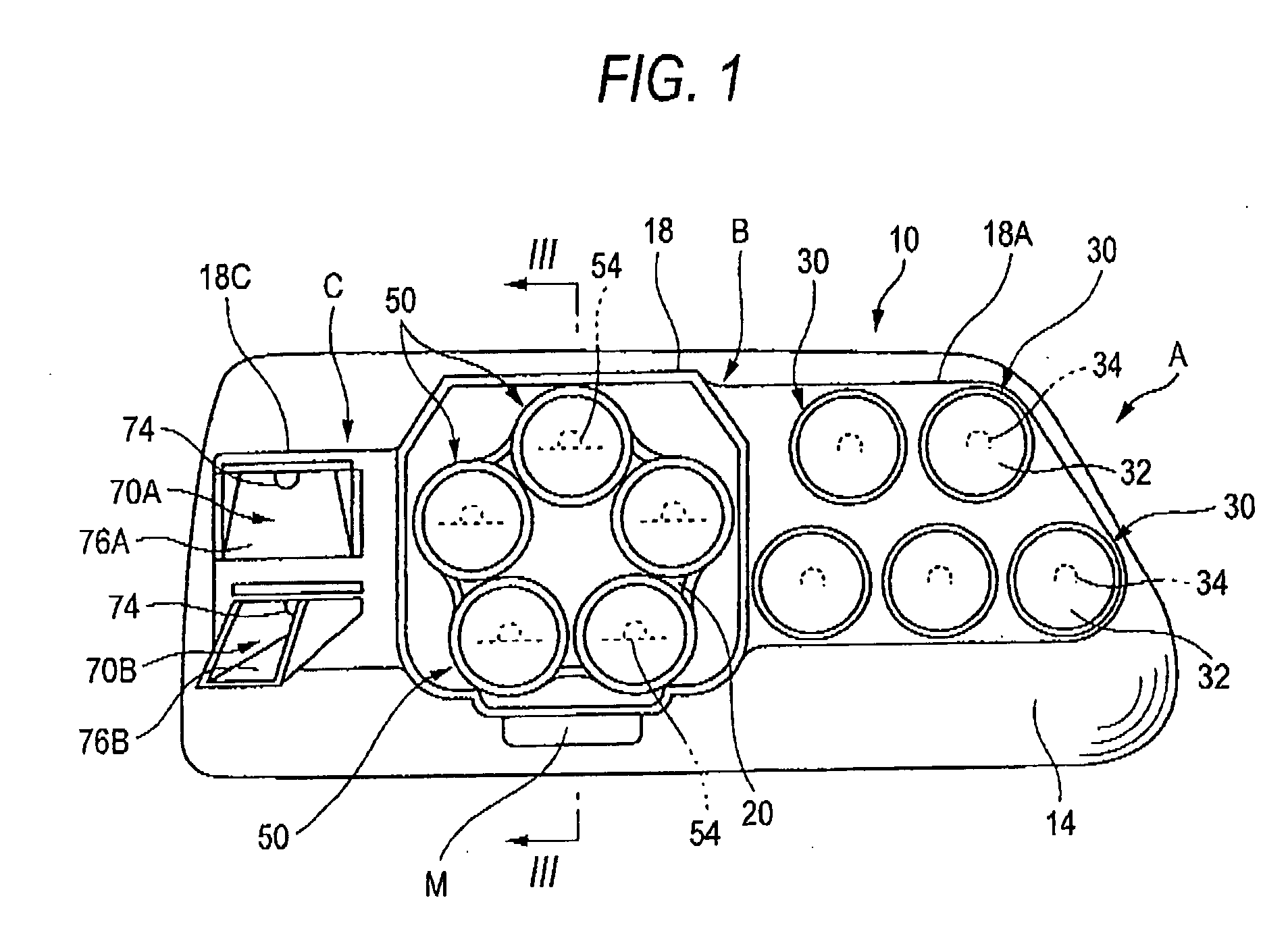

Vehicle lighting device

InactiveUS20070133220A1High positioning accuracyShort timeVehicle headlampsPoint-like light sourceDistribution controlOptical axis

A vehicle lighting device with a lamp compartment having a light source unit disposed therein. The light source unit includes a light emitting device as a light source and a projection lens as a light distribution control member for distributing light. A face bearing portion at a distal end of a lens mounting portion of the light emitting device corresponds to a rear surface of a collar portion disposed along an outer circumference of the projection lens. Complimentary extending projections and stepped portions on the collar portion and lens mounting portion are ultrasonically welded together, and burrs formed during the welding process are prevented from protruding toward the optical axis by an erect wall of the stepped portion.

Owner:KOITO MFG CO LTD

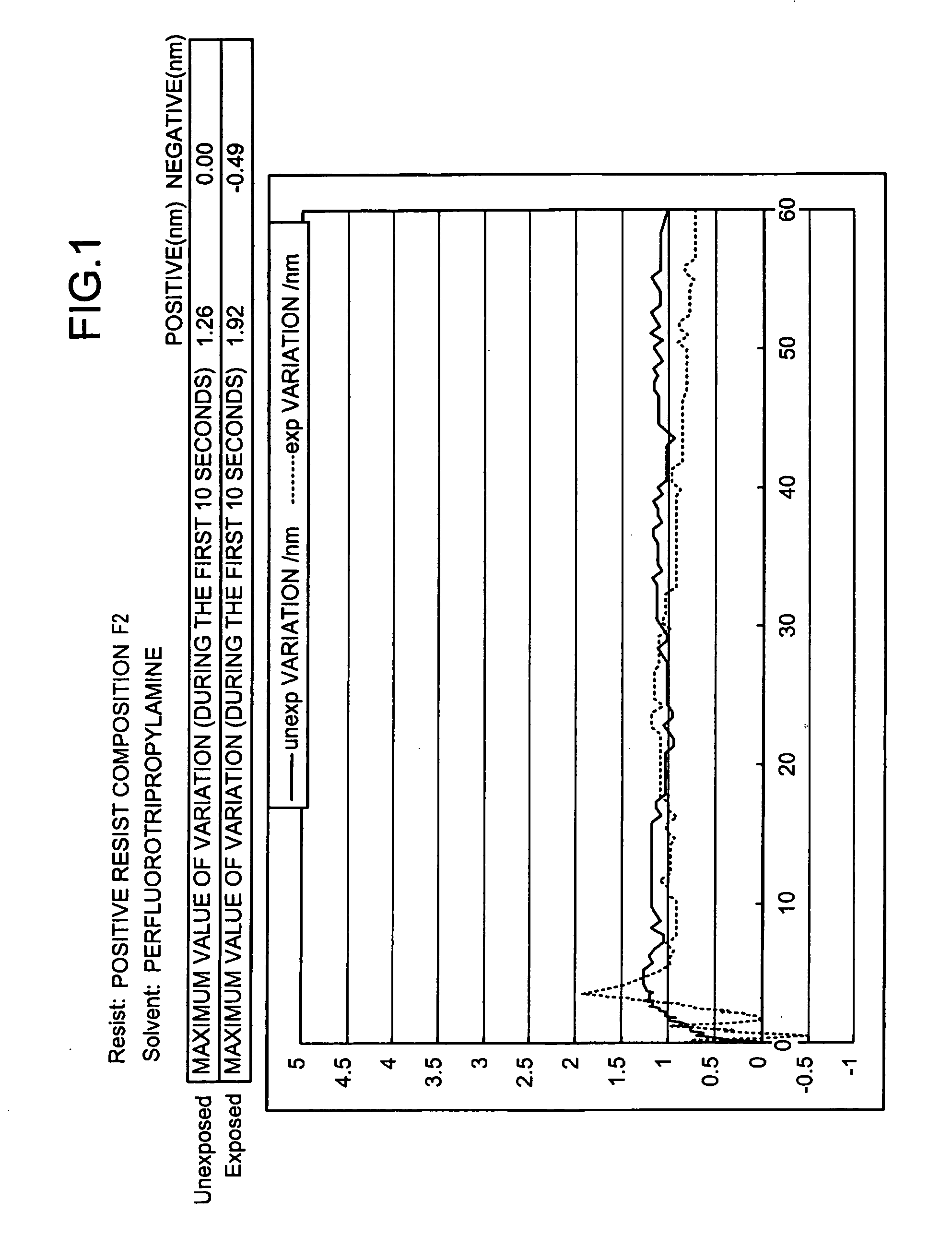

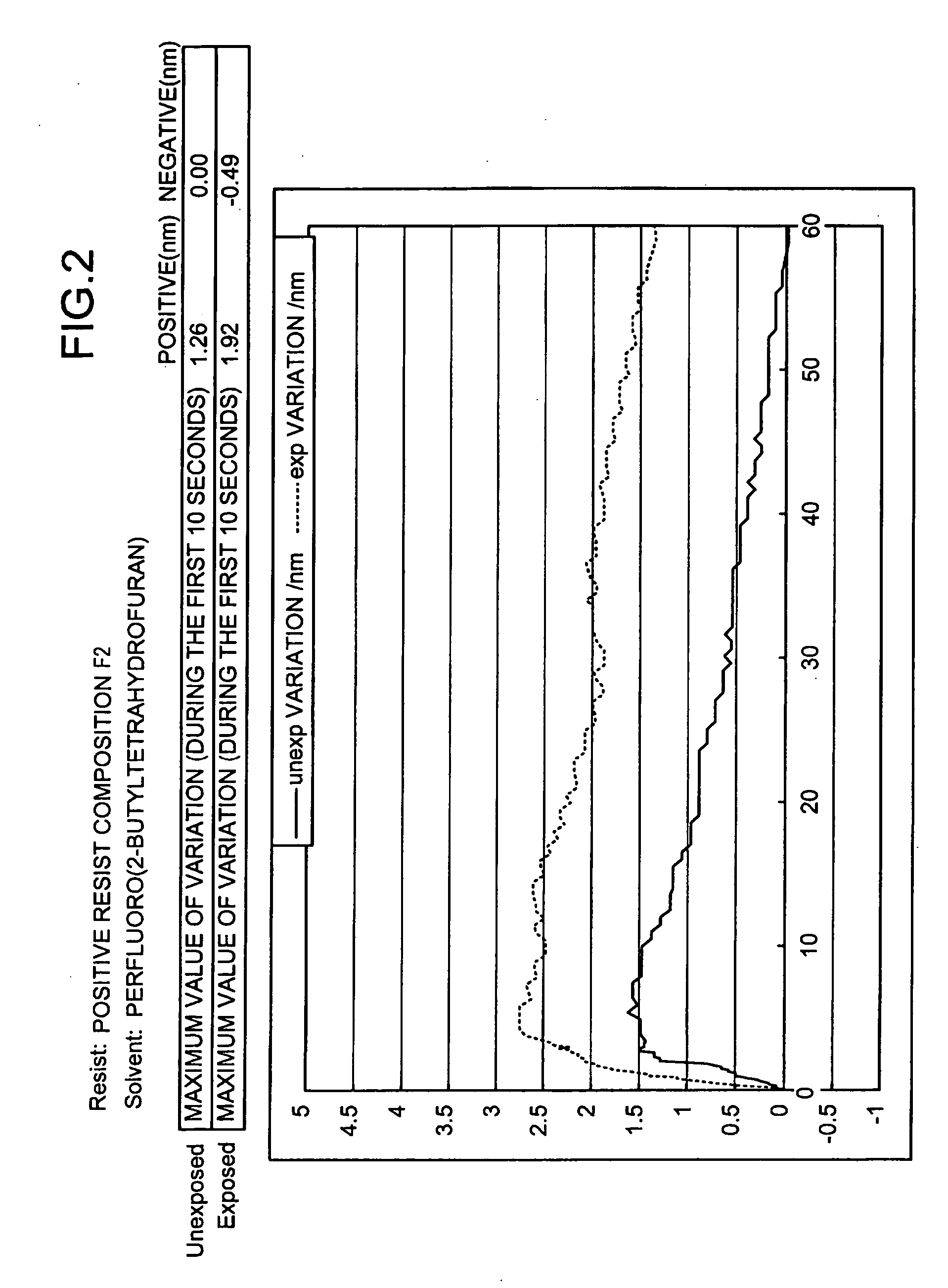

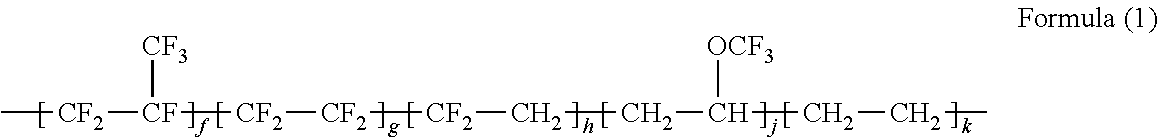

Immersion fluid for use in liquid immersion lithography and method of forming resist pattern using the immersion fluid

InactiveUS20060154188A1High resolutionHigh refractive indexPhotosensitive materialsSemiconductor/solid-state device manufacturingChemistryOptics

An immersion fluid for use in liquid immersion lithography in which a resist film is exposed to light via a fluid. The fluid is transparent to the exposure light used in the liquid immersion lithography and comprises a fluorine-based liquid having a boiling point of 70 to 270° C. A method of forming resist patter includes a step of placing the immersion fluid directly on the resist film or a protective film deposited on the resist film. The present invention prevents alteration of resist film and other films as well as alteration of the fluid during liquid immersion lithography and enables high resolution resist patterning using liquid immersion lithography.

