Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

59results about How to "Shorten pulping cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of soybean milk

ActiveCN104798890AIncrease concentrationNot easy to agglomerateBeverage vesselsMilk substitutesWater vaporDry bean

The invention relates to a preparation method of soybean milk. The preparation method at least comprises the following stages: (a), flour preparation stage: providing a crushing container, a heating element for heating the crushing container and a crushing device, directly heating the crushing container through the heating element, so as to ensure that the temperature of the crushing container is increased to 70-90 DEG C, adding dried beans into the crushing container, crushing the dried beans into bean flour through the crushing device, and ensuring that lipase and beany flavor of the bean flour are removed in the crushing container at ambient temperature; (b), preparation and boiling stage: adding water to the bean flour, so as to prepare the bean flour into pulp, and heating and boiling the pulp till the pulp is well cooked. By adopting the air temperature inside the crushing device, crushing, lipase removal and beany flavor removal are performed at the same time, protein can keep invariant, beany flavor can be effectively removed, and crushing the beans into bean flour firstly can greatly enhance the crushing fineness, so that the soybean milk concentration can be effectively enhanced. In addition, water vapor can be evaporated during crushing of the beans in the high-temperature environment, the bean flour is not easy to agglomerate, and the crushing effect is good.

Owner:JOYOUNG CO LTD

Soybean milk making method of soybean milk machine

ActiveCN105411430AShorten pulping cycleGuaranteed service lifeKitchen equipmentMilk substitutesSoybean oilEngineering

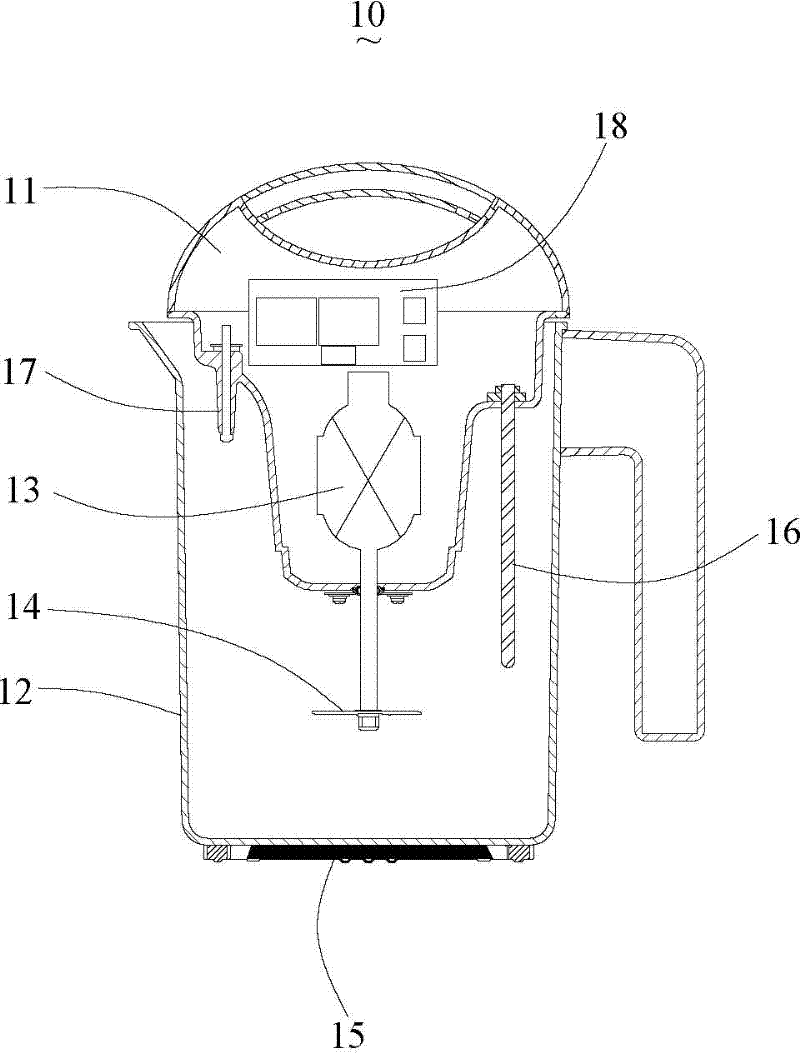

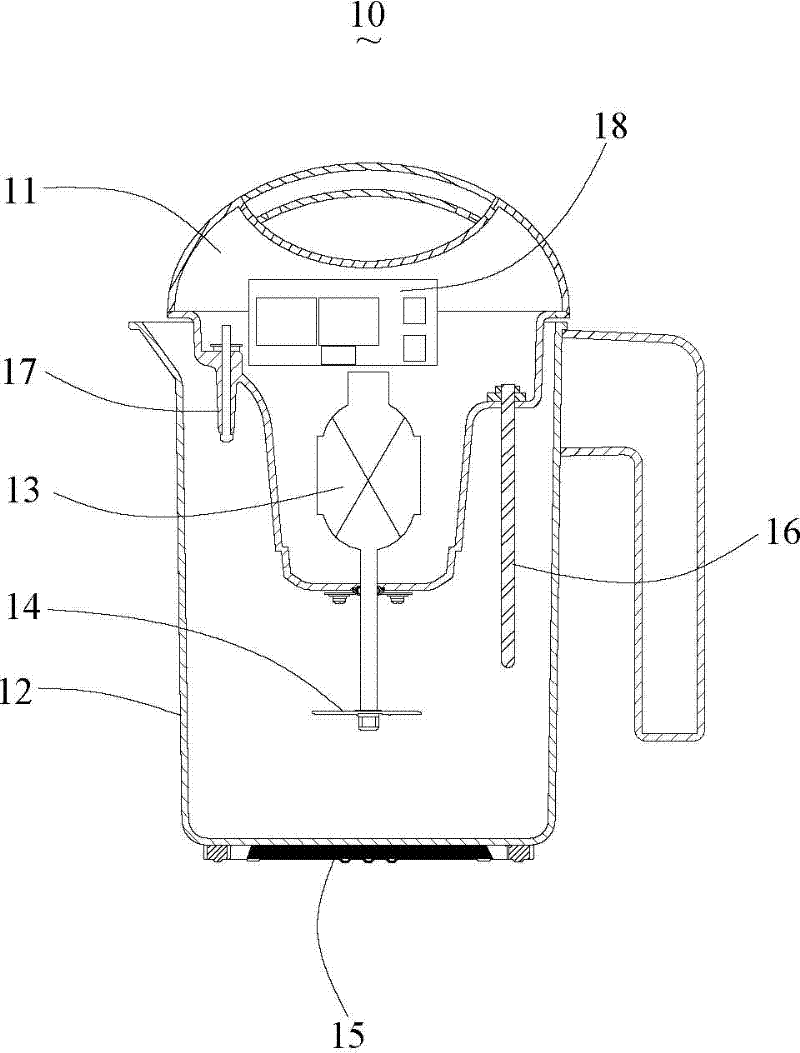

The invention provides a soybean milk making method of a soybean milk machine so as to solve the problems existing in the making process of an existing soybean milk machine, particularly, the problems that noise is too large and the making cycle is too long. A smashing cover is arranged on a machine head of the soybean milk machine. The soybean milk making method is characterized by comprising the steps that firstly, a mixture of materials and water is heated to boil, the materials are softened and float to the liquid surface, and part of the materials are blocked and limited in the smashing cover; then, the boiling state is kept for a preset time, the materials are smashed with a smashing cutter in the kept boiling state, and at the moment, the materials are gradually taken into the smashing cover to be smashed under flowing of slurry; then, the materials are continuously smashed with the smashing cutter; finally, the mixture of the materials and the water continues to be heated so that the materials can be thoroughly cooked. According to the method, the slurry is heated to boil firstly, the boiling state is kept for a certain time, and the materials are smashed in the state, so that soybean milk making noise is greatly reduced, the soybean milk making cycle is shortened, and energy is saved.

Owner:HONGYANG HOME APPLIANCES

Milk making method of soybean milk machine

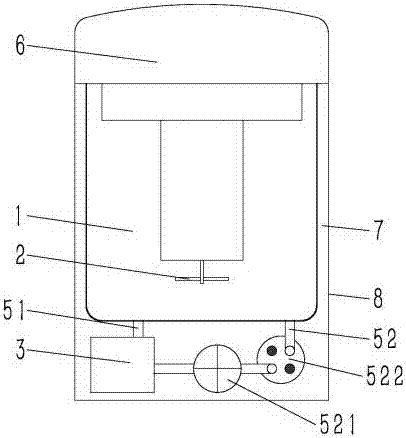

ActiveCN107485289AUniform slurryShorten pulping cycleHollow article cleaningCooking vesselsEngineeringSlurry

The invention relates to a milk making method of a soybean milk machine. The milk making method at least comprises the steps that when the selected milk making amount is lower than 0.8V, milk making is completed at a time in smashing cavity by using milk liquid; when the selected milk making amount is higher than 0.8V, blending needs to be conducted at least once to complete milk making, wherein V is the volume of the smashing cavity. Compared with the prior art, the method improves the blending effect of the milk liquid / paste, caking or layering does not happen, the quality of the milk liquid / paste is improved, and the taste is good; meanwhile, the problems are solved that according to soybean milk machines in the prior art, large-volume milk making and self-cleaning cannot be achieved.

Owner:JOYOUNG CO LTD

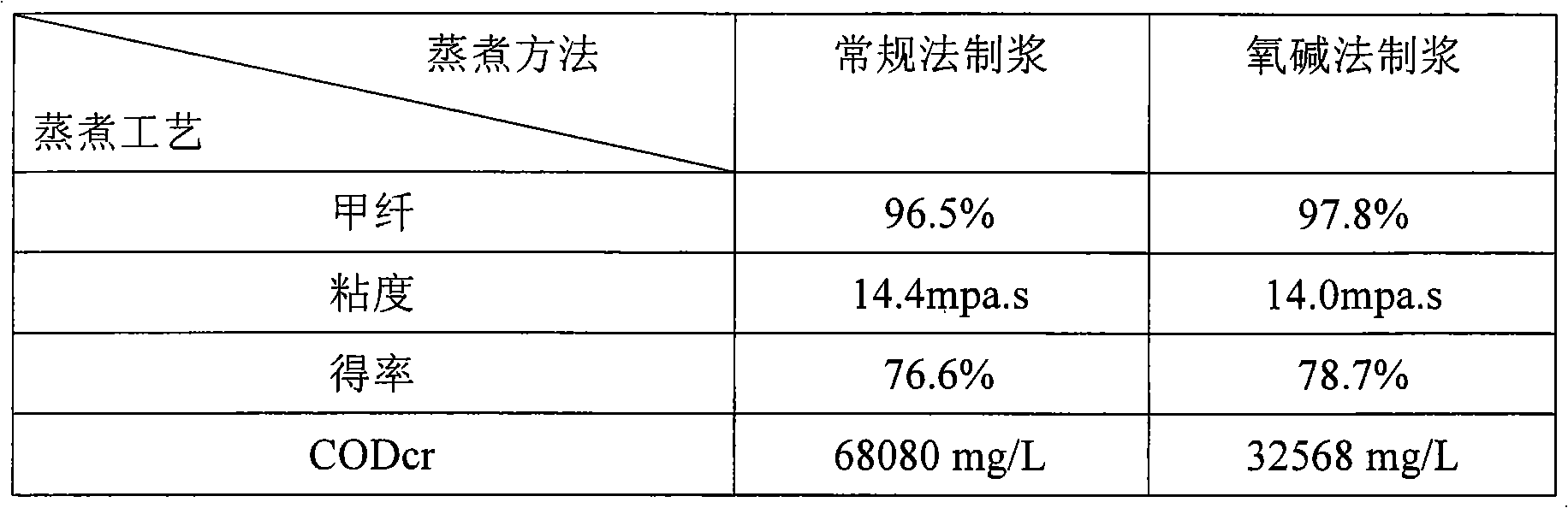

Process for preparing dissolved pulp by oxidative degradation of linters

ActiveCN101289818AReduce pollutionEmission reduction effect is obviousDigestersPulping with inorganic basesDissolving pulpOxygen

The invention discloses a method for making dissolving pulp by oxidative degradation of cotton linters in the oxidative degradation method, aiming at resolving the problems of serious pollution, low yield, long cycle and insufficient resources, etc. existing in the conventional process of making dissolving pulp. The method comprises the following technological steps of cutting and impurity removal, high consistency mixing pretreatment and impurity removal and poly decreasing by continuous oxidative degradation. The method of the invention has the advantages of improving production speed, improving product quality, saving steam and lowering the generation of pollutants.

