Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

216results about How to "High market demand" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

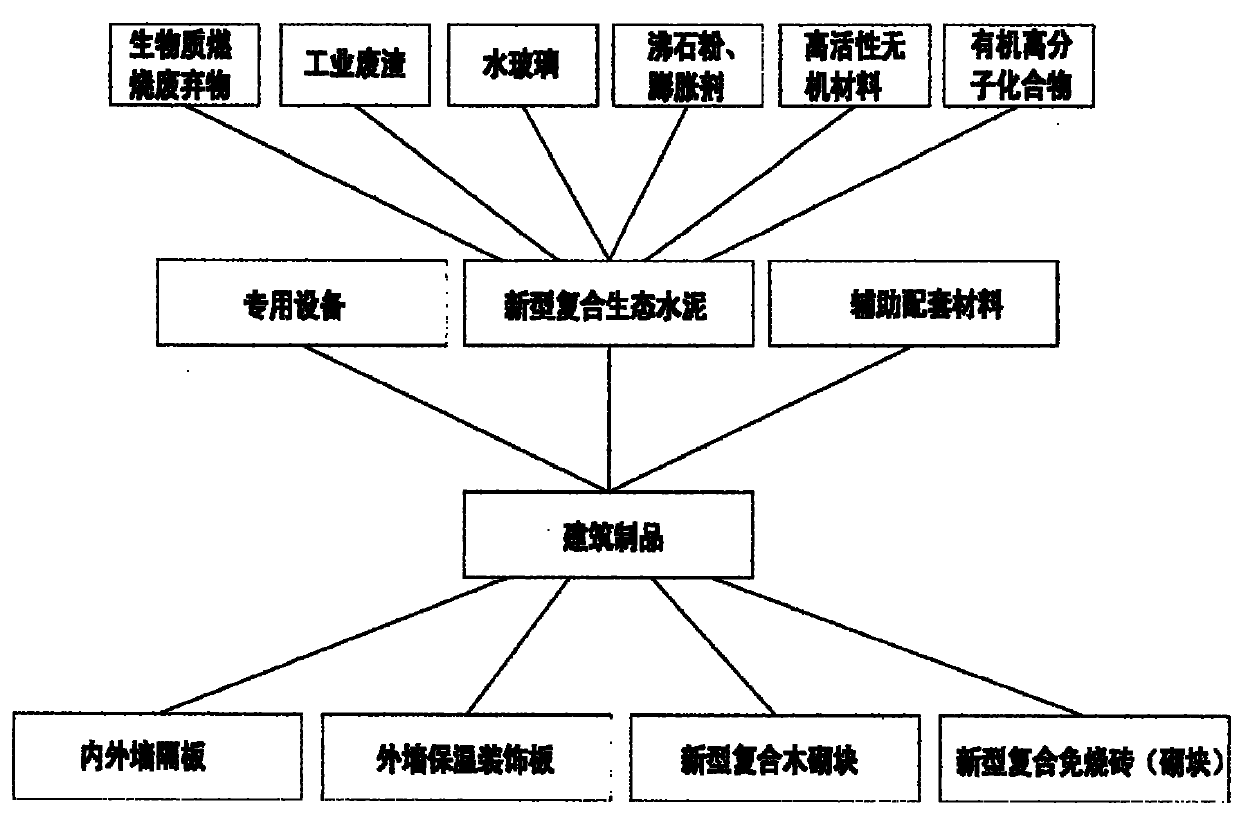

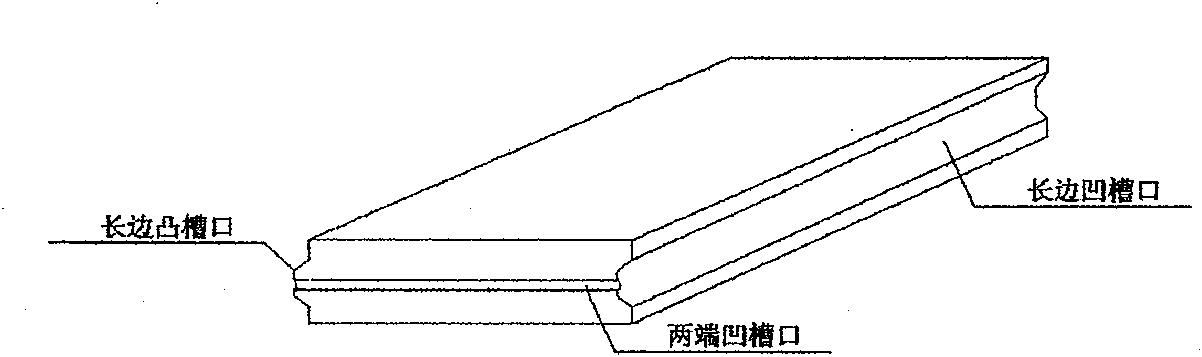

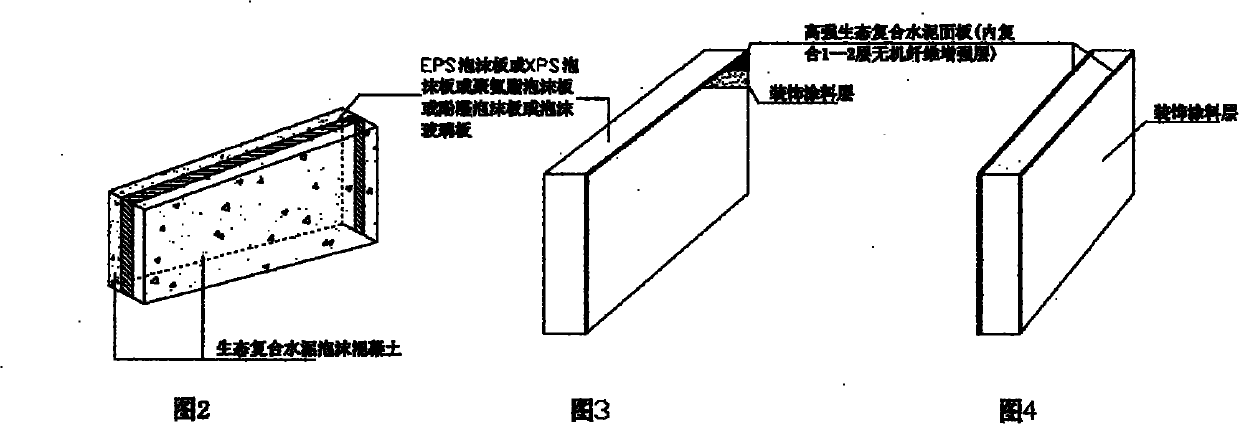

Novel composite ecological cement and product application thereof

InactiveCN101844883AWide range of applicationsHigh market demandSolid waste managementCeramicwareHigh intensityRenewable resource

The invention discloses composite ecological cement produced by using reproducible biomass combustion wastes, industrial residues and the like as main raw materials (the utilization ratio of the biomass combustion wastes and the industrial residues is over 80 percent). The novel gelling material namely the composite ecological cement is combined with other environment-friendly materials such as a paper honeycomb panel and the like to compound and manufacture a novel environment-friendly building product, such as a novel super-lightweight high-strength inner wall composite partition plate (having a dead weight of about 19 kilograms per square meter) special for novel high-rise and multi-layer frame constructions, a 65 percent self-heat preservation lightweight high-strength outer wall partition plate, an outer wall heat preservation and decoration integrative plate, a novel composite wood building block, a novel composite baking-free brick, novel bubble concrete and the like; and all the products are detected by a national level building material detection institution, reach a related product quality standard, are manufactured in factory by using specified machinery, are mounted and manufactured on site and are efficient and economical. The composite ecological cement uses various reproducible resources and various reclaimable wastes to the utmost extent, protects the environment, saves energy, reduces discharge and the overall comprehensive engineering manufacturing cost, and has important economic and social benefits.