Owner:TOKYO OHKA KOGYO CO LTD

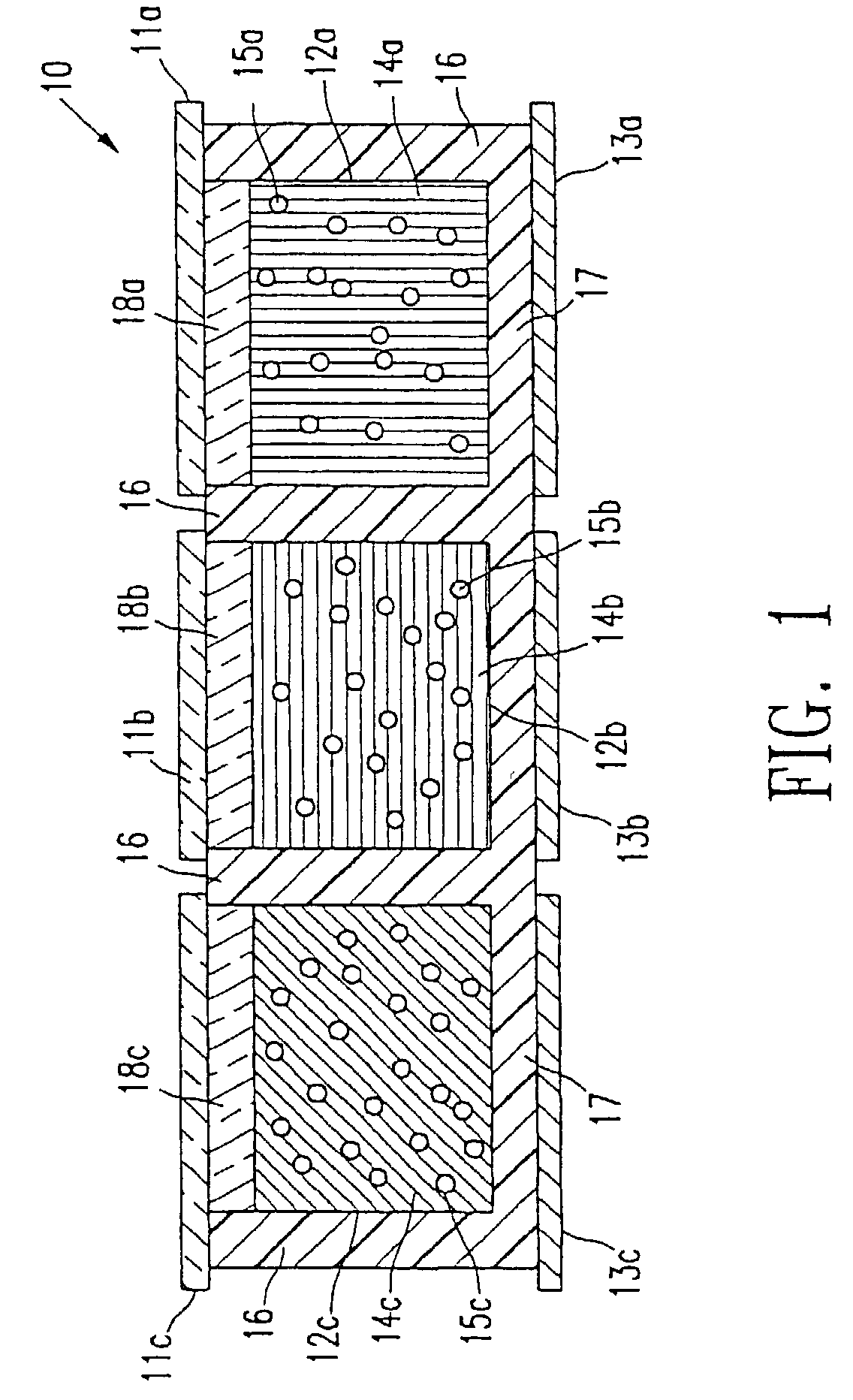

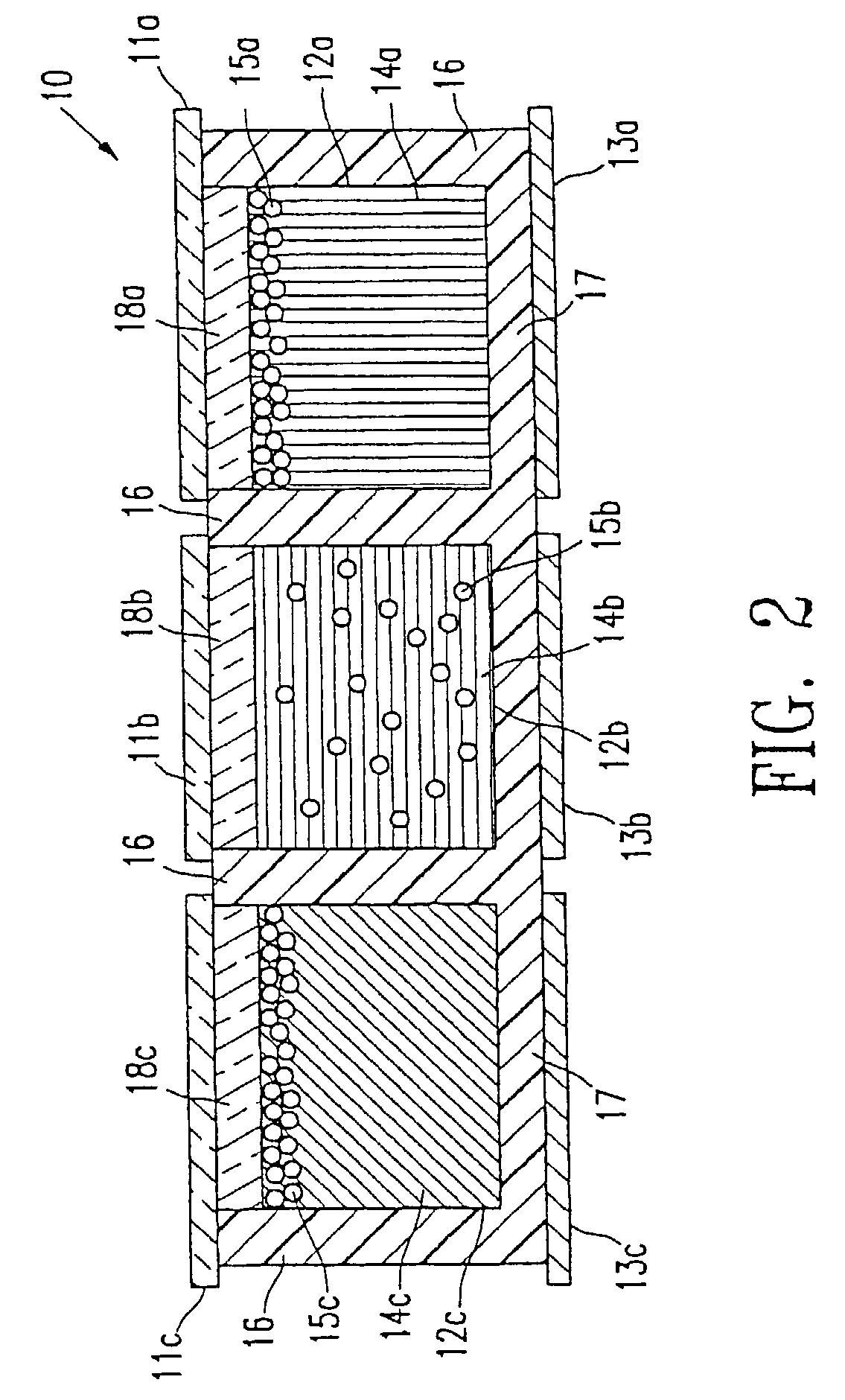

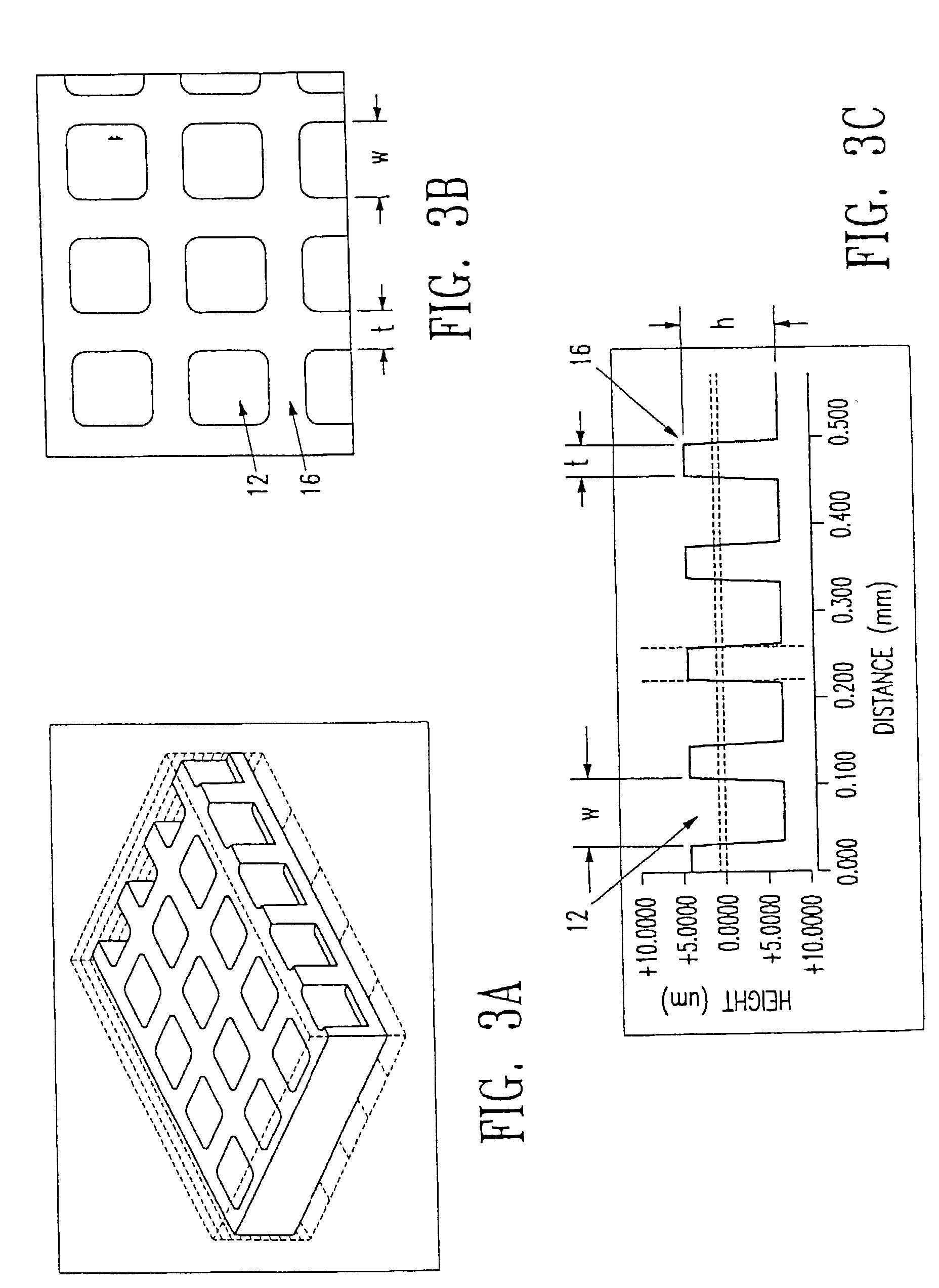

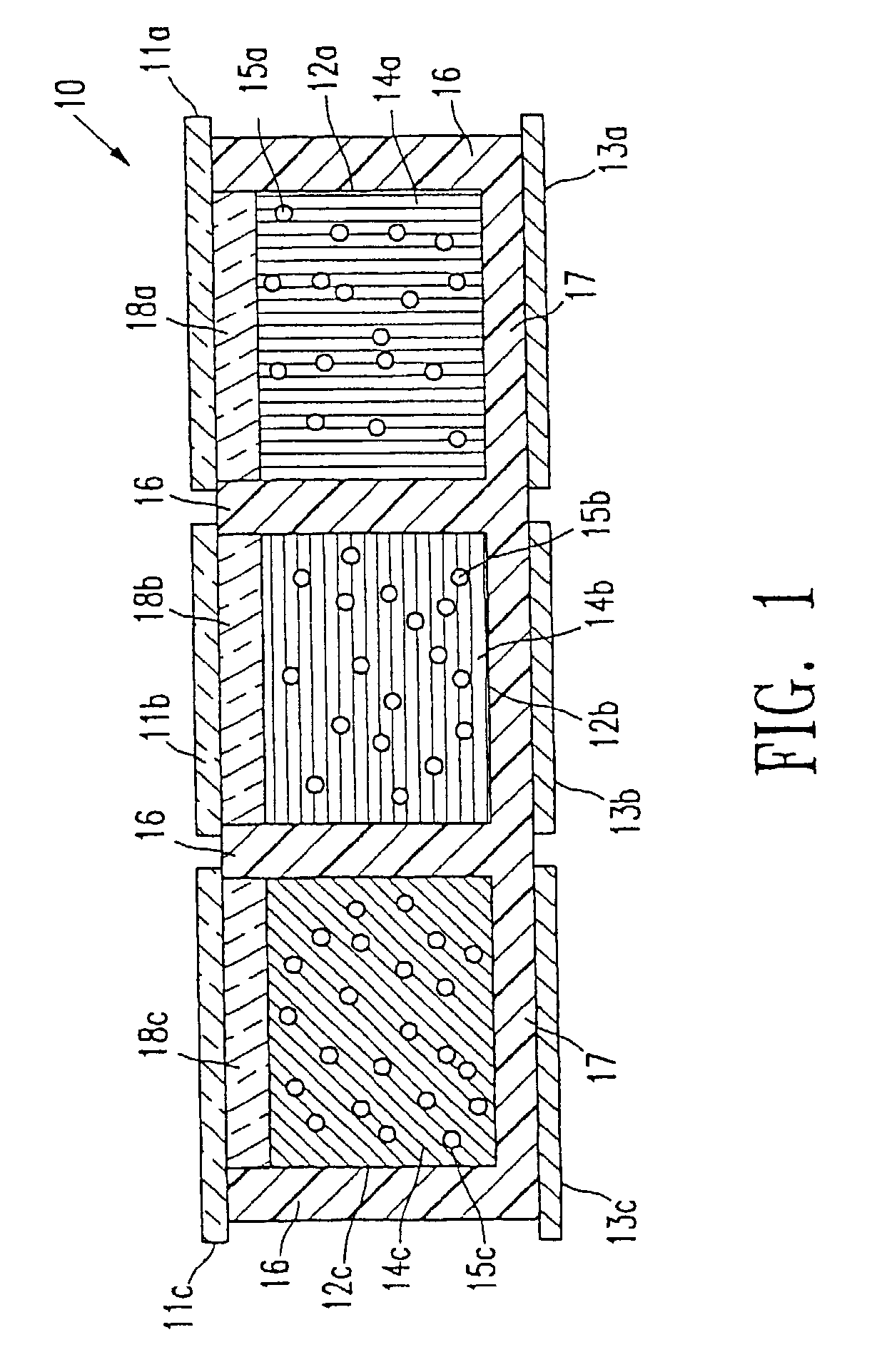

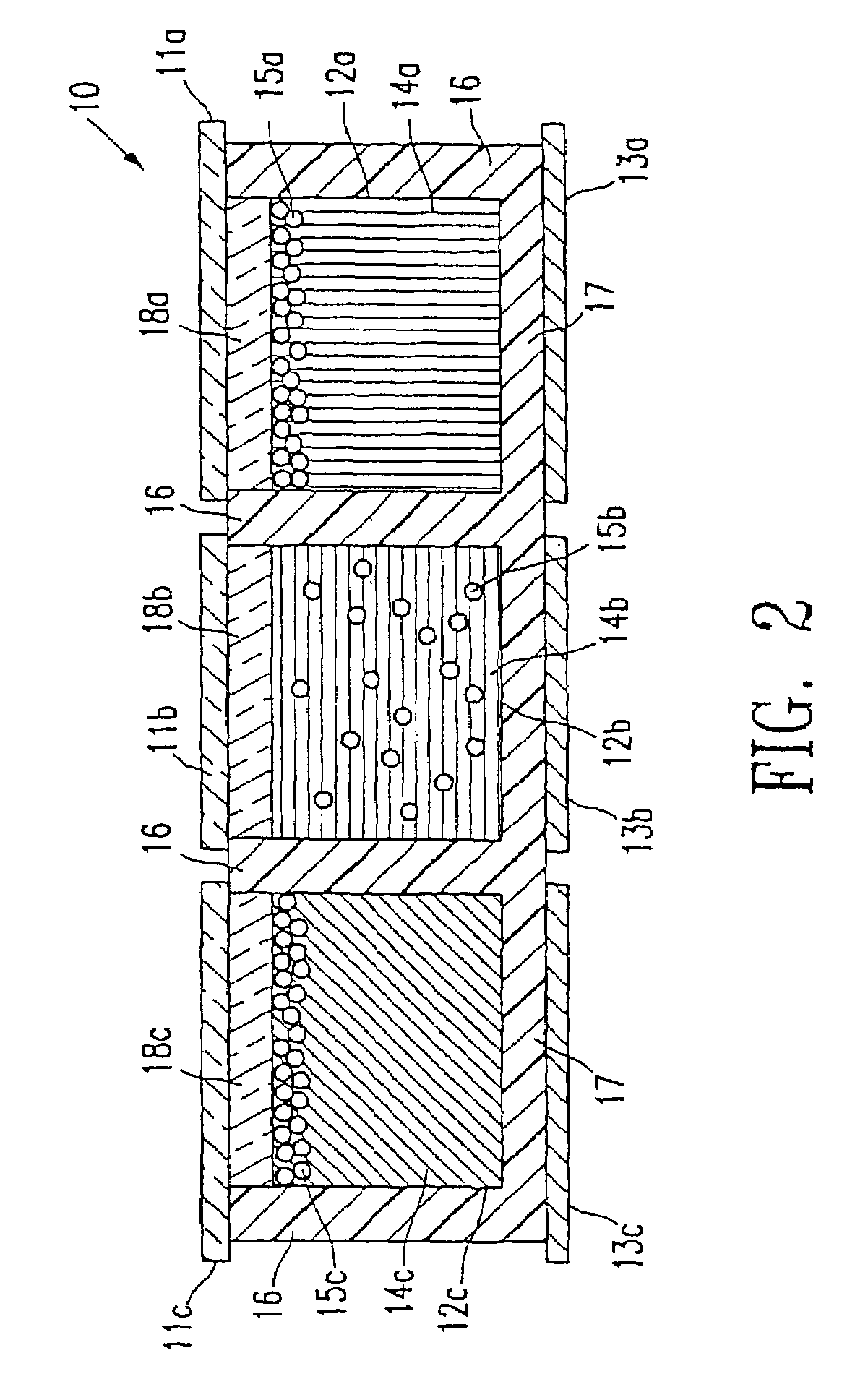

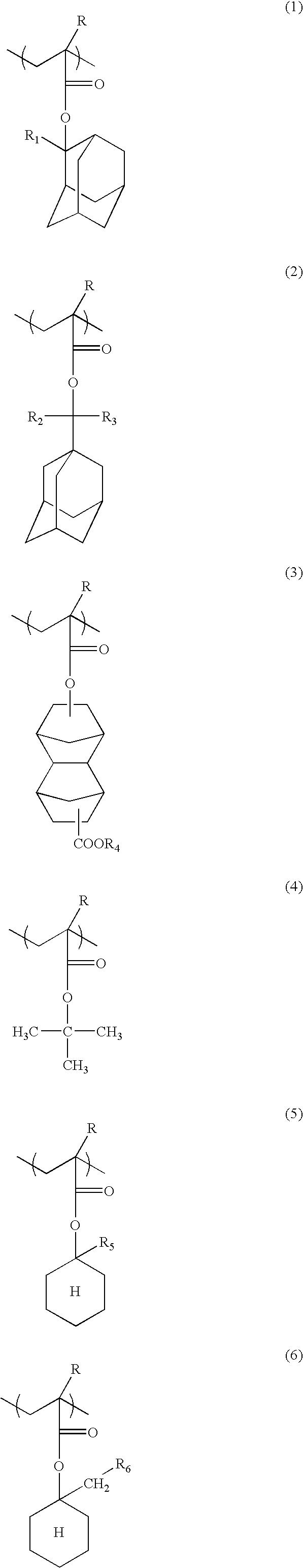

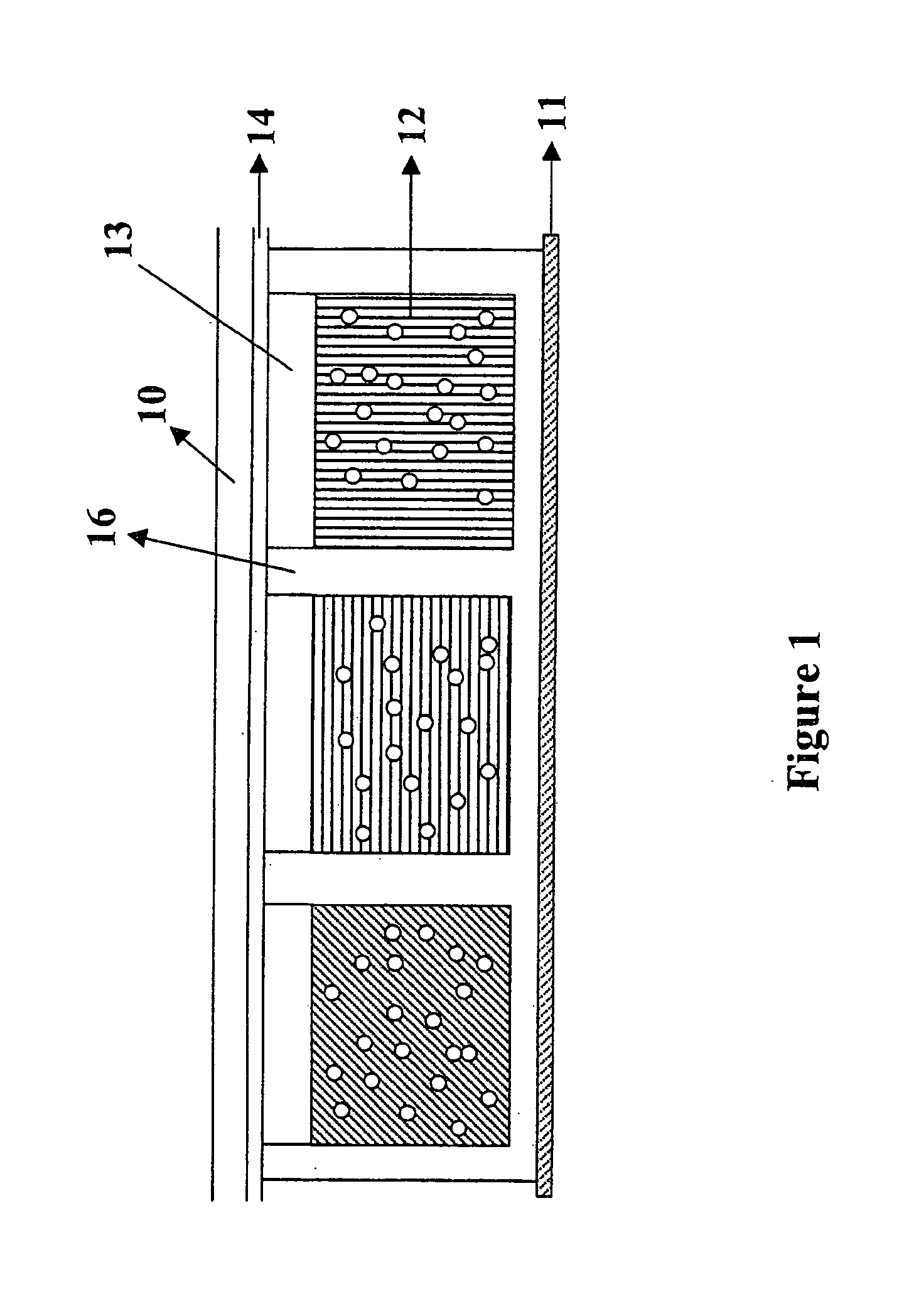

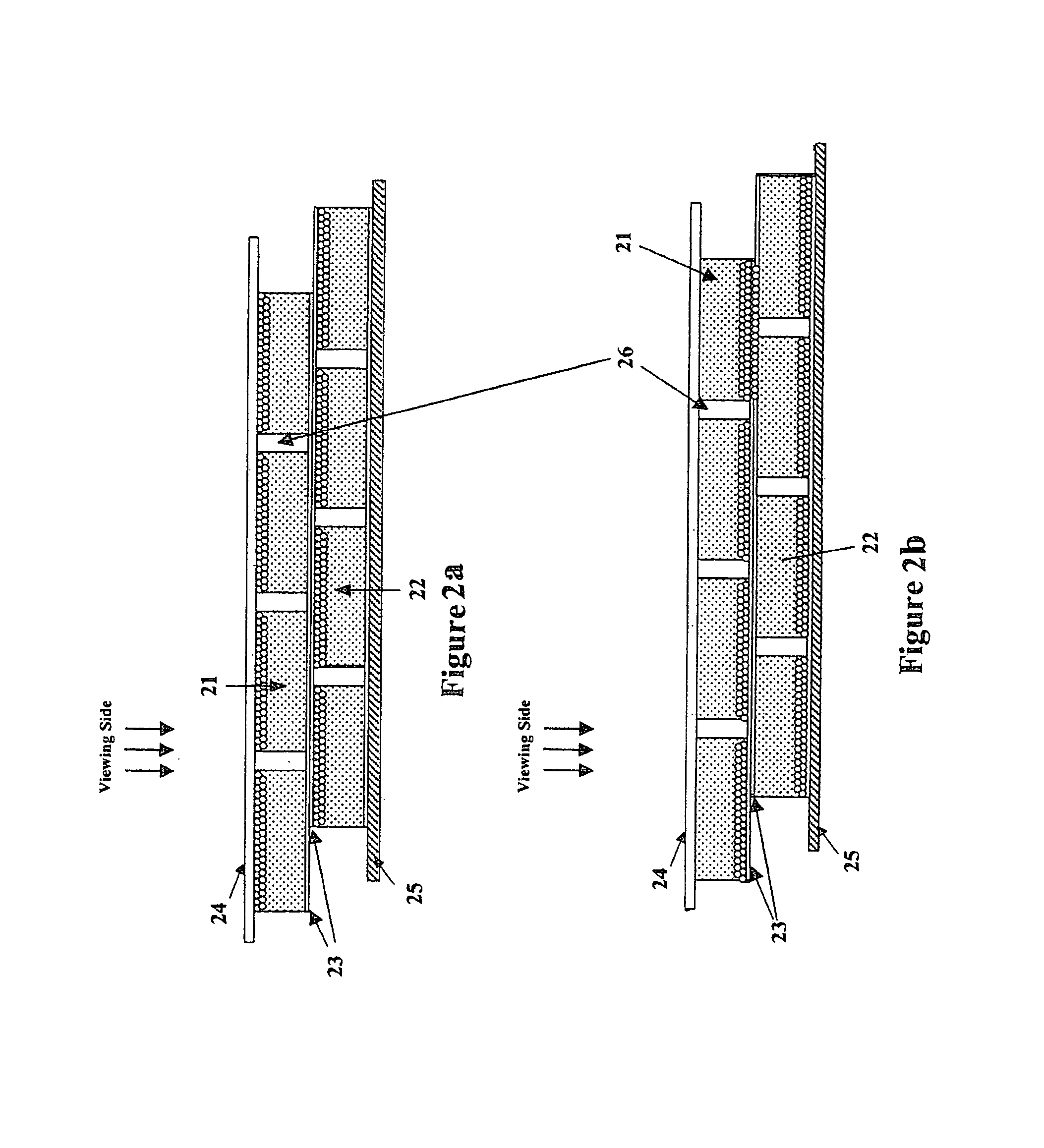

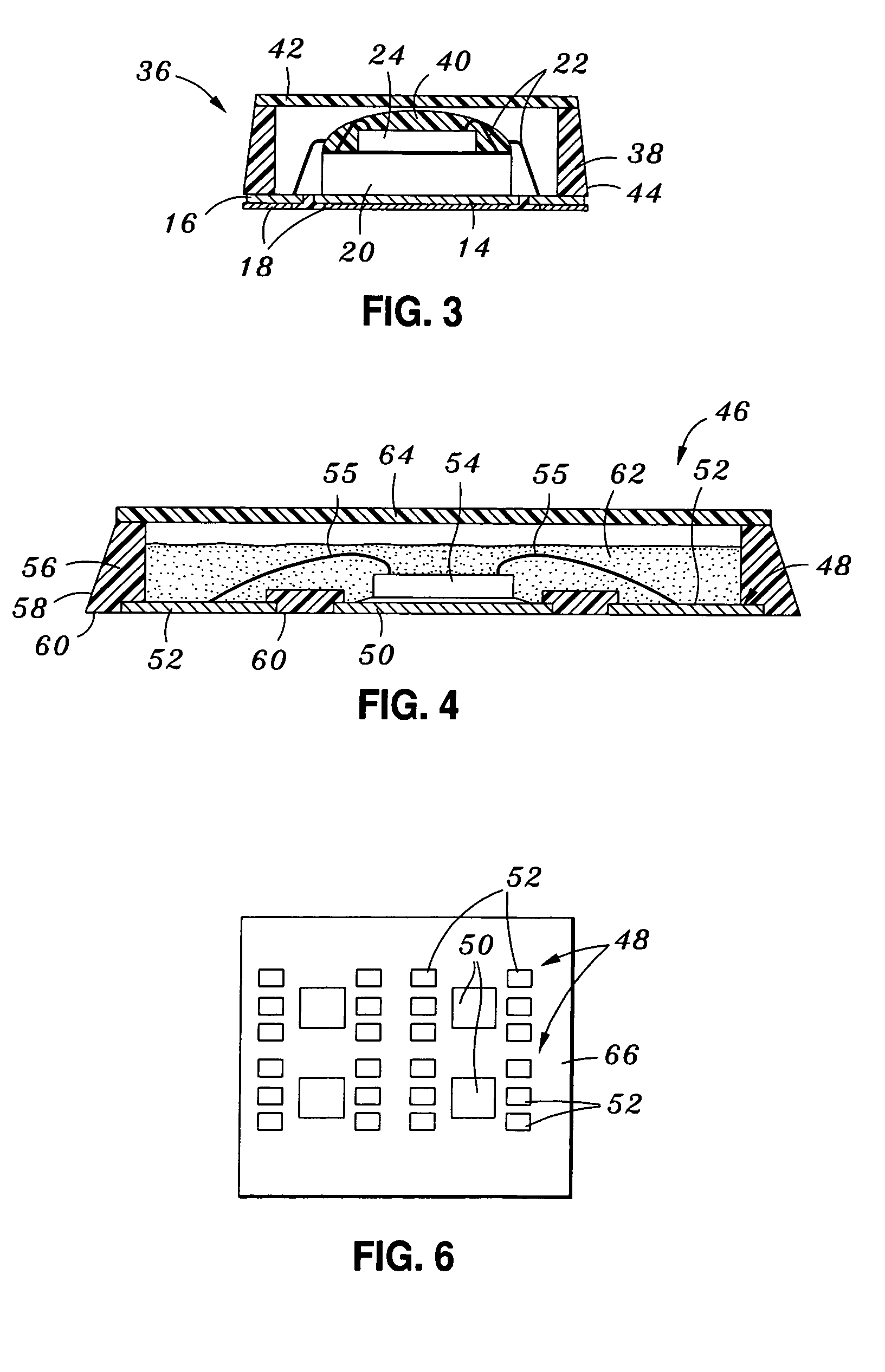

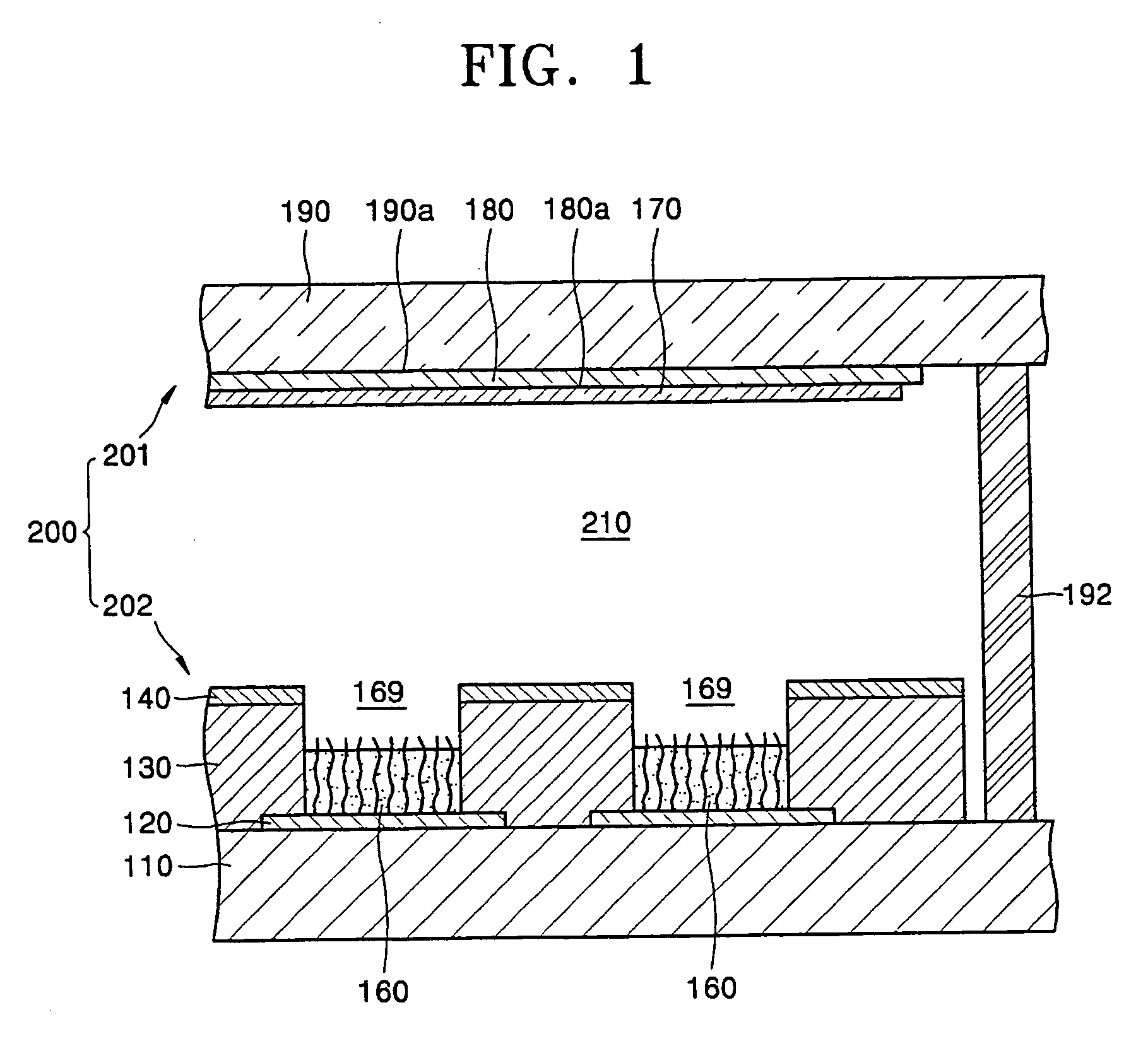

Composition and process for the manufacture of an improved electrophoretic display

InactiveUS7205355B2Free from defectGood wetting propertiesStatic indicating devicesAdhesivesReflectivityDisplay device

The invention relates to a display having improved contrast ratio, switching performance, reflectivity at the Dmin state and structural integrity and methods for its manufacture.

Owner:E INK CALIFORNIA

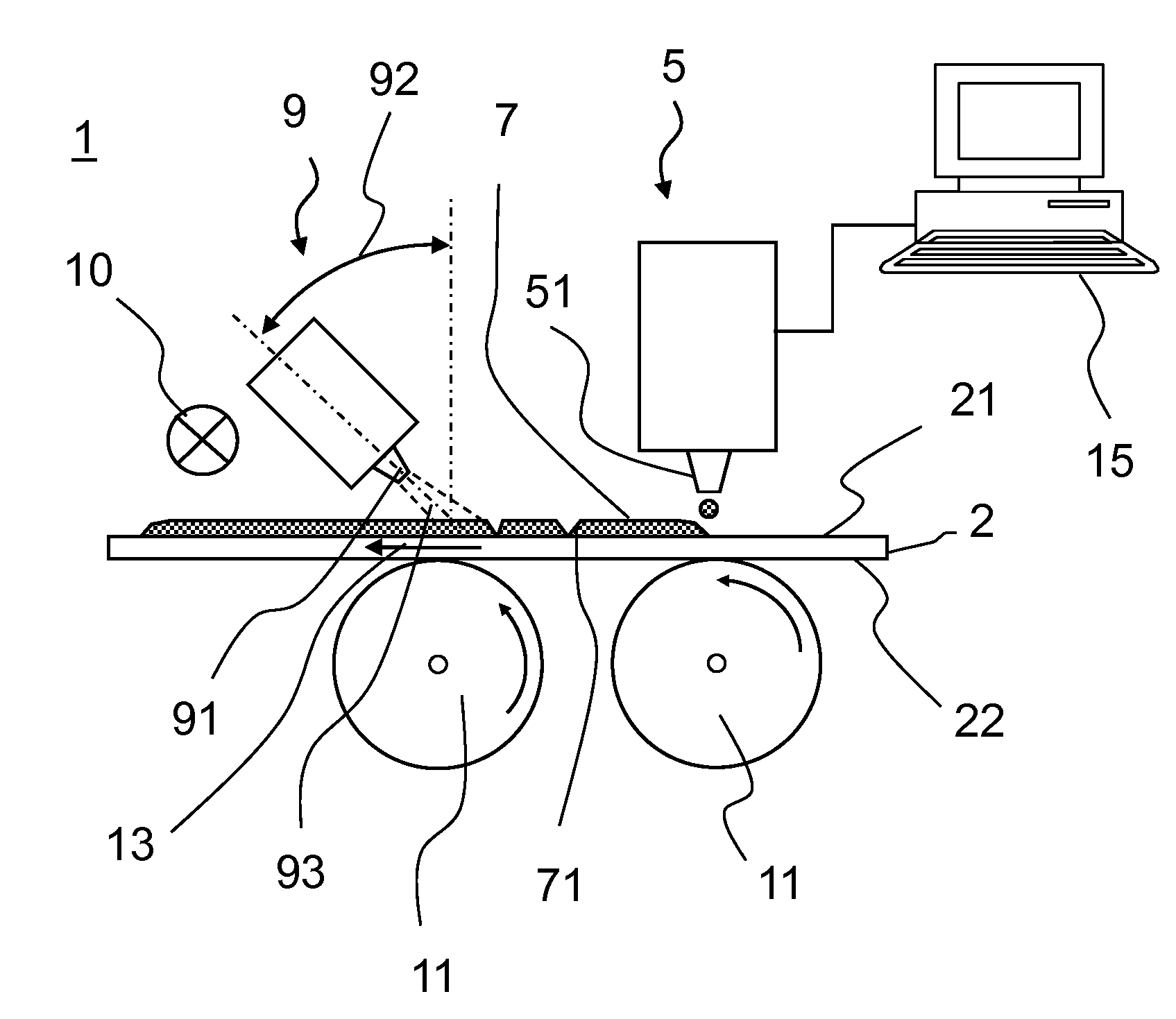

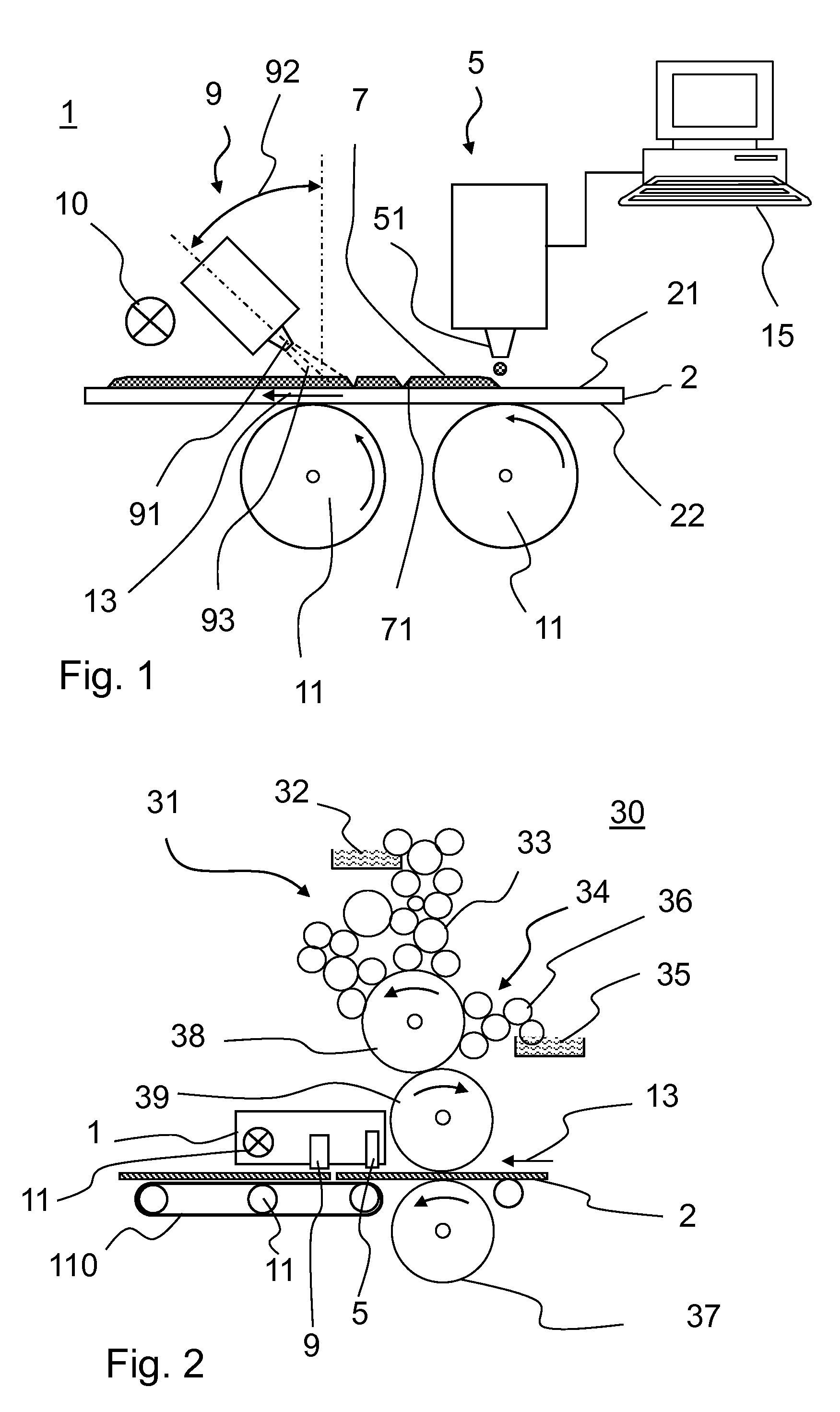

