Temperature detection method for thick liquid in cooking equipment

A technology of cooking equipment and detection method, which is applied to thermometers, thermometers that give average/integrated values, applications of thermometers, etc. Accuracy, the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

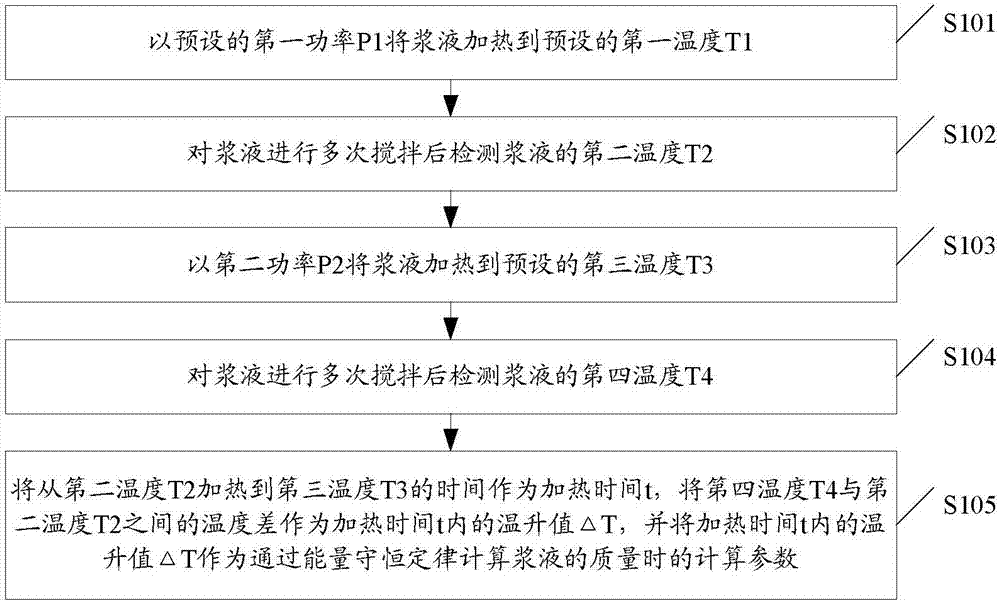

[0040] A method for detecting the temperature of slurry in cooking equipment. One or more temperature sensors are installed in the cooking device, and the temperature sensor is in direct contact with the slurry in the cooking equipment to detect the temperature of the slurry; figure 1 As shown, the method includes steps S101-S105:

[0041] S101. Heat the slurry to a preset first temperature T1 with a preset first power P1.

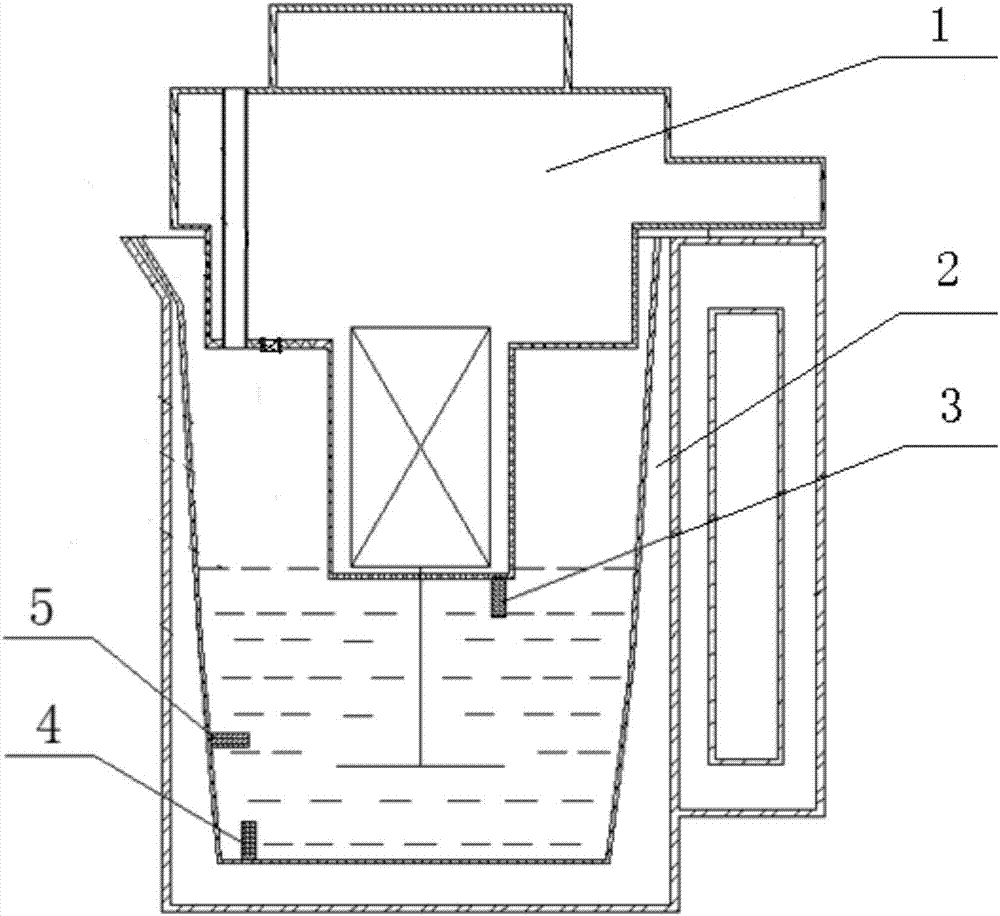

[0042] In the embodiment of the present invention, in order to accurately detect the temperature of the slurry in the cooking device, one or more temperature sensors need to be set in the cooking device in advance, and in order to accurately detect the temperature of the slurry, the temperature sensor needs to be able to communicate with the cooking device when it is set. direct contact with the slurry. Such as figure 2 As shown, it is a simple schematic diagram of the structure of the soybean milk machine, which includes a machine head 1 and a cup body...

Embodiment 2

[0074] The difference between this embodiment and the first embodiment is that the third temperature T3 may be the boiling point temperature of the slurry or the anti-overflow temperature.

[0075] Optionally, the third temperature T3 includes: a slurry boiling point temperature and an anti-overflow temperature.

[0076] In the embodiment of the present invention, when the third temperature T3 includes the slurry boiling point temperature and the anti-overflow temperature, the temperature measurement can have a standard according to the boiling point temperature and the anti-overflow temperature, which increases the accuracy of the temperature measurement, and the third temperature The temperature T3 is set higher, which can shorten the pulping cycle.

[0077] Optionally, when the third temperature T3 is the anti-overflow temperature: t=t-Δt, Δt is the time from the foaming of the slurry to the foam contacting the anti-overflow electrode; wherein, Δt=k*P+n; k , n is a constan...

Embodiment 3

[0081] The difference between this embodiment and the first embodiment is that the compensation of the temperature of the circuit board inside the head of the cooking device, the temperature of the motor and / or the temperature of the lower cover of the head of the cooking device to the calculation of the slurry quality is added.

[0082] Optionally, the energy conservation law includes: P*η*t=C*m*ΔT+ΔC;

[0083] Among them, P is the heating power within the temperature change ΔT time, η is the heating efficiency, m is the mass of the slurry, t is the heating time, C is the specific heat capacity of water, and ΔC is the mass compensation amount.

[0084] In the embodiment of the present invention, in addition to the energy absorbed by the slurry during heating, the heat absorption and heat dissipation of other components such as the head part will affect the measurement of m, so ΔC is added in the calculation of the slurry quality, that is, other components in the cooking equipm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com