Owner:汪超

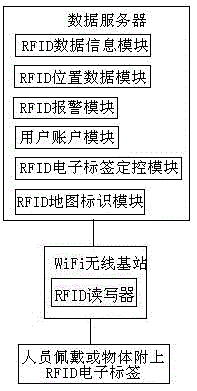

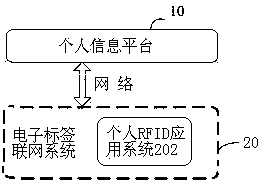

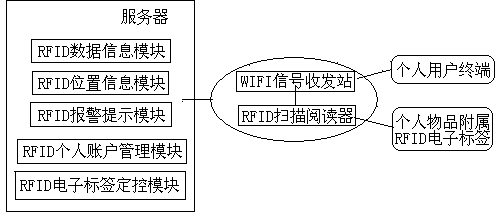

RFID (Radio Frequency Identification) electronic label-based private article monitoring system

InactiveCN103150531AHigh market demandDigital data authenticationSensing record carriersPublic placeData information

The invention relates to a RFID (Radio Frequency Identification) electronic label-based private article monitoring system. Electronic labels are attached on private articles, and a special network information platform is utilized to submit the information of the electronic labels, so that the information of the electronic labels is bound with personal identities and personal communication terminals; when an article is lost, a network platform terminal reports to an owner or a security department, and feeds back the location and time of the appearance of the electronic label belonging to the article; and the RFID electronic label-based private article monitoring system is suitable for tracking and intelligently managing private articles in airports, railway stations, buses, department stores and other public places. The system comprises a data server and the RFID electronic labels, which are connected via a wireless network, the data server comprises a RFID data information module, a RFID position data module or a RFID alarm module, wherein the RFID position data module is used for recoding and tracking the information of the articles with the RFID electronic labels, and the RFID alarm module is used for giving alarm according to the motion of wearers or the articles or / and time.

Owner:周良文

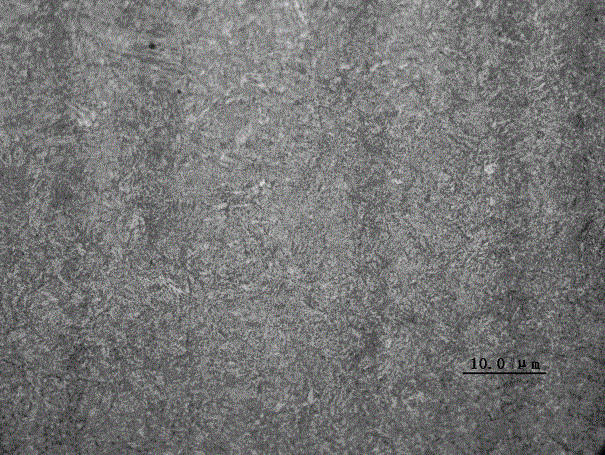

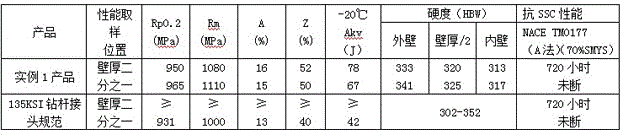

130KSI-grade and 135KSI-grade corrosion-resistant drill tool steel for oil and gas fields and manufacturing method thereof

ActiveCN107177797AImprove strength and toughnessMeet anti-H

<sub>2</sub>

S corrosion characteristics requirementsFurnace typesHeat treatment furnacesMechanical propertyContinuous rolling

The invention relates to high-toughness and hydrogen sulfide corrosion resistant round steel and a manufacturing method thereof. The round steel comprises, by mass, 0.25-0.40% of C, 0.20-0.45% of Si, 0.95-1.50% of Mn, 1.35-1.90% of Cr, less than or equal to 0.002% of S, less than or equal to 0.008% of P, 0.75-1.30% of Mo, 0.10-0.30% of Ni, 0.05-0.25% of V, 0.010-0.050% of Nb, 0.10-0.30% of Cu, less than or equal to 0.050% of Al, 0.0005-0.005% of Ca, and the balance Fe and unavoidable impurity elements. The hot-rolled round steel is produced through a process route of continuous casting-continuous rolling-annealing, the round steel is subjected to heat treatment directly, or a machined semi-finished drill tool is subjected to heat treatment. On the premise that related 130KSI and 135KSI synthesized mechanical properties are met correspondingly, according to an America NACE TM0177 standard hydrogen-sulfide-resistant stress corrosion test, a product is not broken for 720 hours under the condition that 70% of nominal yield stress is pre-loaded in a saturated H2S solution. The material is suitable for 130KSI-strength-grade and 135KSI-strength-grade drill tools under the mining environment of acidic oil and gas fields.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

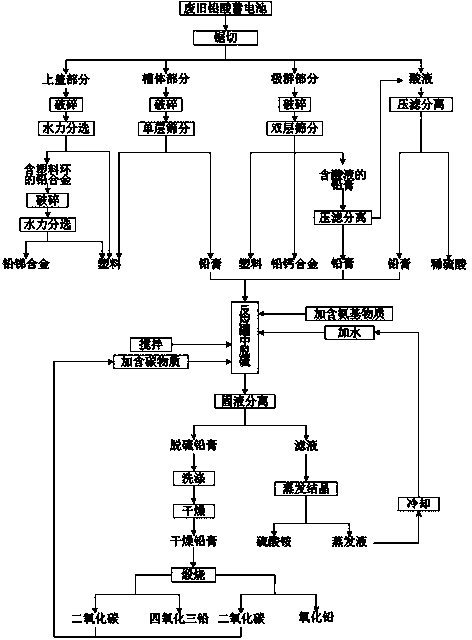

Method for recycling used lead-acid batteries in full circulation mode

InactiveCN103794834AAchieve separationGuaranteed normal processingMetal sawing devicesWaste accumulators reclaimingLEAD TETROXIDELead oxide

The invention relates to a method for recycling used lead-acid batteries in a full circulation mode. According to the technical scheme, a band sawing machine for cutting the used lead-acid batteries is used for sawing and cutting a used lead-acid battery into an upper cover, a groove body, an electrode set and acid liquid, and the upper cover, the groove body, the electrode set and the acid liquid are respectively processed to obtain lead-antimony alloy, plastic, lead plaster, lead-calcium alloy and dilute sulphuric acid. Then, the lead plaster is added into a reaction tank, amidogen-contained substances are added to the lead plaster, stirring is conducted, desulfurization is conducted after carbon-contained substances are added, solid-liquid separation is conducted, and therefore desulfurated lead plaster and filter liquid are obtained. Then, the filter liquid is evaporated and crystallized to obtain ammonium sulfate, and liquid evaporated in the evaporation and crystallization process is cooled to the room temperature and recycled. The washed desulfurated lead plaster is dried, and the dried desulfurated lead plaster is roasted at the temperature larger than 400 DEG C and smaller than or equal to 500 DEG C or at the temperature larger than 500 DEG C and smaller than or equal to 650 DEG C to obtain lead tetroxide or lead oxide. The method has the advantages of being simple in process, low in recycling cost, high in recycling rate, high in product purity and environmentally friendly.

