Milk making method of soybean milk machine

A soymilk machine and pulping technology, which is applied to chemical instruments and methods, cleaning methods and utensils, beverage preparation devices, etc., can solve the problems of less blending times of thick pulp, large pulping volume span, and inability to produce large volumes, etc. To achieve the effect of shortening the pulping cycle and uniform pulp quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

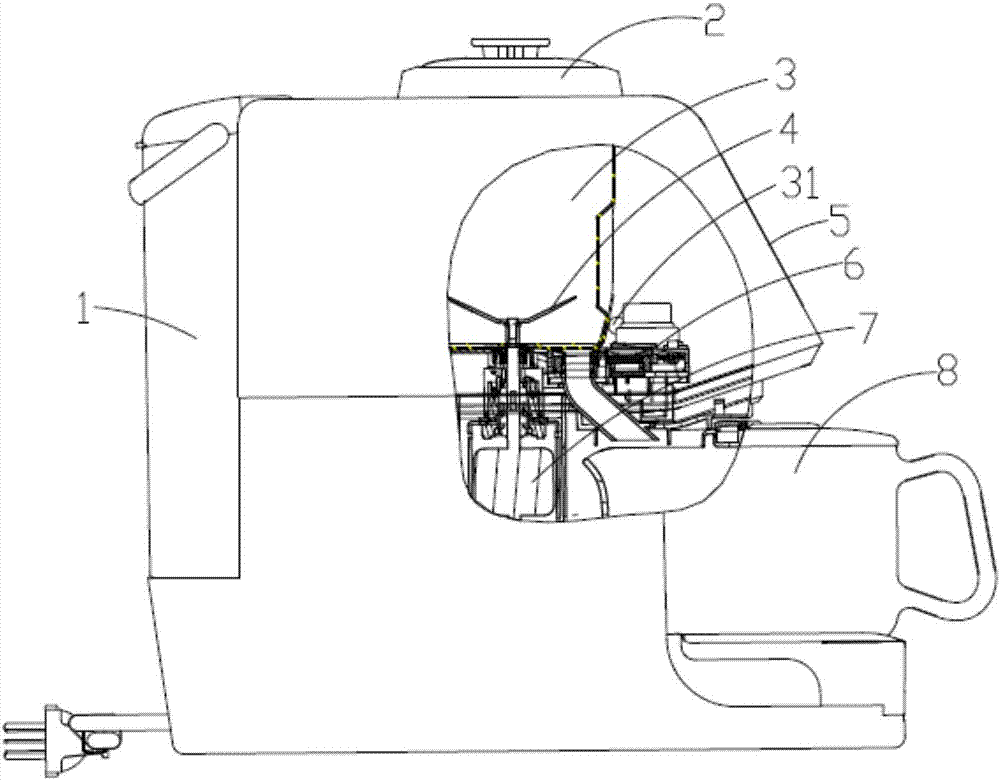

[0034] Such as figure 1 Shown is the first embodiment of the present invention. The soybean milk machine includes a water tank 1, a cup cover 2, and a crushing container 3. The water tank is used to supply water to the crushing container. The heater 31 is arranged at the bottom of the crushing container for heating the crushing container. The motor 7 is arranged at the bottom of the crushing container. The shaft runs through the bottom of the crushing container, the cutter 4 is fixed on the shaft end, the pulp discharge valve 6 is fixed on the bottom of the crushing container, the slurry cup 8 is set at the bottom of the pulp discharge valve, and the operation panel 5 is used to activate the pulping process, which is convenient for users to carry out corresponding processing. Selection of pulping function and pulping capacity.

[0035] In this embodiment, the pulping method of the soymilk machine includes at least two pulping processes with different pulping capacities, where...