Owner:YIBIN GRACE GROUP CO LTD

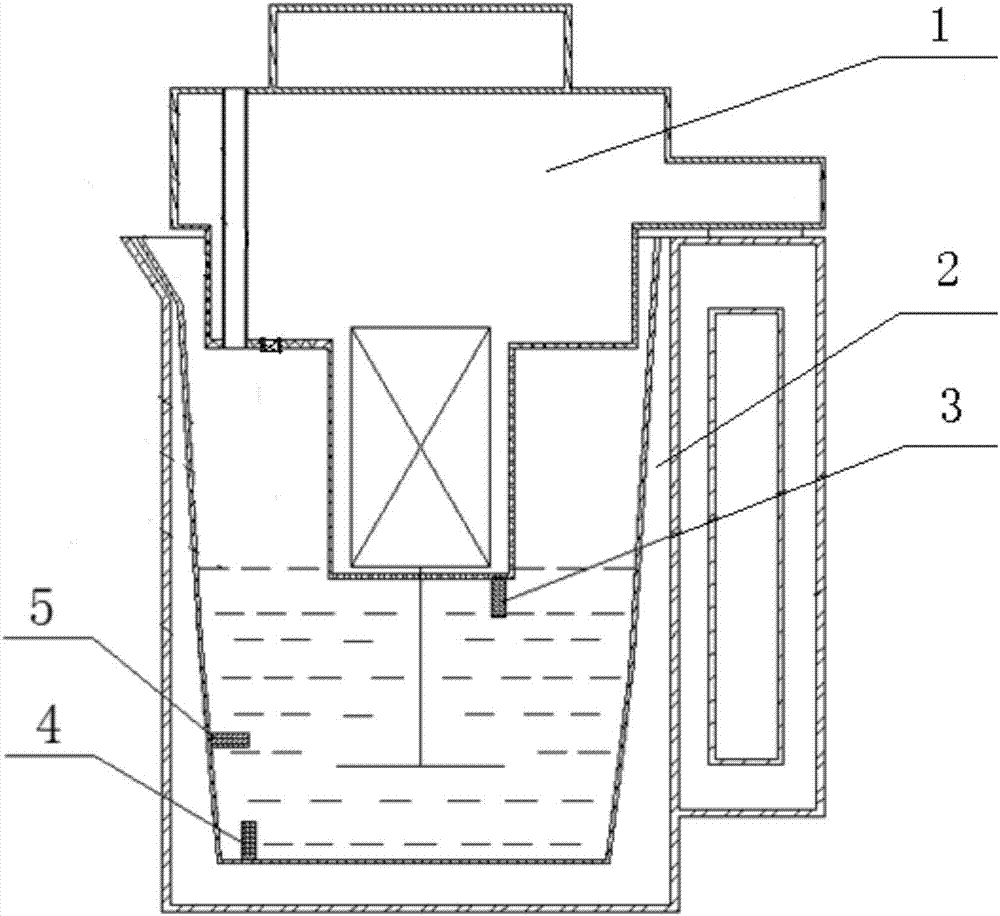

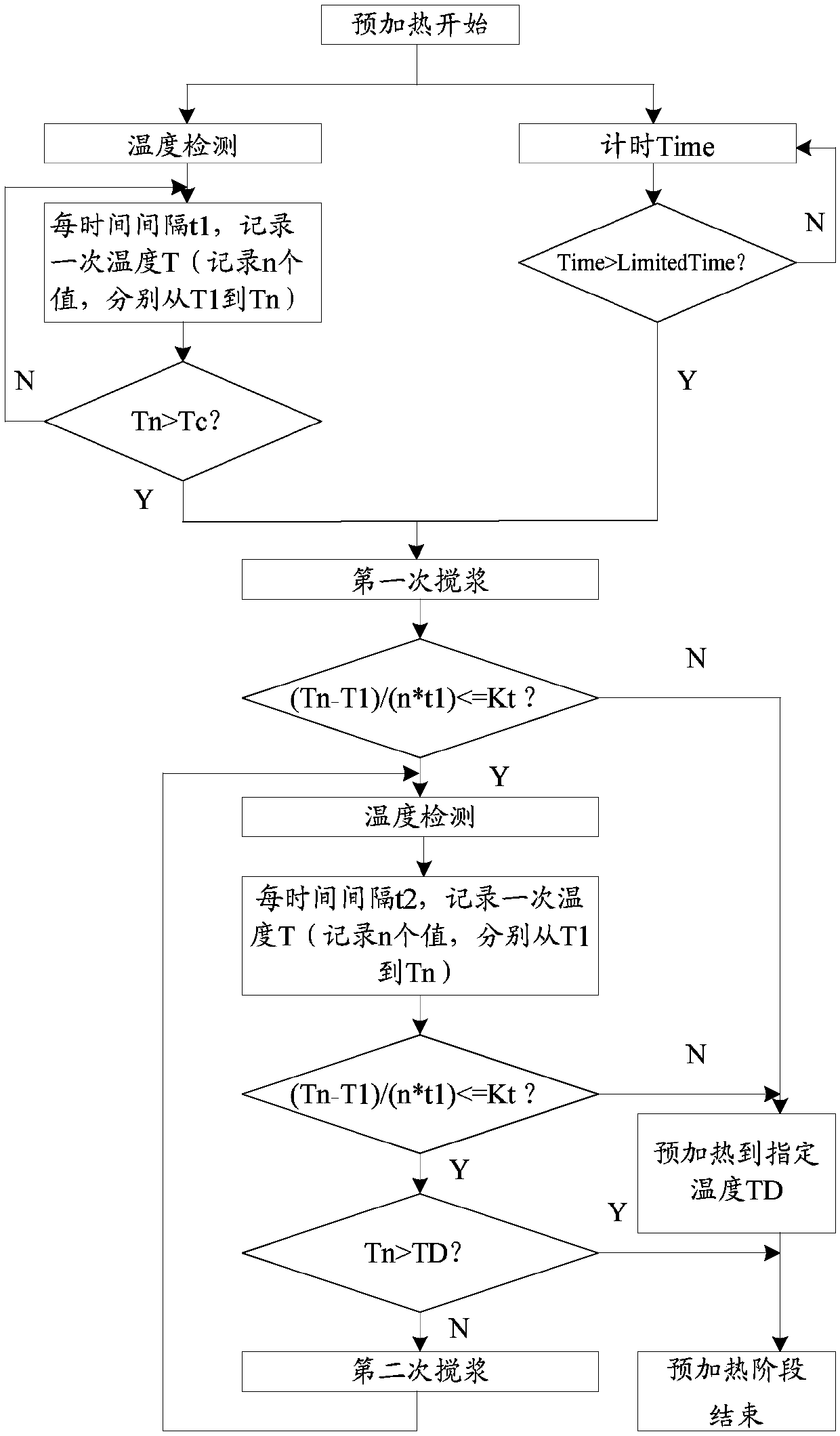

Capacity-self-adaptive pulping method

ActiveCN104872292AAccurate measurementPrecise pulping capacityMilk substitutesThermal energyElectricity

The invention relates to a capacity-self-adaptive pulping method which comprises the following stages: (1), a preheating stage, to be specific, starting a heating device for heating to T1, continuously heating to T2, wherein delta T is equal to T2 minus T1, calculating out electric energy consumed when the temperature is increased to T2 from T1 by a control device, wherein a preset heat efficiency coefficient eta and a specific heat capacity c are stored in the control device, m represents the pulping capacity, and W<electricity> represents electric energy, and calculating out the pulping capacity by the control device according to the law of conservation of energy, namely heating electric energy*eta is equal to thermal energy absorbed during temperature increase and the formula is that (eta)W<electricity> is equal to cm(delta)T; (2), a smashing stage, to be specific, adjusting smashing frequency, smashing time and / or smashing power by the control device according to the pulping capacity; (3), a decocting stage, to be specific, adjusting the heating time and / or heating power by the control device according to the pulping capacity. Therefore, intelligent optimization of pulping parameters is realized and an optimum pulping effect is realized.

Owner:HONGYANG HOME APPLIANCES

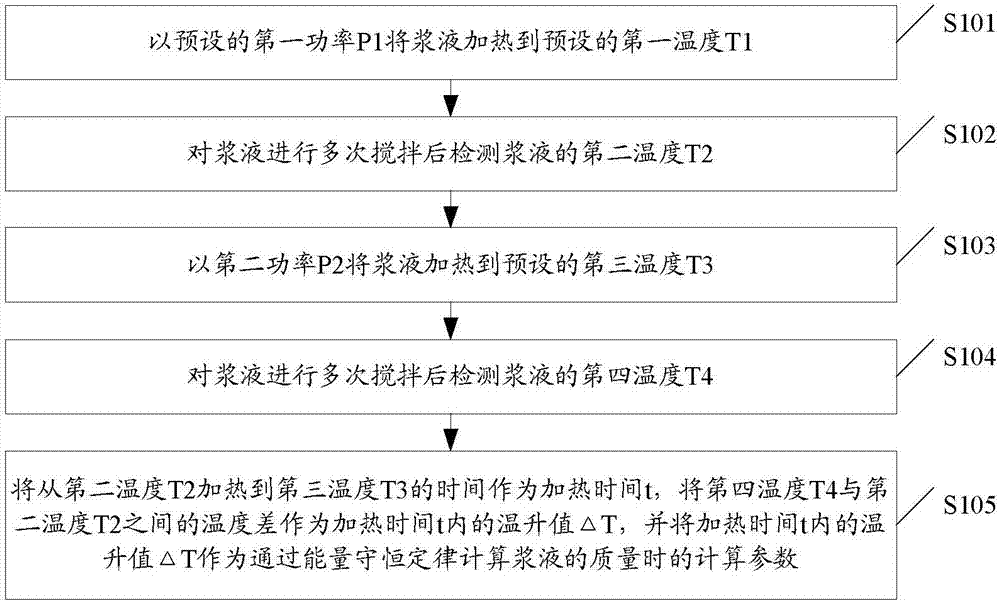

Temperature detection method for thick liquid in cooking equipment

ActiveCN107192476AWell mixedUniform temperatureThermometers using mean/integrated valuesThermometer applicationsHeating timeSlurry

The invention discloses a temperature detection method for thick liquid in cooking equipment. One or multiple temperature sensor(s) is / are installed in the cooking equipment, make(s) direct contact with the thick liquid in the cooking equipment, and is / are used to detec the temperature of the thick liquid. The method comprises that the thick liquid is heated to a preset first temperature T1 in a preset first power P1; the thick liquid is stirred for multiple times, and then a second temperature T2 of the thick liquid is detected; the thick liquid is heated to a preset third temperature T3 in a second power P2; the thick liquid is stirred for multiple times, and then a fourth temperature T4 of the thick liquid is detected; and time that the thick liquid is heated from the second temperature T2 to the third temperature T3 serves as heating time t, a temperature difference between the fourth temperature T4 and the second temperature T2 serves as a temperature rise value deltaT within the heating time t, and deltaT serves as a calculation parameter which is used to calculate the weight of the thick liquid via the law of conservation of energy.

Owner:JOYOUNG CO LTD

Rapid soybean milk making method of soybean milk maker

ActiveCN104545455AReduce the temperatureShorten the timeBeverage vesselsMilk substitutesCold airEngineering

The invention relates to a rapid soybean milk making method of a soybean milk maker. A cooking stage also includes the step of overflow prevention, the hot air in a pulverizer is sucked away by a sucking pump, the outside cold air rapidly enters the pulverizer via an air inlet under the difference between the outside air pressure and the air pressure in the pulverizer, the air which flows at high speed breaks rising soybean milk bubbles and decreases the surface temperature of the soybean milk liquid, so that overflow is prevented, consequently, the hot steam of cooking is sucked away by the sucking pump, the surface temperature of the soybean milk bubbles is decreased, the bubbles rapidly expand and break according to the principle of thermal expansion and contraction when the gas temperature in the bubbles is higher than the outside temperature, negative pressure is generated in the pulverizer as the hot steam is sucked away, the outside air is formed into high-speed airflow under the effect of pressure difference and is rapidly replenished into the pulverizer, the high-speed airflow also can break the bubbles of the soybean milk liquid, and thereby the efficiency of overflow prevention is increased greatly.

Owner:JOYOUNG CO LTD

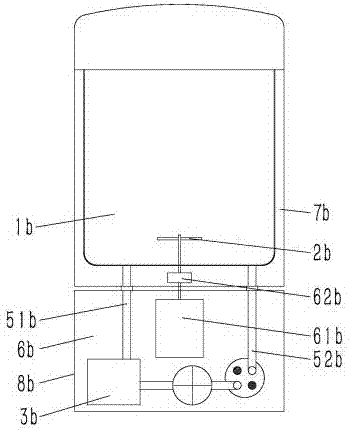

Soybean milk making method of energy-saving soybean milk machine

The invention relates to a soybean milk making method of an energy-saving soybean milk machine. The method comprises the following steps that a, water with the set amount is injected in a small-space pulverizator from a water tank; b, a motor is then started to drive a pulverization knife to rotate to pulverize materials in the small-space pulverizator, the water tank is heated through a heating element, and the heat of water is transferred to the interior of the small-space pulverizator to cook milk / a paste; c, the cooked milk / the cooked paste is discharged to a milk collection cup; d, water with the set amount is injected to the small-space pulverizator again from the water tank, and the milk / the paste in the small-space pulverizator is then discharged to the milk collection cup again. When the soybean milk making method of the energy-saving soybean milk machine is compared with the prior art, water in the water tank is heated through the heating element, the heat of the water is transferred to the small-space pulverizator, and accordingly the materials in the small-space pulverizator are preheated and cooked, the heat of the water in the water tank is reasonably and effectively utilized, energy is saved, the water tank can be continuously heated and kept warm and the soybean milk making period can also be effectively shortened.

Owner:JOYOUNG CO LTD

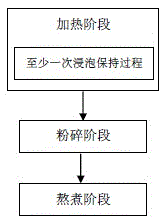

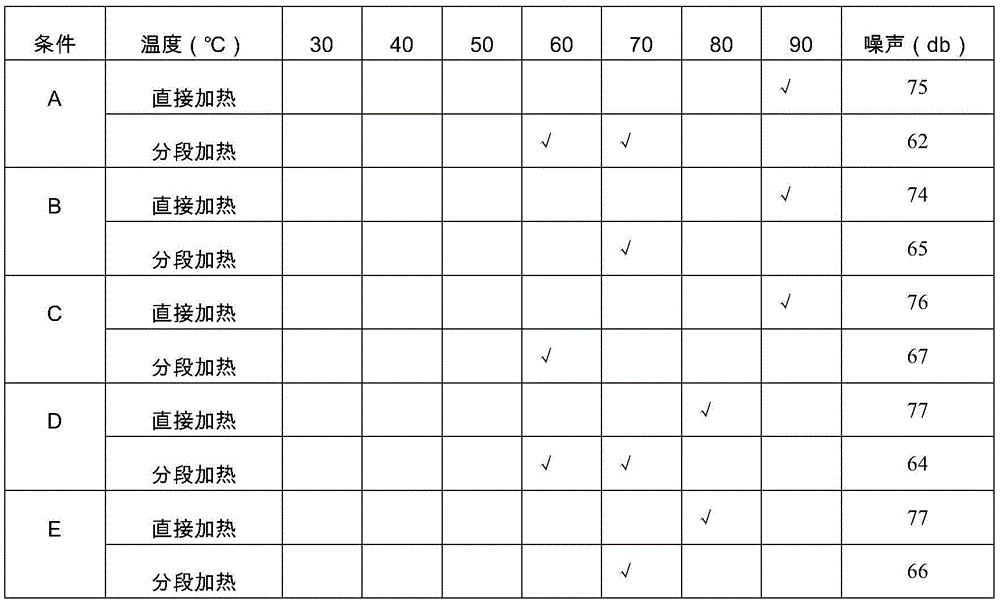

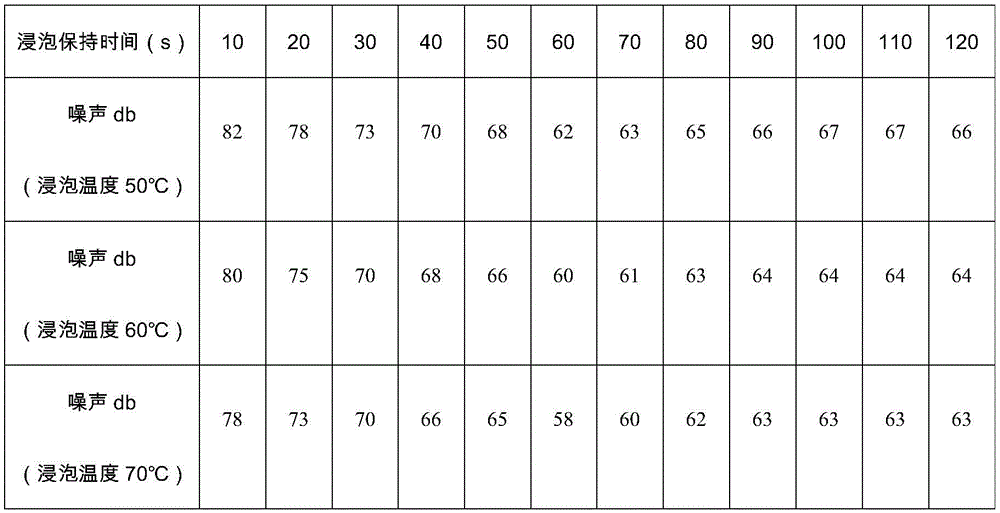

Low noise soya-bean milk making method for soya-bean milk machine

The invention provides a low noise soya-bean milk making method for a soya-bean milk machine, which can solve the problem that the conventional soya-bean milk machines cause excessive noise during a soya-bean milk making process. Soya-bean milk is made of water and soybeans. The soya-bean milk machine includes a heating device and a crushing cutter. The low noise soya-bean milk making method includes the following steps: a, a heating stage: before the heating device heats the water to a first preset temperature, a soybean soaking retaining process is performed at least once at a temperature less than the first preset temperature, and the soybean soaking retaining process lasts for a preset duration. b, a crushing stage: the crushing cutter crushes mixture of the water and the soybeans into milk; and c, a boiling stage: the heating device heats the milk till the milk is well done. According to the method, the heating stage and the crushing stage are separated, and the soaking retaining process is added to the heating stage, and in this way, materials are soaked in a temperature range of soybean water-swelling mutation, the materials fully absorb water and are softened, and the subsequent crushing peak noise can be effectively decreased.

Owner:JOYOUNG CO LTD

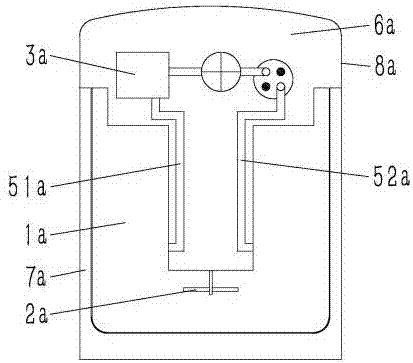

Altitude adaptive soya-bean milk manufacture method and soya-bean milk machine thereof

The invention relates to an altitude adaptive soya-bean milk manufacture method and a soya-bean milk machine thereof. In a heating stage, the altitude adaptive soya-bean milk manufacture method comprises an altitude judgment step of providing an overflow-proof electrode, a temperature sensor and a control device with at least two soya-bean milk manufacturing procedures, wherein the overflow-proofelectrode and the temperature sensor are electrically connected with the control device; the temperature sensor detects the practical temperature value of preheated water and soya-bean contained materials till foams touch the overflow-proof electrode; the control device is preset with a temperature set value; and according to a comparison result between the practical temperature value and the preset temperature value, the soya-bean milk manufacturing procedure is selected. Compared with the prior art, the boundedness for people to use the soya-bean milk machine in the highland is solved, and people in the highland can drink the soya-bean milk with higher quality.

