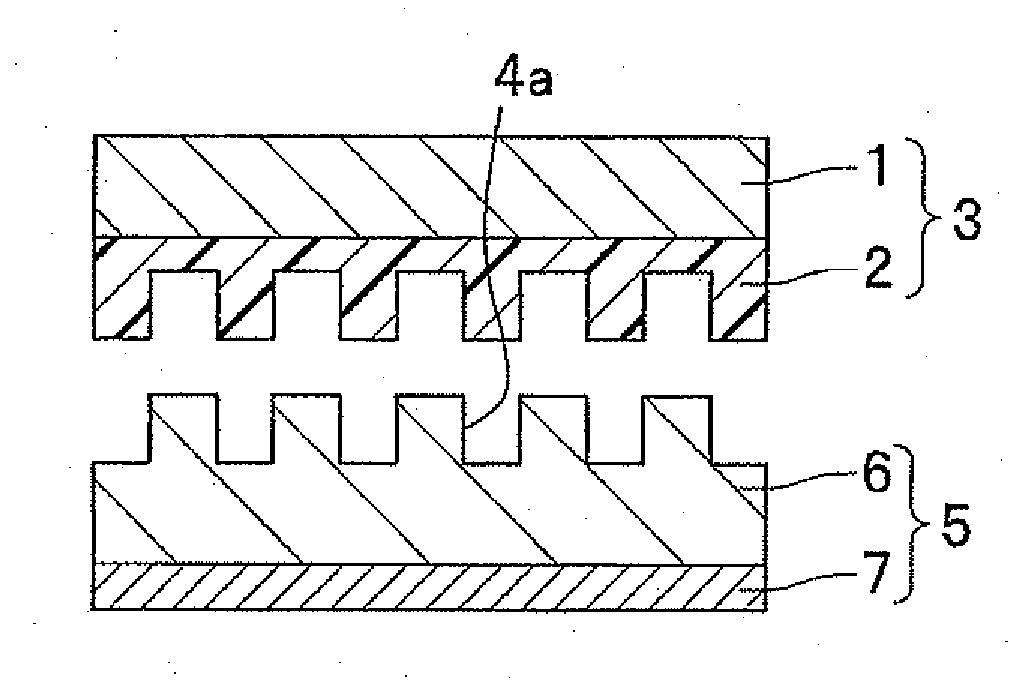

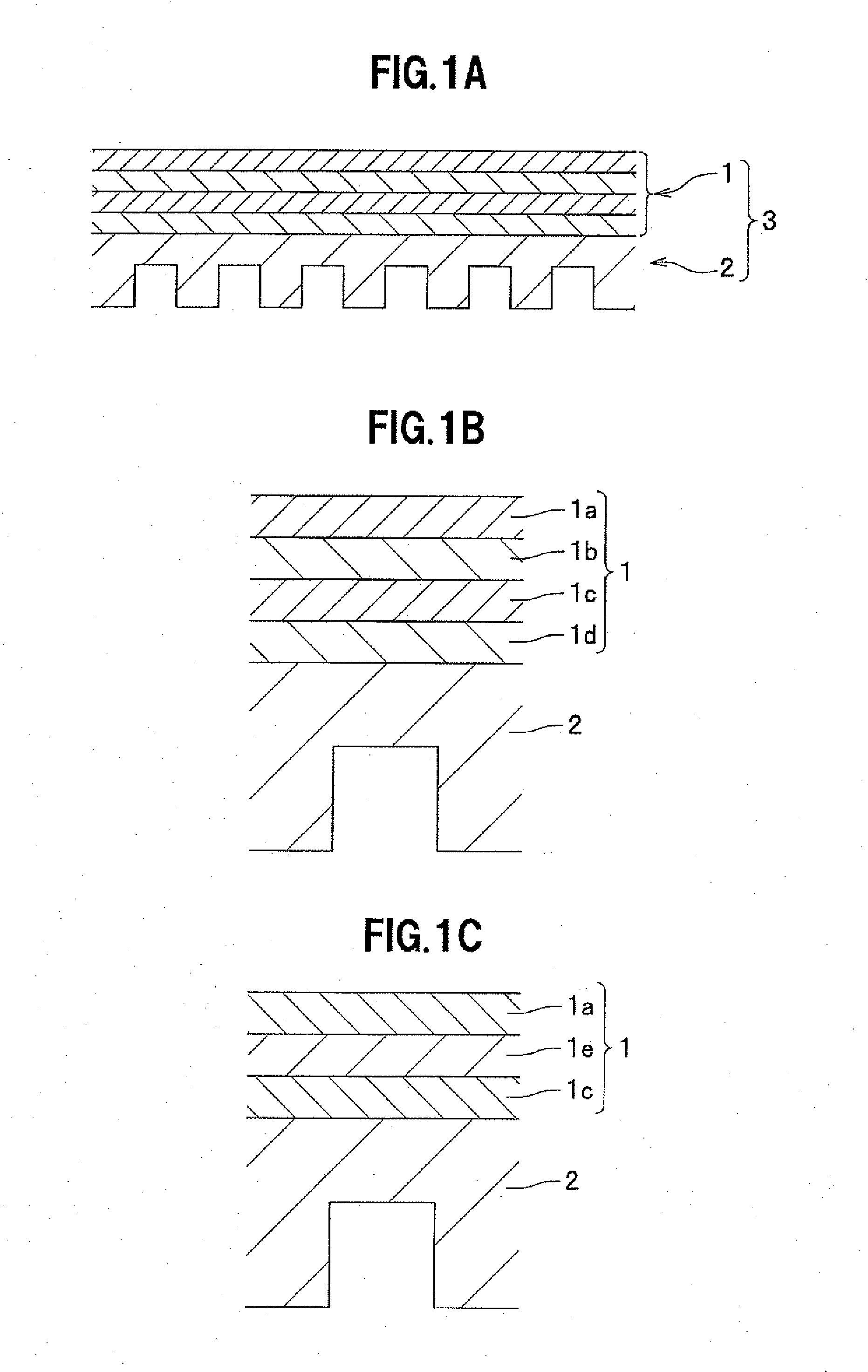

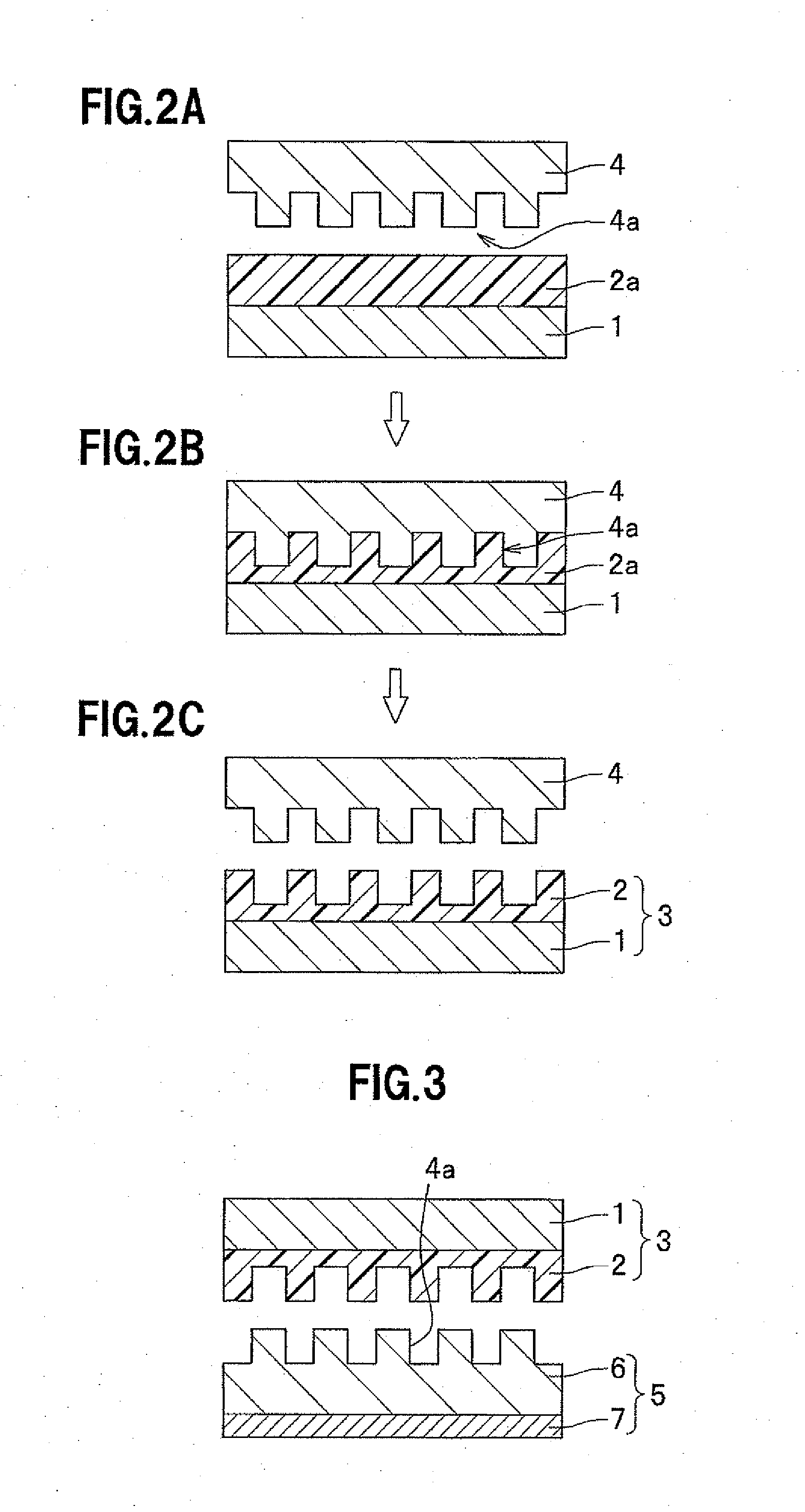

Stamper for transferring fine pattern and method for manufacturing thereof

a technology of transfer and fine pattern, which is applied in the direction of manufacturing tools, photomechanical equipment, instruments, etc., can solve the problems of increasing exposure time (drawing time), shrinking of fine pattern, and difficult processing of fine pattern by photolithography technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

embodiments

[0055]Next, the present invention will be explained more specifically with reference to the following examples. In the following explanations, units “phr (per hundred resin)” and “%” are based on weight unless otherwise stated.

example 1