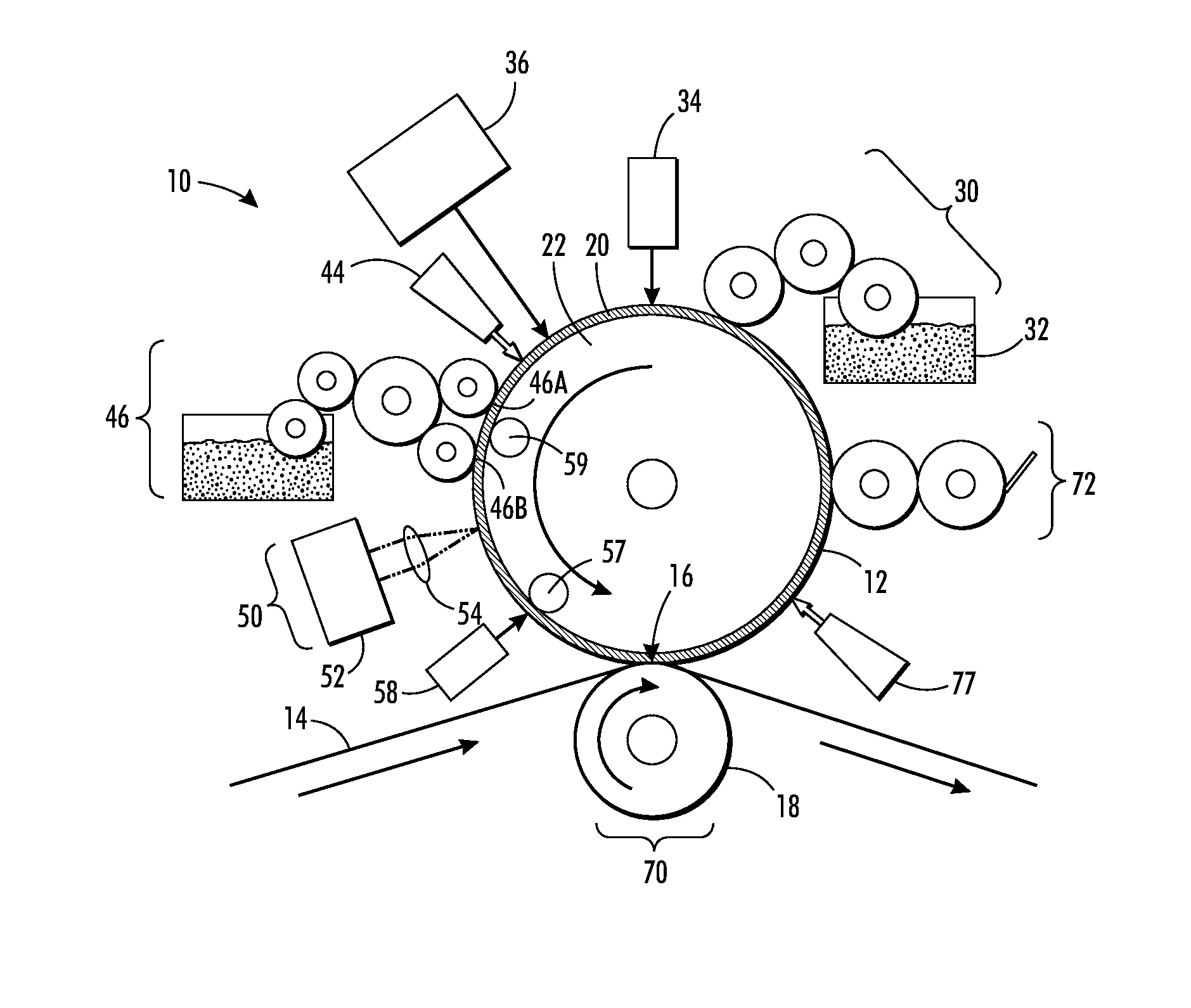

Method and apparatus for applying plastic coatings

InactiveUS20100221449A1Free from defectShorten driving distancePaper coatingPretreated surfacesPaper sheetAirflow

The invention relates to an apparatus for applying coatings to surfaces of substrates in the form of paper, cardboard, or plastic films, preferably for finishing printed materials. The apparatus comprisesa coating unit for applying coating material in fluid form to the substrate surface, anda device for smoothing the still fluid film applied to the substrate surface by the coating unit, the device including a unit for generating a gas stream which is directed onto the substrate surface coated with the film, and which smoothes the film while at least partially removing interfering structures on the film surface such as depressions, elevations, and craters before the coating material cures.