Owner:JOYOUNG CO LTD

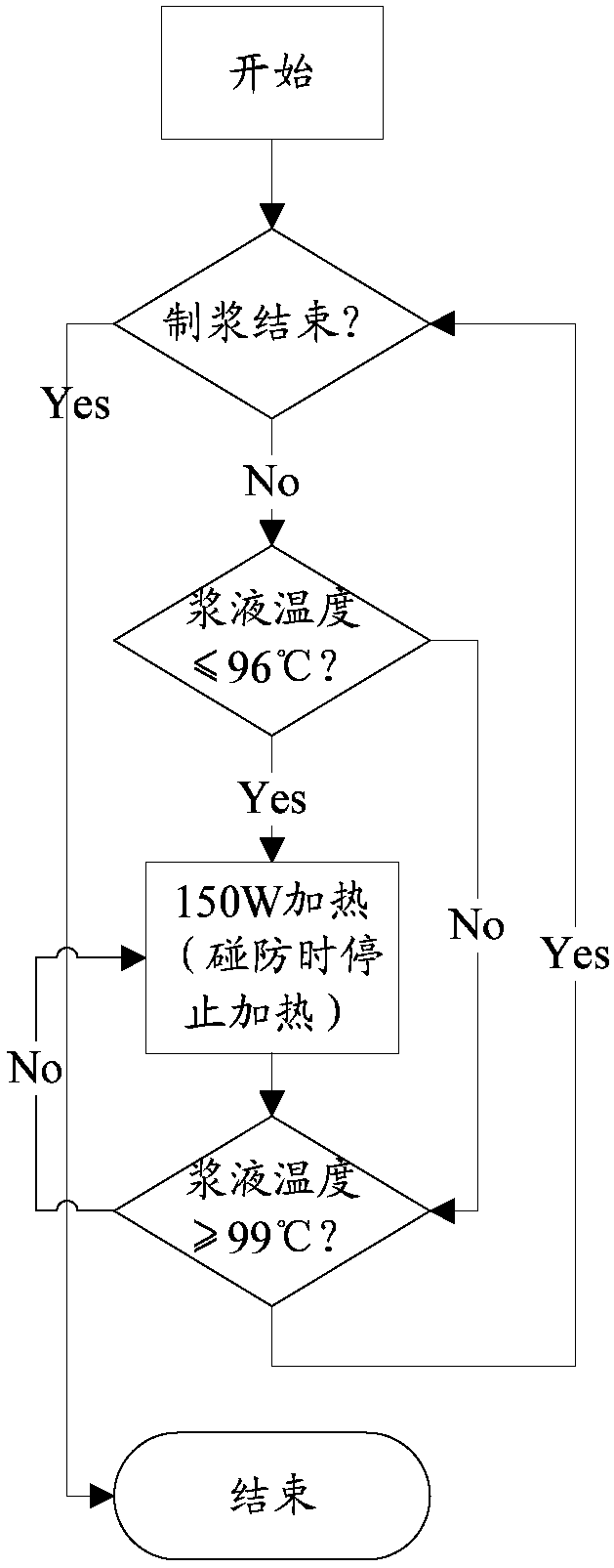

Soybean milk maker milk making control method

ActiveCN107713756AStable temperatureShorten pulping cycleBoiling over preventionBoiling processSlurry

The invention discloses a soybean milk maker milk making control method. The milk making process of a soybean milk maker comprises a heating phase, a crushing phase and a boiling phase; the soybean milk maker milk making control method comprises the step that in the crushing phase, milk is heated at low power according to the milk temperature, wherein the low power ranges from 0 W to 150 W. Accordingly, it is guaranteed that the milk temperature is stabilized at a certain temperature, the boiling process does not need to be additionally added, the milk making cycle is saved, and the problem that the overflowing problem caused by the thermal inertia and energy accumulation is effectively prevented.

Owner:JOYOUNG CO LTD

Soybean milk making method of rapid soybean milk maker

ActiveCN102771575AAvoid wastingReduce wasteBeverage vesselsMilk substitutesHigh concentrationWater resources

The invention relates to a soybean milk making method of a rapid soybean milk maker. The soybean milk making method at least comprises the steps: injecting the water of capacity V1 in a small-space smasher at a time, and heating the water in the small-space smasher through a heating device, draining the heated water to a milk receiving cup and mixing the milk in the milk receiving cup. Compared with the prior art, the residue of high-concentration milk / paste in the small-space smasher can be reduced, so that waste is avoided; furthermore, the water resources for cleaning at later stage can be effectively reduced, and the waste of water resources can also be reduced.

Owner:JOYOUNG CO LTD

Control method for making soybean milk of soybean milk machine

The embodiment of the invention discloses a control method for making soybean milk of a soybean milk machine. The soybean milk machine comprises a machine head. A motor is arranged on the machine head. The process for making soybean milk comprises the following steps: a pre-heating phase, a pre-crushing phase, a crushing phase and a boiling phase. The working phases of the motor comprise a pre-crushing phase and a crushing phase. A fixing seat is arranged below the motor and located on the outer surface of the machine head. The fixing seat can directly contact soybean milk liquid. The method comprises the following steps: adjusting the speed of the motor in different phases of the process of making soybean milk in order to control the motor to emit heat, transferring the heat generated by heating of the motor through the fixing seat to soybean milk liquid such that the soybean milk liquid is heated in the working phase of the motor.

Owner:HONGYANG HOME APPLIANCES

Soya-bean milk production method with efficient pulverization and noise reduction

ActiveCN105941635AFully water-swellableImprove crushing efficiencyMilk substitutesSlurryNoise reduction

The invention relates to a soya-bean milk production method with efficient pulverization and noise reduction. The method at least comprises the following steps: (a) a step of pre-heating and soaking, in which, water and materials are added in a heating cup of a heating apparatus, a pre-set temperature no less than 70 DEG C is achieved by heating at a heating rate in a range of 3 DEG C per minute to 10 DEG C per minute, and the next step is carried out; (b) a step of pulverization, in which, water and materials in the cup are pulverized into a thick liquid through rotation of a pulverization blade driven by an electric motor, and the next step is carried out; and (c) a step of cooking, in which, the thick liquid in the cup of the heating apparatus is heated until the thick liquid is fully cooked. Through comparison with the prior art, according to the technical scheme, the method enables the water absorption and expansion rate between epidermis and cotyledon of soya-beans to be preferably uniform, so that the soya-beans can fully absorb water and swell. The method has improved pulverization efficiency and has the function of noise reduction.

Owner:JOYOUNG CO LTD

Treatment process and equipment of waste books

ActiveCN106149438AReduce power consumptionEmission reductionPaper recyclingPulp beating/refining methodsPulp and paper industryEnergy consumption

The invention discloses a treatment process and equipment of waste books and belongs to the technical field of waste paper recycling. The treatment process sequentially includes the steps, from top to bottom, of firstly, using an edge-cutting machine to cut off the edges, with glue or iron nails, of the waste books; secondly, using a hydrapulper to crush the waste books obtained after the first step, and using a ink-removing overflow pipe to discharge ink during the crushing; thirdly, using a pulping machine to make the crushed materials into pulp, performing ink removing while stirring during pulping, and discharging the removed ink through an ink discharge pipe; fourthly, using a concentrator to perform concentration; fifthly, storing the concentrated pulp in a pulp storage tank. The treatment process and equipment has the advantages that the process and equipment is simplified, energy consumption is lowered, the discharge of industrial waste liquid is reduced, the pulping efficiency and quality of the waste books are increased, and the process and equipment is widely applicable to waste paper treatment.

Owner:徐州市全鑫毛制品有限公司

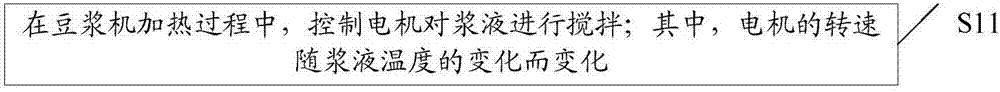

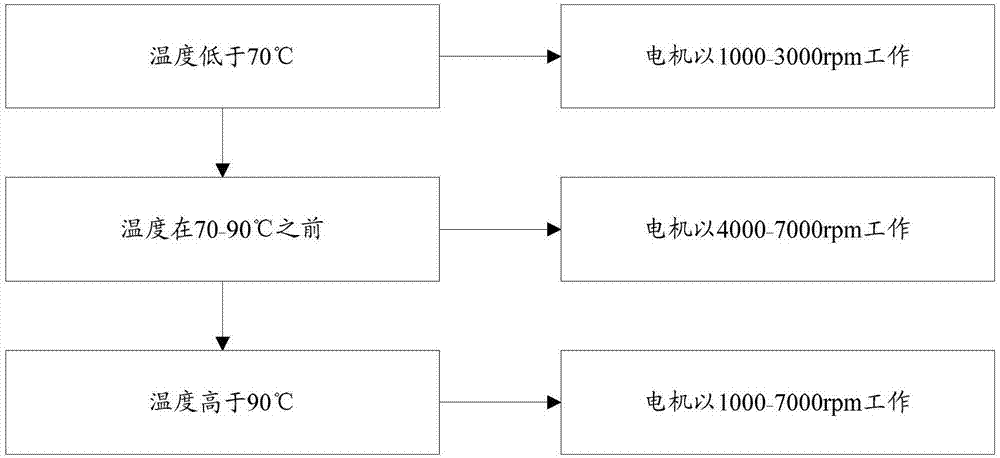

Control method of soybean milk machine

The embodiment of the invention discloses a control method of a soybean milk machine. The control method comprises the following step that during the heating process of the soybean milk machine, a motor is controlled for stirring soybean milk liquid, wherein the rotation speed of the motor changes along with the change of the temperature of the soybean milk liquid. Due to the technical scheme of the embodiment, soybean milk liquid is stirred at low rotation speed during the heating process of the soybean milk machine, the pre-grinding effect is achieved, the whole pulping period is saved, meanwhile, the temperature of the soybean milk liquid is enabled to be relatively uniform, and the overflow phenomenon caused by thermal inertia is reduced.

Owner:JOYOUNG CO LTD

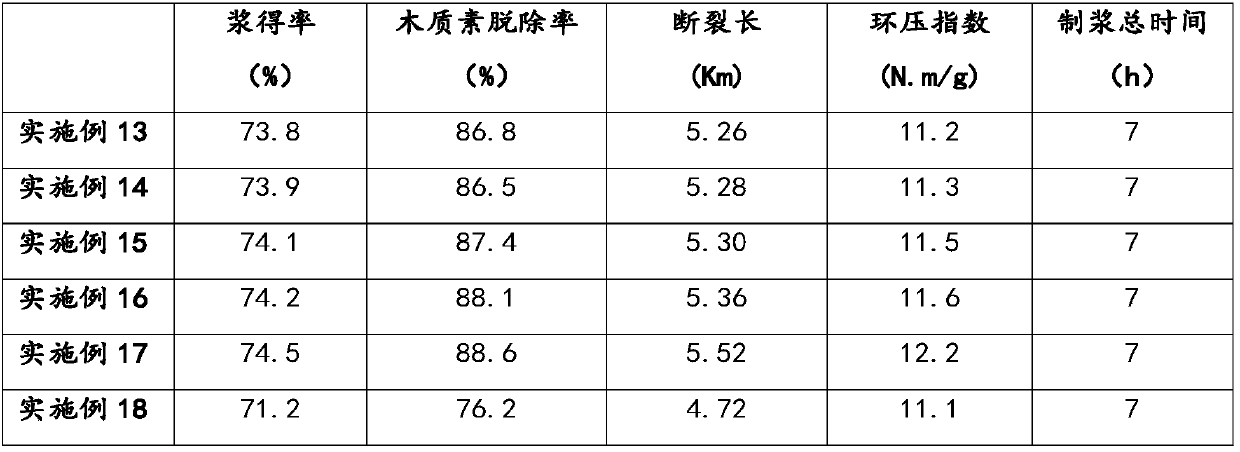

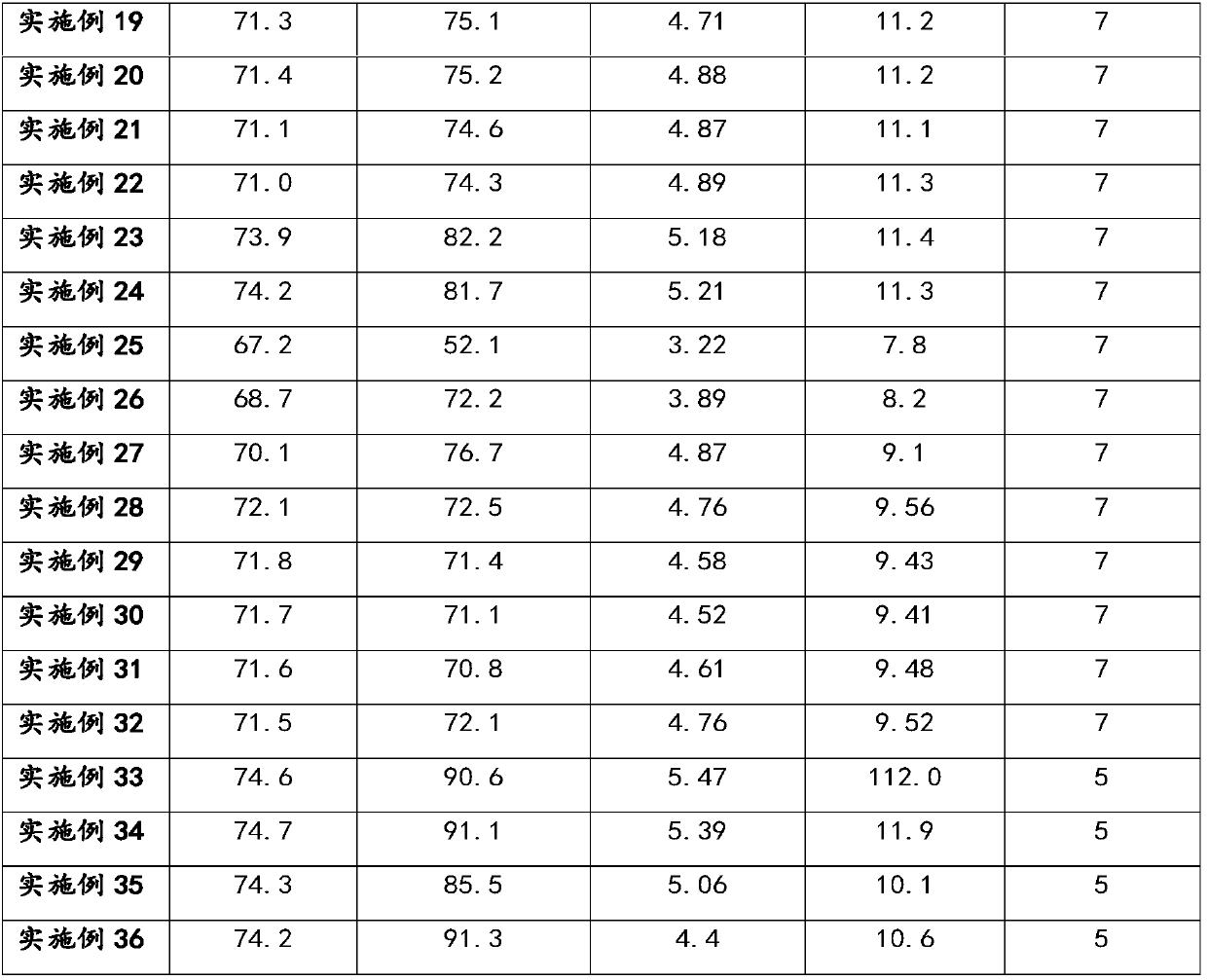

Lignin removing pulping agent and plant fiber lignin removing pulping method

ActiveCN107938411AFast removalResidue reductionCellulose treatment using microorganisms/enzymesFiberMicrobial agent

The invention provides a lignin removing pulping agent and a plant fiber lignin removing pulping method, and relates to the technical field of plant fiber pulping. The lignin removing pulping agent comprises a composite biological enzyme agent, a composite microbial agent and a chemical auxiliary agent, wherein the mass ratio of the composite biological enzyme agent to the composite microbial agent to the chemical auxiliary agent is (4-6):(2-3):(2-3). The composite biological enzyme agent comprises laccase, ligninase, hemicellulase, xylanase, glucosidase, lipoxygenase and coenzyme, wherein themass ratio of the laccase to the ligninase to the hemicellulase to the xylanase to the glucosidase to the lipoxygenase to the coenzyme is (3-5):(2-3):(1-2):(1-2):(1-2):(1-2):(1-2). The technical problem that pulping by using a microorganism preparation cannot meet the high-efficiency high-quality requirement of the papermaking industry at present is relieved; through the combination of the composite biological enzyme agent, the composite microbial agent and the chemical auxiliary agent, the removal rate of lignin from the plant fibers is accelerated, the pulping cycle is shortened, and the lignin residue in the papermaking slurry is reduced.