Owner:襄阳远锐资源工程技术有限公司 +1

Low-temperature toughness S355G10+M wide and heavy steel plate for oceanographic engineering and production method of low-temperature toughness S355G10+M wide and heavy steel plate

The invention discloses a low-temperature toughness S355G10+M wide and heavy steel plate for oceanographic engineering. By adopting a compound addition component design of low-carbon, Nb, Ti, Ni and Cr and avoiding addition of V alloy, the cost of raw materials is low; by using a 320mm large section continuous casting billet, under the condition of low compression ratio, a roughing large reductiontechnology is sufficiently exerted, and rolling passes and the rolling reduction rate are reasonably assigned; an S355G10+M product with excellent low-temperature toughness is produced by using a TMCP process technology, and the rolled steel plate does not need subsequent heat treatment such as normalizing, so that the cost of the procedures is low.

Owner:NANJING IRON & STEEL CO LTD

Preparation process of sesame oil with strong flavor

InactiveCN103666744AReduce manufacturing costReduce labor intensityFatty-oils/fats productionBiotechnologyMaillard reaction

The invention provides a preparation process of sesame oil with strong flavor. The sesame oil with strong flavor is prepared via a Maillard reaction. The process comprises the following steps: smashing high-temperature sesame cakes; adding water for dissolving, and mixing; adding alkaline protease for performing enzymolysis; deactivating the enzymatic hydrolysate; mixing the enzymatic hydrolysate with refined sesame oil; heating to 130-150 DEG C; making amino acid in sesame undergo the Maillard reaction with reducing sugar generate a substance with strong flavor; after finishing the reaction, cooling, centrifuging and filtering to obtain the sesame oil with strong flavor. The obtained sesame oil has the advantages of strong flavor, good product quality, low process cost, high yield and easiness in popularizing.