Owner:SCHMID RHYNER

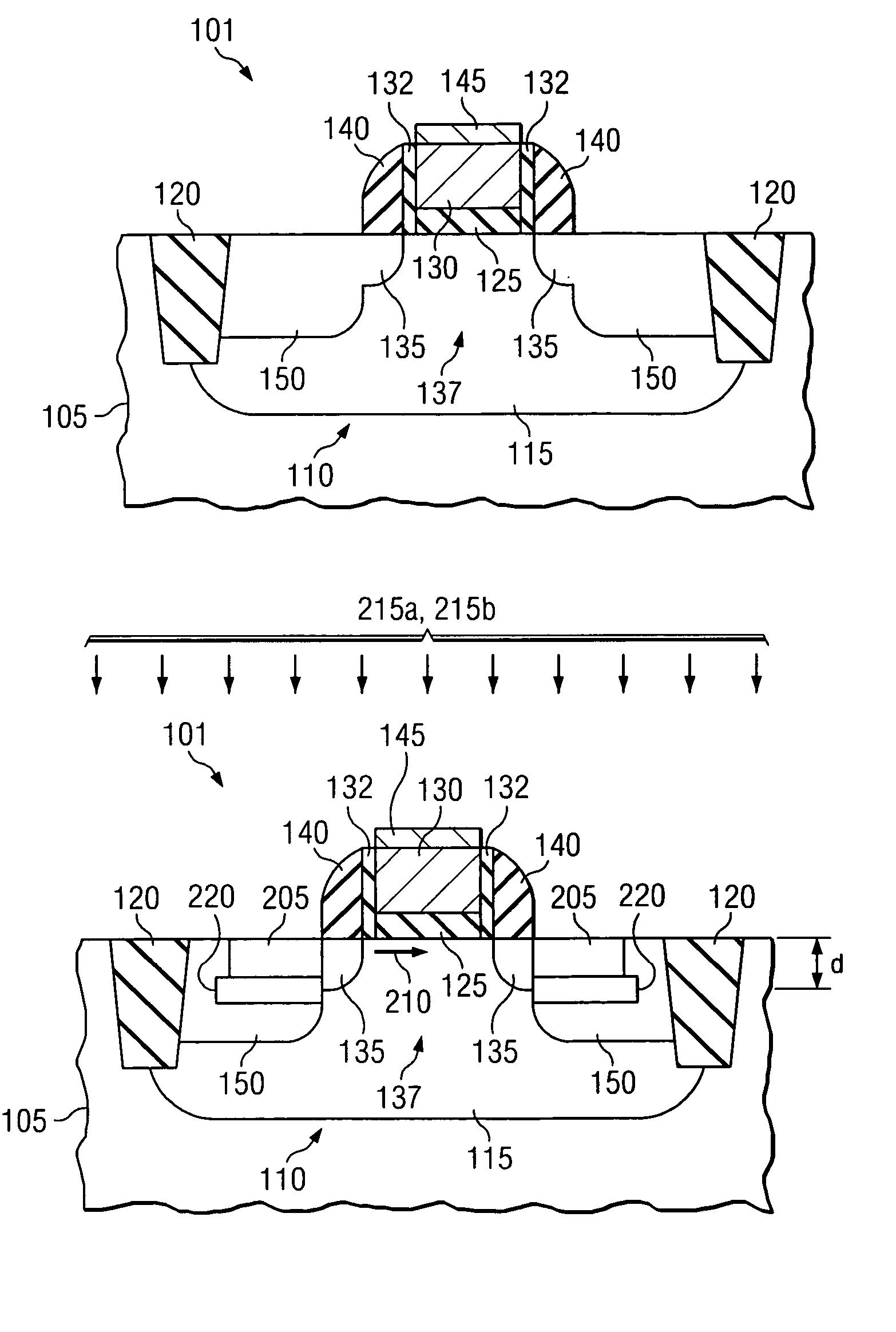

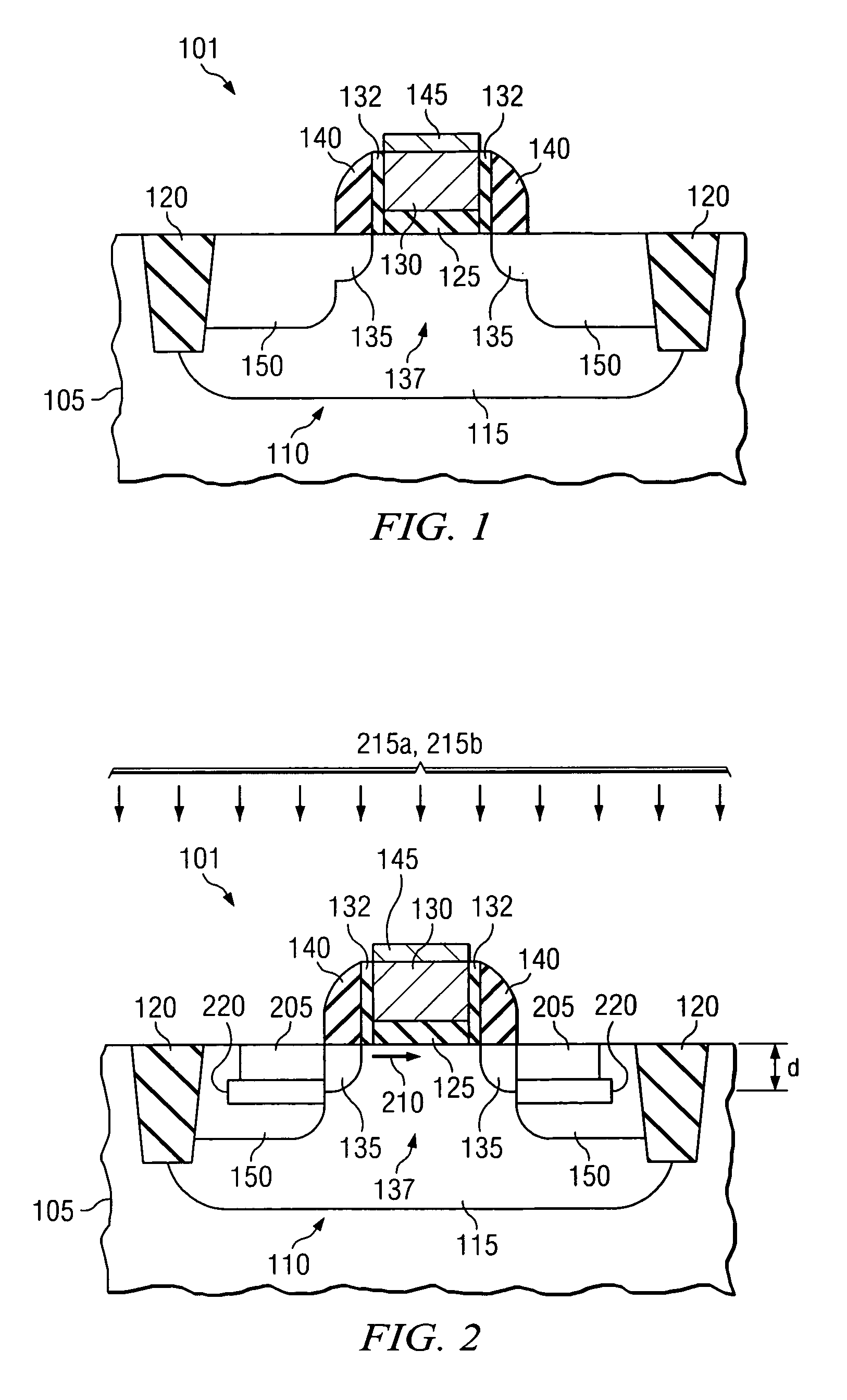

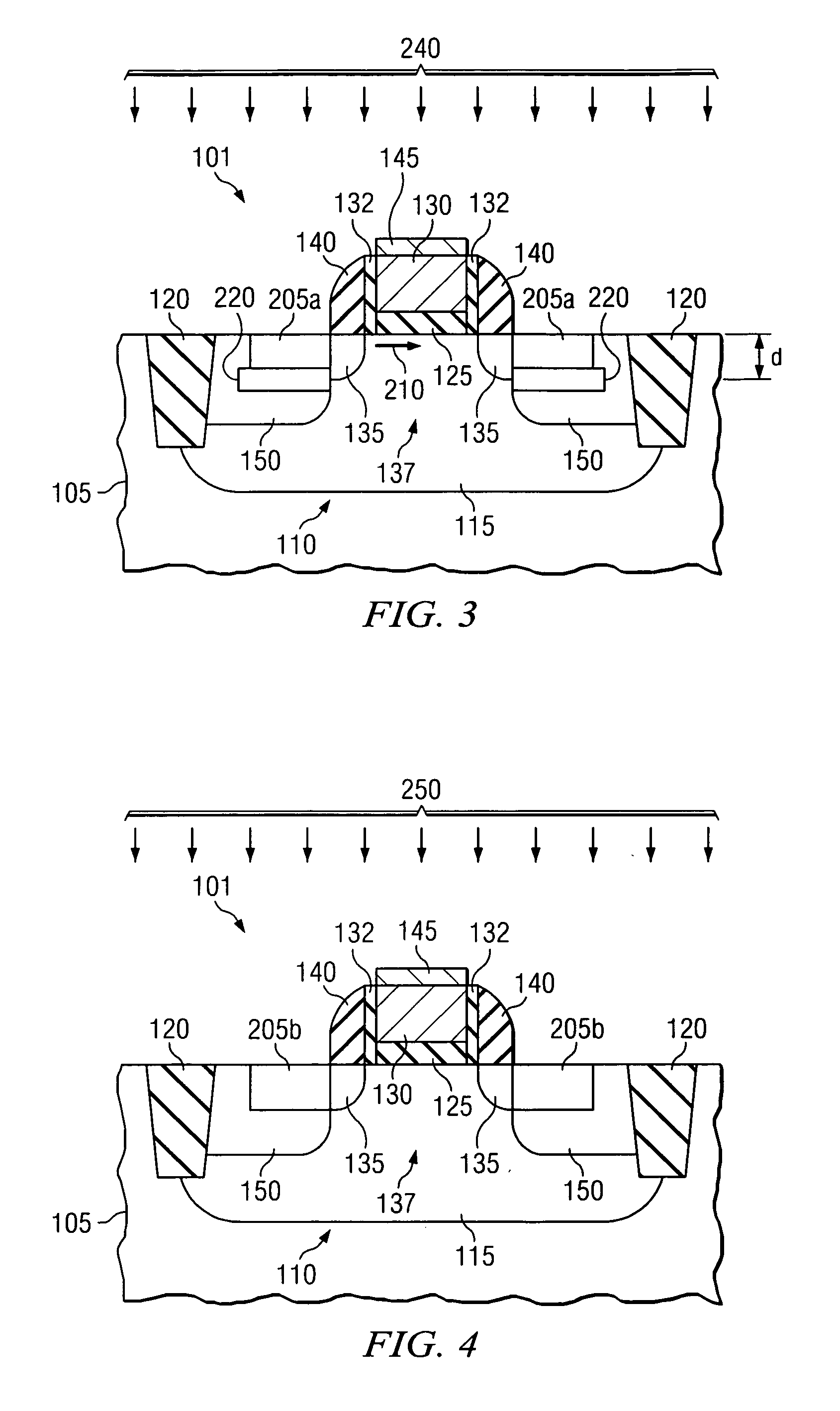

Defect-free SiGe source/drain formation by epitaxy-free process

InactiveUS20070173022A1Low costReduce throughputTransistorSemiconductor/solid-state device manufacturingMOSFETCharge carrier mobility

MOSFET transistors having localized stressors for improving carrier mobility are provided. Embodiments of the invention comprise a gate electrode formed over a substrate, a carrier channel region in the substrate under the gate electrode, and source / drain regions on either side of the carrier channel region. The source / drain regions include an embedded stressor having a lattice constant different from the substrate. In a preferred embodiment, the substrate is silicon and the embedded stressor is SiGe. Implanting a portion of the source / drain regions with Ge forms the embedded stressor. Implanting carbon into the source / drain regions and annealing the substrate after implanting the carbon suppresses dislocation formation, thereby improving device performance.

Owner:TAIWAN SEMICON MFG CO LTD

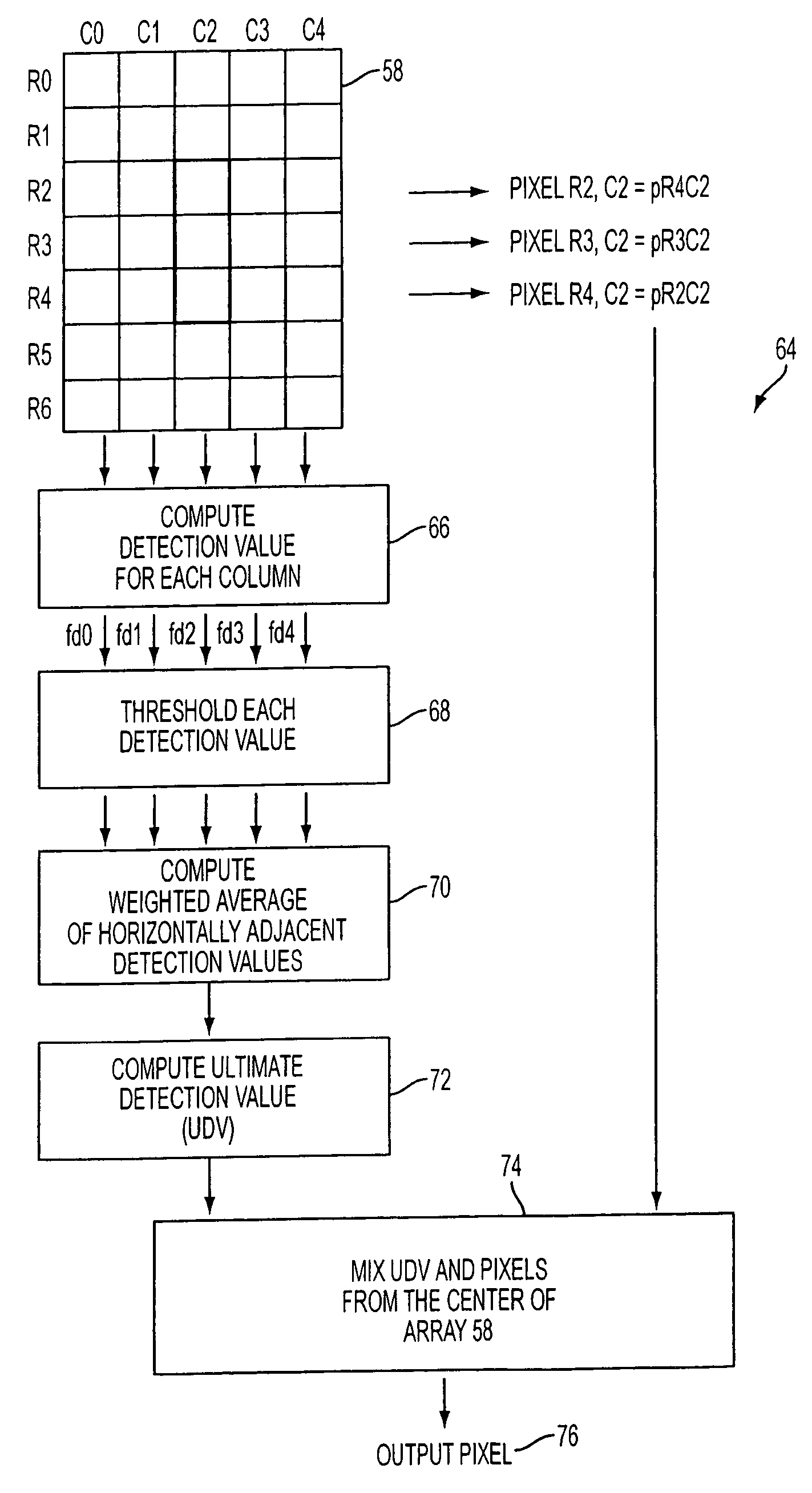

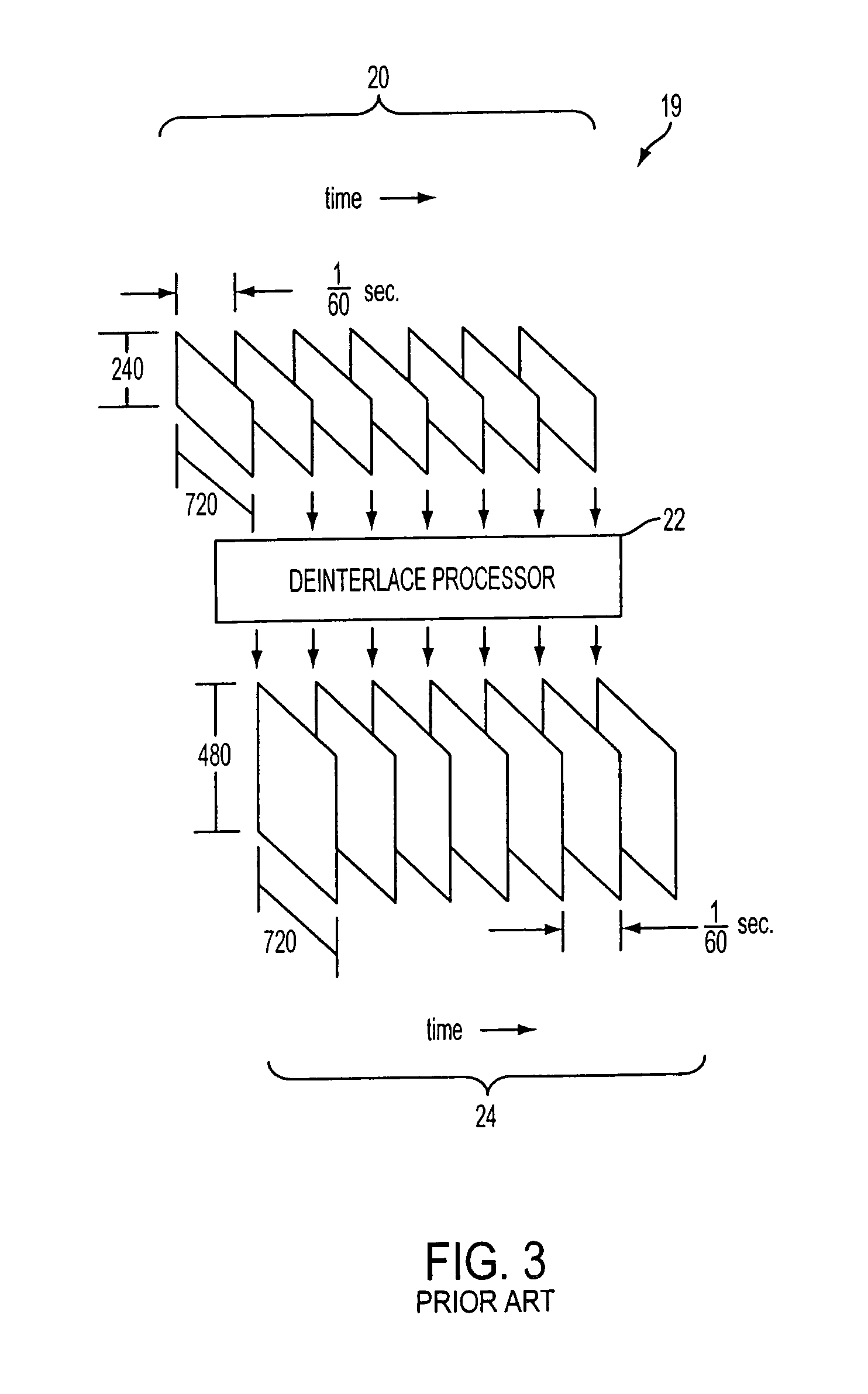

Method and apparatus for deinterlacing digital video images

InactiveUS7027099B2Detection and reduction of motion artifactReduce impactTelevision system detailsPicture reproducers using cathode ray tubesDigital videoInterlaced video

A digital image processor is provided. The digital image processor includes a deinterlacing processor that is implemented upon a digital processing unit. The deinterlacing processor is coupled to an input operable to receive an interlaced video stream, a digital memory for storing portions of the interlaced video signal, and an output operable to transmit a deinterlaced video stream. The deinterlacing processor is operable to perform frequency analysis upon the received interlaced video stream in order to generate the deinterlaced video stream having reduced motion artifacts.

Owner:LATTICE SEMICON CORP

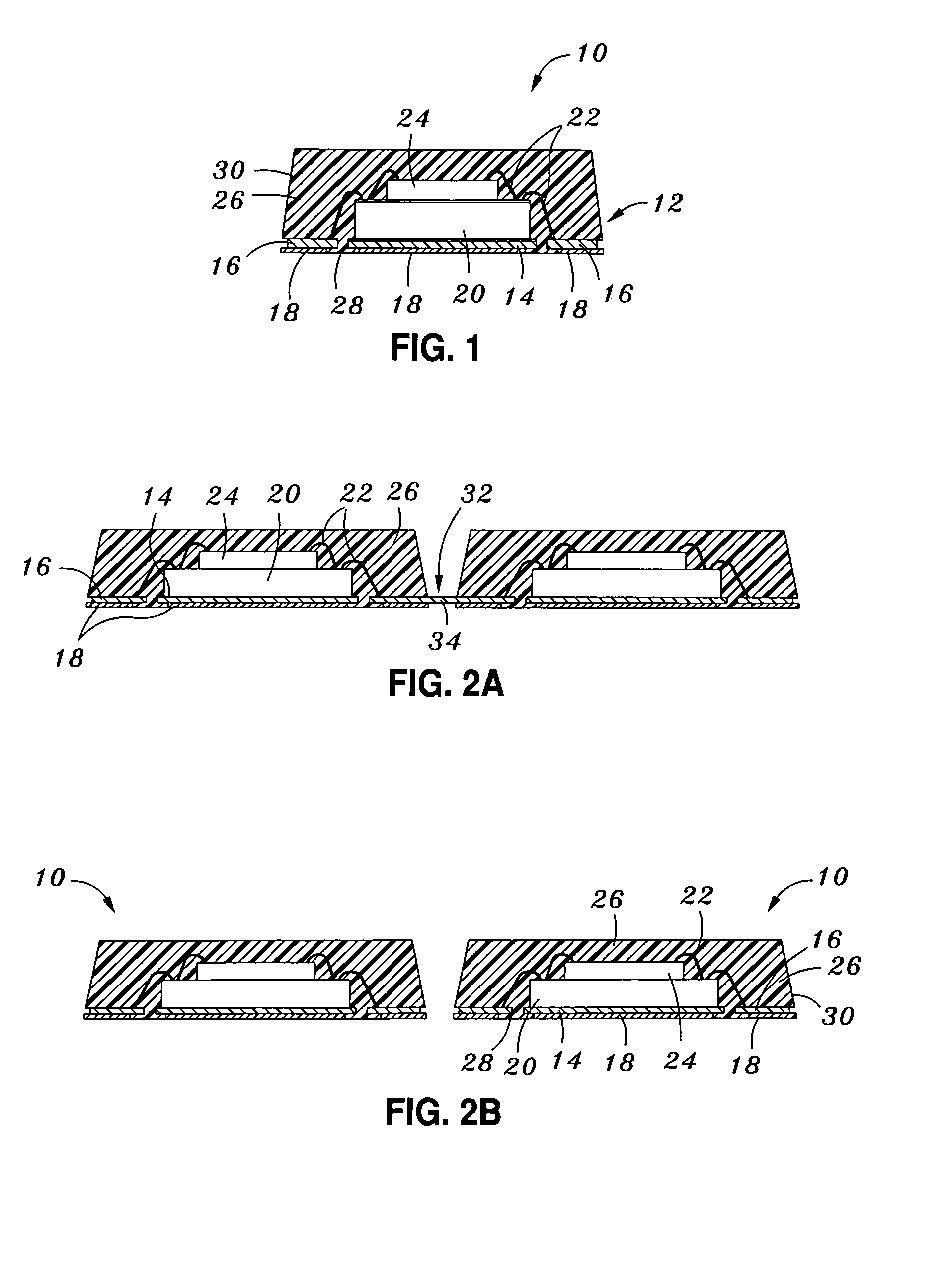

Etch singulated semiconductor package

InactiveUS7507603B1Low costFree from defectSemiconductor/solid-state device detailsSolid-state devicesPunchingSemiconductor package

In accordance with the present invention, there is provided various methods of simultaneously fabricating a plurality of semiconductor packages (e.g., cavity type semiconductor packages) wherein the singulation process is achieved using etching techniques as opposed to more conventional cutting techniques such as sawing or punching. Such etching techniques are inherently lower in cost and free from many of the defects induced by other cutting techniques.