Owner:北京华通盛世科技有限公司

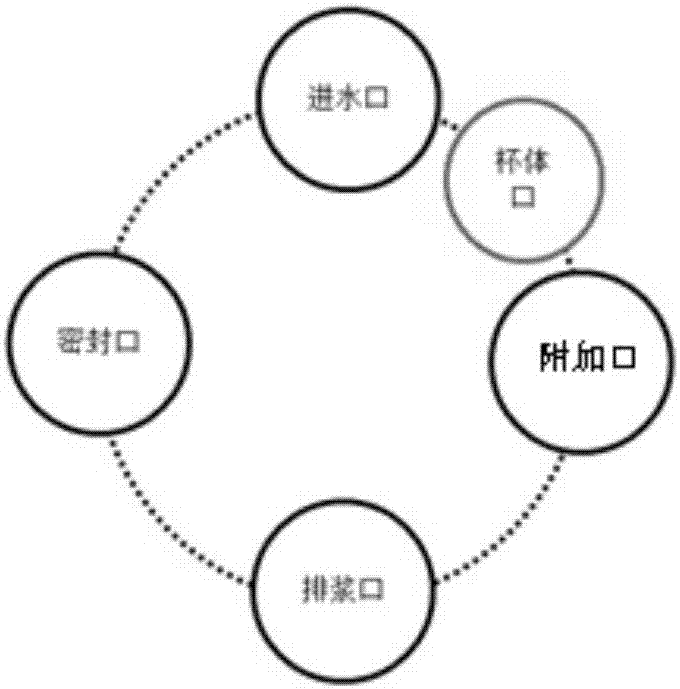

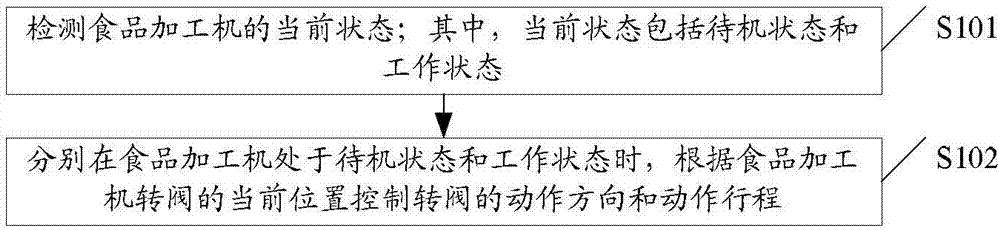

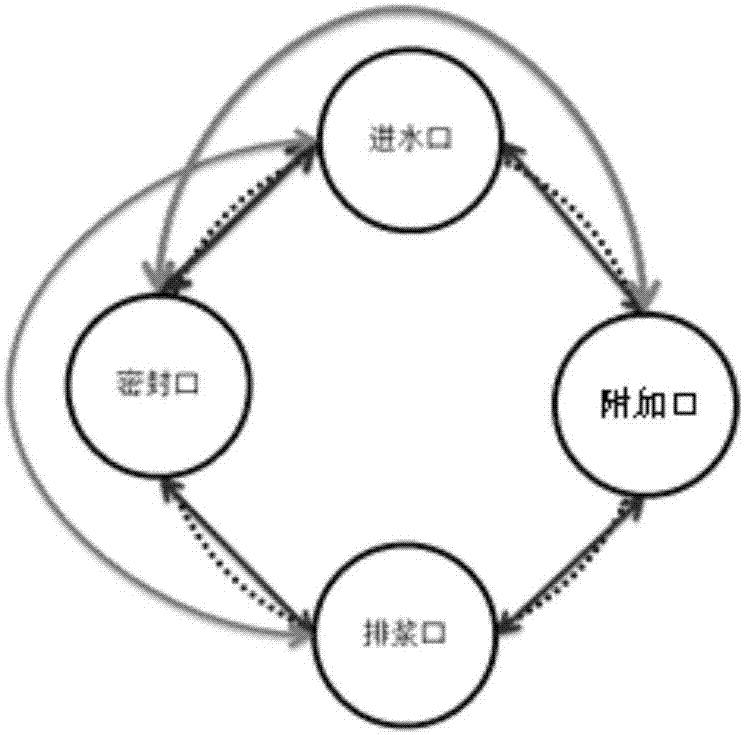

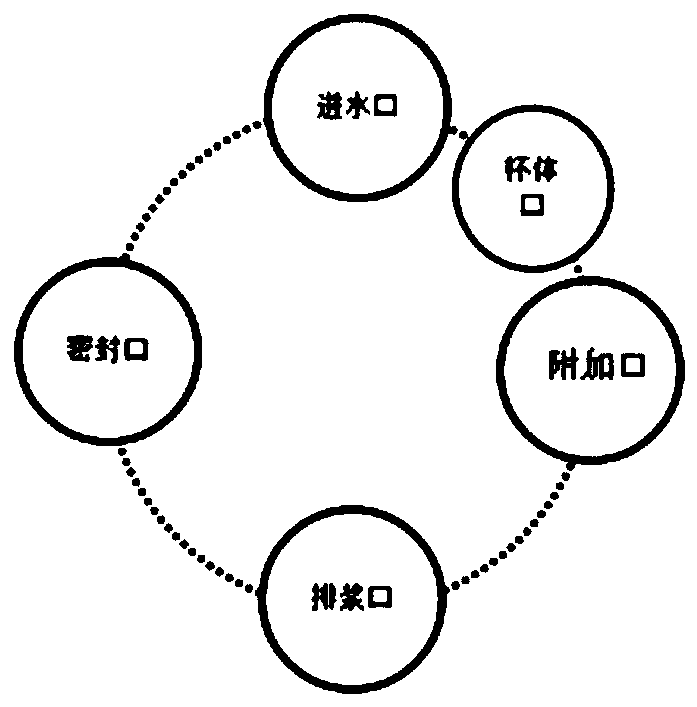

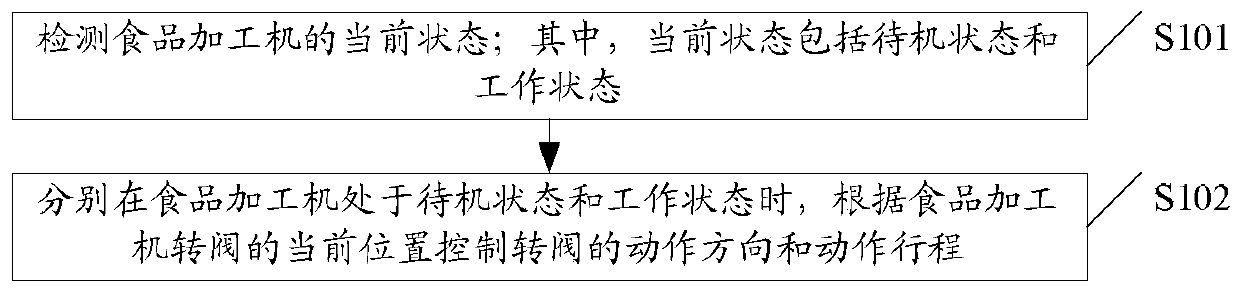

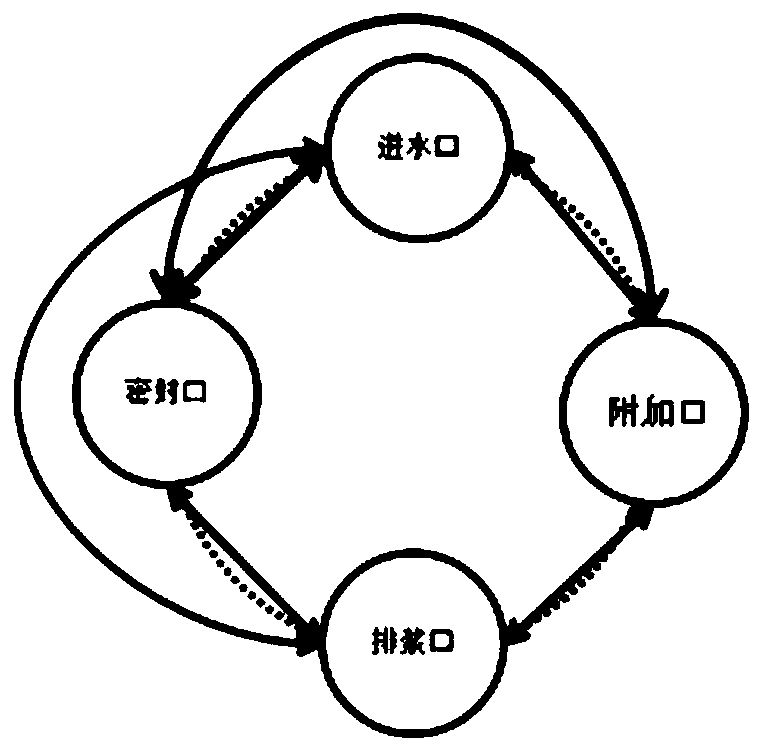

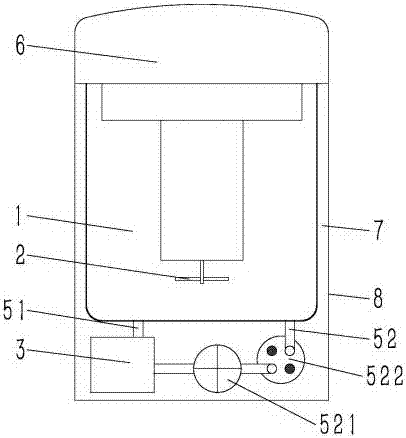

Rotary-valve control method of food processor

An embodiment of the invention discloses a rotary-valve control method of a food processor. A Rotary valve of the food processor comprises an upper rotary valve body and a lower rotary valve body, the upper rotary valve body is in charge of pipeline switching between a cup and a water inlet, a sealing port, a pulp discharge port and an additional port, and the lower rotary valve body is in charge of switching between the pulp discharge port and a wastewater box; the method includes: detecting current states of the food processor, wherein the current states include the standby state and the working state; controlling motion direction and motion range of the rotary valve according to the current location of the rotary valve of the food processor in the standby state and the working state respectively. By the arrangement, the optimum motion path can be automatically judged according to pulping conditions, safe and reliable switching of pipelines is guaranteed, motion time of the rotary valve is shortened, and pulping circle is shortened.

Owner:JOYOUNG CO LTD

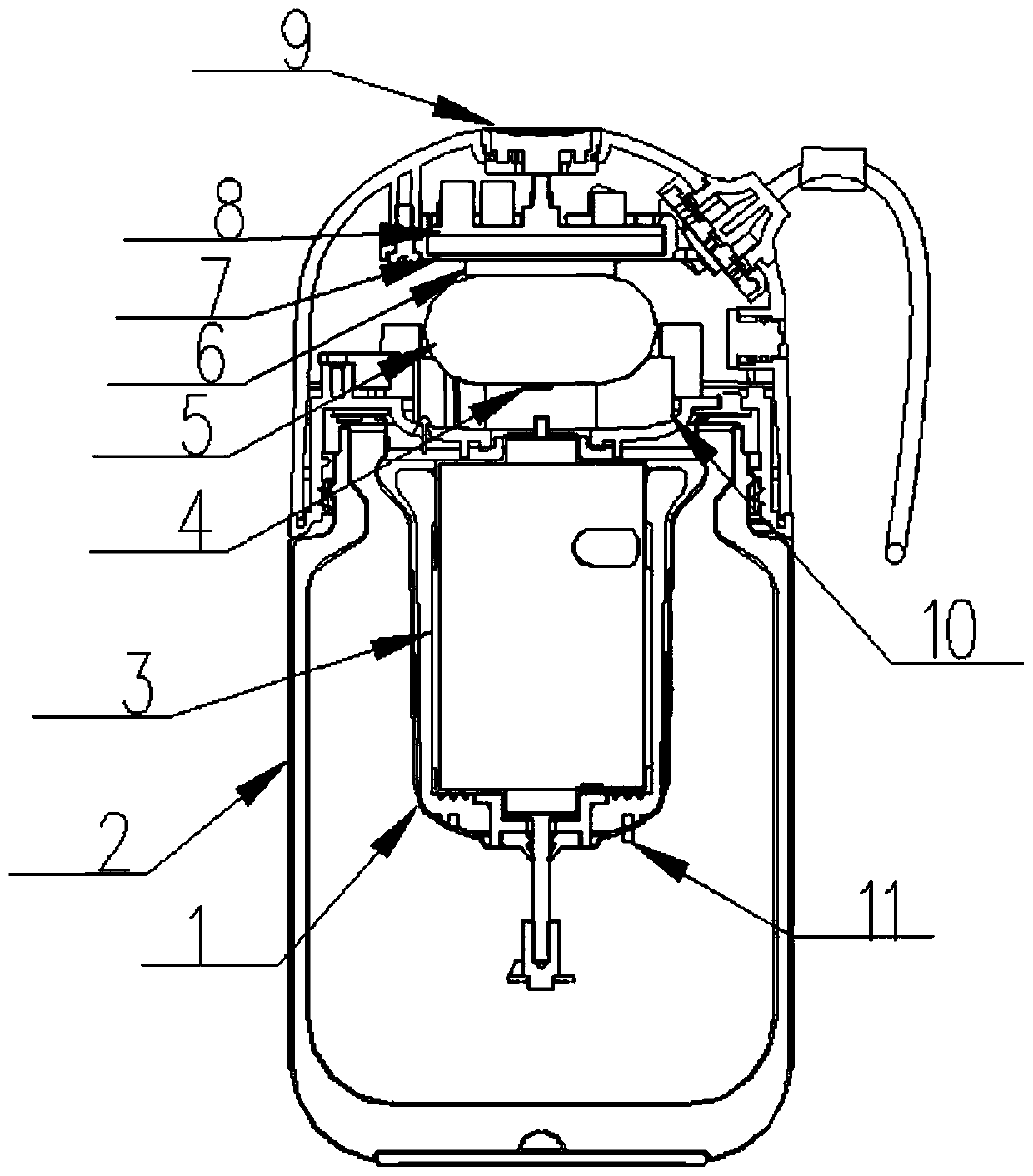

Control method of food processor

ActiveCN111000463AImprove experienceFast pulpingElectric motor controlKitchen equipmentProcess engineeringCold drinks

The embodiment of the invention discloses a control method of a food processor. The food processor comprises an electric power storage device and a first temperature sensor which are arranged on a machine head, and power is supplied to the food processor through the power storage device. The method comprises the steps of detecting the temperature T of materials in a cup body in real time through afirst temperature sensor; calculating a material average temperature TP according to a plurality of material temperatures T detected within a preset time length t; comparing the average temperature TP of the materials with a pulping temperature threshold value T0; judging whether the materials are cold materials or hot materials according to a comparison result, and executing a current food processing function by adopting a corresponding food processing procedure according to a judgment result, wherein the food processing procedure comprises a cold drink processing procedure and a hot drink processing procedure. According to the scheme of the embodiment, the corresponding food processing flow is matched by distinguishing cold drink from hot drink, it is guaranteed that the cold drink function rapidly makes milk, the hot drink function is good in smashing effect, the overflow risk is avoided, and the intelligence of the whole machine is improved.