Embodiment 2

[0047] The difference between this embodiment and Embodiment 1 is that this embodiment includes more than two pulping capacities, and the soybean milk machine also includes a pulping process with a third pulping capacity V3. When V30.8V, the pulping process of the third pulping capacity is consistent with the pulping process of the second pulping capacity. Here, the third does not mean that the soybean milk machine has three pulping capacities, but refers to any other pulping capacity except the first pulping capacity and the second pulping capacity.

[0048] Here still take the crushing container with a volume of 1000ml as an example. The soybean milk machine has four pulping capacities of 300ml, 600ml, 900ml, and 1200ml. Since the pulping volumes of 300ml and 600ml are less than 0.8V, the pulping process of these two pulping volumes requires The pulping process with the minimum pulping capacity is consistent, that is to say, it is consistent with the pulping process of 300ml ...

Embodiment 3

[0050] The pulping method of the soymilk machine is different from Embodiment 1 in that: the soybean material is crushed in the crushing container to form a raw thick pulp; After heating and curing in the slurry cup, the production is completed.

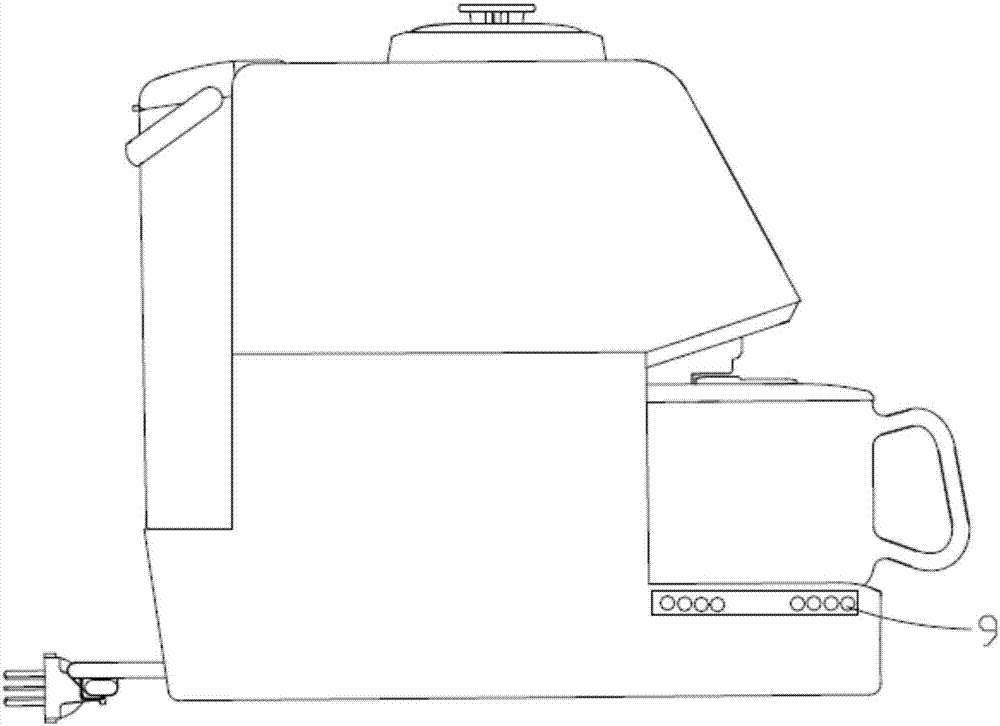

[0051] Therefore, if figure 2 As shown, a heating device 9 is provided at the bottom of the cup 8 of the soymilk machine, and the heating device can be arranged on the cup or the body of the soymilk machine. The liquid is heated. When the soya-bean milk that makes in the pulverizing container is raw thick pulp, be discharged into the soya-bean milk that utilizes heating device 9 butt joints in the milk cup to ripen.

[0052] For example: when the crushing container volume is 1000ml and the pulping volume is 1200ml, the pulping process is as follows:

[0053] Inject 400-500ml of water into the crushing container, and then drive the cutter 4 through the motor 7 to crush the water and food in the crushing container. After the slurr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com