Method for preparing phenolic resin and phenolic resin foaming body

A technology of phenolic resin and foam, which is applied in the preparation of phenolic resin and the field of phenolic resin foam, which can solve the problems of low foam compressive strength, low thermal conductivity, high water absorption, etc., and achieve low water absorption, reduce pollution, and content Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention provides a kind of preparation method of phenolic resin, comprises the following steps:

[0029] a) Mix molten phenol, alkali catalyst and alkali lignin, heat up to 170°C-300°C for reflux reaction, the alkali lignin is alkali lignin extracted from crops;

[0030] b) adding formaldehyde to the reaction liquid obtained in the step a), cooling to 60° C. to 90° C. and continuing the reflux reaction to obtain a phenolic resin.

[0031] The present invention uses phenol, formaldehyde and alkali lignin extracted from crops as raw materials to prepare phenolic resin. Since alkali lignin will affect the reaction between formaldehyde and phenol, the present invention first phenolizes alkali lignin, and then reacts with formaldehyde , to obtain a phenolic resin with better activity. In the present invention, the activity of described phenolic resin is characterized by active time, refers to according to ISO9771-1995: the mensuration of false adiabatic temperature ri...

Embodiment 1

[0079] After crushing the corn cobs, cooking them in sodium hydroxide solution, centrifuging the obtained cooking liquor and filtering it with a nanofiltration membrane to obtain a dope with an alkali lignin content of 60%.

Embodiment 2

[0081] To 100 g of molten phenol, add 10 g of a 50% sodium hydroxide aqueous solution and 50 g of the alkali lignin concentrate prepared in Example 1, distill at atmospheric pressure to 170° C., and reflux for 150 minutes, then cool the reaction system to 70° C. , adding 281g of formaldehyde solution with a mass concentration of 37% to continue the reaction for 90min, cooling to 50°C, adjusting the pH value of the reaction system to 7, and vacuum dehydrating the reaction mixture to a viscosity of 9000cp / 25°C to obtain a lignin phenolic resin.

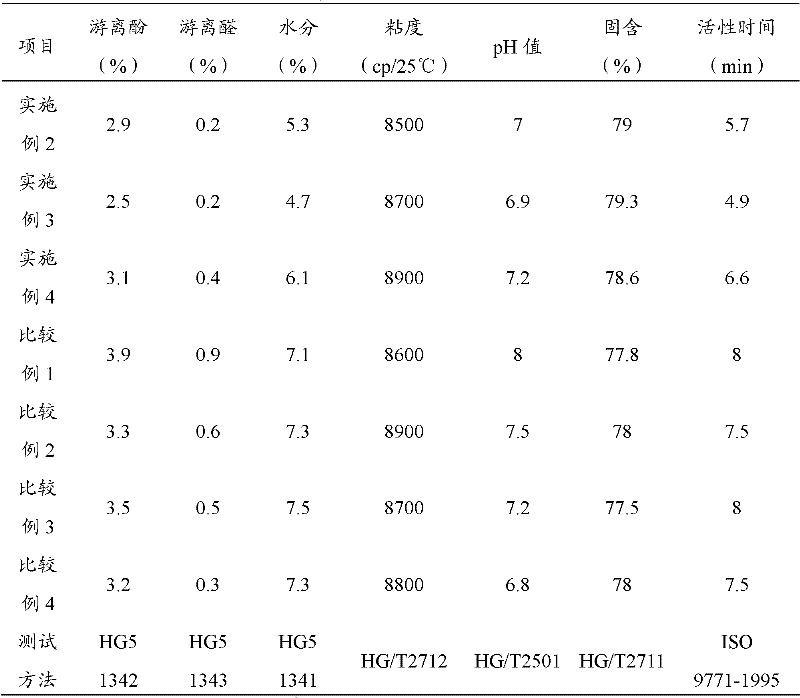

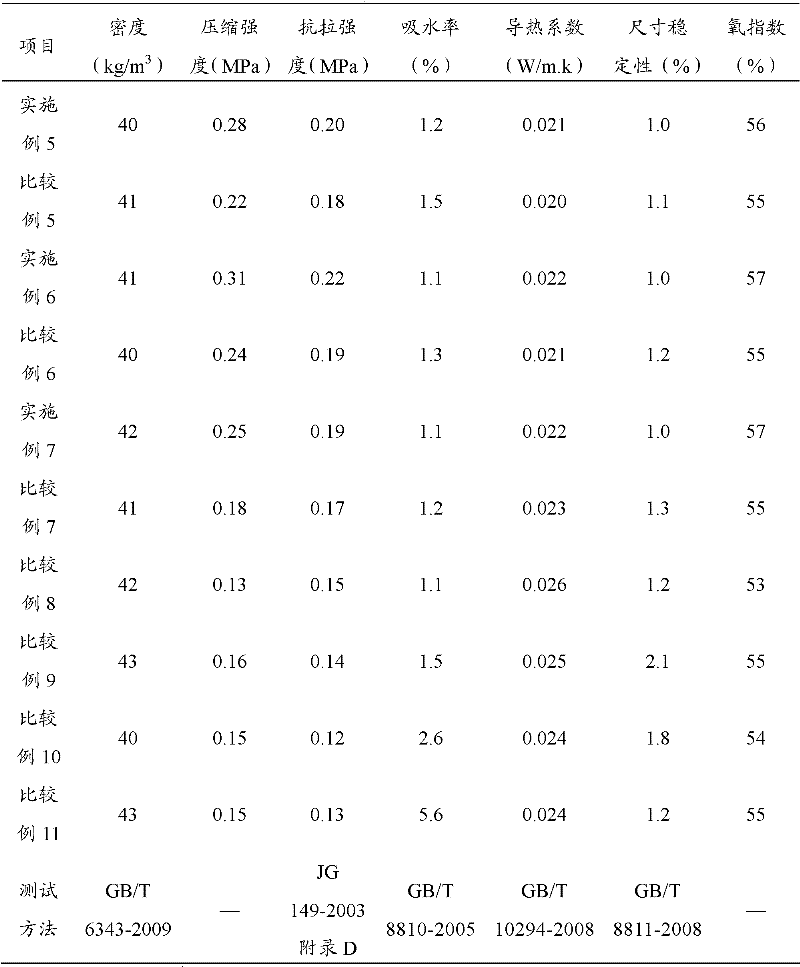

[0082] The performance test of the lignin phenolic resin was carried out, and the results are shown in Table 1. Table 1 shows the performance parameters of the lignin phenolic resin provided by the examples and comparative examples of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com