Owner:JOYOUNG CO LTD

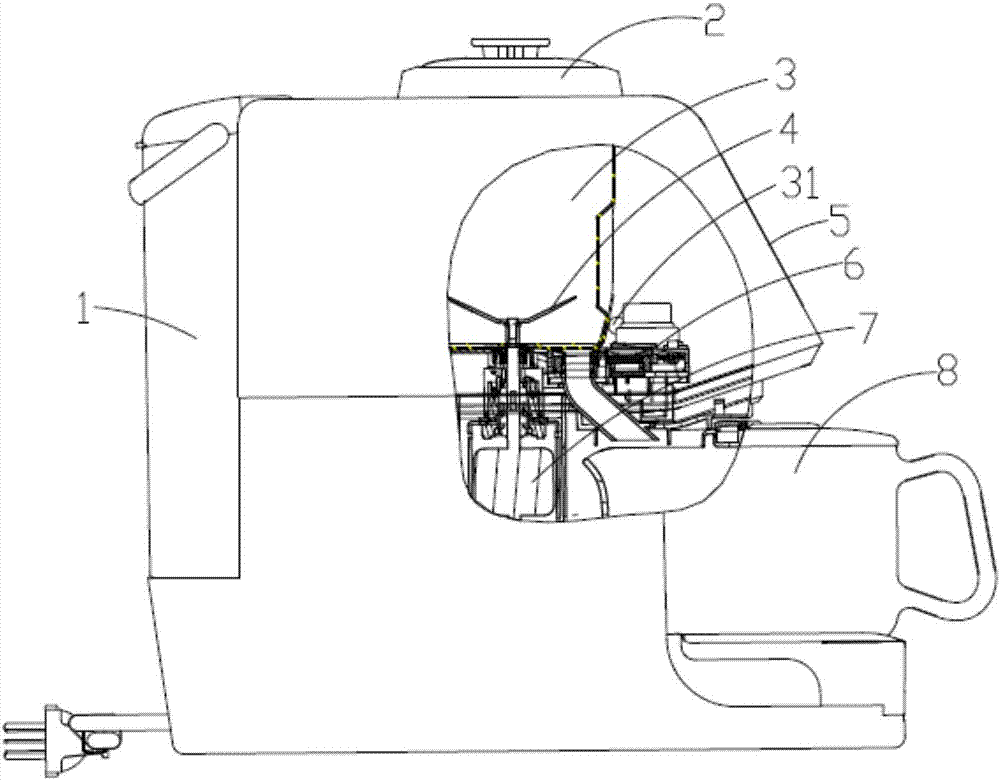

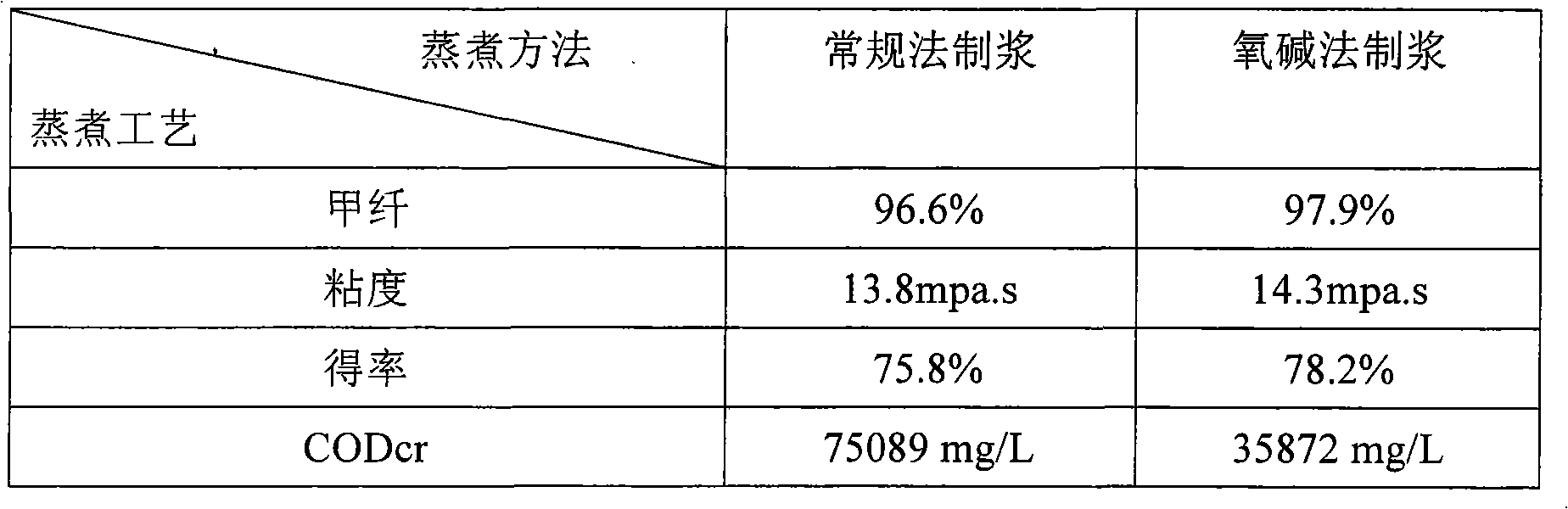

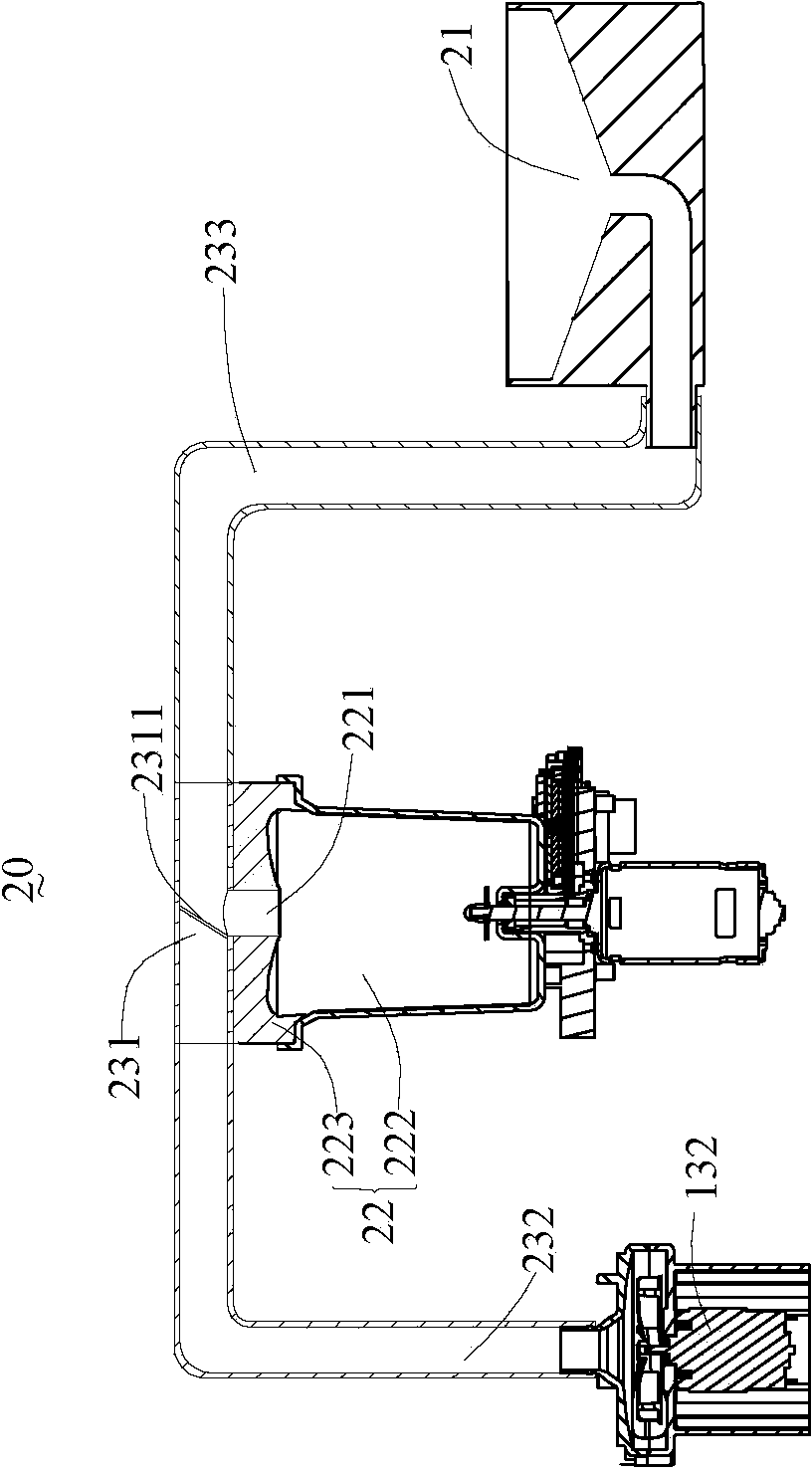

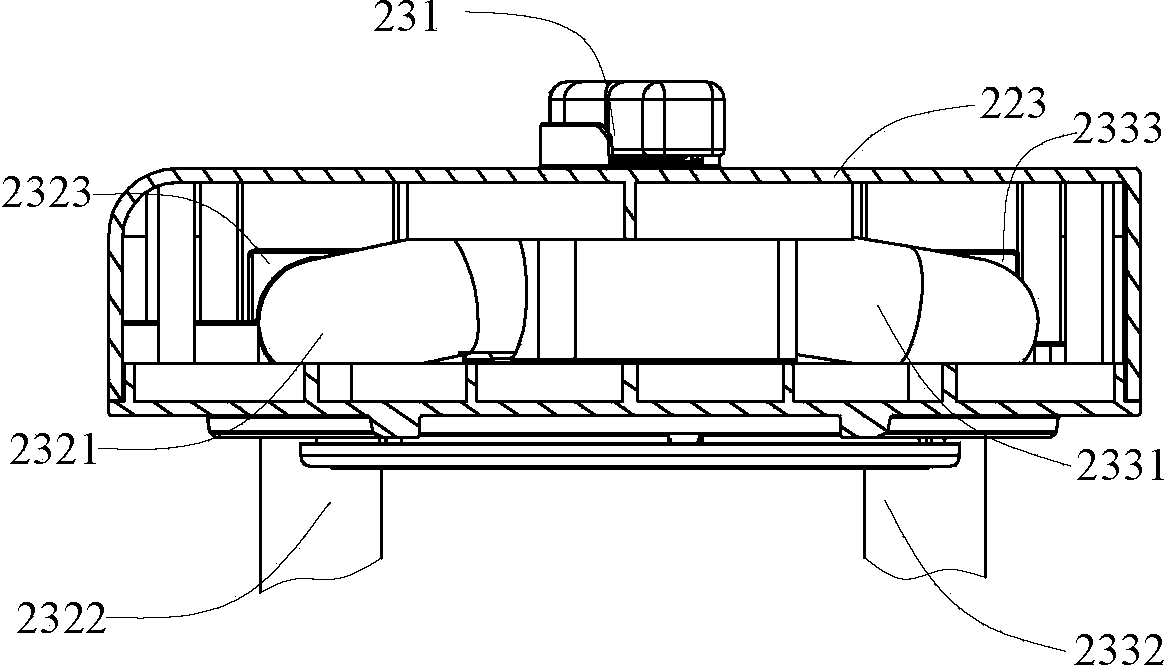

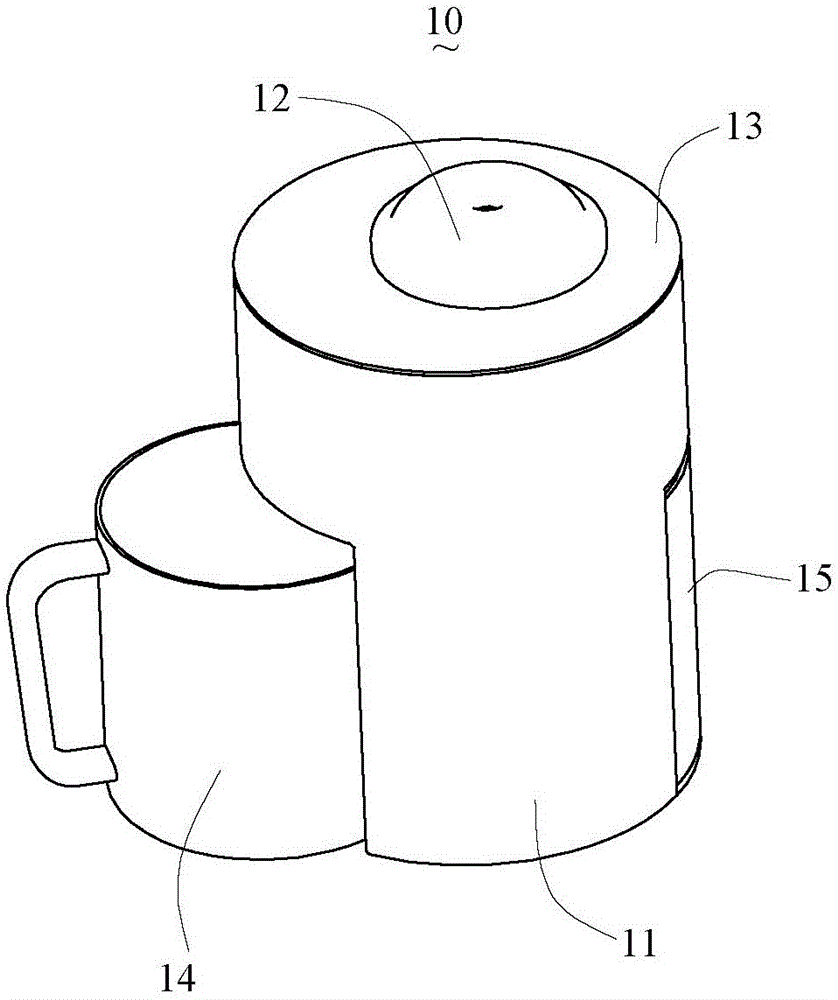

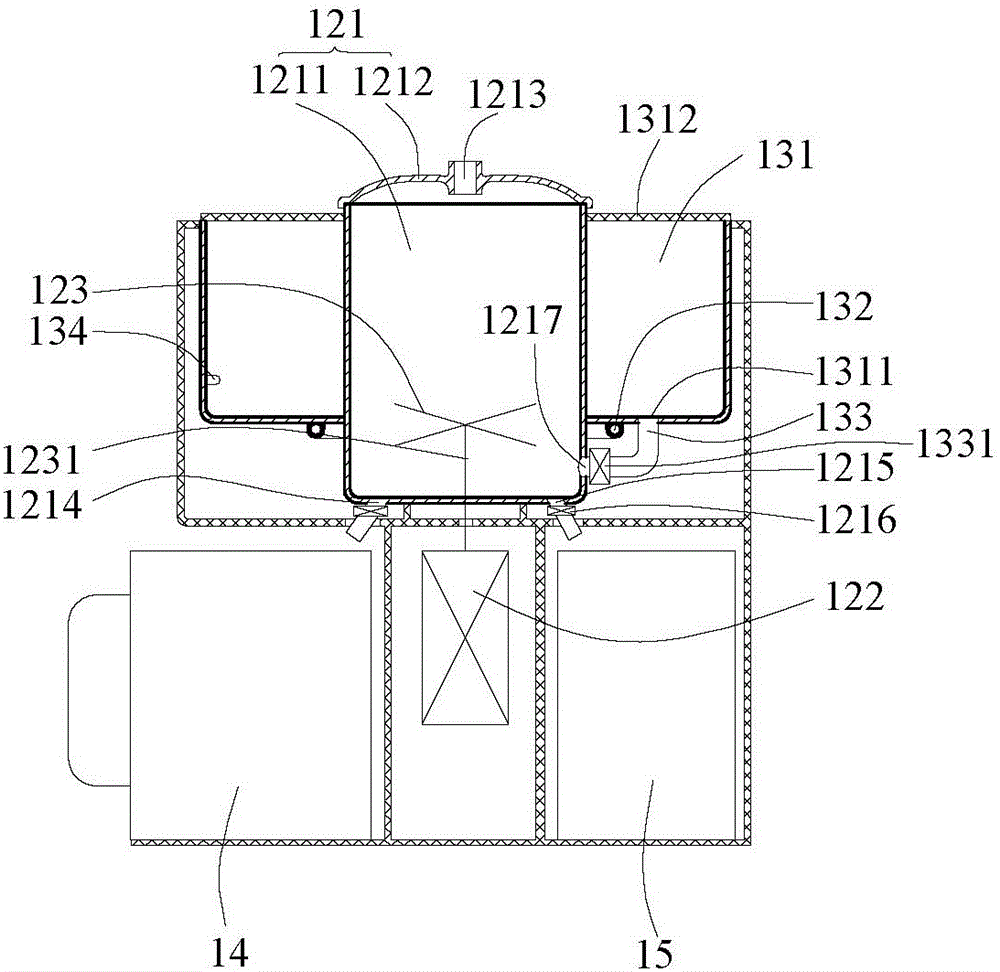

Soybean milk machine and soybean milk making method of same

The invention provides a soybean milk machine and a soybean milk making method of the same. The machine comprises an enclosure, a soybean milk making container used to store soybean milk making materials and water, as well as a smashing device used to smash the soybean milk making materials and water in the soybean milk making container. The machine is characterized in that the soybean machine also comprises a water tank and a steam generator used to heat water in the tank so as to form steam; and a first channel used for water entering from the soybean milk making container to the water tank, as well as a second channel used for steam entering from the water tank to the soybean milk making container are disposed between the water tank and the soybean milk making container. According to the invention, a user does not need to pour water into the water tank separately and only needs to put the soybean milk making materials and water with certain amounts and proportions into the soybean milk making container. During soybean milk making, the water in the soybean milk making container enters the water tank via the first channel and is used at least for steam formation during steam heating; and the water tank may not be sensed by the user. Furthermore, the water tank is hidden in the enclosure. In other words, the water tank cannot be seen or sensed by the user.