Owner:湖北长坂雄风植物油股份有限公司

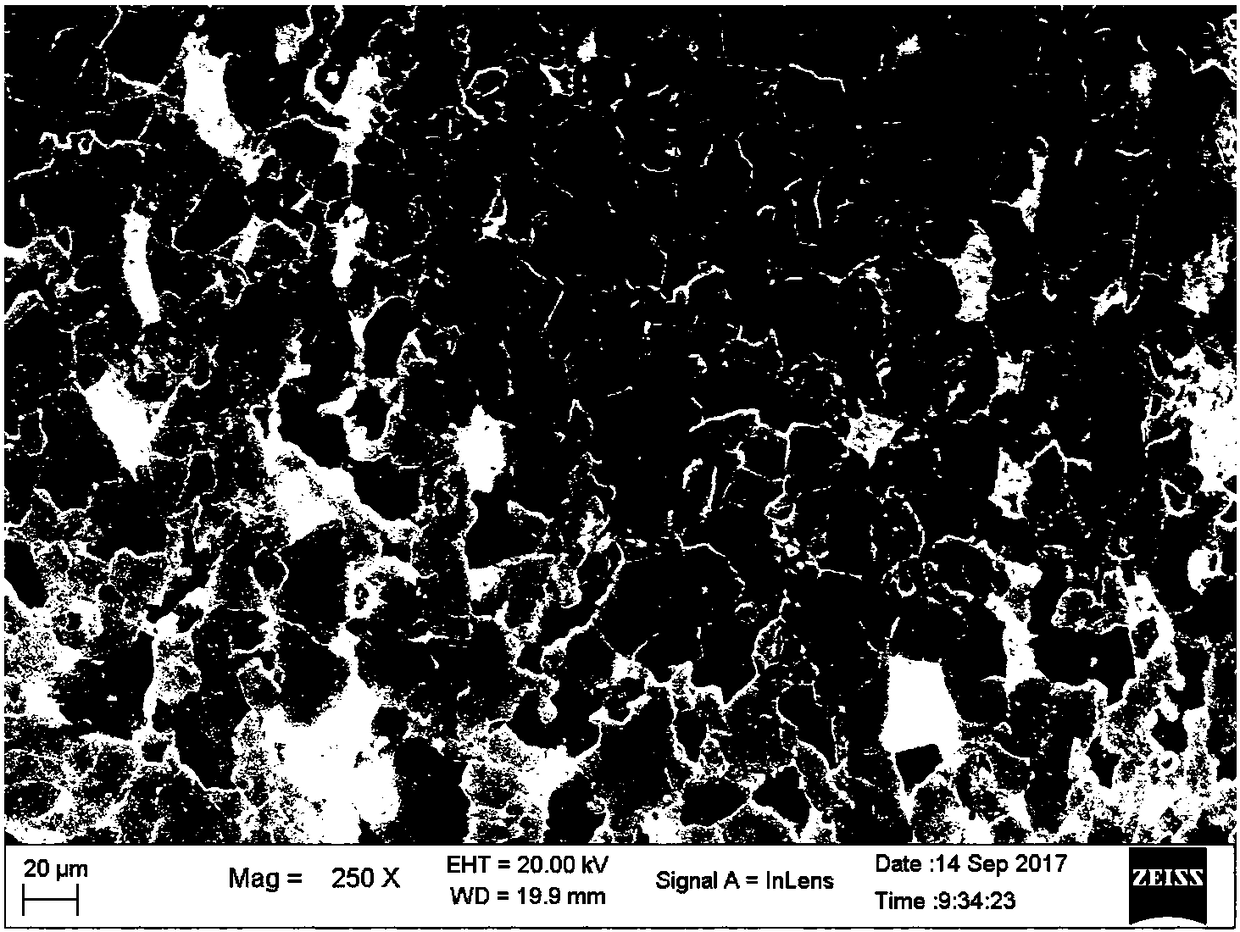

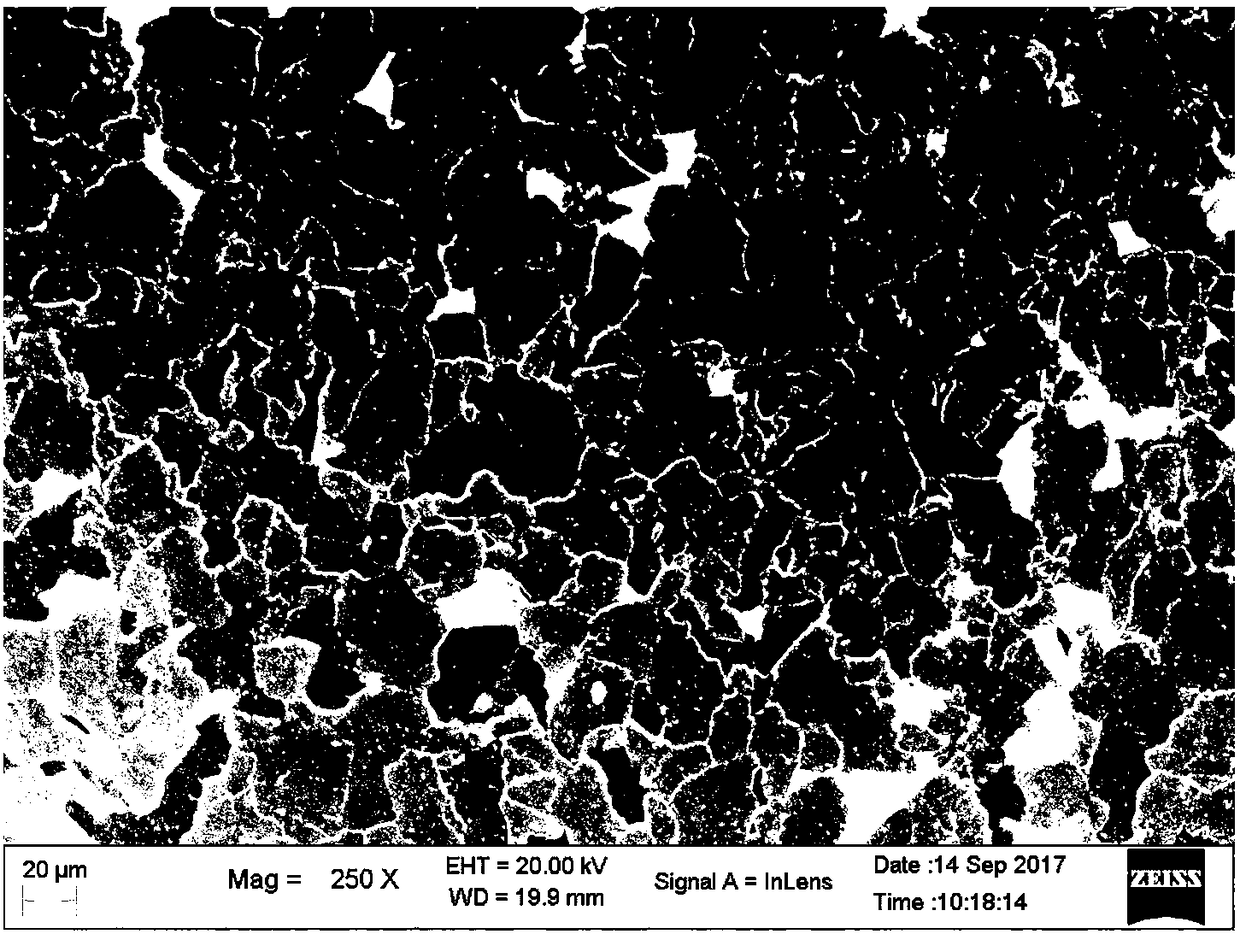

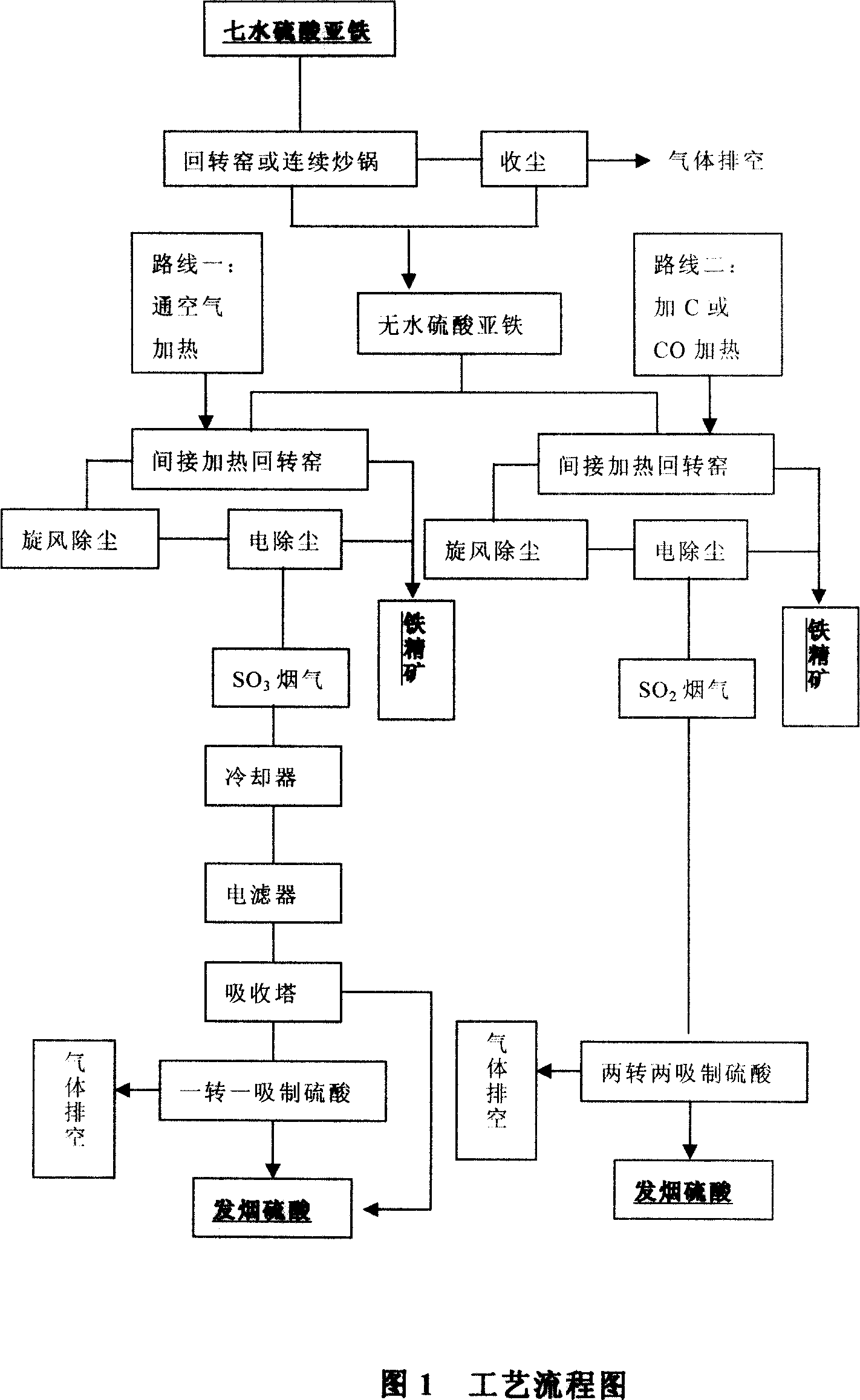

Method for producing vitriol and iron ore concentrate using ferrous sulfate

InactiveCN1994868AReduce adverse effectsAchieve mass productionSulfur-trioxide/sulfuric-acidFerric oxidesTitanium oxideMaterials science

The invention discloses a manufacturing method of sulfuric acid and fine ferric ore based on ferrous sulfate heptahydrate as by-product of titanium oxide, which is characterized by the following: heating anhydrous ferrous sulfate in the rotary kiln at 700-1000 deg. c; decomposing to obtain fine ferric ore and sulfur oxide gas under reducing atmosphere; using normal two-rotation two-adsorption technique to make sulfuric acid; purifying flue gas for sulfur trioxide and little of sulfur dioxide; adsorbing sulfur trioxide through concentrated sulfuric acid to produce fuming nitric acid; making residual sulfur dioxide gas into normal one-rotation one-adsorption technique to make sulfuric acid.