Owner:AMKOR TECH SINGAPORE HLDG PTE LTD

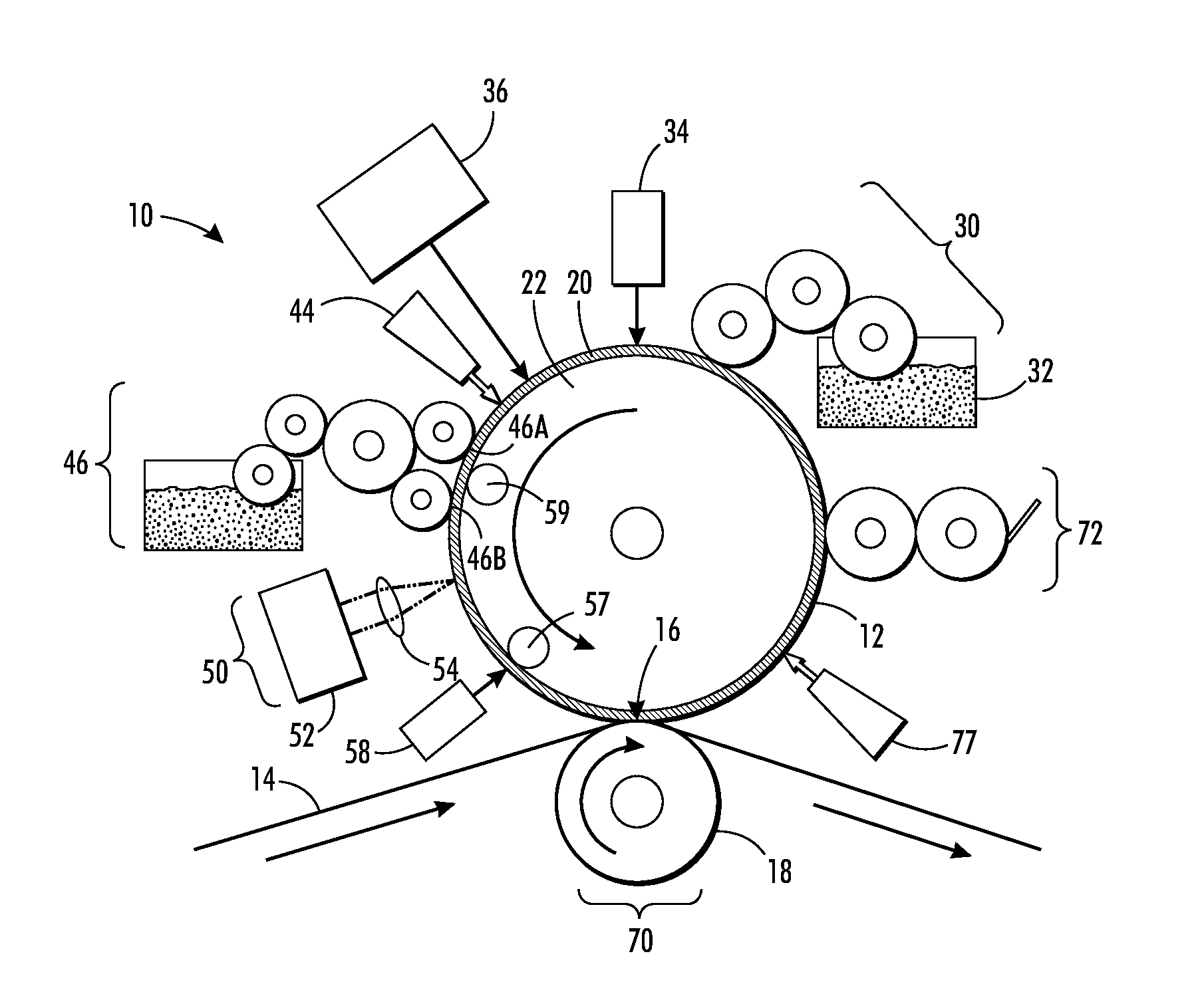

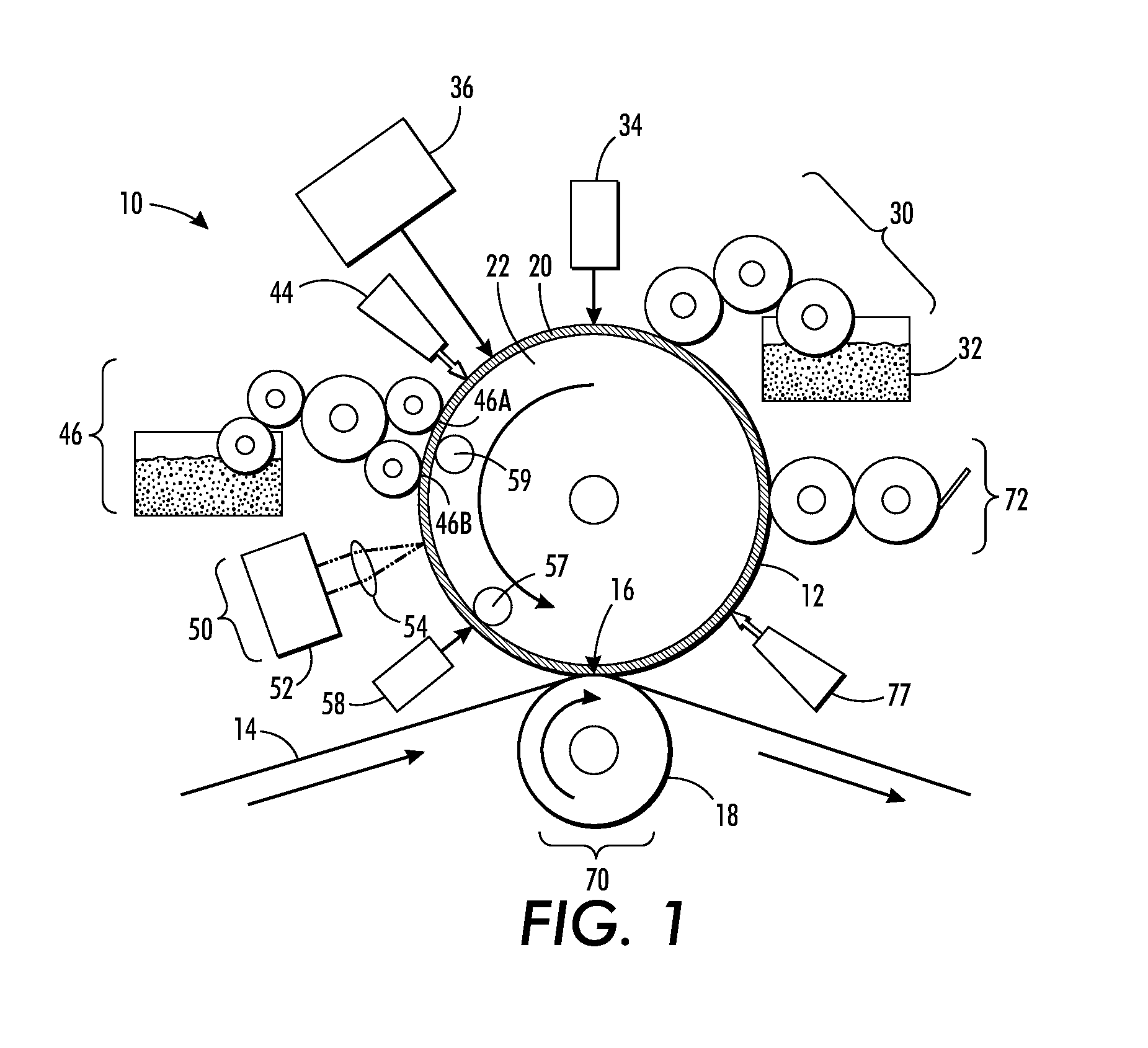

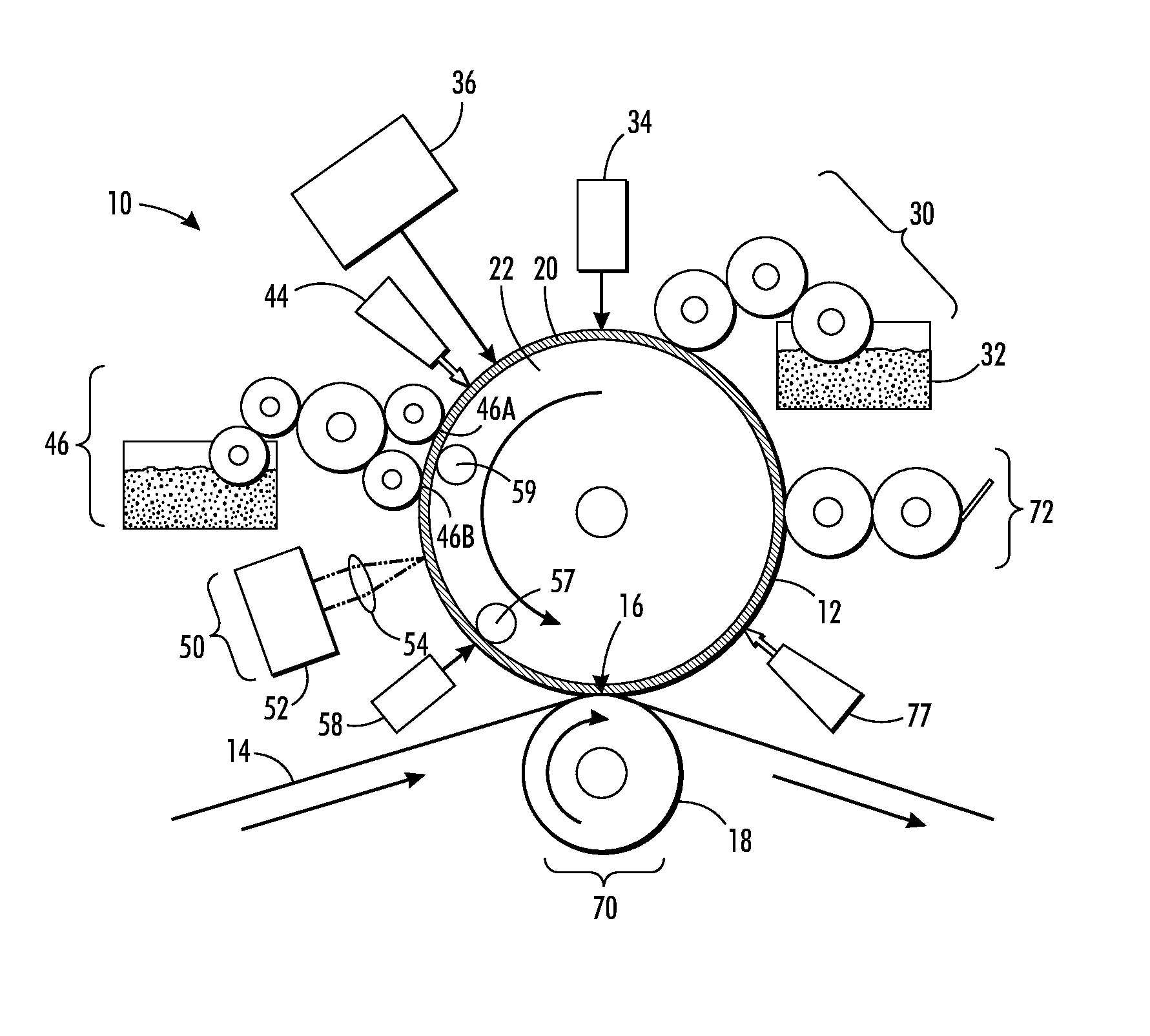

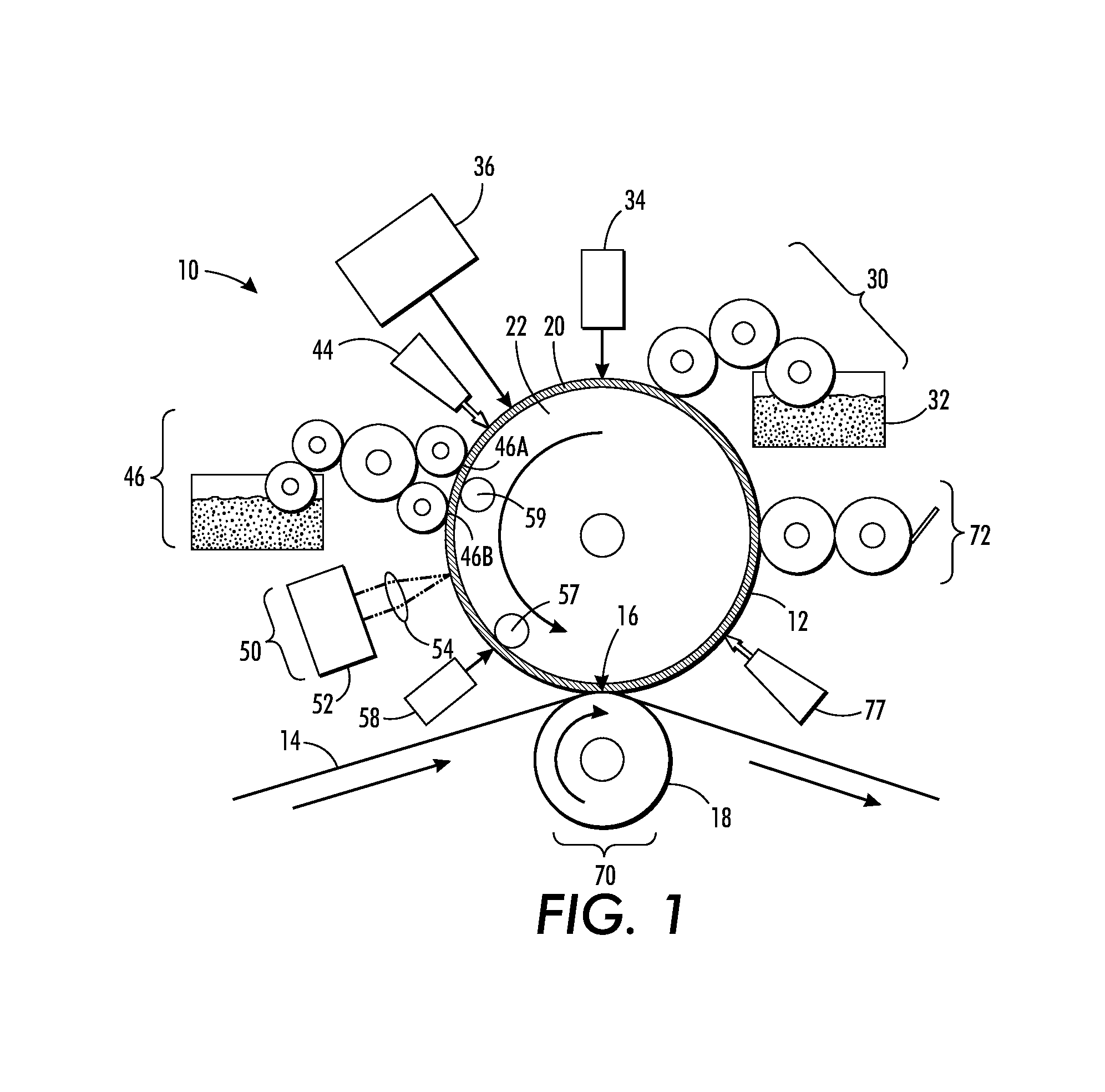

Imaging member for offset printing applications

ActiveUS20140060352A1Uniform layersFree from defectPlaten pressesPlate printingSurface layerPerfluoropolyether

An imaging member includes a surface layer comprising a fluoroelastomer-perfluoropolyether composite formed from a reaction mixture comprising a fluoroelastomer and a perfluoropolyether compound. Methods of manufacturing the imaging member and processes for variable lithographic printing using the imaging member are also disclosed.

Owner:XEROX CORP

Carbon nanotube, electron emission source including the same, electron emission device including the electron emission source,and method of manufacturing the electron emission device

InactiveUS20050244325A1Few defectImprove reliabilityElectric discharge tubesNanoinformaticsCarbon nanotubeElectron

A carbon nanotube (CNT) with Raman spectrum having a G band and a D band, includes a ratio of a G band peak integral IG and a D band peak integral ID is 5 or greater. Further, there is an electron emission source including the CNT, an electron emission device including the electron emission source and a method of manufacturing the electron emission device. The electron emission source including the CNT has preferred current density, so the electron emission device using the electron emission source is highly reliable.

Owner:SAMSUNG SDI CO LTD

Composition and process for the sealing of microcups in roll-to-roll display manufacturing

InactiveUS8361356B2Improve adhesionQuality improvementSludge treatmentVolume/mass flow measurementCrystallographyElectrophoresis

The invention relates to a novel sealing composition for the manufacture of an electrophoretic or liquid crystal display, and a sealing process using the composition. The composition allows electrophoretic or liquid crystal cells to be seamlessly sealed and the sealing layer free of any defects.

Owner:E INK CALIFORNIA

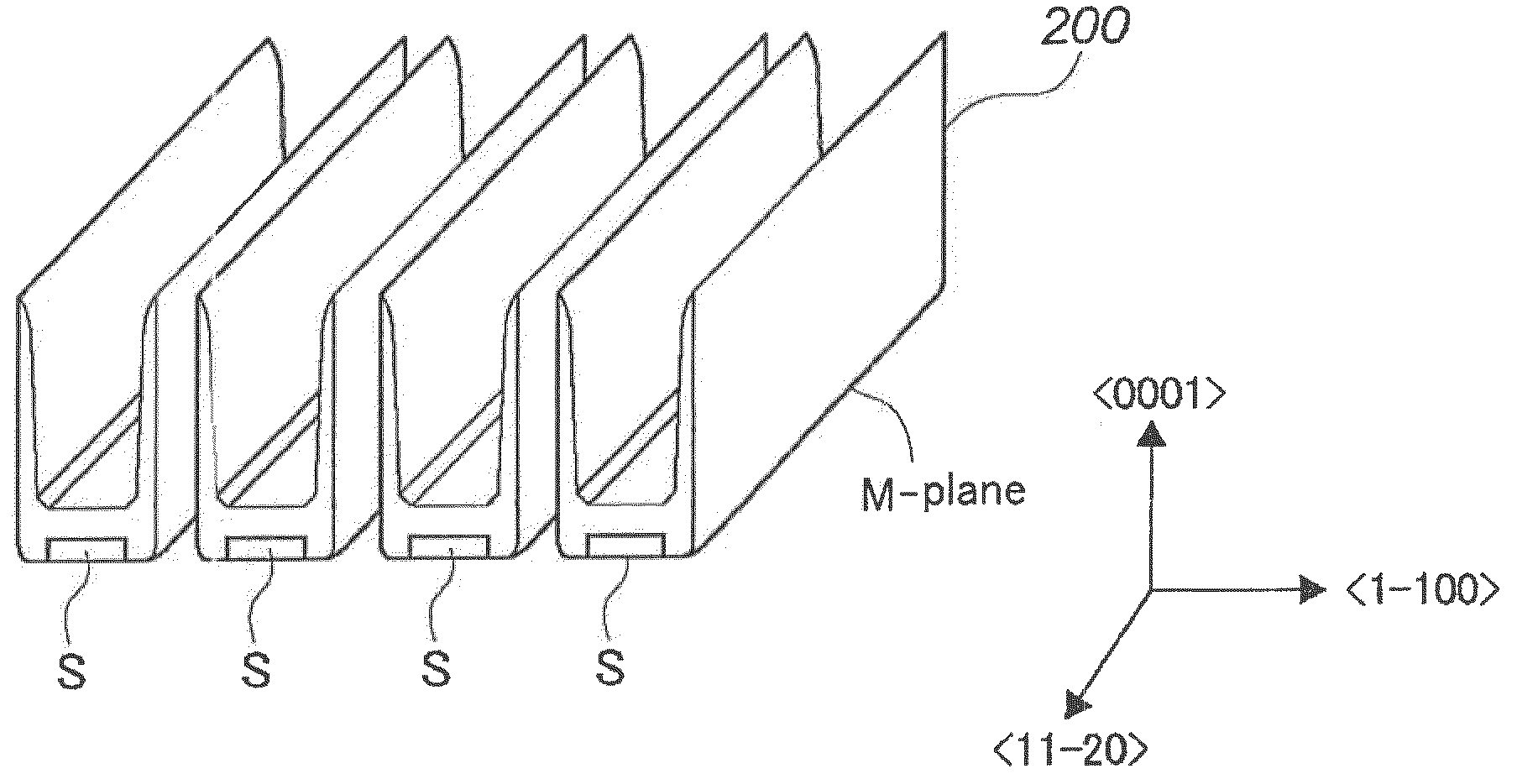

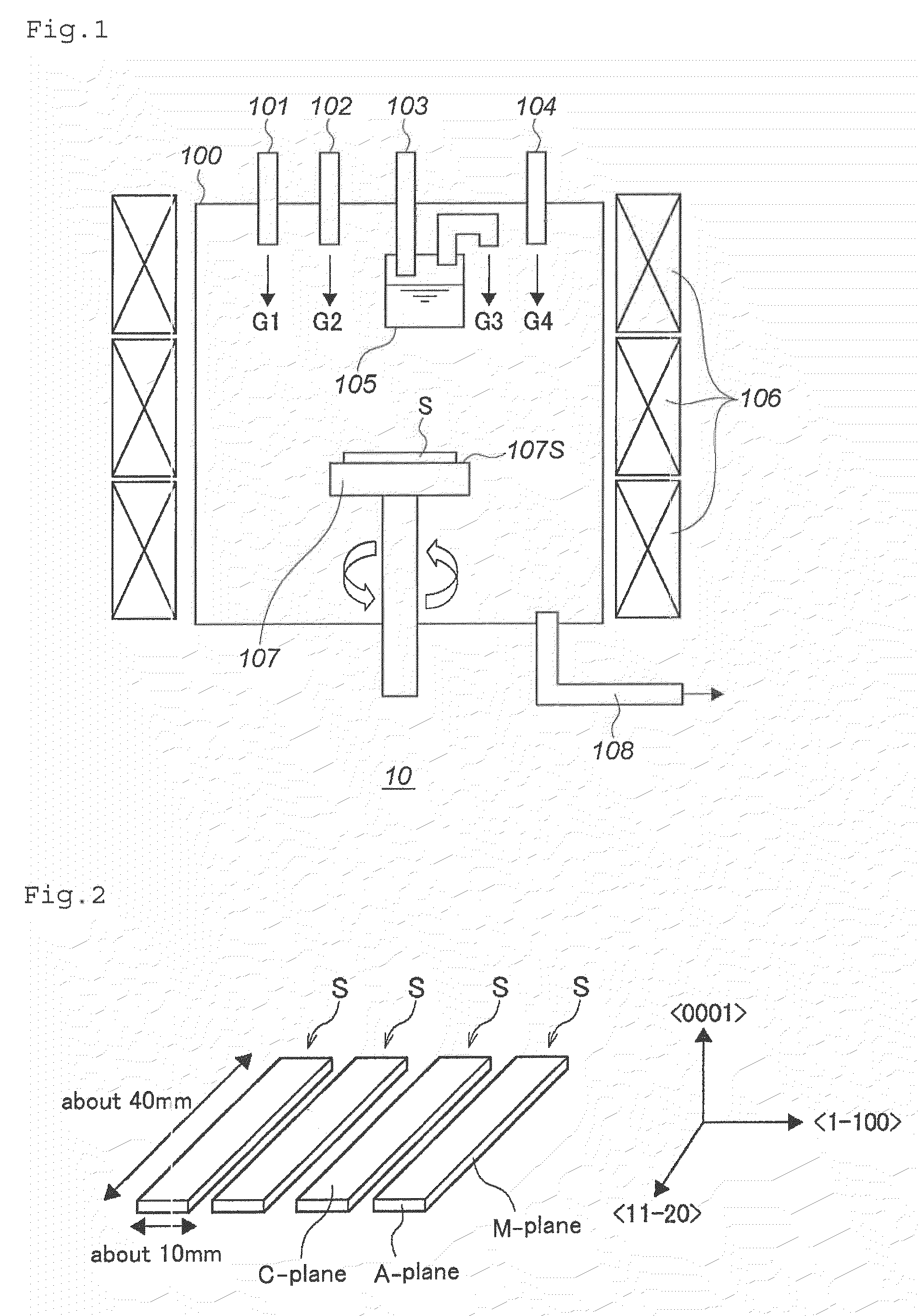

Method for producing group iii nitride semiconductor crystal, group iii nitride semiconductor substrate, and semiconductor light- emitting device

InactiveUS20100148212A1Quality improvementGood substratePolycrystalline material growthSemiconductor/solid-state device manufacturingGas phaseOptoelectronics

The method for producing a group III nitride semiconductor crystal of the invention comprises a step of preparing a seed crystal having a non-polar plane followed by growing a group III nitride semiconductor from the non-polar plane in a vapor phase, wherein the growing step includes growing the group III nitride semiconductor so as to extend in the +C-axis direction of the seed crystal. A group III-V nitride semiconductor crystal having high quality and a large-area non-polar plane can be obtained by the method.