Owner:JOYOUNG CO LTD

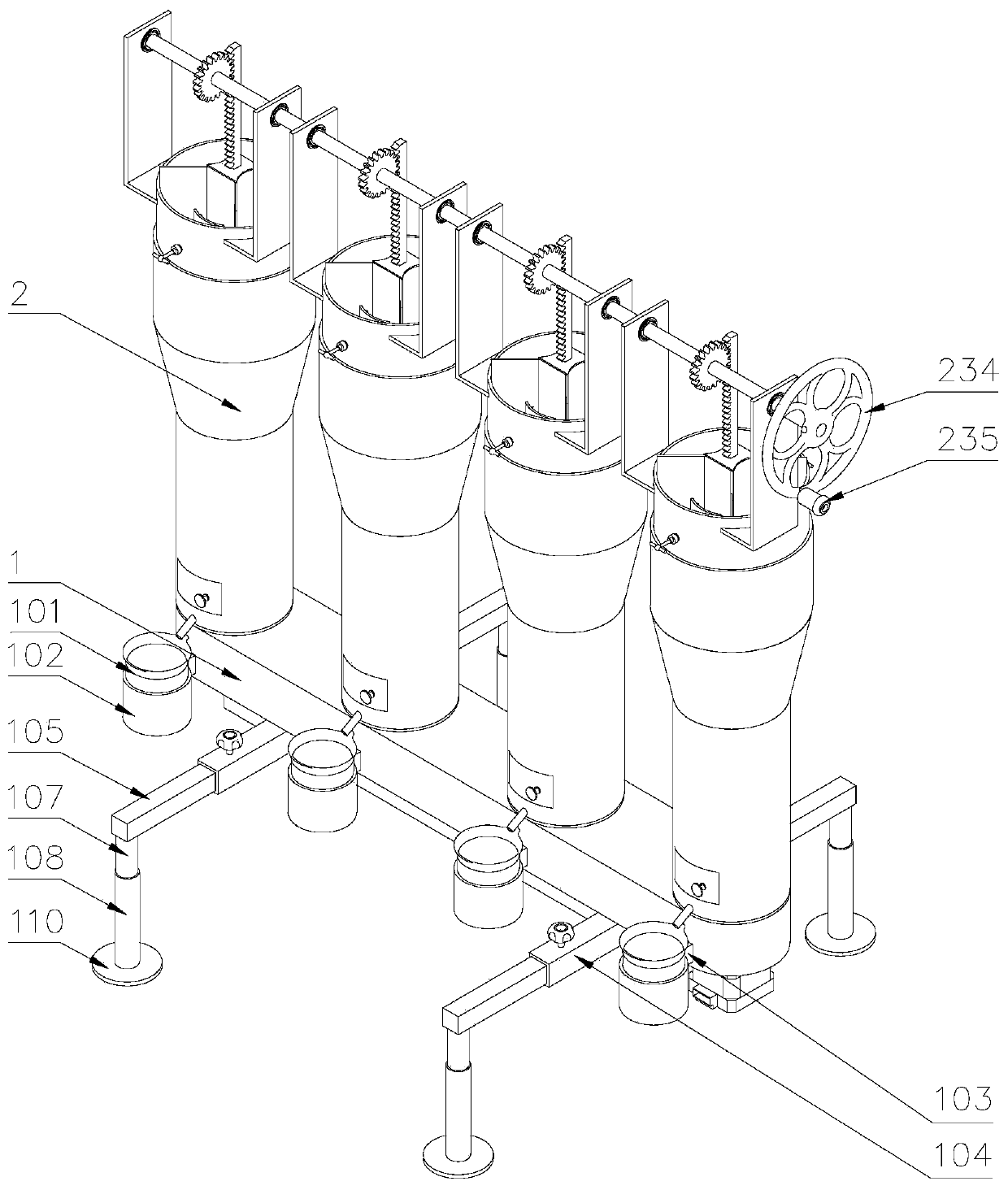

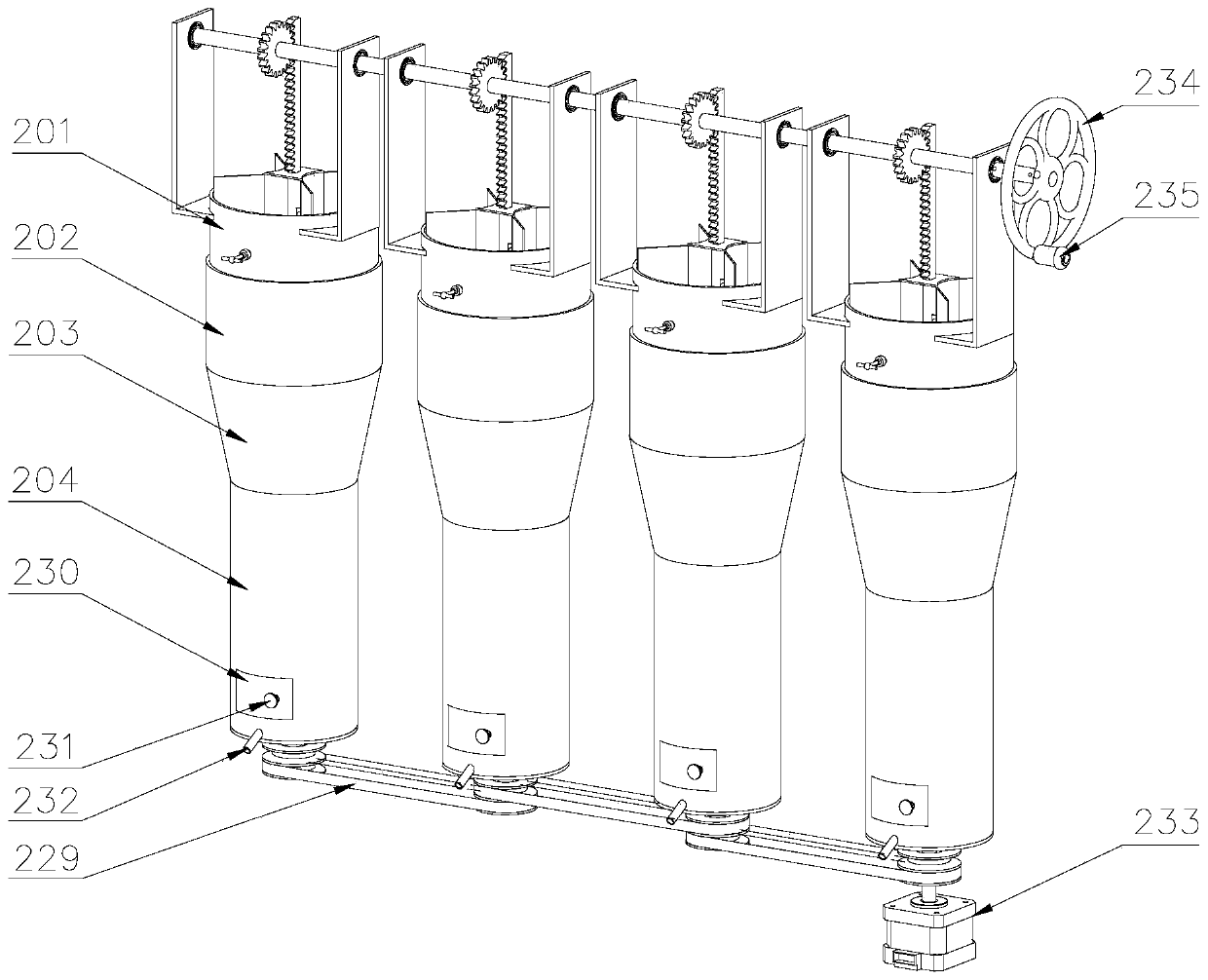

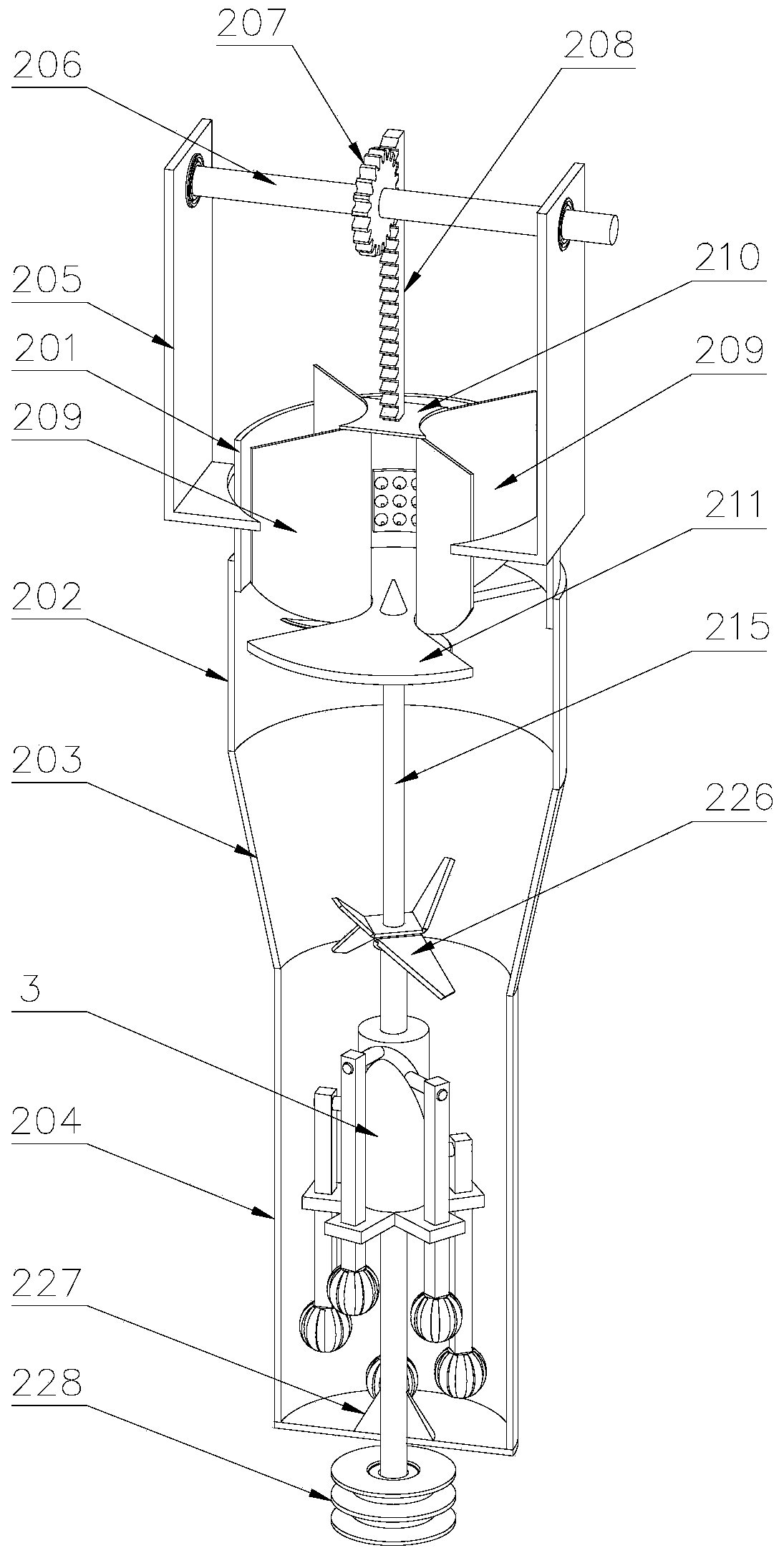

Fruit sampler for food detection

PendingCN109946112AShorten pulping cycleImprove detection efficiencyWithdrawing sample devicesFleshFruit juice

The invention discloses a fruit sampler for food detection. Multiple sampling devices are arranged, for each sampling device, a cutting tank is arranged outside the lower end of each sample tank in asleeving manner, and the cutting tank, a smashing box and a collecting box are connected in sequence. A hand wheel is arranged at one end of a first rotating shaft, gears are arranged on the first rotating shaft, a rack meshed with the gear is arranged on one side of each gear, cutters which are symmetrically distributed are arranged on one side of the lower part of each rack and are arc-shaped orV-shaped, orthographic projection of the lower part of each cutter is V-shaped, breaking blades are arranged on one side in the smashing box, the lower end of a second rotating shaft extends out of each collecting box and is provided with a belt wheel, and the belt wheels at the lower ends of the adjacent sampling devices are connected through a belt; a motor is fixedly mounted at one end of a transmission case, and a liquid outlet guide pipe is arranged on one side of the lower part of each taking door. Multiple pulp making devices are arranged and perform pulp making on multiple sampling fruits simultaneously, the fruit pulp making cycle is shortened, and the fruit detection efficiency is improved; besides, juice and flesh are separated after pulp making, respective sampling detection of the juice and flesh is facilitated, and accuracy of fruit sampling detection is improved.

Owner:INST OF QUALITY STANDARDS & TESTING TECH FOR AGRO PROD OF SHANDONG ACADEMY OF AGRI SCI

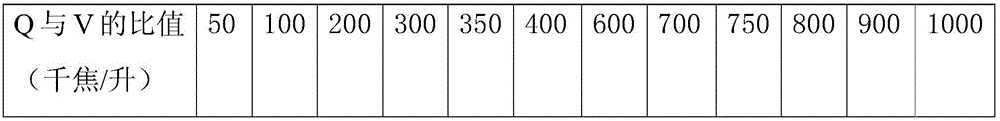

Method for preparing safe and nutritional soybean milk

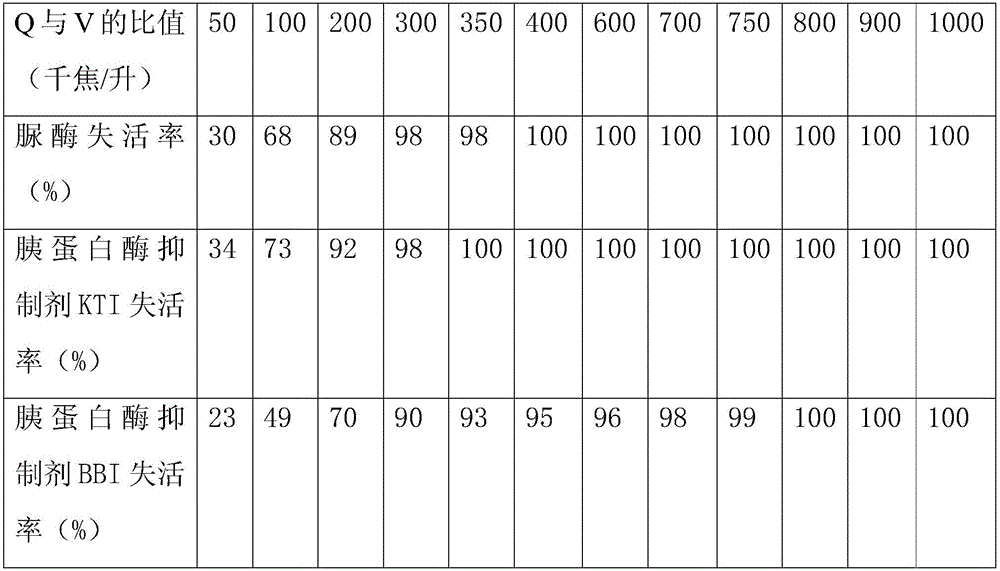

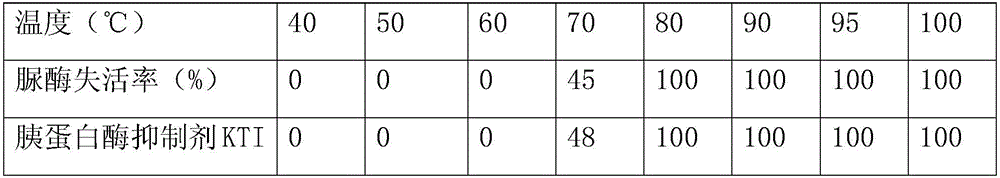

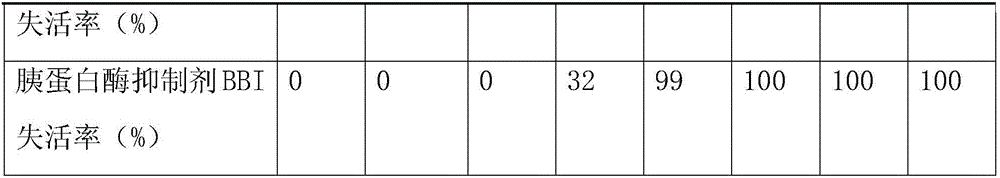

ActiveCN105935084AImprove inactivation efficiencyFacilitate conductionMilk substitutesFood scienceStopped workRadiation-Total

The invention relates to a method for preparing safe and nutritional soybean milk; a motor, a crushing cutter, a heating device and a cup body are provided; the method at least includes the following several stages: (1) a crushing stage including a step of adopting the motor to drive the crushing cutter to rotatingly crush a material and a step of allowing the motor to stop working; and (2) a heating stage including a step of adopting the heating device to heat a liquid in the cup body and a step of allowing the heating device to stop heating. In the method for preparing the safe and nutritional soybean milk, the radiation total heat of the heating device is Q, the soybean milk preparing total amount is V, and the ratio of Q to V is 300-800 kJ / L. Therefore, urease and trypsin inhibitors in the soybean milk can be fully inactivated, and thus the soybean milk is allowed to be more nutritional and safer.