Owner:KUNMING UNIV OF SCI & TECH

Method for producing polymerization cementitious material with red mud and bauxite tailings

ActiveCN102491657ASolve pollutionSolve resource problemsCement productionRed mudBiological activation

The invention relates to a method for producing a polymerization cementitious material through comprehensive utilization of red mud and bauxite tailing resources. The method is characterized in that the production process adopts red mud and bauxite tailings as main raw materials, which are subjected to drying, batching, high temperature activation, admixture adding, ball milling and other processes in order so as to obtain a cementitious material. After encountering water, the material undergoes a polymerization reaction and form strength. Tests show that the obtained product has the characteristics of high strength, no alkali-aggregate effect, low cost and good cohesiveness, etc. The method provided in the invention can effectively solve the environmental pollution and resource problems of red mud and bauxite.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

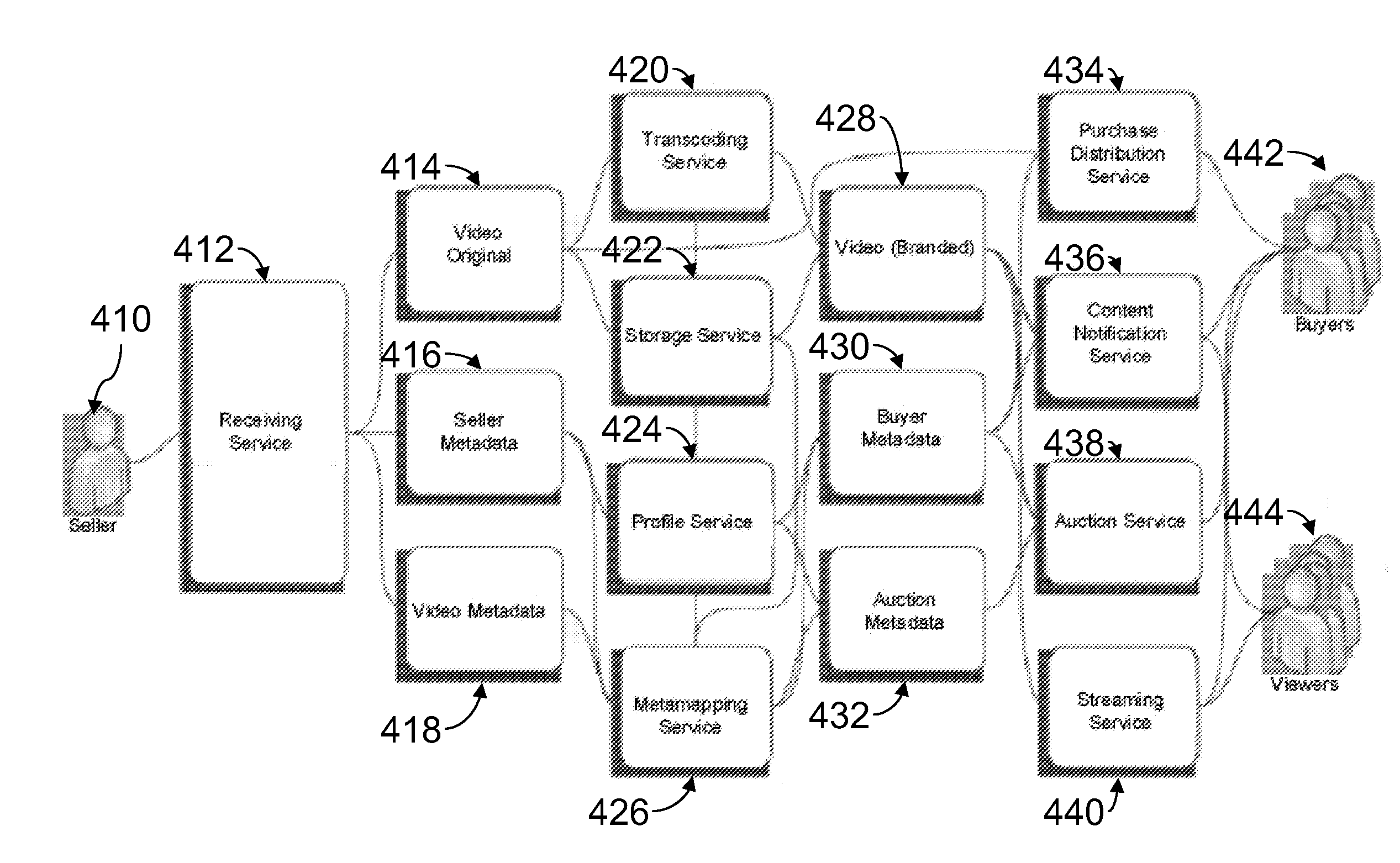

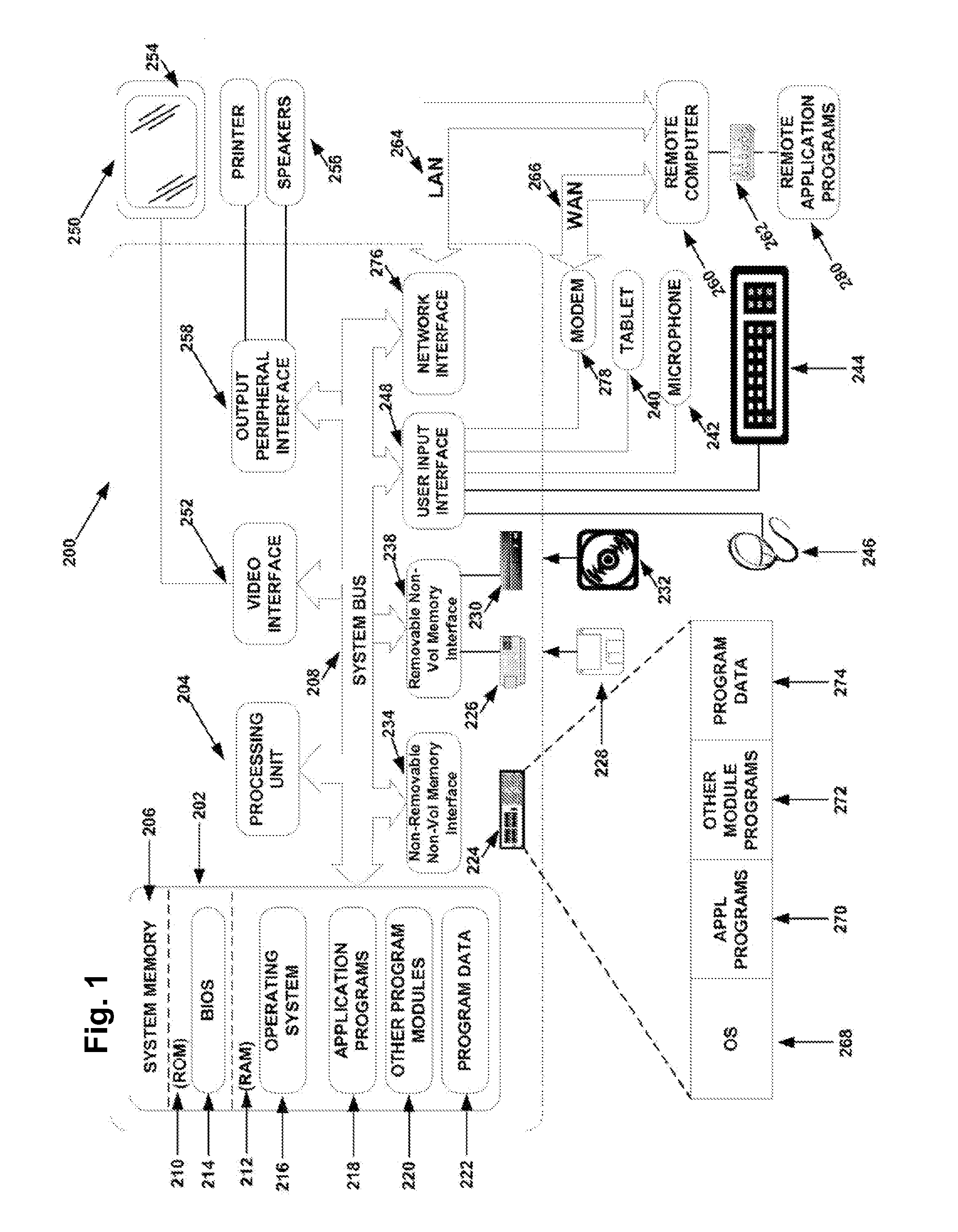

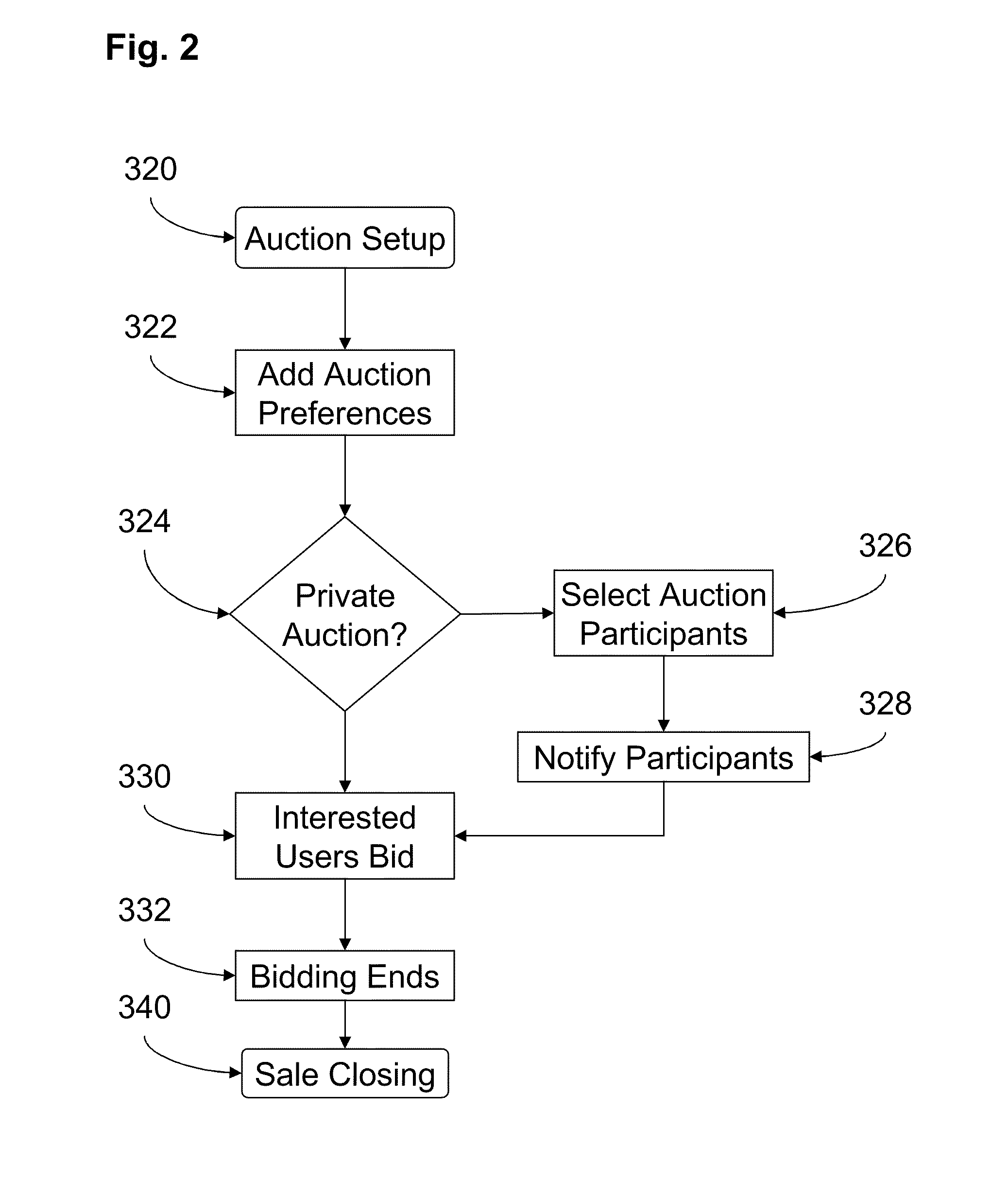

Method, system, and storage device for an online content marketplace and exchange

InactiveUS20090259564A1High market demandIncrease contentCredit schemesCommerceInternet privacyEncryption

A method, system, and storage device for an online content marketplace and exchange which enables independent content creators to protect their content while permitting interested buyers to financially compete over the rights to the content, thus achieving true market value for the creator based upon the market's willingness to pay for the content. The method is capable of receiving content (e.g. video, audio, image, etc.), transcoding the content, applying encryption and watermarks, configuring an auction, conducting the auction, finalizing the auction, and releasing the original content to the winning bidder.

Owner:BARKERDING THOMAS PIKE

Method for extracting TiO 2 and SiO 2 in blast furnace slag

The invention relates to a method for extracting TiO 2 and SiO 2 in blast furnace slag, comprising the steps of dissolving the blast furnace slag with hydrochloric acid, treating the filtrate with alkali, separating TiO 2 and the SiO 2, and the like. The method can completely recover titanium component and silicon component in the blast furnace slag, and has low cost, little pollution and high efficiency.

Owner:MICROVAST POWER SYST CO LTD

Production method of earthworm cast-based ecological organic fertilizer

InactiveCN102649652AReduce energy consumptionImprove recycling rateBio-organic fraction processingProductsWater contentChemistry