Owner:MITSUBISHI CHEM CORP

High aspect ratio parts of bulk metallic glass and methods of manufacturing thereof

Bulk metallic articles having a high-aspect ratio that are formed of bulk metallic glass, that are net-shaped and that are produced under process conditions that maximize the quality and integrity of the parts as well as the life of the mold tool, thus minimizing production costs, and manufacturing methods for producing such articles are provided.

Owner:CALIFORNIA INST OF TECH

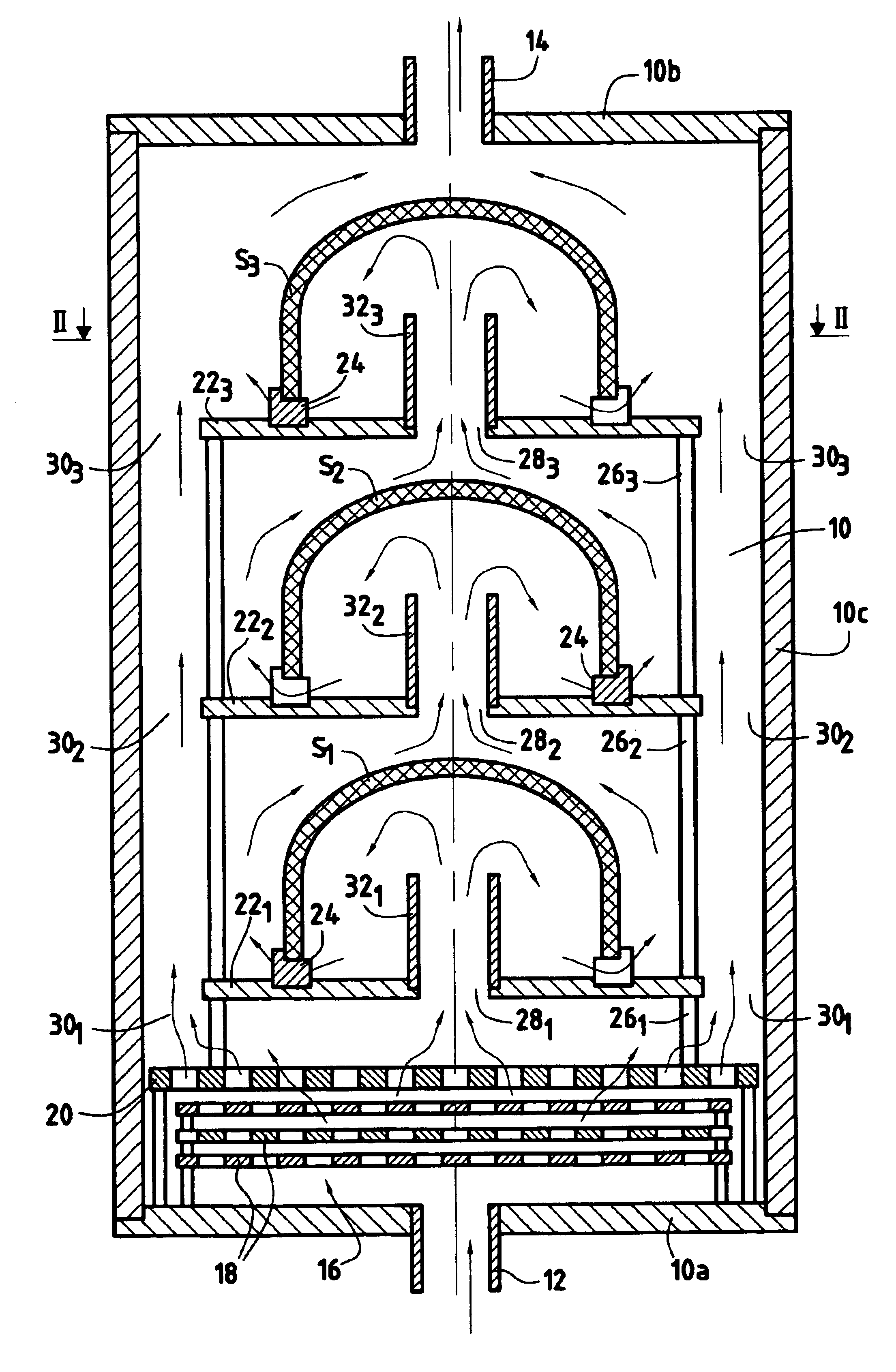

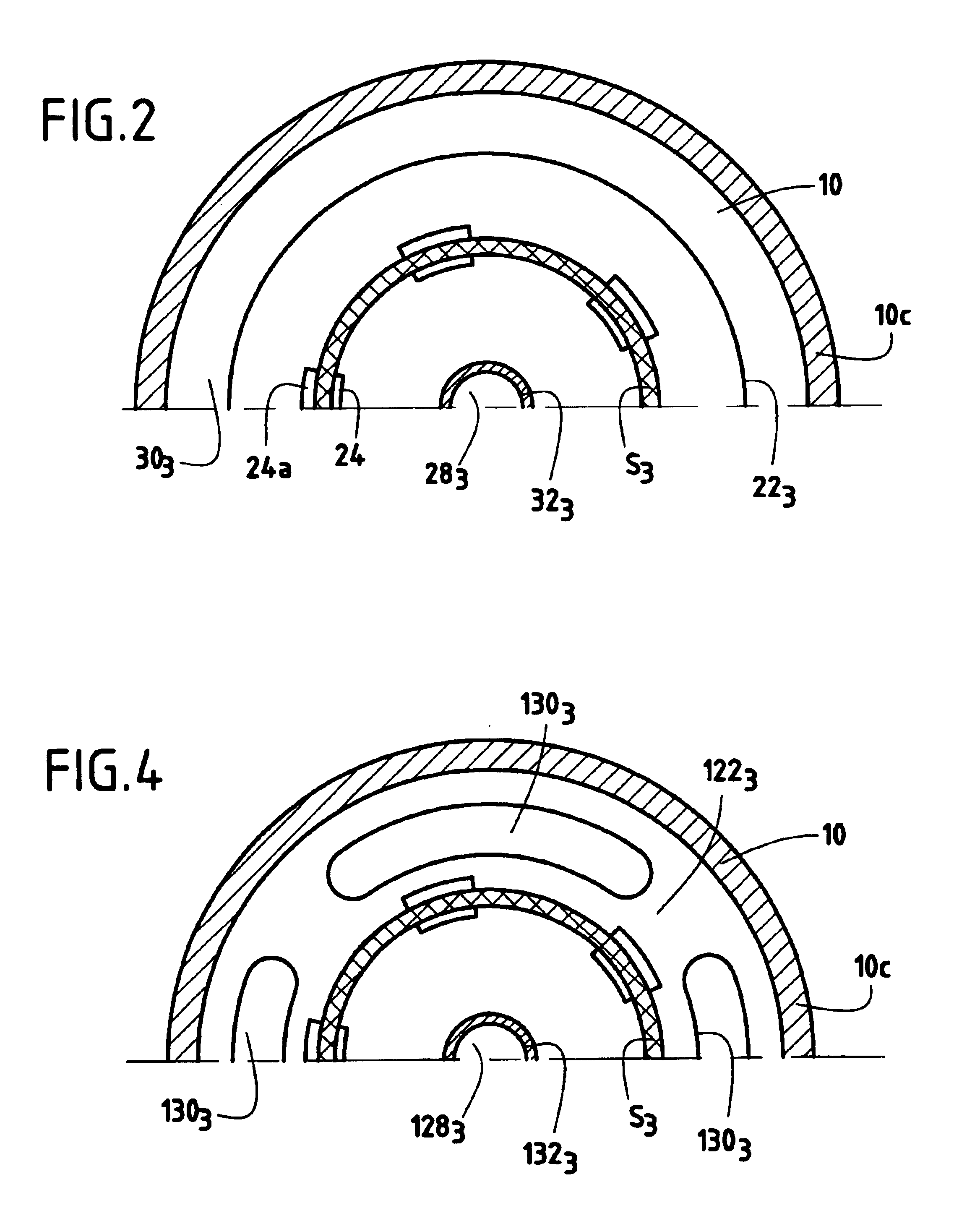

Densifying hollow porous substrates by chemical vapor infiltration

InactiveUS6942893B2Free from defectUniform densificationLiquid surface applicatorsChemical vapor deposition coatingPorous substrateReactive gas

A porous substrate having a concave inside face and an outside face is disposed in an enclosure, and reactive gas is introduced into the enclosure to densify the substrate. At least a portion of the gas is divided into two non-zero fractions. The first fraction of the gas is fed to the inside face of the substrate. The second fraction of the gas is fed to only the outside face of the substrate. Alternatively, the first fraction of the gas is fed via a tooling extending into an inside volume defined by the concave inside face of the substrate.

Owner:GERAKL

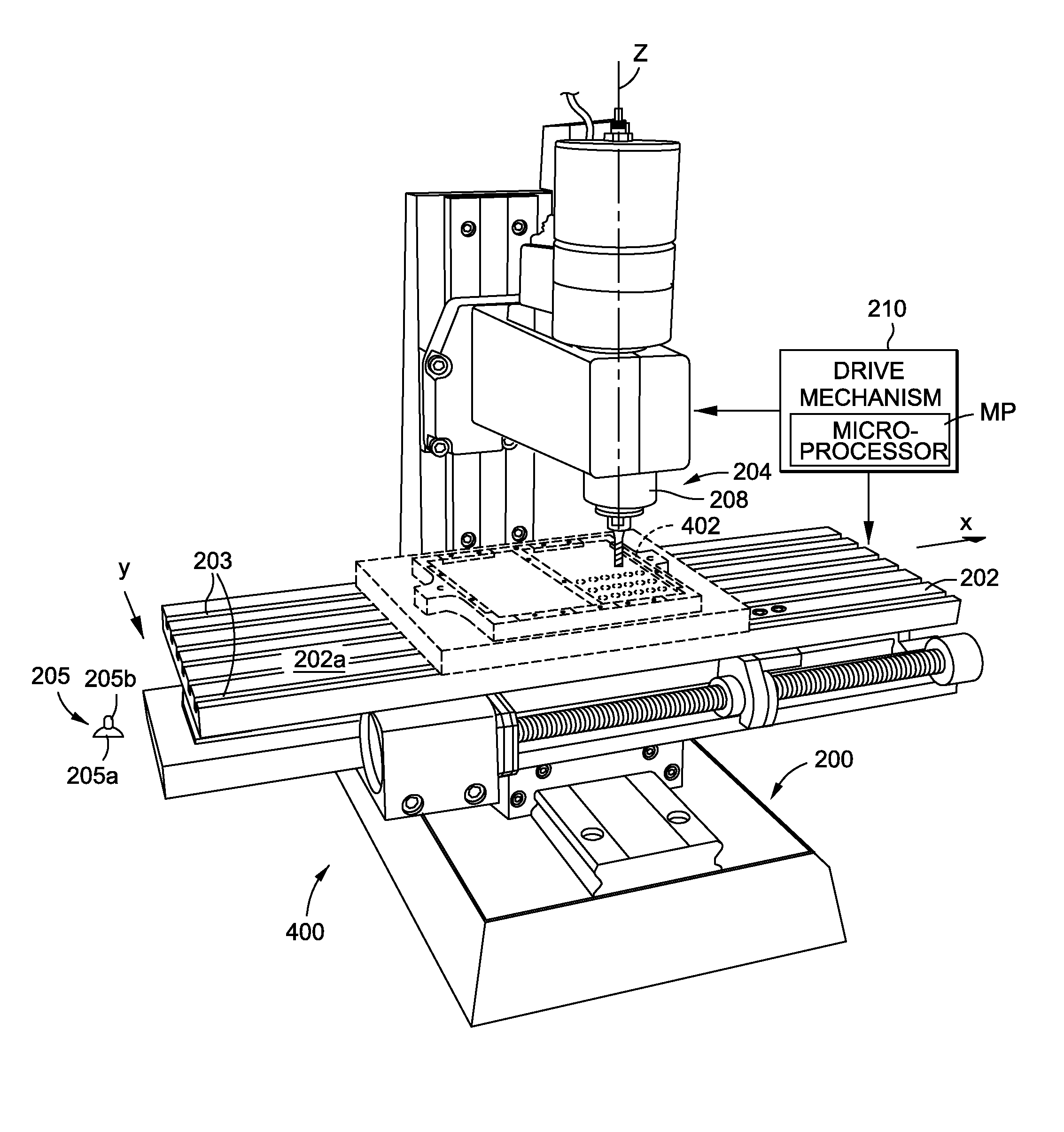

Jig device and apparatus and method of making a dental prosthesis or pattern therefor

ActiveUS20110104642A1Precise cuttingFree from defectDental implantsImpression capsDenturesProsthesis

A jig device holding a work piece is used with a milling machine that cuts from the work piece a prosthesis having a surface essentially free of defects. The jig device is inserted repeatedly into the machine in the same predetermined location, even upon inverting the jig device. This maintains the spatial relationship between the jig device and milling so, at start up, they are always in the same exact spatial relationship. The milling machine partially cuts through a first side of the work piece to form in the work piece a cavity having a surface part corresponding to at least a portion of the prosthesis being made. The jig device is then removed from the machine, inverted and reinserted into the machine at the same predetermined location. A support material is placed in the cavity prior to reinserting the jig device. Upon reinserting the jig device, the machine precisely cuts through an opposed side of the work piece to form within the work piece a prosthesis having a surface essentially free of defects. The prosthesis is supported within the work piece by the support material. The prosthesis and support material are separated to complete our method.

Owner:OBRIEN DENTAL LAB

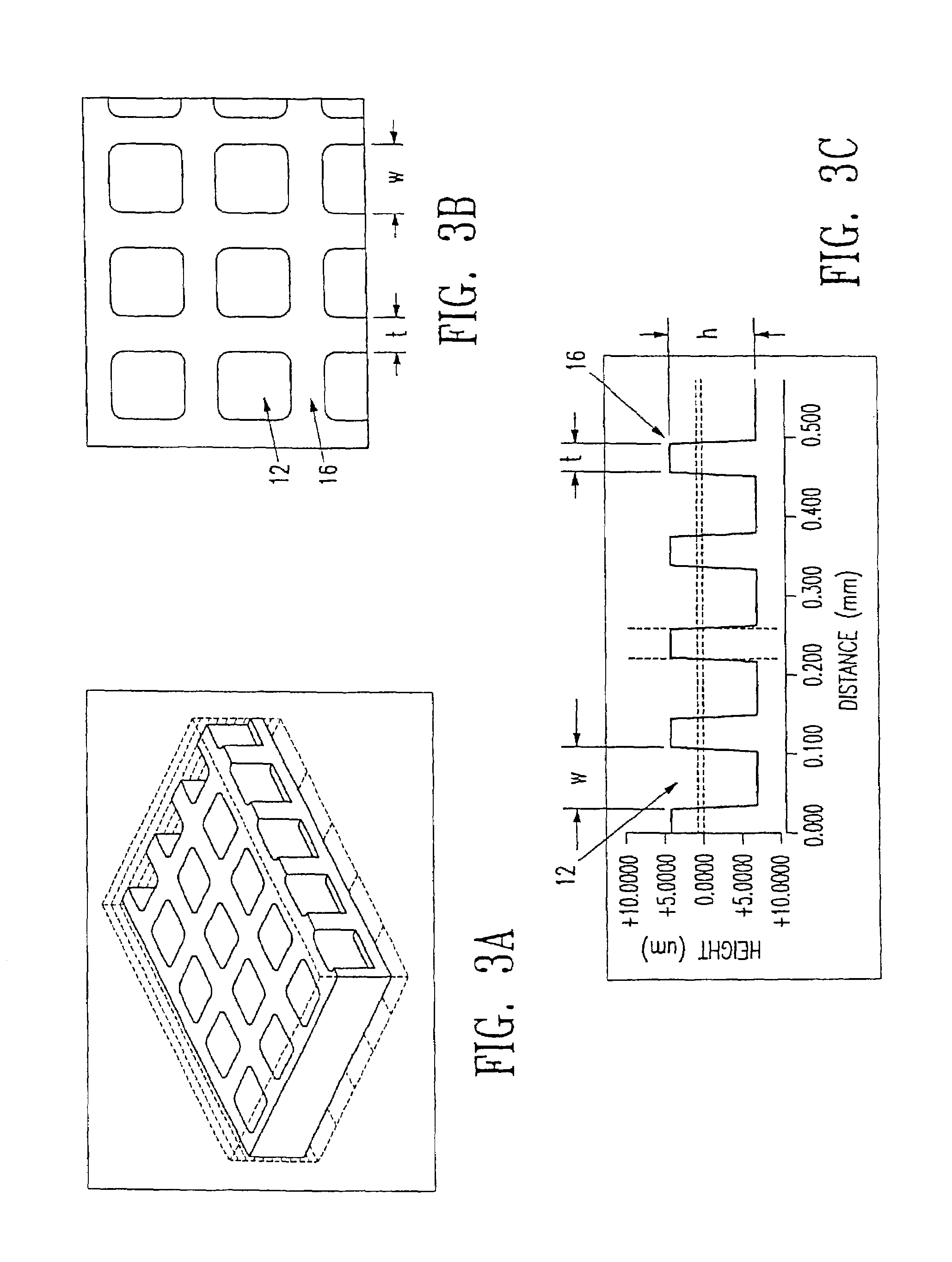

Textured imaging member

InactiveUS20140060360A1Uniform layersFree from defectPlaten pressesDiffusing elementsEngineeringRadiation

An imaging member includes a surface layer comprising a matrix material, an aerogel component, and a radiation-absorbing filler. Methods of manufacturing the imaging member and processes for variable lithographic printing using the imaging member are also disclosed.

Owner:XEROX CORP +1

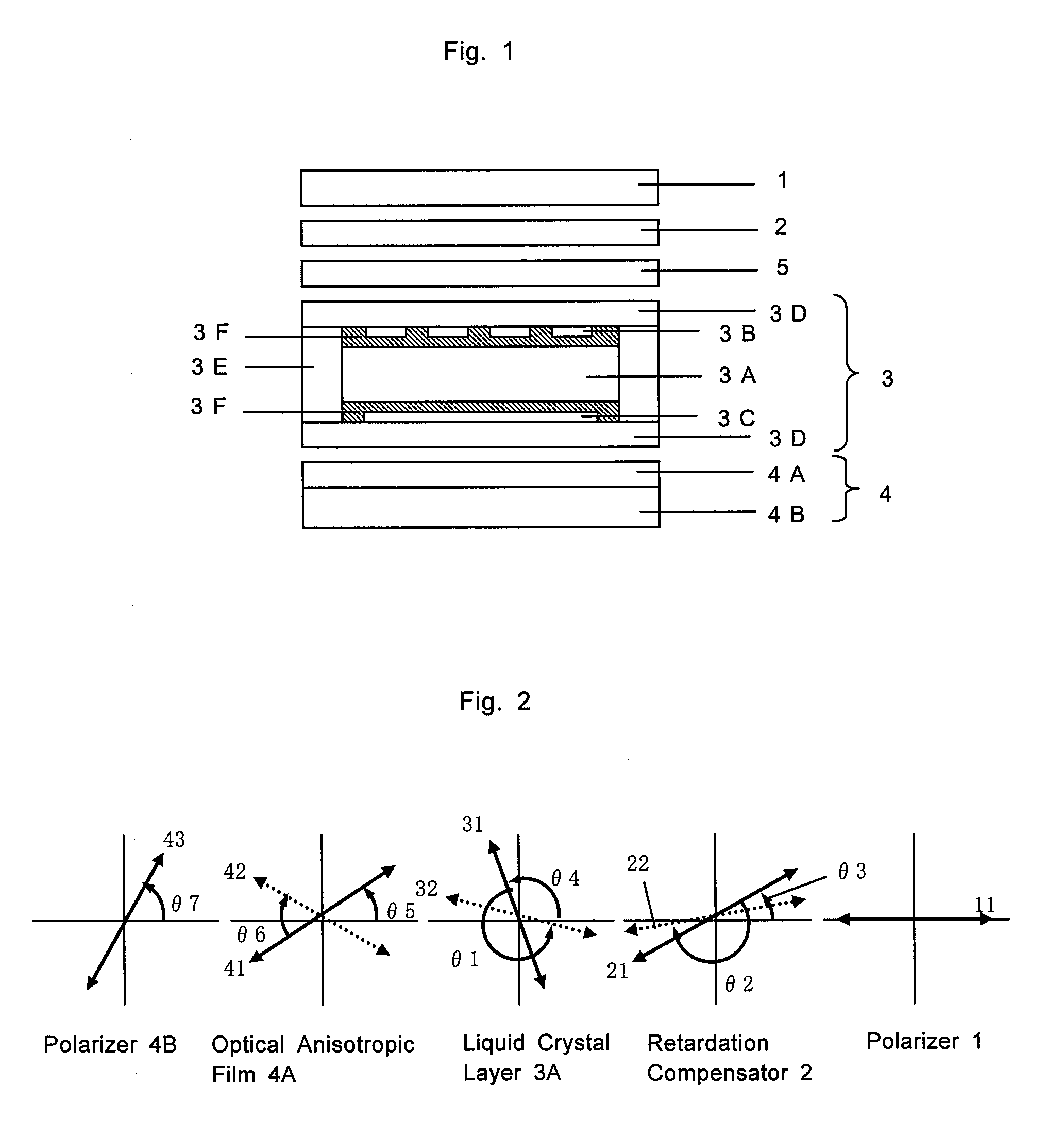

Circular Polarizer, Process for Producing the Same, Optical Film, Liquid Crystal Display Device and Electroluminescence Device

InactiveUS20080106675A1Less strainRemove defectLiquid crystal compositionsSolid-state devicesLiquid-crystal displayPolarizer

A circular polarizer includes at least an optically anisotropic element, a transmissive protection film and a polarizing element sandwiched therebetween. The optically anisotropic element has a liquid crystal layer aligned on a cellulose triacetate film and a retardation of approximately ¼ wavelength in the visible light region. The liquid crystal layer includes a liquid crystal film with a fixed twisted nematic alignment. The circular polarizer is suppressed in thickness by simplifying the layer structure without causing defects, such as peeling off the layers, even under elevated temperature and humidity condition and makes it possible to set arbitrarily the angle of the alignment axis direction of the optically anisotropic element including a liquid crystal layer with a fixed twisted alignment with respect to the absorption axis of the polarizing element, so that the optically anisotropic element and polarizing element both in the form of an elongate film can be laminated continuously to one another.