Owner:JOYOUNG CO LTD +1

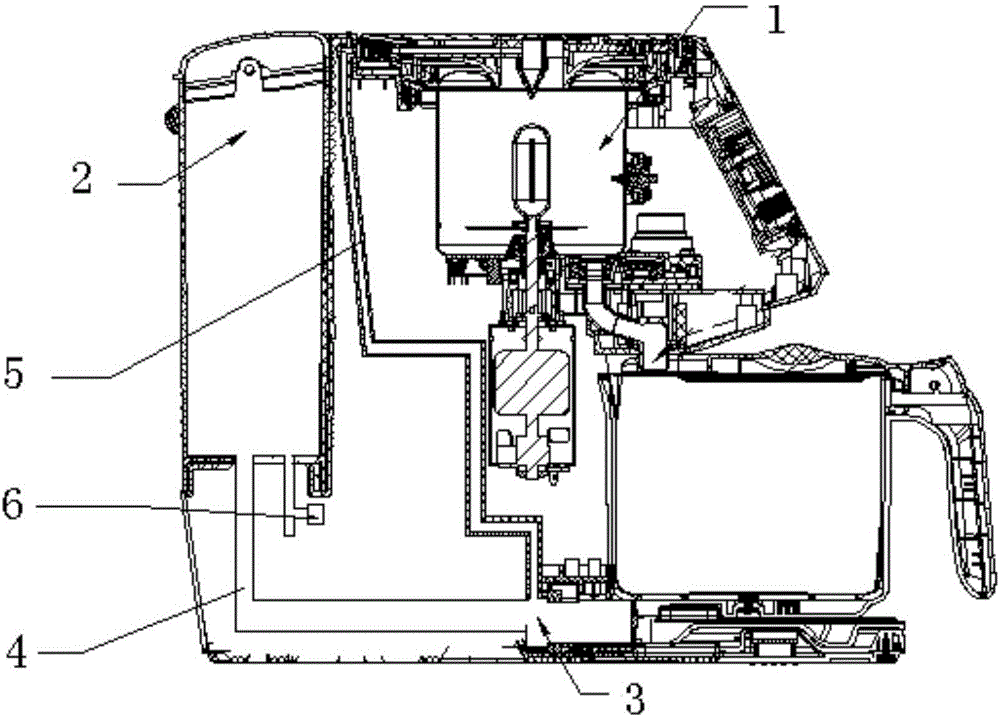

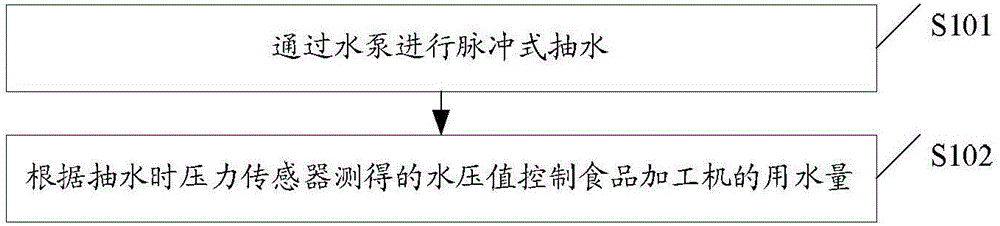

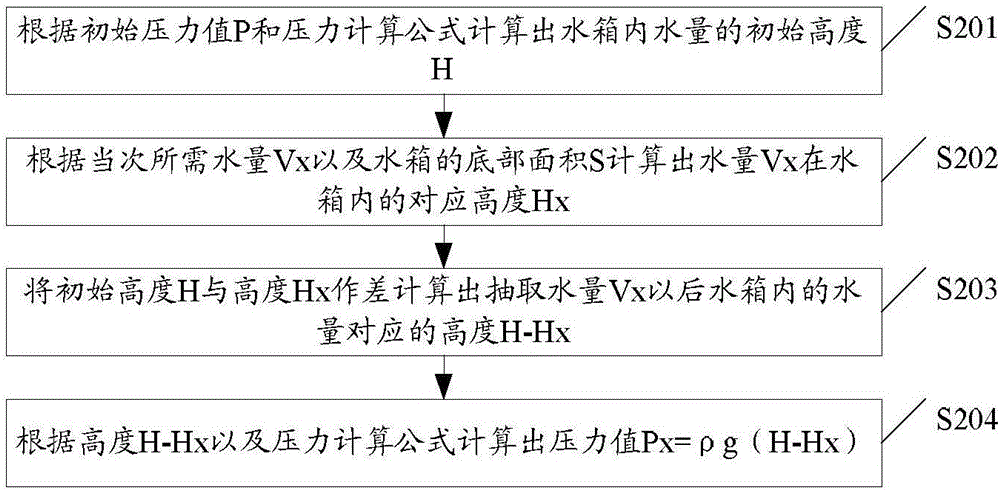

Water quantity control method of food processing machine

The invention discloses a water quantity control method of a food processing machine. The food processing machine comprises a crushing cavity, a water tank, a water pump, a water inlet pipe which connects the water tank and the water pump and a water pipe which connects the crushing cavity and the water pump. The water pump extracts water in the water tank through the water inlet pipe and transports the extracted water to the crushing cavity through the water pipe. The food processing machine also comprises a pressure sensor. The method comprises the steps of carrying out pulse water pumping through the water pump, and controlling the water quantity of the food processing machine according to a water pressure value measured by the pressure sensor in extracting the water. Through a scheme of the embodiment of the invention, the fine measurement and control of the water quantity can be realized, the precise water quantity is provided, the scheme is simple and is universal, and the requirements of different functions and different water quantities can be satisfied.

Owner:JOYOUNG CO LTD

Method for preparing safe and nutritional soybean milk

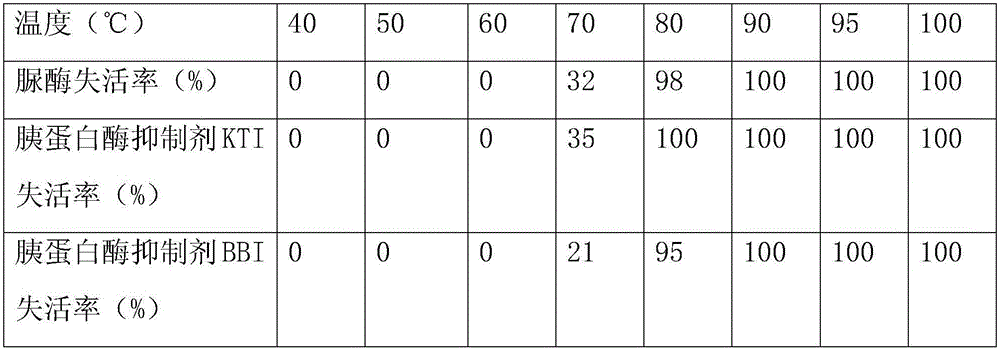

PendingCN105935083AImprove inactivation efficiencyImprove thermal stabilityMilk substitutesFood scienceStopped workTrypsin inhibitor

The invention relates to a method for preparing safe and nutritional soybean milk; a motor, a crushing cutter, a heating device and a cup body are provided; the method at least includes a crushing stage and a heating stage; the crushing stage includes a step of adopting the motor to drive the crushing cutter to rotatingly crush a material and a step of allowing the motor to stop working; the heating stage includes a step of adopting the heating device to heat a liquid in the cup body and a step of allowing the heating device to stop heating, wherein after the temperature of the liquid in the cup body is 80 DEG C or more, the total time for heating the liquid in the cup body by the heating device is 4 to 15 minutes. Therefore, urease and trypsin inhibitors in the soybean milk can be fully inactivated, and thus the soybean milk is allowed to be more nutritional and safer.

Owner:JOYOUNG CO LTD

Pulping method of food processor

InactiveCN107198469AImprove thermal stabilityReduce loadKitchen equipmentMilk substitutesPulp and paper industryMotor load

The invention provides a pulping method of a food processor. The food processor comprises a cup body, a heating device, and a grinding device. The cup body is used for containing pulping materials and water, the heating device heats the pulping materials and the water in the cup body, and the grinding device grinds the pulping materials and the water in the cup body. The food processor is characterized in that the grinding device comprises a movable grinding head installed on a rotary shaft and a fixed grinding cylinder installed on the movable grinding head in a sleeving mode. The pulping method comprises the steps of heating the pulping materials and the water in the cup body to 90 DEG C, and maintaining the temperature of 90 DEG C or above for t1, afterwards making the grinding device rotate to drive the pulping materials and water to pass through the gaps between the movable grinding head and the static grinding cylinder in the axial direction of the grinding device so as to further grind the pulping materials, wherein the duration t1 is 3-15 minutes. The pulping method of the food processor is conducive to softening of the pulping materials; meanwhile, the motor load is lowered, and the phenomenon that the food processor gets stuck is avoided.

Owner:HONGYANG HOME APPLIANCES

Freeze wall breaking soybean milk making method of household soymilk machine and household soymilk machine

InactiveCN105249853AReduce crushing efficiencyReduced flexibilityKitchen equipmentMilk substitutesMotor driveIntercellular space

The invention relates to a freeze wall breaking soybean milk making method of a household soymilk machine. The method includes the following stages: (1) a preprocessing stage: soaking dry soybeans and allowing the dry soybeans to fully absorb water to be saturated, and freezing the soybeans into ice soybeans; (b) an unfreezing stage: putting the ice soybeans into a cup and unfreezing and softening the ice soybeans; (c) a crushing stage: a motor drives a crushing cutter to rotate to crush the soybeans into soymilk liquid. The soybeans absorb water to expand, so that cell interiors and intercellular spaces of the soybeans are filled with water. According to the temperature transfer law, ice crystals are formed from outside to inside during a freezing process, and free water in outer layers of cell walls firstly forms into the ice crystals; at this time, the internal parts of the cell walls are liquid, the cell walls are made to deform for the first time by squeezing of the internal and external pressure, and then the ice crystals are formed in the internal parts of the cells, and the volume is expanded to squeeze the cell walls to cause a second deformation of the cell walls, so that the cell walls of the soybeans are broken.

