Stone multi-stage smashing device for ore mining

A crushing device and stone technology, which is applied in the field of ore mining, can solve the problems of not meeting the requirements of building stones, large size of ordinary stones, and affecting the price of ore, so as to ensure safe and stable use, complete crushing, and reduce equipment damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

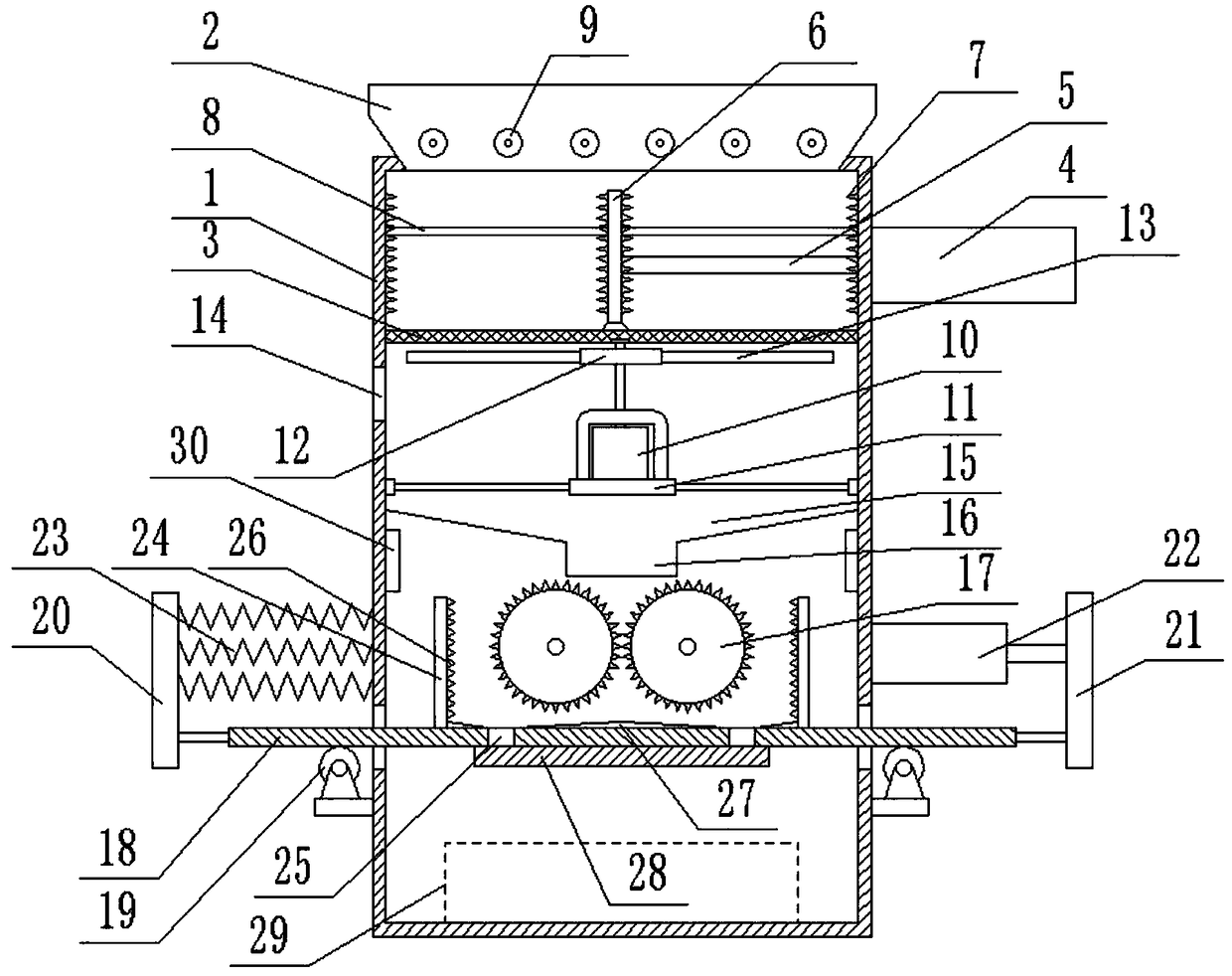

[0020] Please refer to the figure. In the embodiment of the present invention, a multi-stage crushing device for ore using stone materials includes a shell 1, a filler port 2, a screen 3, a drive motor 10 and a crushing roller 17; the filler port 2 is connected to the shell On the top of the body 1, there are a plurality of limiting rollers 9 horizontally distributed in the filling opening 2. The two ends of the central axis of the limiting roller 9 are fixed on the filling opening 2. The limiting roller 9 rotates around the central axis. The distance between them is 30-50mm, and the loaded stones fall from between the limiting rollers 9 to reduce the entry of large stones into the device.

