Fully automatic pulp molding multi-station equipment and production process

A pulp molding and production process technology, used in textiles and papermaking, etc., can solve the problems of difficulty in setting the accuracy of the upper and lower template positions, inability to realize the setting mechanism, dislocation of the upper and lower molds, etc., achieving moderate height and small heating deformation , more easily adjustable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

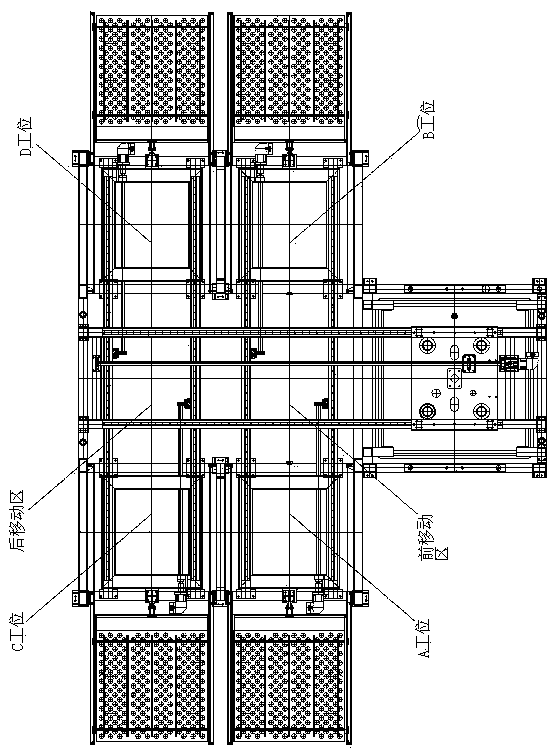

[0052] When using electric heating and heat conduction oil heating, it is a three-station integrated equipment for automatic pulp molding machine, and it is a four-station integrated equipment for automatic pulp molding machine when steam heating is used.

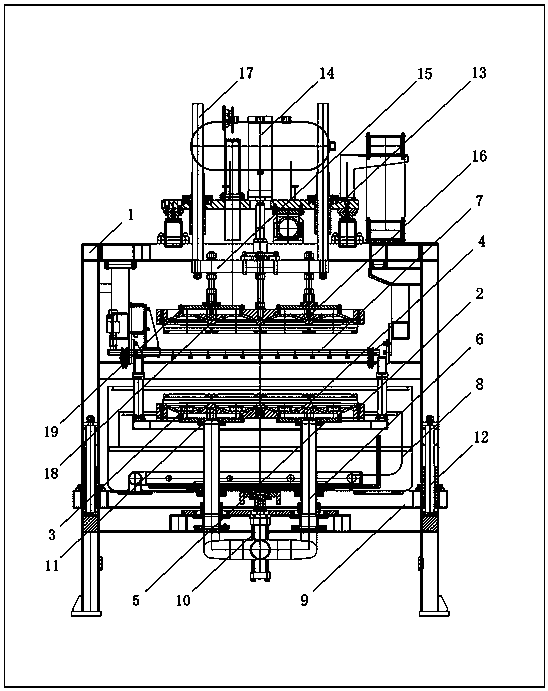

[0053] Adsorption molding device see ( image 3 )and( Figure 4 ) Assembly diagram of the forming mechanism. Including: 1. Forming frame; 2. Forming template; 3. Dispersed airflow baffle; 4. Forming mold mounting plate; 5. Forming formwork air duct cover; 6. Forming formwork main air pipe; , slurry tank; 9, pulp tank support frame; 10, slurry tank lifting drive cylinder; 11, main pipe sealing ring tile cover; 12, pulp tank lifting guide shaft; 13, transfer template support plate; 14, transfer template drive cylinder; 15. Adjustment frame of the transfer template; 16. Transfer template; 17. Guide shaft of the transfer template; 18. Mounting plate of the transfer template; 19. Air channel cover of the transfer template; 20....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com