Pulping method of food processor

A food processing machine and pulping technology, which is applied in the field of food processing, can solve the problems of heavy motor load, jamming, motor stalling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

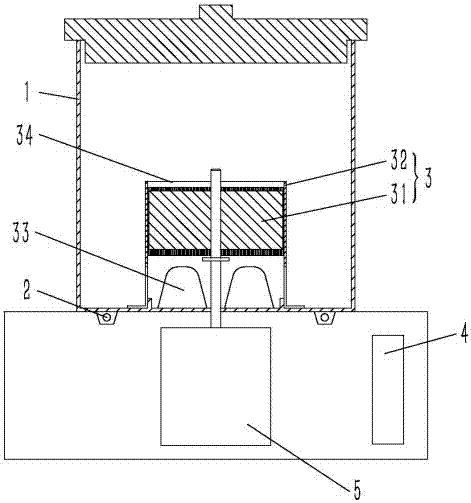

[0016] Such as figure 1 As shown, a food processing machine includes a cup body 1 for holding pulping materials and water, a heating device 2 for heating the pulping materials and water in the cup body, and detecting the temperature of the pulping materials and water in the cup body The temperature detecting device, the grinding device 3 for pulverizing the pulping material and water in the cup body, and the control device 4, the heating device 2, the temperature detecting device, the grinding device 3 and the control device 4 are electrically connected. Wherein, the grinding device 3 includes a dynamic grinding head 31 installed on the rotating shaft of the motor 5 and a static grinding cylinder 32 sleeved on the dynamic grinding head. The motor 5 drives the dynamic grinding head 31 to rotate relative to the static grinding cylinder 32 . The motor in this embodiment is located in the machine base below the cup body 1. Correspondingly, the grinding device 3 is located at the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com