Soybean milk maker milk making control method

A control method and technology for a soymilk machine, applied in the directions of preventing overflow, household appliances, and applications, can solve problems such as poor heat dissipation, energy overflow, and low detection temperature, and achieve intelligent control, save pulping cycle, and ensure slurry. effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

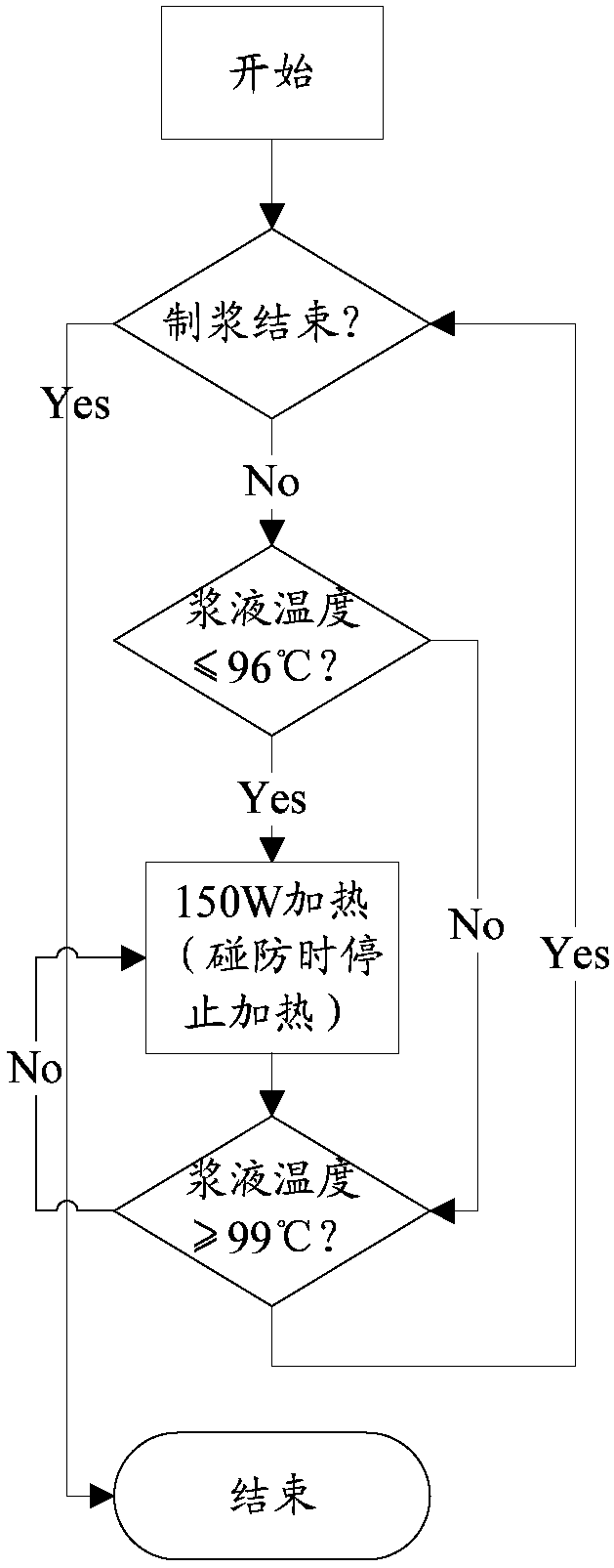

[0055] A method for controlling the pulp of a soybean milk machine. The pulping process of the soybean milk machine includes: a heating stage, a crushing stage and a boiling stage in sequence; figure 1 As shown, the method may include S101:

[0056] S101. In the crushing stage, heat the slurry with a low power according to the temperature of the slurry; wherein, the low power may include: 0-150W.

[0057] In the embodiment of the present invention, in order to solve the overflow problem during the soymilk making process and shorten the soymilk making cycle, low-power heating can be performed during the motor operation and interval waiting process in combination with temperature judgment in the crushing stage.

[0058] Optionally, heating the slurry with low power according to the temperature of the slurry may include:

[0059] Detect the temperature of the slurry in the crushing stage through the preset temperature sensor;

[0060] When the temperature of the slurry is great...

Embodiment 2

[0067] This embodiment further limits the first temperature threshold on the basis of the first embodiment.

[0068] Optionally, the first temperature threshold includes: 92°C-96°C.

[0069] In the embodiment of the present invention, if the first temperature threshold setting temperature is too high, the temperature of the slurry can easily be lower than the first temperature threshold after the heating and anti-collision is completed, and the slurry will be heated again just after the anti-collision. causing overflow problems. If the set temperature of the first temperature threshold is too low, due to low-power heating, the slurry temperature may not meet the requirement by the end of pulping, and there is a risk that the soybean milk will not be cooked. The temperature range of 92°C-96°C can prevent the slurry from overflowing and ensure the degree of cooking of the soybean milk, which is a better value range for the first temperature threshold.

Embodiment 3

[0071] In this embodiment, on the basis of the first embodiment, the value range of the small power is further limited.

[0072] In the embodiment of the present invention, if the heating power is too large, there will be problems of heat accumulation and thermal inertia, which may also cause overflow after collision. However, the low-power heating power in the crushing stage is limited in the range of 0-150W, which can solve the above problems.

[0073] Optionally, the low-power heating power in the crushing stage is preferably 100-120W;

[0074] In the embodiment of the present invention, this power range is selected because: the heating tube is transmitted to the slurry through the steel cup body, and there is a certain energy loss. If the above-mentioned small power is too small, the power actually used for slurry heating will be due to There is not much energy loss left, so the effect of heating the slurry cannot be achieved. If the above-mentioned small power is too la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com