Capacity-self-adaptive pulping method

A self-adaptive pulping technology, applied in applications, dairy products, milk substitutes, etc., can solve the problems of overcooked soybean milk, small pulping capacity range, easy overflow, etc., to achieve accurate pulping capacity and optimal pulping effect , test the exact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

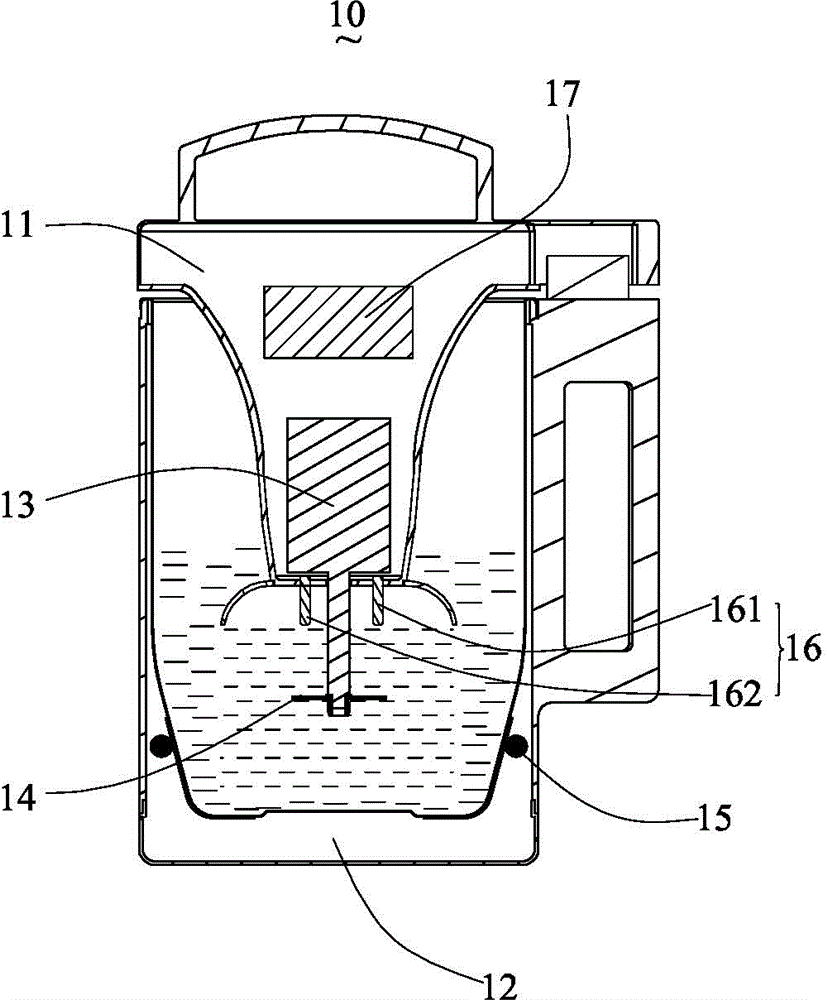

[0030] see figure 1 A schematic diagram of a soymilk machine used in the first preferred embodiment of the capacity-adaptive pulping method, the soymilk machine 10 includes a machine head 11, a cup body 12, a motor 13, a crushing tool 14, a heating device 15, and a temperature sensor 16 and a control device 17, the motor 13 is installed in the machine head 11, the motor 13, the heating device 15, the temperature sensor 16 are electrically connected to the control device 17, the motor 13 drives the crushing cutter 14 to rotate, and the crushing cutter 14 is located in the cup body Inside the cup body 12, the temperature sensor 16 is used to detect the temperature of the slurry in the cup body 12.

[0031] In this embodiment, the temperature sensor 16 includes a first NTC temperature sensor 161 at the T1 temperature point and a second NTC temperature sensor 162 at the T2 temperature point. In this way, the two temperature points of temperature T1 and T2 can be accurately measur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com