The invention discloses a production method of an earthworm cast-based ecological organic fertilizer. The production method comprises the following steps of: selecting organic solid waste with carbon-nitrogen ratio of 1:23-28 as a matrix, wherein the water content is 52-68 percent and the pH value is 6-7; inoculating 1-2 kg of Daping No. 2 earthworms into the matrix every square meter at 15-25 DEG C; separating continuously produced earthworm cast to serve as a raw material for producing the organic fertilizer; adding a rotten organic fertilizer which is inoculated with antagonistic bacteria into the earthworm cast; after performing amplification culture on the beneficial microorganisms therein; adding an insect repellent plant material therein according to the amount which is 0.5-4.5 percent of the weight of the materials; uniformly mixing to obtain the ecological organic fertilizer. The production method has the characteristics of rational design, convenience in operation, large-scale application and environmental friendliness; the prepared organic fertilizer has a good application effect and high applicability; and the produced organic fertilizer integrates the characteristics of a microbial fertilizer, an organic fertilizer and an inorganic fertilizer and has the characteristics of multiple functions, multiple effects and full nutrition.

Owner:宋忠俭

Deep-drawn-grade Ti-IF cold-rolled steel plate and preparation method thereof

The invention discloses a deep-drawn-grade Ti-IF cold-rolled steel plate. The cold-rolled steel plate comprises the following chemical components in percentage by mass: 0.001-0.003% of C, 0.004-0.006% of Si, 0.14-0.16% of Mn, P not more than 0.010%, S not more than 0.006%, and 0.055-0.075% of Ti. The invention further discloses a preparation method of the deep-drawn-grade Ti-IF cold-rolled steel plate. A steel strip prepared by the deep-drawn-grade Ti-IF cold-rolled steel plate has such performances as low yield ratio, excellent plasticity, high plastic strain ratio and excellent punching formation, and is suitable for the demands of such complex forming modes as the punching process.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Personal article monitoring integrated application system based on RFID electronic tag

InactiveCN103886273APrevent and reduce silo problemsQuality improvementDigital data authenticationSensing record carriersPublic placeElectronic tagging

Owner:周良文

Culture medium for producing selenium-enriched pleurotus eryngii

A culture medium used for producing Se-enriched pleurotus eryngii is prepared by mixing cotton seed coats, bran coats, corn cobs, Astragalus roots and / or leftovers of Ganodorma lucidum, pulverized lime, gypsum powder and corn flour through sterilization. By adopting the culture medium for the Se-enriched pleurotus eryngii, the produced Se-enriched pleurotus eryngii has a Se content which is increased to 0.368 percent from 0.023 percent of the common culture media, namely, improved by 16 times, simultaneously, the organic Se occupies 99.5 percent of the full Se. The raw materials of the culture medium have wide sources and low cost, the produced leurotus eryngii with high nutritive value and large market demand.