[0056]First, a silsesquioxane derivative OX-SQ SI-20 (Toagosei Limited) (1 phr) having a plurality of oxetanyl groups is mixed with an Adeka OPTOMER SP-172 (Asahi Denka Corporation) (0.06 phr) which is a cationic polymerization initiator in order to prepare a photo-curable resinous compound of a fine structure layer.

[0057]Next, a supporting substrate (20 millimeters*20 millimeters, 0.7 millimeters thick) whose surface is coupling-treated with a KBM403 (Shin-Etsu Silicones Co., Ltd.) is prepared. A resinous compound which will be a fine structure layer is dropped on the coupling-treated surface of the supporting substrate. Next, a ultraviolet light having wavelength of 365 nanometers is irradiated for 120 seconds with a quartz master mold, in which hole patterns (180 nanometers in diameter, 180 nanometers in spacing, and 200 nanometers in height) are formed on a releasing-treated surface with a OPTOOL DSX (Daikin Industries, Ltd.), being pressed against the photo-curable resinous com...

example 2

[0058]The stamper having the fine structure layer is manufactured by a similar method to that described in Example 1. At that time, a silsesquioxane derivative Q-4OG (Toagosei Limited) (1 phr) having eight epoxy groups is mixed with the Adeka OPTOMER SP-172 (Asahi Denka Corporation) (0.06 phr) which is the cationic polymerization initiator in order to manufacture the photo-curable resinous compound of the fine structure layer. Using this photo-curable resinous compound, by the similar method to that described in Example 1, the stamper is manufactured, continuous transferring is performed, measurement is performed by AFM, and an error is evaluated. A maximum dimensional-error in height of the fine structure pattern after 50 times transferring is on the order of 3%, and accurate and continuous transferring can be performed by the stamper without releasing treatment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Elasticity | aaaaa | aaaaa |

| Light | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com