Owner:JOYOUNG CO LTD

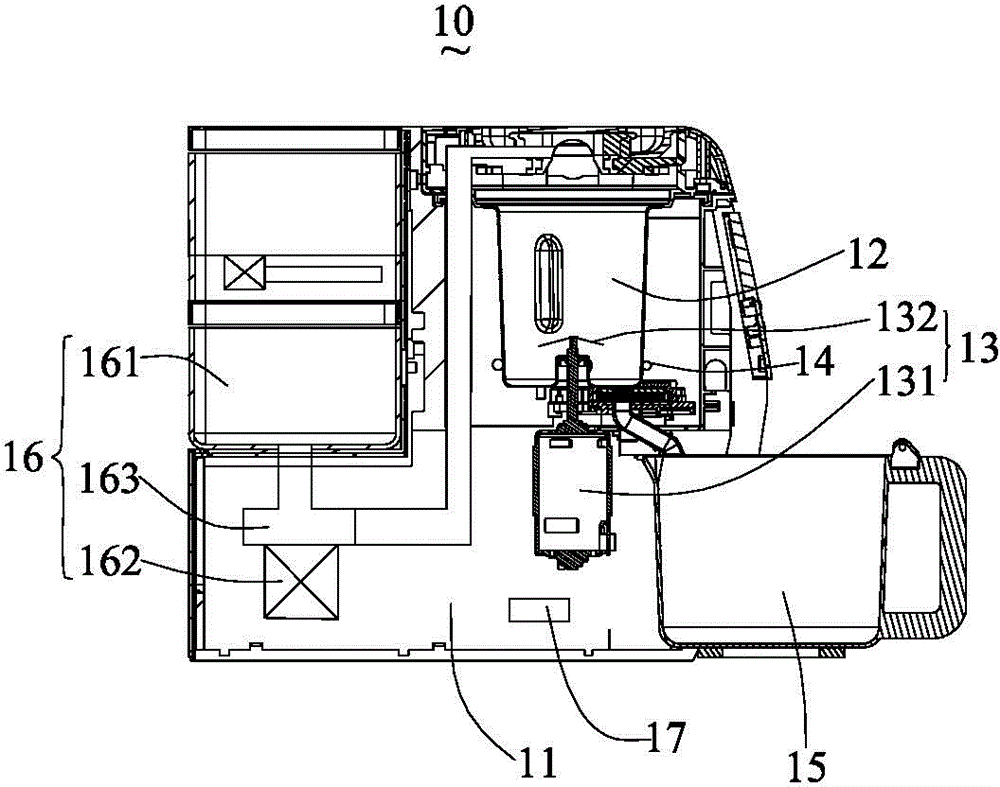

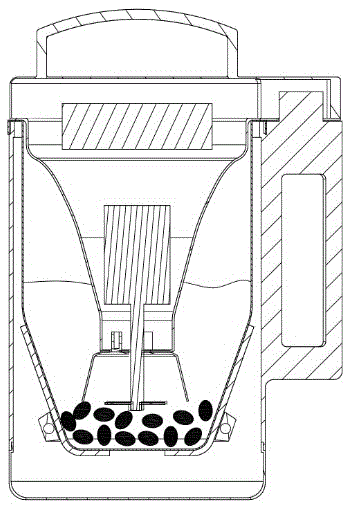

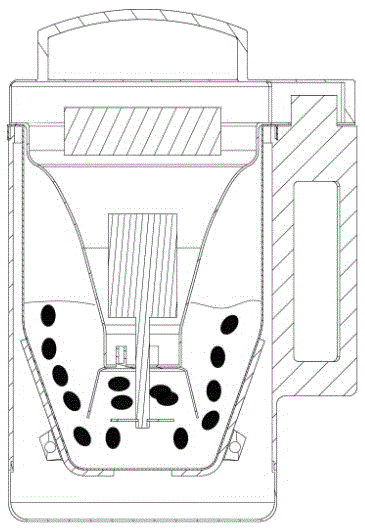

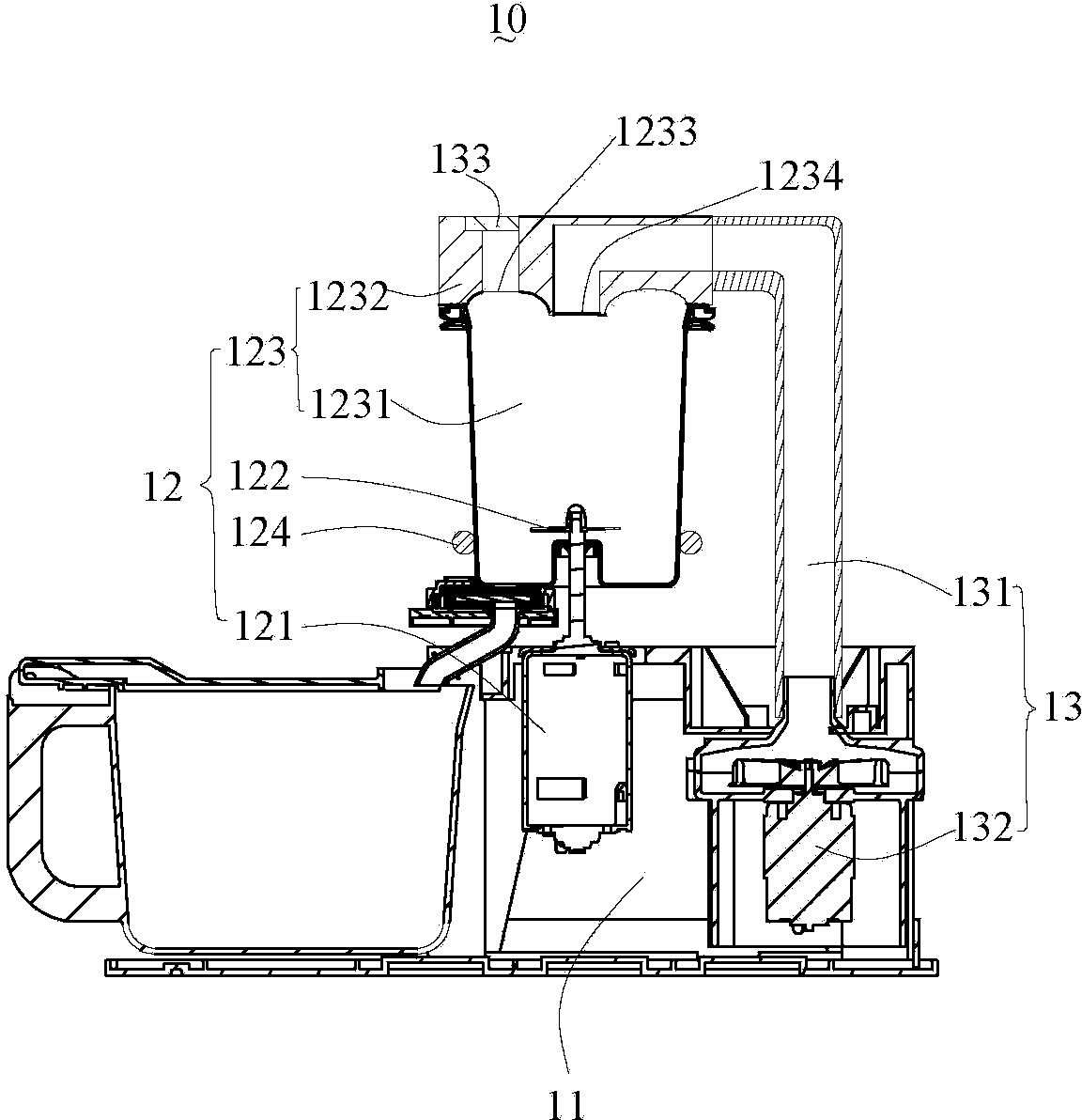

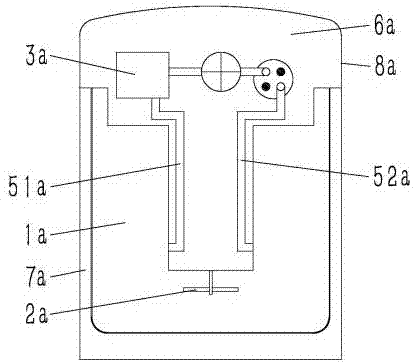

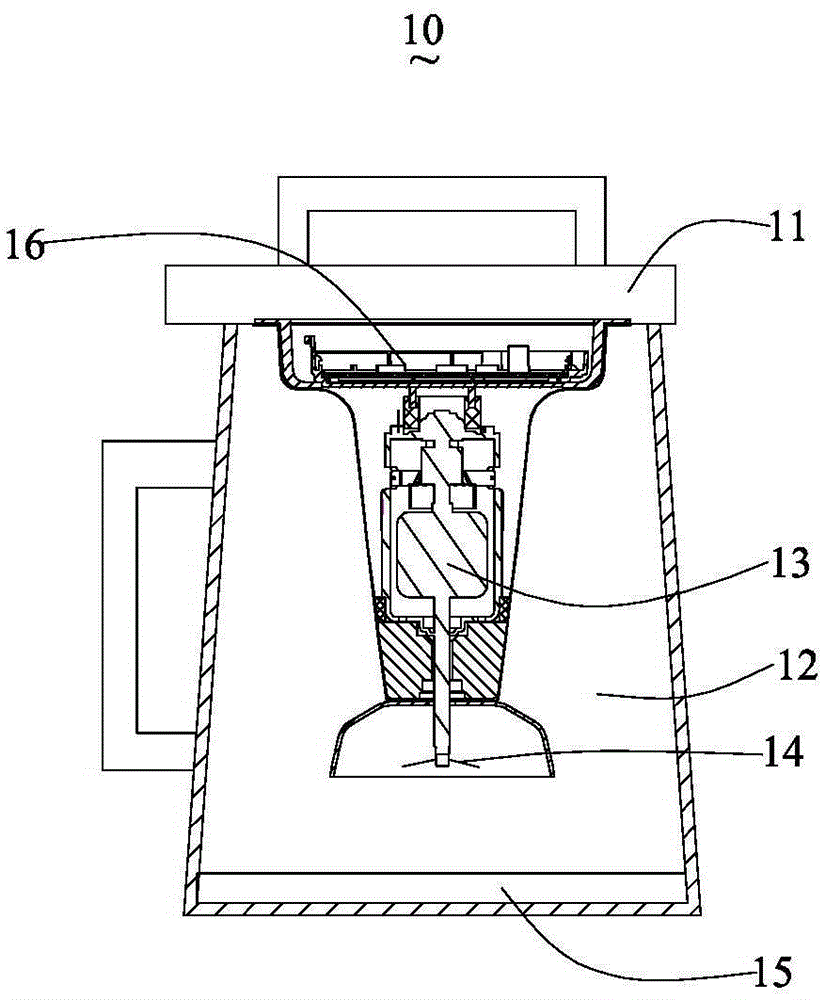

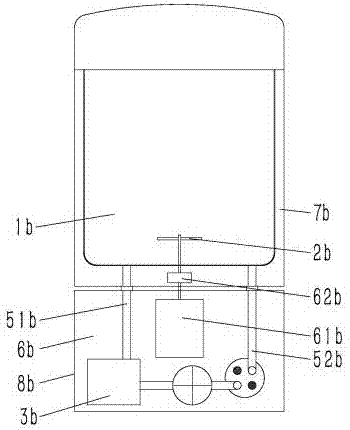

energy saving soymilk machine

ActiveCN103445679BRealize comprehensive utilizationLow costBeverage vesselsMilk substitutesProcess engineeringMechanical engineering

The invention relates to a low-cost soybean milk machine. The water supply unit and the cooking unit are combined to realize the integration of water supply and cooking. The water tank is arranged around a small space pulverizer. The heat is conducted to the small space pulverizer, and the water tank is provided with a water outlet hole, and the side wall or bottom wall of the small space pulverizer is provided with a water inlet hole, and the water outlet hole and the water inlet hole are connected through a pipeline, and the water tank is connected to the small space through the pipeline. Water is supplied to the pulverizer. In this way, while heating the water in the water tank, the heat of the water is conducted to the small-space pulverizer, thereby preheating the materials and boiled pulp in the small-space pulverizer. One heating element can not only heat the water tank but also pulverize the small space. The device can be heated or kept warm, which greatly reduces the manufacturing cost of the soybean milk machine, and at the same time, the heat of the water in the water tank can be reasonably and effectively used to save energy.

Owner:JOYOUNG CO LTD

Soybean milk preparation method capable of effectively controlling false boiling of soybean milk machine

The invention relates to a soybean milk preparation method capable of effectively controlling false boiling of a soybean milk machine. The soybean milk machine comprises a cup body, a smashing device,a heating device and an overflow prevention electrode, the smashing device is arranged in the cup body, the heating device heats the cup body, the method comprises (a) smashing stages: including a primary smashing stage and a secondary fine smashing stage, the primary smashing stage is the stage where water and materials are subjected to primary smashing, the secondary fine smashing stage is thestage where a milk liquid obtained after primary smashing is subjected to fine smashing again, a false boiling identification step is arranged between the primary smashing stage and the secondary finesmashing stage, and the false boiling identification step is the stage where the milk liquid obtained after primary smashing is heated to touch the overflow prevention electrode, and then the secondary fine smashing stage is started again. Compared with the prior art, the nutrients can be well released and the flavor can be formed, false boiling can be effectively controlled, and the smashing fineness is high.

Owner:JOYOUNG CO LTD

A kind of food processing machine rotary valve control method

An embodiment of the invention discloses a rotary-valve control method of a food processor. A Rotary valve of the food processor comprises an upper rotary valve body and a lower rotary valve body, the upper rotary valve body is in charge of pipeline switching between a cup and a water inlet, a sealing port, a pulp discharge port and an additional port, and the lower rotary valve body is in charge of switching between the pulp discharge port and a wastewater box; the method includes: detecting current states of the food processor, wherein the current states include the standby state and the working state; controlling motion direction and motion range of the rotary valve according to the current location of the rotary valve of the food processor in the standby state and the working state respectively. By the arrangement, the optimum motion path can be automatically judged according to pulping conditions, safe and reliable switching of pipelines is guaranteed, motion time of the rotary valve is shortened, and pulping circle is shortened.

Owner:JOYOUNG CO LTD

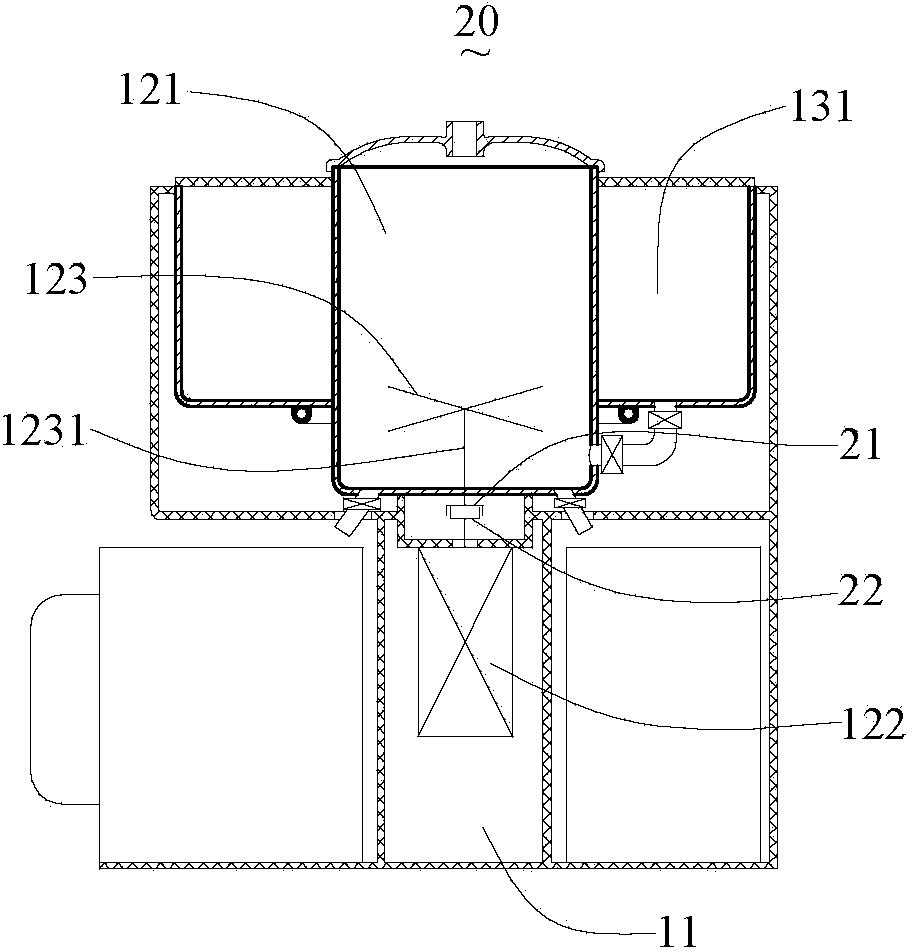

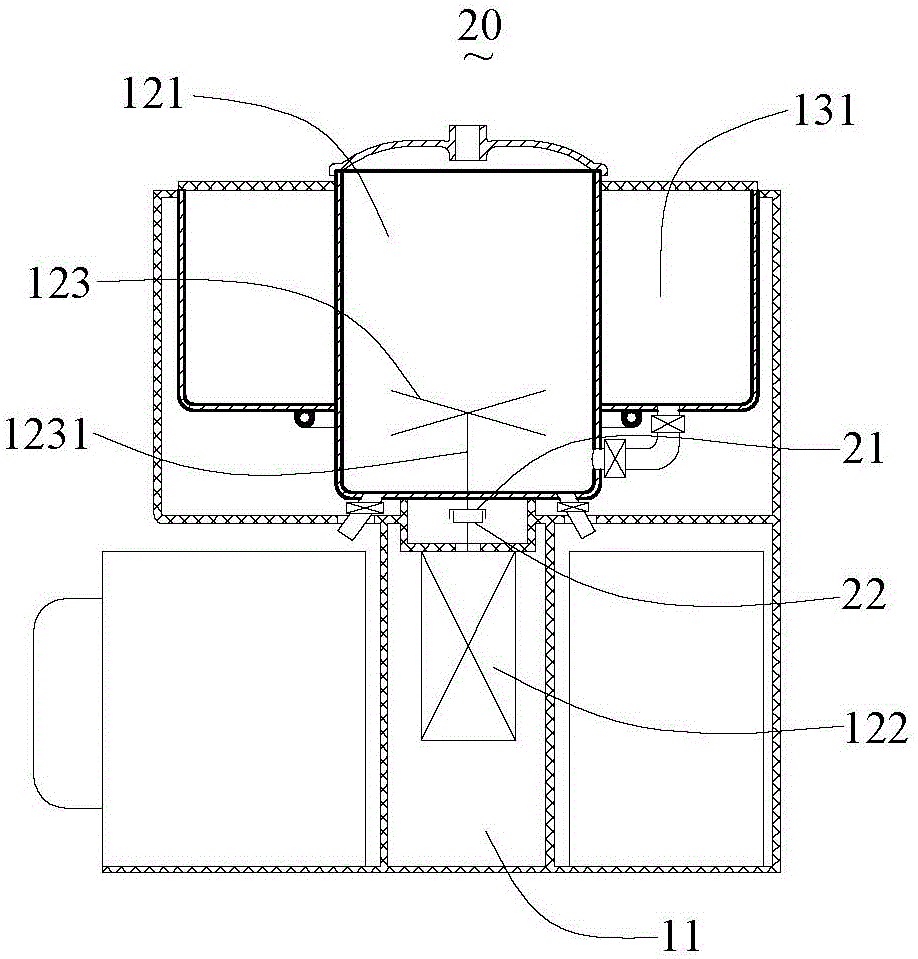

Soybean milk machine and booked soybean milk making method of same

The invention provides a soybean milk machine and a booked soybean milk making method of the same. The machine comprises an enclosure, a soybean milk making container used to store soybean milk making materials and water, as well as a smashing device used to smash the soybean milk materials and water in the soybean milk making container. The machine is characterized in that the soybean machine also comprises a water tank, a residual water box and a steam generator used to heat the water in the water tank so as to form steam; and a first channel for water entering from the soybean milk making container to the water tank, a second channel for steam entering form the water tank to the soybean milk making container, a third channel used for water entering from the water tank to the soybean milk making container, as well as a fourth channel used for water discharge from the soybean milk making container to the residual water box are disposed between the water tank and the soybean milk making. According to the invention, a user does not need to pour water into the water tank separately and only needs to put the soybean milk making materials and water with certain amounts and proportions into the soybean milk making container. Besides steam heating boiling, a booking function can be achieved by the residual water box.

Owner:HONGYANG HOME APPLIANCES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com