Owner:SHANXI TAIYUE EDIBLE FUNGUS

Starch based biodegradable flexible packing materials, and preparation method

A biological degradable soft packing material of starch base is a type of soft film packing material made of starch, plasticizer and filler. The material can be degraded thoroughly under natural condition after it is buried underground for 3-4 monthes.

Owner:郭志伟

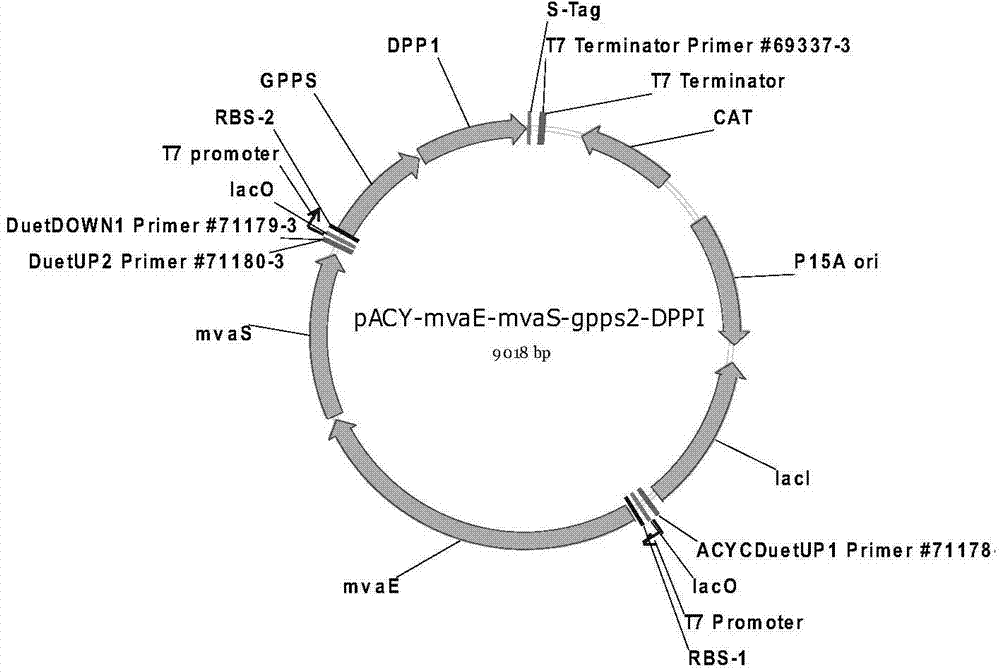

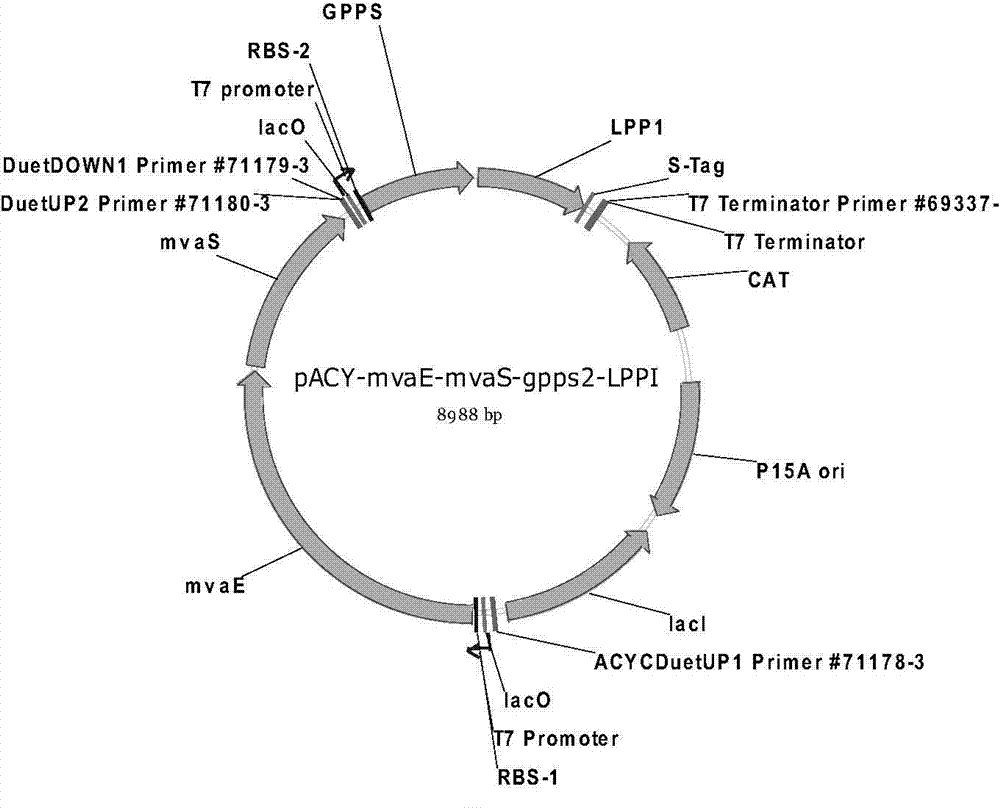

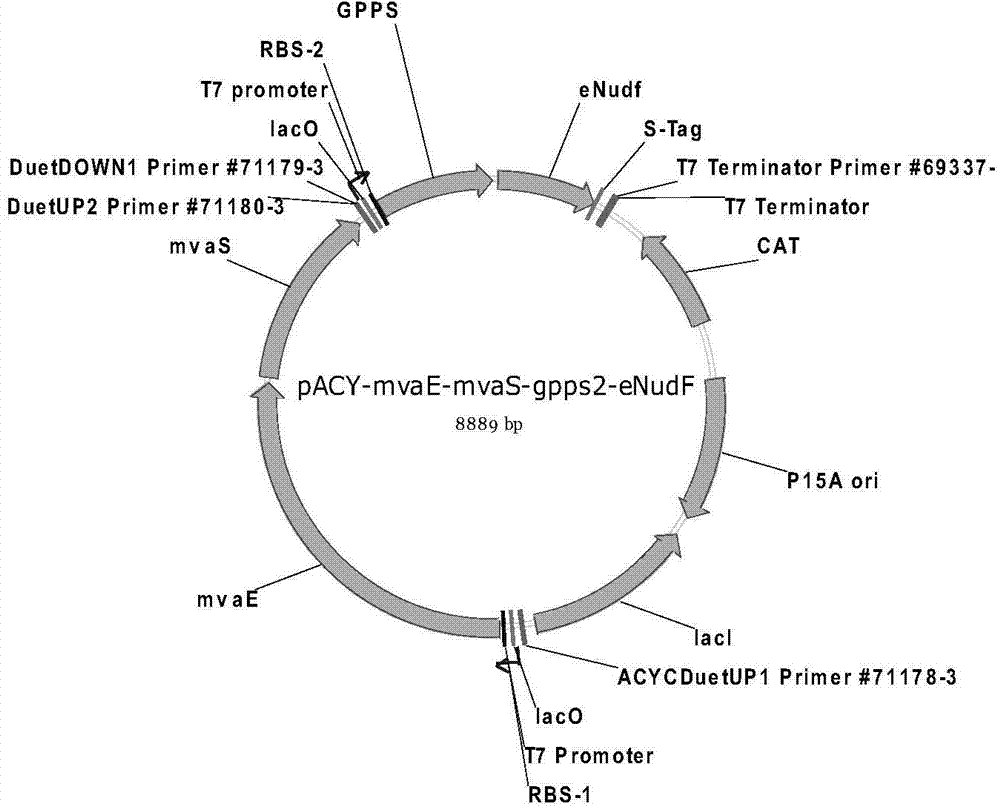

Genetically engineered bacterium co-generating geraniol and nerol and construction method and application thereof