Owner:NIPPON OIL CORP

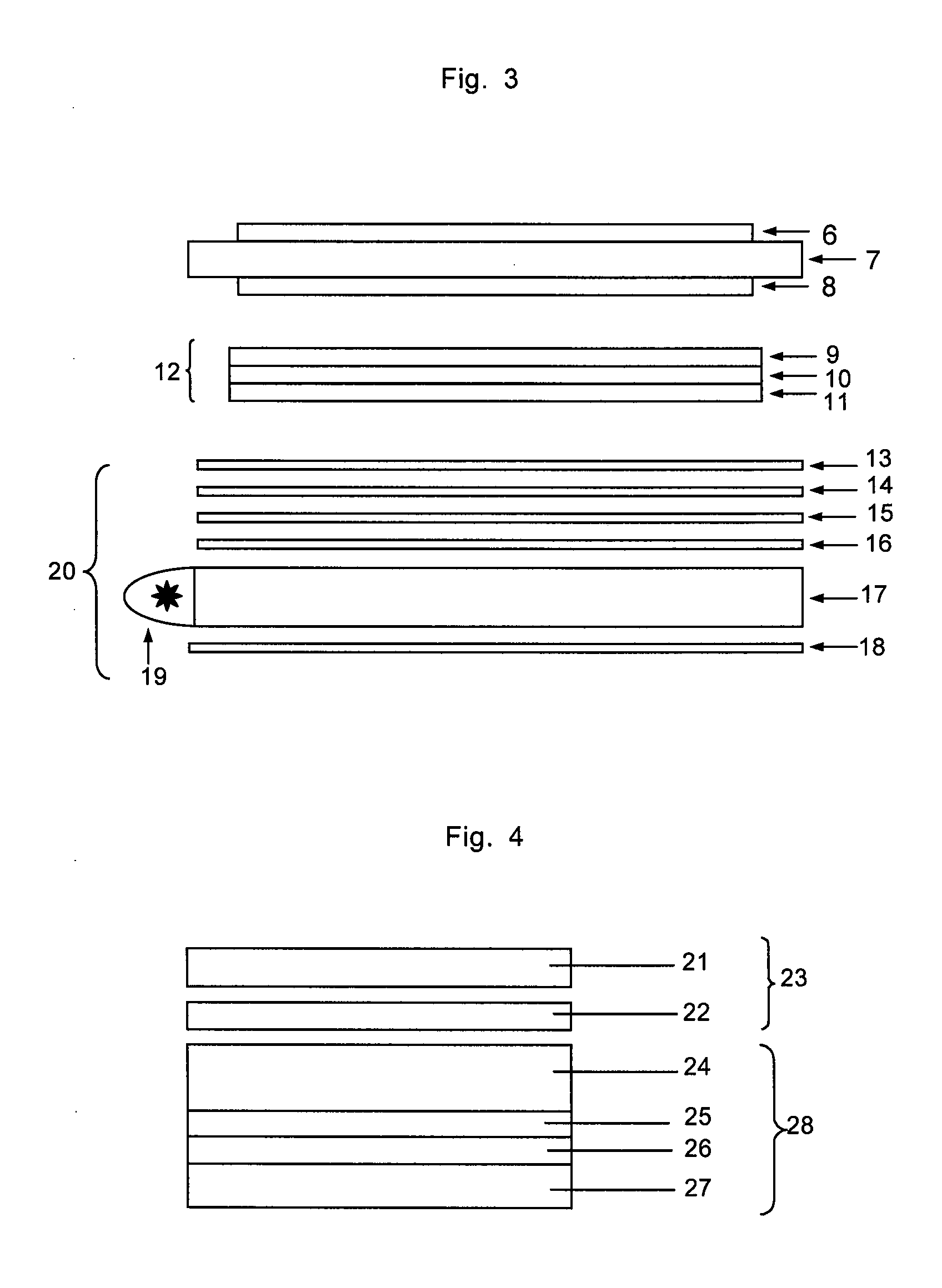

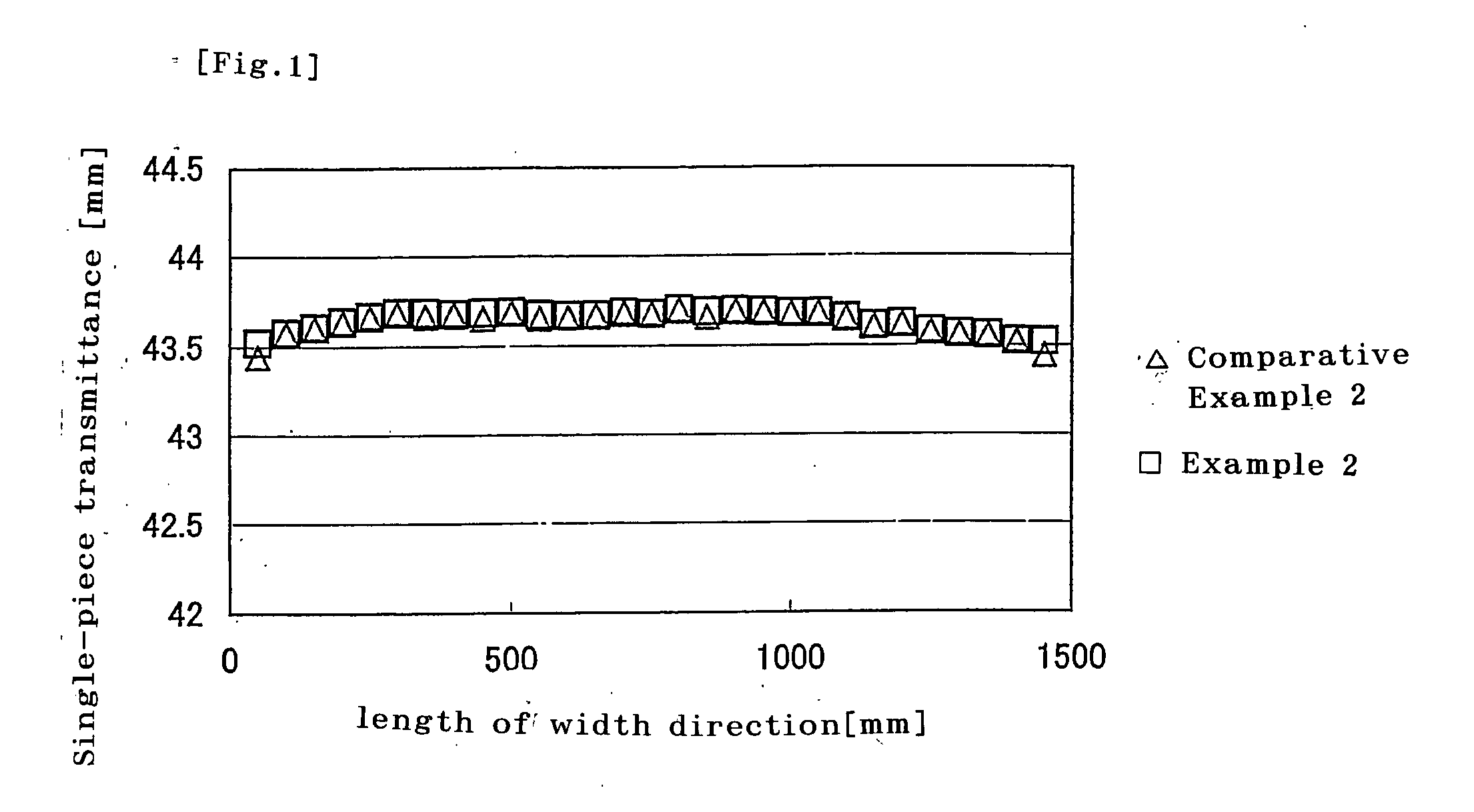

Method of Producing Polarizing Plate, Polarizing Plate, Optical Film, and Image Display Therewith

InactiveUS20080007829A1Large effective widthArea yieldPolarising elementsOptical articlesTectorial membraneDisplay device

A method of producing a polarizing plate of the present invention comprises the steps of: bonding a protective film to at least one side of a polarizing film that is produced through at least uniaxial stretching and has an absorption axis in the uniaxial stretching direction, and removing by cutting at least one of the edges of the polarizing film that are substantially parallel to the direction of the absorption axis before the bonding the protective film. The method widen the effective width of the polarizing plate, and a large size polarizing plate was obtained.

Owner:NITTO DENKO CORP

Imaging member for offset printing applications

InactiveUS20140060363A1Uniform layersFree from defectPlaten pressesCeramic shaping apparatusEngineeringSurface layer

An imaging member includes a surface layer comprising a silicone rubber and an infrared-absorbing filler. Methods of fabricating the imaging member and processes for variable lithographic printing using the imaging member are also disclosed.

Owner:XEROX CORP

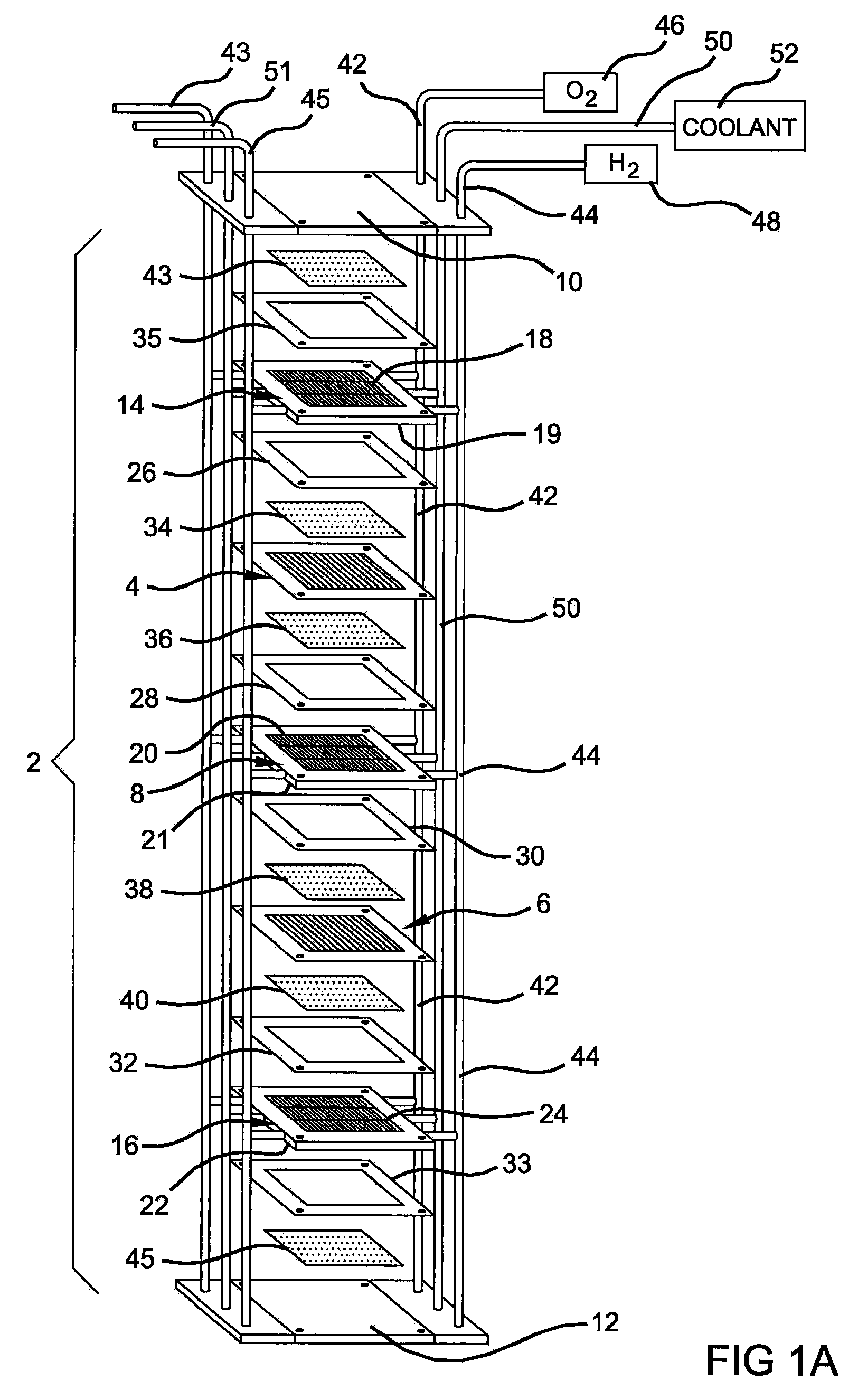

Fuel cell separator plate surface treatment by laser ablation

InactiveUS20080305385A1Reduce contact resistanceMaintain resistancePrimary cellsElectrode carriers/collectorsConductive polymerMetallic materials

A composite separator plate for use in an electrochemical fuel cell as well as a method of forming same is disclosed. The plate may be formed of polymeric material and electrically conductive material having a non-conductive polymeric outer layer by compression molding, or alternately of a metallic material having an outer metal oxide layer. Contact regions of the plate surface are subsequently ablated with a laser to remove the outer layer of material from the plate. The removal of the outer layer reduces the contact resistance of the plate when used in an electrochemical fuel cell stack, while offering adequate strength and corrosion resistance for the fuel cell stack environment.

Owner:GM GLOBAL TECH OPERATIONS LLC

Fixture used to prepare semiconductor specimens for film adhesion testing

InactiveUS6936843B2Eliminates time-consuming polishingEliminates notching stepSemiconductor/solid-state device testing/measurementControlling laminationUltimate tensile strengthLarge sample

The present disclosure pertains to a method of preparing a test specimen for testing of the bonding strength of a layer of additive material to a crystalline substrate, or testing of the bonding strength of one layer of additive material to a second layer of additive material, where both layers of additive material overlie a crystalline substrate. The method includes both test specimen “cutting” from a large sample of material and preparation of an individual test specimen for four-point adhesion testing. Also described is a fixture which is useful for cutting the individual test specimen from the large sample of material.

Owner:APPLIED MATERIALS INC

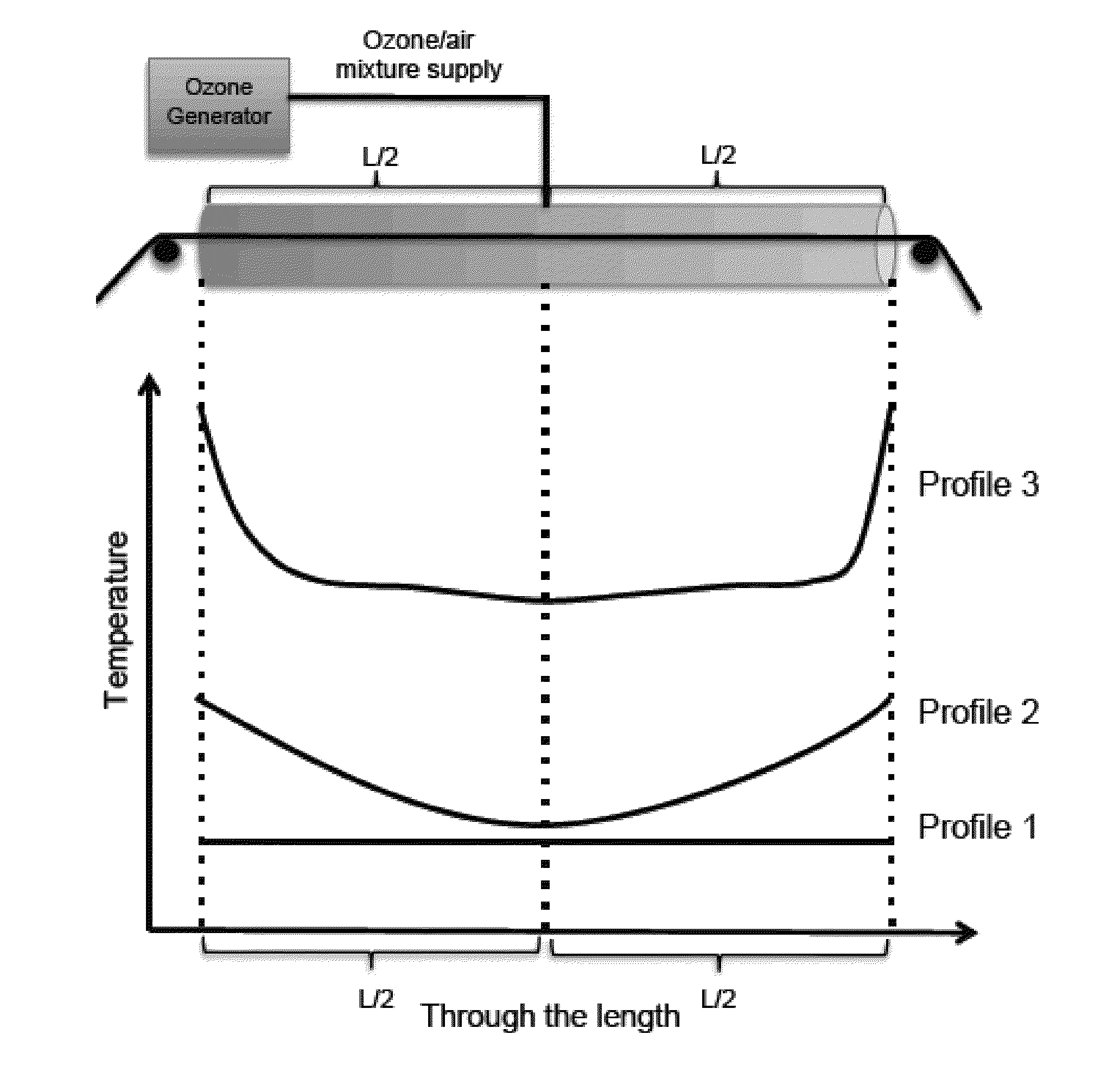

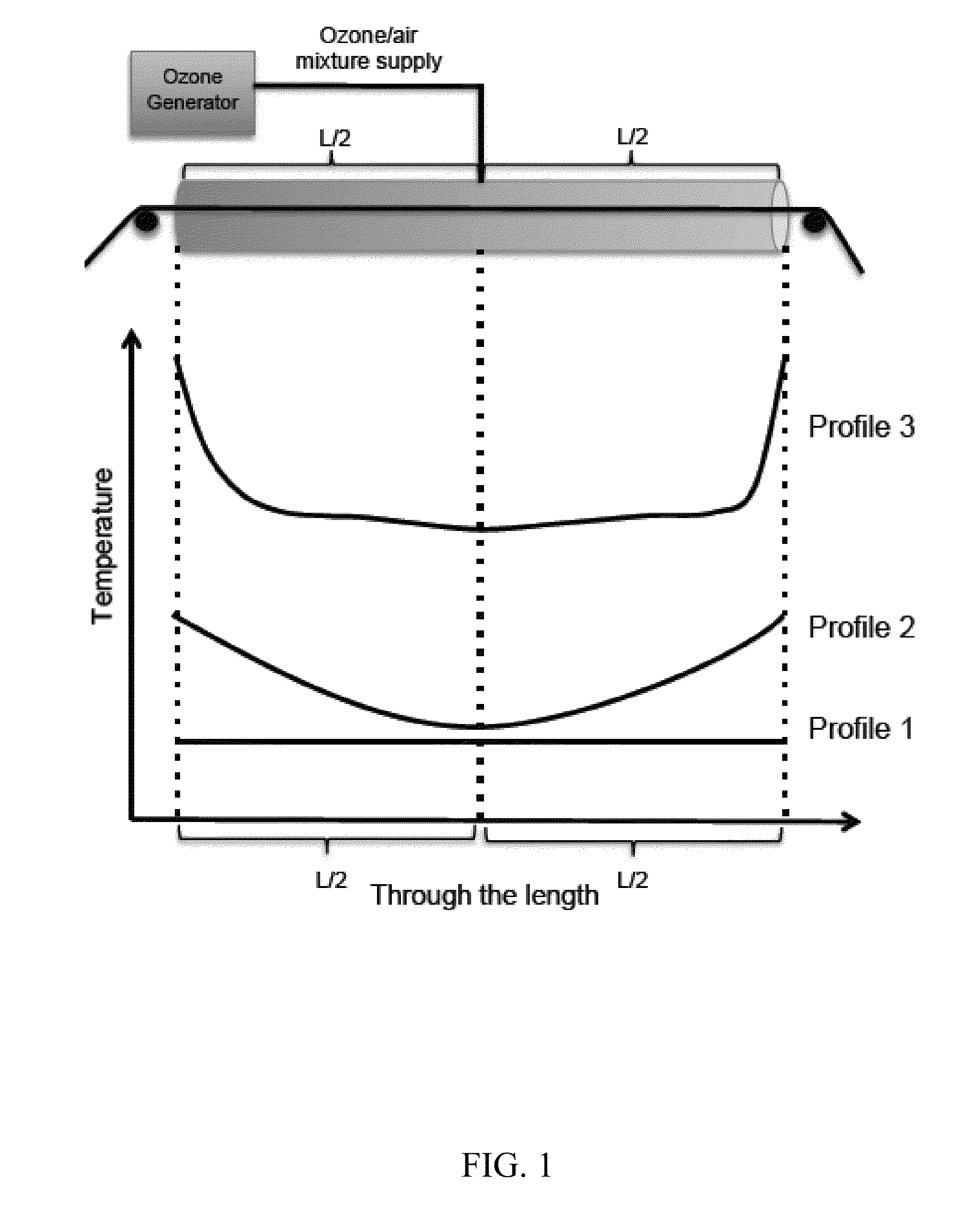

Apparatus and process for the surface treatment of carbon fibers

InactiveUS20130196155A1Improve adhesionIncreasing surface atomic oxygen contentPigmenting treatmentLiquid surface applicatorsFiberCarbon fibers

A method for surface treating a carbon-containing material in which carbon-containing material is reacted with decomposing ozone in a reactor (e.g., a hollow tube reactor), wherein a concentration of ozone is maintained throughout the reactor by appropriate selection of at least processing temperature, gas stream flow rate, reactor dimensions, ozone concentration entering the reactor, and position of one or more ozone inlets (ports) in the reactor, wherein the method produces a surface-oxidized carbon or carbon-containing material, preferably having a surface atomic oxygen content of at least 15%. The resulting surface-oxidized carbon material and solid composites made therefrom are also described.