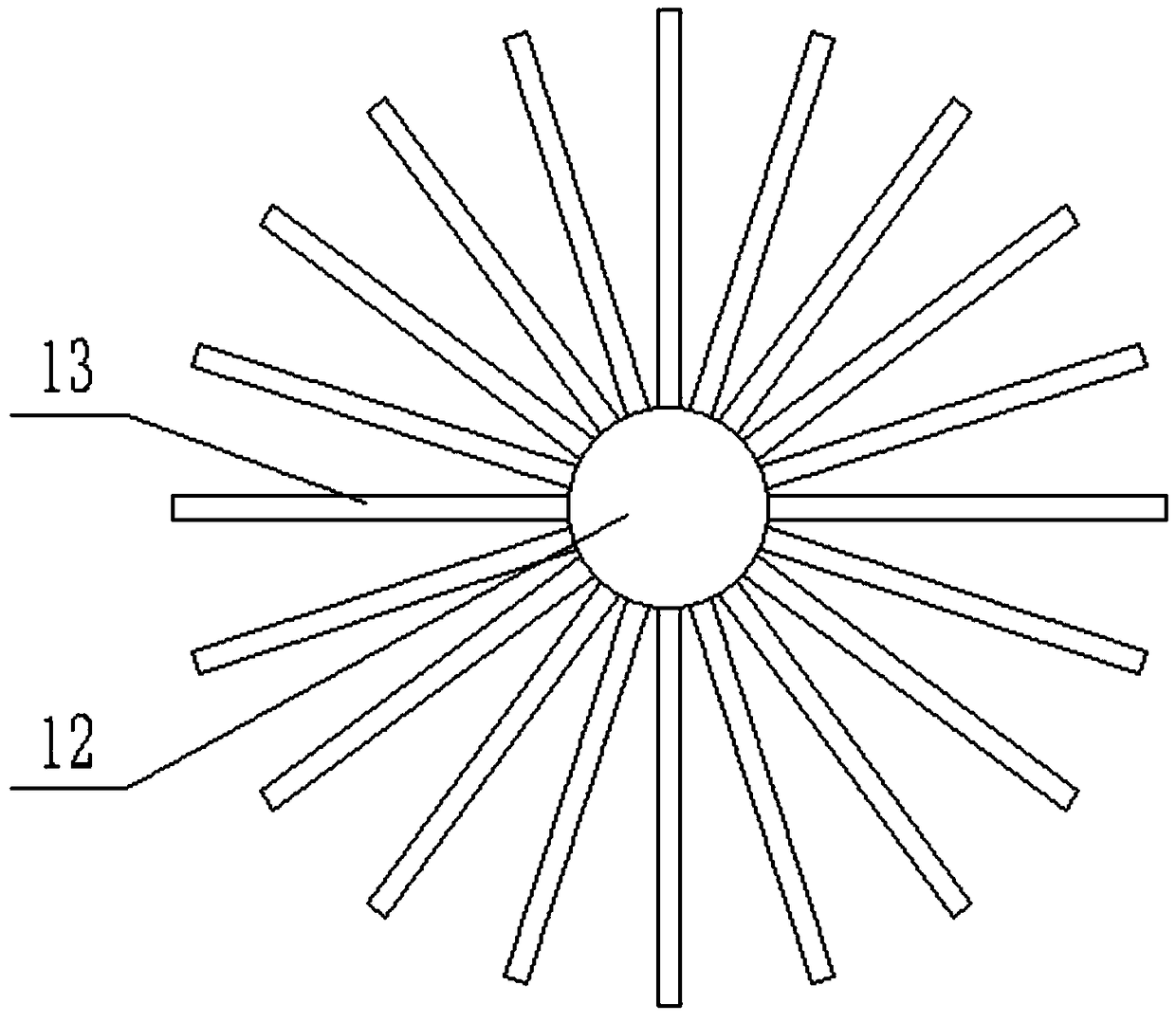

[0021] The upper part of the housing 1 is fixed with a horizontal screen 3, through which the stones are filtered through the screen 3, so that the fine stones fall from the screen 3; a vertical squeeze plate 6 is arranged above the screen 3 The front and rear ends of the extrusion plate 6 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com