Electrospun micro-nanofiber reinforced aerogel flexible thermal insulation material and its preparation method

A flexible and fiber-reinforced airgel technology, applied in the field of thermal insulation materials, can solve the problem of affecting the mechanical structure stability of fiber/aerogel composite materials, increasing the gas phase thermal conductivity of composite materials, and reducing the thermal insulation performance of composite materials, etc. problems, to achieve the effect of reducing interface bonding defects, increasing gas thermal resistance and convective heat transfer resistance, and improving thermal energy utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

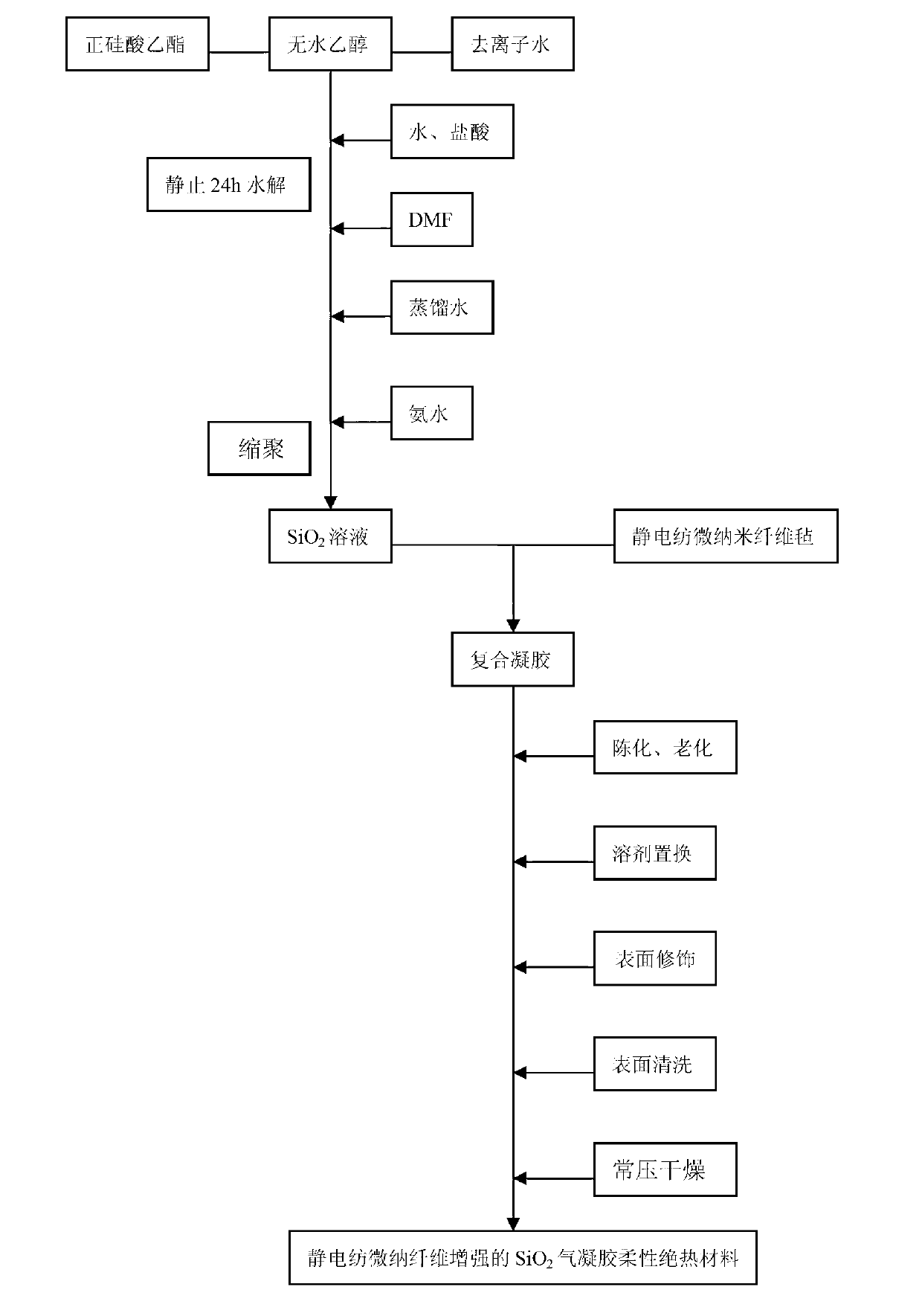

Method used

Image

Examples

Embodiment Construction

[0038] The electrospun micro-nano fiber reinforced airgel flexible thermal insulation material of this embodiment is composed of PVDF (polyvinylidene fluoride) electrospun micro-nano fiber felt and SiO with high thermal insulation performance. 2 airgel composite.

[0039] The preparation steps of electrospun PVDF micro-nano fiber felt are as follows:

[0040] (1) Add PVDF particles to DMF (N,N-dimethylformamide solvent), in which the mass concentration of PVDF is 25%, and stir in a constant temperature water bath at 65°C until PVDF is completely dissolved;

[0041] (2) Using an electrospinning device, the spinning process parameters are: injection speed 0.03~0.04mm min -1 , voltage 12KV, drum receiver distance 15cm, drum running speed 4m·min -1 , the lateral movement speed of the syringe is 12cm·min -1 ;

[0042] (3) Inject the mixture of PVDF and DMF into the syringe, fix it on the metering pump for spinning, and make an electrospun micro-nano fiber mat with a certain thick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com