Owner:UT BATTELLE LLC

Optical filter for display, process for the preparation of the same, and display and plasma display panel provided with the optical filter

InactiveUS20110019278A1Inhibition effectEasily groundedMagnetic/electric field screeningSolid cathode detailsDisplay deviceArea ratio

[Problem to be Solved]To provide an optical filter for display provided with an earth electrode which can be easily prepared, and a process for the preparation thereof.[Means for Solving Problem]An optical filter for display provided with an electrode part of a conductive metal layer comprising a transparent substrate, the conductive metal layer provided on a surface of the substrate, and a functional layer provided on a surface of the conductive layer, wherein the conductive metal layer is exposed in a large number of island-shaped areas at a side edge or its vicinity of the functional layer, and the number of the island-shaped areas is 25 to 250 / cm2 in an intermittent band-shaped region and an area ratio of the island-shaped areas is 2 to 50% based on the intermittent band-shaped region, the intermittent band-shaped region being defined by a band-shaped area having a perpendicular width between the most inside point and the most outside point of the island-shaped areas, and a process for the preparation thereof.

Owner:BRIDGESTONE CORP

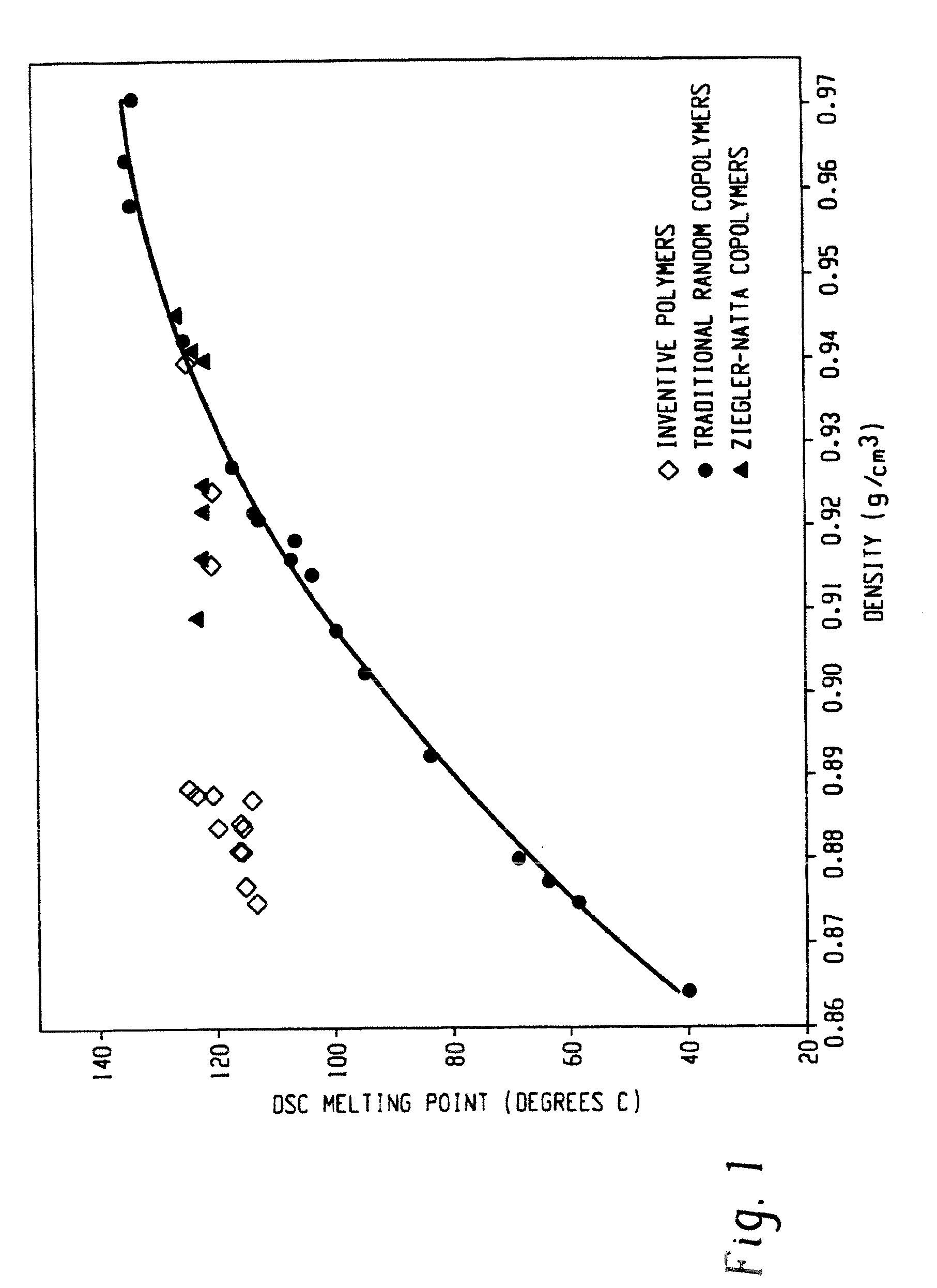

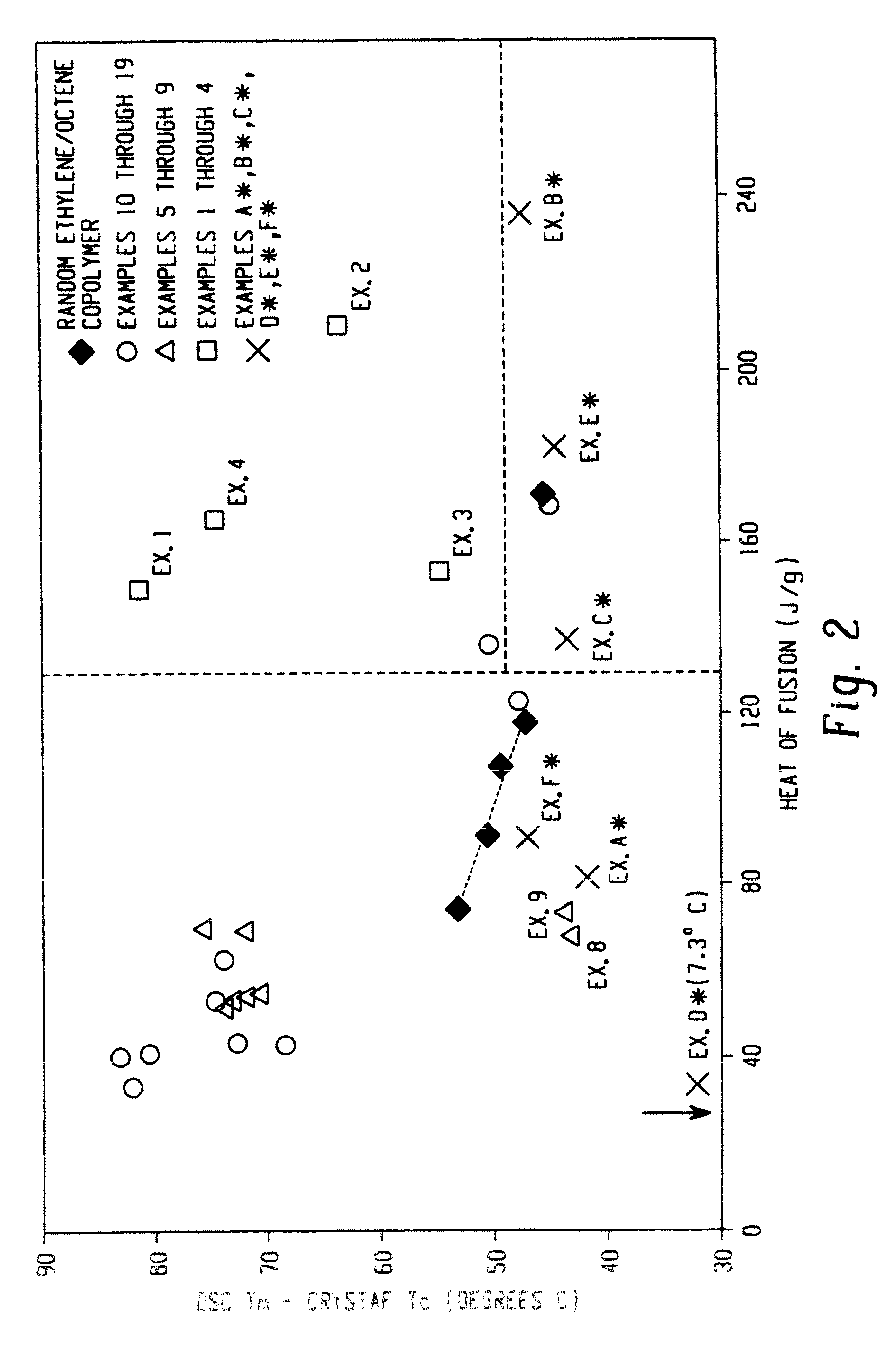

Thermoforming, scratch-resistant, low gloss compositions comprising interpolymers of ethylene/alpha-olefins

ActiveUS20100152361A1Improve scratch resistanceDesirable gloss propertyMixingPolypropylenePolymer composition

This invention relates to polymer compositions comprising at least one ethylene / α-olefin interpolymer and a branched and / or high melt strength polypropylene, methods of making the polymer compositions, and molded, overmolded, extruded into profiles or thermoformed products made from the polymer compositions. The polymer compositions may have reduced post-thermoformed sheet and post extruded (profile) gloss properties and / or improved scratch-resistant properties.

Owner:DOW GLOBAL TECH LLC

Carrier and developer for electrostatic image development, and image formation method and apparatus

InactiveUS20070020552A1Improve liquidityAvoid stickingElectrographic process apparatusDevelopersImage formationEngineering

The present invention provides a carrier for electrostatic image development, and a developer, an image formation method and an image formation apparatus using the carrier. The carrier is carrier particles. When the carrier particles each have a coating layer on a magnetic particle, the carrier has a total energy amount of 1500 to 3000 mJ. When the carrier particles each have a coating layer on a magnetic powder-dispersed particle, the carrier has a total energy amount of 1000 to 1500 mJ. The total energy amount is measured with a powder rheometer at a tip end speed of a rotor of 100 mm / s and a helix angle of the rotor of −5°. The total energy amount is a value of a portion of the carrier in a measurement container which portion is contained in the region between the packed surface of the carrier and a surface disposed under the packed surface by 70 mm.

Owner:FUJIFILM BUSINESS INNOVATION CORP

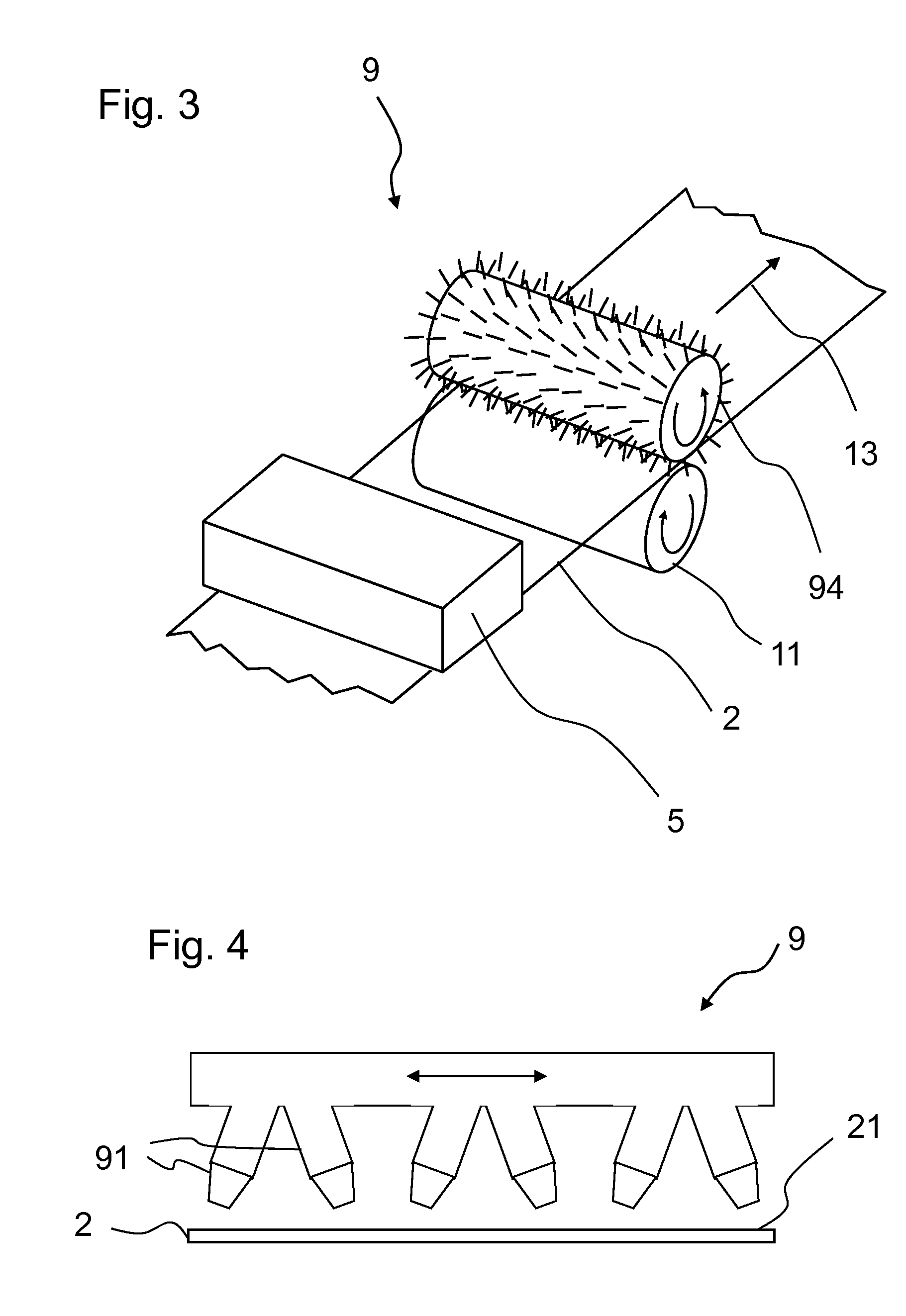

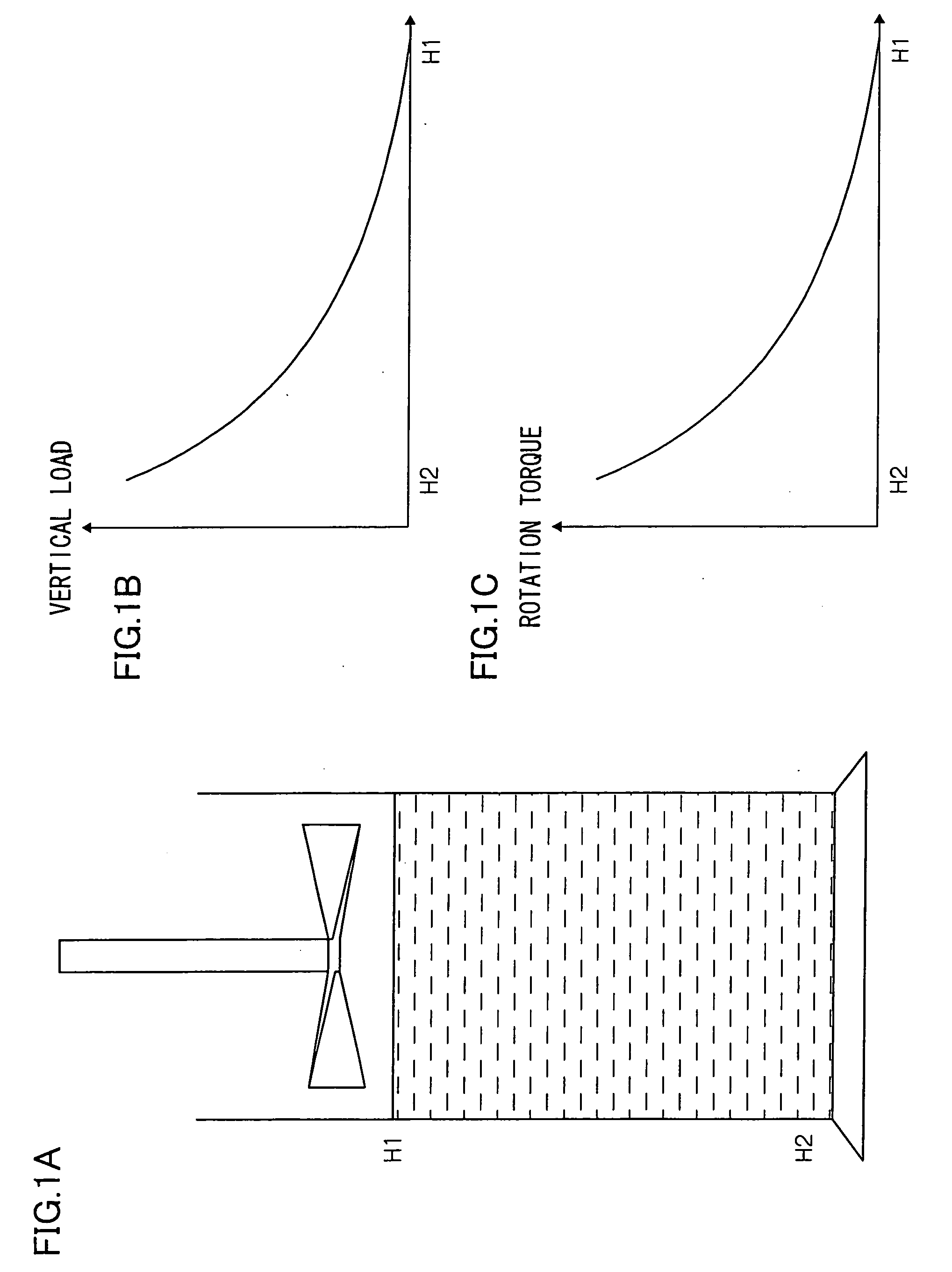

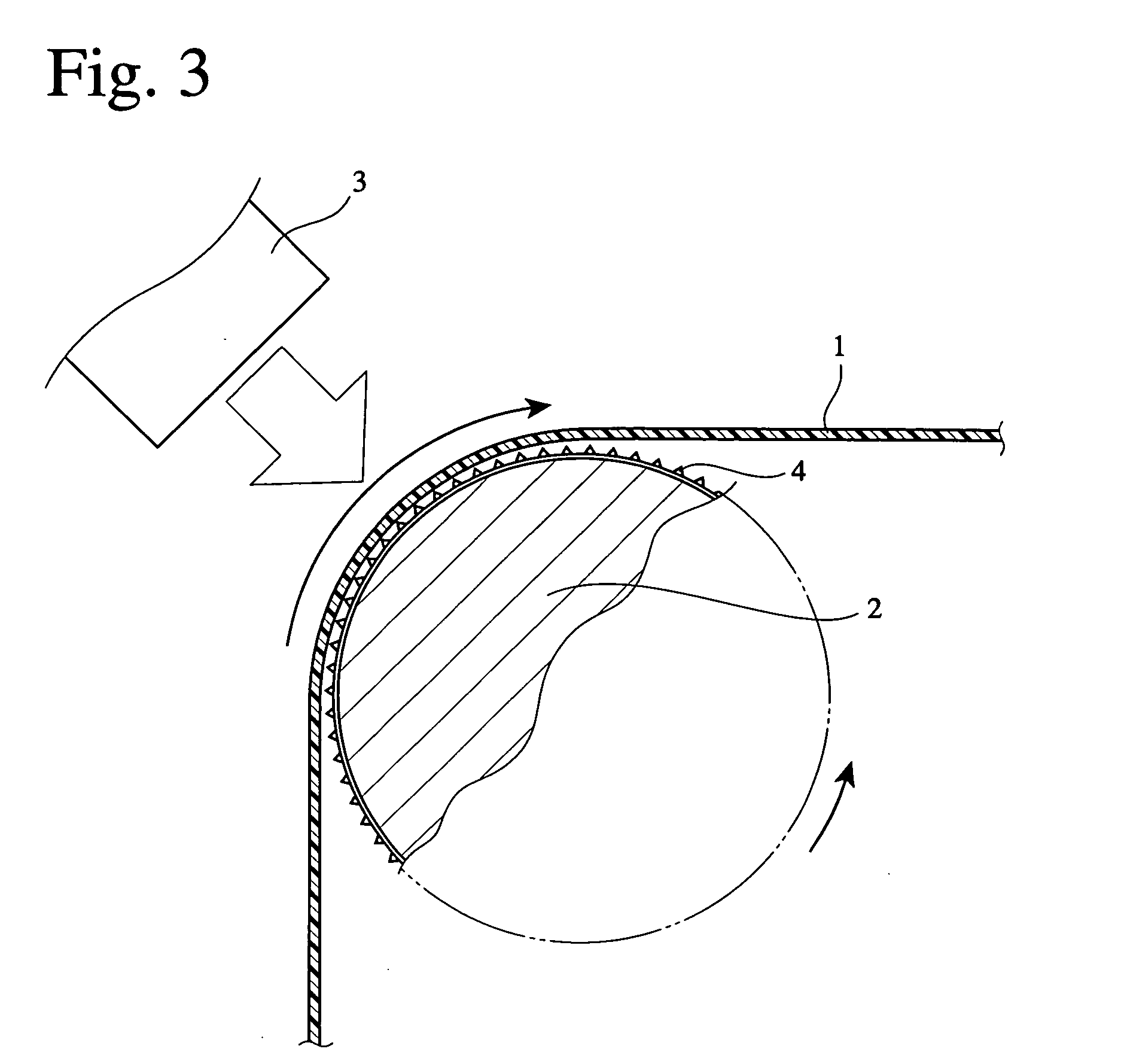

Linearly easy-to-rupture thermoplastic resin film, and method and device for manufacturing the resin film

InactiveUS20050233102A1Easily torn straightFree from defectStampsFlexible coversEngineeringSliding contact

A method for forming substantially parallel linear scratches on a thermoplastic resin film, comprising bringing the film into sliding contact with a means having a lot of fine projections for forming linear scratches, and pressing the film onto the linear-scratch-forming means from the opposite side of the linear-scratch-forming means by a film-pressing means, in a region in which the film is in sliding contact with the linear-scratch-forming means.

Owner:KAGAWA SEIJI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com