Control method of food processor

A food processing machine, food processing technology, applied in the direction of motor control, control system, adaptive control, etc., can solve the problems of user personal injury, affect user experience, unable to identify the state of hot and cold drinks and adjust the pulping process, etc., to achieve improvement The whole machine is intelligent and the effect of improving the user experience effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

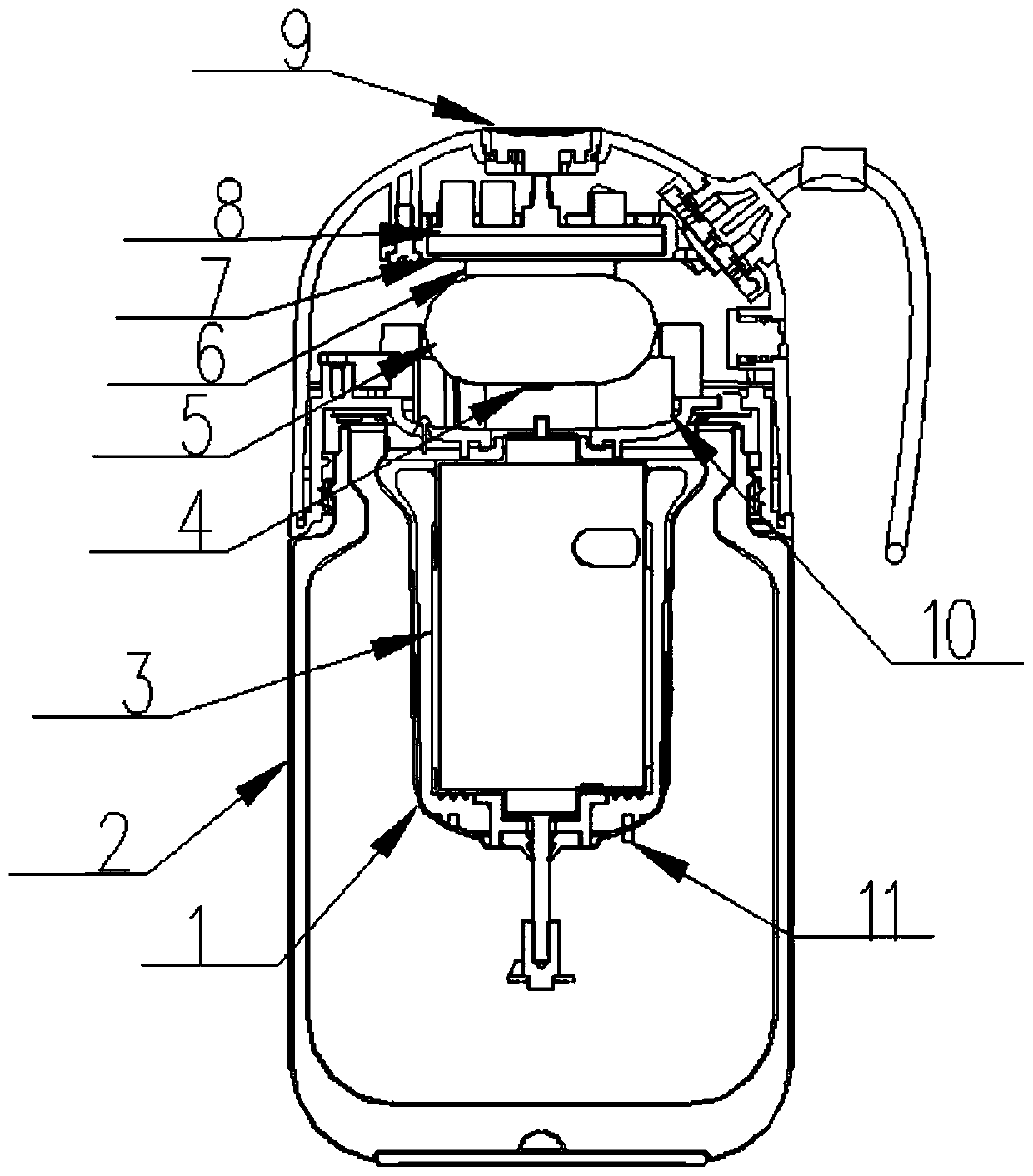

[0063] An embodiment of the present invention provides a control method for a food processor, which may include: a cup body, a machine head, an electrical storage device and a first temperature sensor arranged on the machine head; the food processor The machine is powered by the power storage device, and the method may include S101-S104:

[0064] S101. Detect the temperature T of the material in the cup in real time through the first temperature sensor;

[0065] S102. Calculate the average material temperature TP according to multiple material temperatures T detected within the preset time period t;

[0066] S103. Comparing the average material temperature TP with the preset pulping temperature threshold T0;

[0067] S104. Determine whether the material is cold or hot according to the comparison result, and execute the current food processing function according to the corresponding food processing program according to the determination result; the food processing program may ...

Embodiment 2

[0075] On the basis of the first embodiment, this embodiment provides an embodiment scheme of identifying whether the machine is continuous pulping through the detection and judgment of the first temperature sensor on the machine head combined with the second temperature sensor on the surface of the electrical storage device.

[0076] In an exemplary embodiment of the present invention, the surface of the electrical storage device may be provided with a second temperature sensor; the method may further include:

[0077] detecting the surface temperature Td of the electrical storage device through the second temperature sensor;

[0078] Judging whether the food processing machine is continuous pulping according to the surface temperature Td, and determining the subsequent food processing procedure according to the judgment result and whether the material is cold or hot.

[0079] In an exemplary embodiment of the present invention, when the user closes the cover to start the fun...

Embodiment 3

[0098] On the basis of the first or second embodiment, this embodiment provides specific embodiment schemes with different functions of hot and cold drinks and configuration of different pulping processes.

[0099] In an exemplary embodiment of the present invention, when the system determines that it is a cold drink function, or when the material is determined to be a cold material, the system can match the cold drink pulping process (that is, adopt a cold drink processing program), and the specific program can include: After the user starts the function, The system can start the motor to work at full speed for D seconds, and after the end, the light will be on to remind the user that the pulping is completed.

[0100] In an exemplary embodiment of the present invention, when the system determines that it is a hot drink function, the system can match the hot drink pulping process (that is, adopt a hot drink processing program): after the user starts the function, the system ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com