ActiveCN103898037AFast growthShort fermentation cycleBacteriaMicroorganism based processesEscherichia coliGenetically engineered

The invention discloses a genetically engineered bacterium co-generating geraniol and nerol and a construction method and an application thereof, and belongs to the technical field of generic field. According to the genetically engineered bacterium disclosed by the invention, acetyl coenzyme A acyltransferase / hydroxymethyl glutaryl coenzyme A reductase, 3-hydroxyl-3-methyl glutaryl coenzyme A synthase, mevalonic acid kinase, mevalonic acid-5-phosphokinase, mevalonic acid-5-diphosphonic acid decarboxylase, isopentenylpyrophosphate isomerase, geranyl diphosphonic acid synthetase and geraniol synthetase or phosphatase are expressed. The metabolic pathways of geraniol and nerol synthesized in escherichia coli are successfully constructed by genetic engineering means, and glucose is biologically converted into geraniol and nerol.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Thermal-insulating block and manufacturing process thereof

ActiveCN101838130AAppropriate dry bulk densityReduce wearSolid waste managementCeramic shaping apparatusSlagThermal insulation

The invention discloses a thermal-insulating block which uses dry-method desulphurized ash as a main raw material and also comprises 30 to 50 percent of micropowder slag waste material or fly ash in weight percentage content. In the invention, the dry-method desulphurized ash and the slag or the fly ash are utilized as the main raw materials of the thermal-insulating block, the characteristic of smaller original relative humidity of the dry-method desulphurized ash is fully utilized, and a light thermal-insulating block with certain and suitable dry volume density is obtained by controllingproper temperature and through autoclaved curing. In the invention, an aggregate is synthesized by utilizing the dry-method desulphurized ash and the micropowder slag or the fly ash as the raw materials, and other aggregates do not need to be added, thereby the abrasion of production equipment is reduced, the processing process is simplified, the comprehensive utilization of the dry-method desulphurized ash solid waste is finally realized, and meanwhile, the energy saving and the thermal insulation of a product are realized by utilizing the characteristics of low thermal conduction coefficient and good thermal-insulating effect of the dry-method desulphurized ash material per se.

Owner:FUJIAN LONGKING

S460G2+M steel plate for seaborne weldable structure and production method thereof

ActiveCN108374122AAchieve economyIncrease production capacityFurnace typesHeat treatment furnacesSteelmakingSlow cooling

The invention discloses an S460G2+M steel plate for a seaborne weldable structure and a production method thereof and relates to the field of metallurgy. The production method comprises the followingsteps: carrying out steelmaking: utilizing a large-section continuous casting blank and adopting a continuous casting blank type C segregation accurate control technology to segregate the center of the continuous casting blank for C0.5 and C1.0 grades; heating: adding the casting blank into a heating furnace and heating, wherein the heating coefficient is greater than or equal to 10.0min / cm and the heating temperature is 1180 to 1220 DEG C; rolling: under a low compression ratio, adopting a two-stage controlled rolling technology, wherein the temperature of first-stage rolling is 980 to 1150 DEG C, the final two-path reduction rate of rough rolling is greater than or equal to 20 percent and the initial rolling temperature of the second stage is less than or equal to 820 DEG C; cooling: putting a rolled steel plate into an ultra-rapid cooling system and rapidly cooling, wherein the re-reddening temperature is 550 to 590 DEG C; then carrying out stacking and slow cooling, wherein the stacking time is 72h or more. The steel plate developed by the invention reach performance requirements of EN10225 standards, and economical and batch production of the steel plate can be realized; utilization requirements under seaborne various working conditions and bad natural environments are met.

Owner:NANJING IRON & STEEL CO LTD

Environment-friendly mono-component polyurethane waterproof paint and preparation method thereof

InactiveCN103865374AEasy constructionEasy to operatePolyurea/polyurethane coatingsPlasticizerPrepolymer

The invention relates to a polyurethane waterproof paint and a preparation technology thereof, and aims to provide an environment-friendly polyurethane waterproof paint capable of being prepared through a simple method and a preparation method thereof. The preparation method comprises the following steps: (1) preparing a prepolymer: adding polyether and a plasticizer into a reactor to carry out a dehydration treatment; after the water content in the system meets the requirement, adding MDI into the reactor, carrying out reactions at a temperature of 70 to 100 DEG C for a while, cooling the reactor to a temperature of 40 DEG C or less, discharging the materials, and storing the materials in a sealed container; (2) heating the prepolymer obtained in the step (1) to a temperature of 50 to 60 DEG C, adding an inorganic filler, which has been dried in advanced, a catalyst, and other auxiliary agents into the prepolymer, and evenly stirring so as to obtain the target product. The environment-friendly mono-component polyurethane waterproof paint has the advantages of simpler construction, more convenient operation, no free TDI in the paint, little odor, benefit for environment and health of workers, and large market demand.

Owner:哈尔滨六环涂料化工有限公司

Chrome free or less chrome main tanning agent for leather and preparation process thereof

InactiveCN1465718ALow priceRich varietyAntifouling/underwater paintsTanning treatmentReduced doseTannin

The leather tanning agent having no chrome or having little chrome is made up by using amine material containing carboxymethyl group and aliphatic aldehyde compound through the processes of N-carboxymethylation reaction and ring-closing reaction. In addition to oxazolidine naphthenicbase its molecular structure also contains several functional groups of aldehyde group, carboxyl group, hydroxyl group and quaternary amino-group. Said main tanning agent can be combined with vegetable tannin extract, also can be combined with chrome for tanning leather, and can raise wet and thermal stabilizing of the finished leather and reduce dose of chrome by 30-40%.

Owner:SICHUAN UNIV

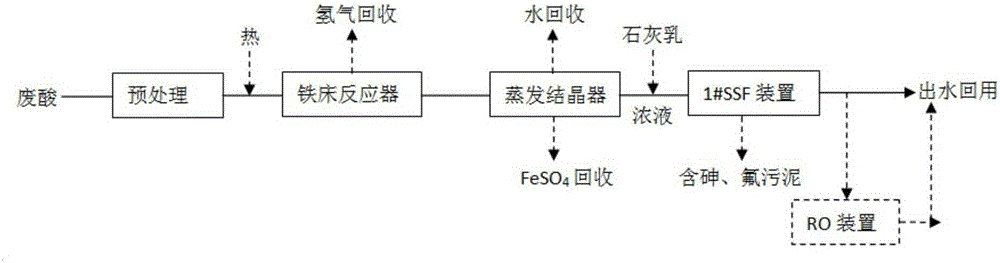

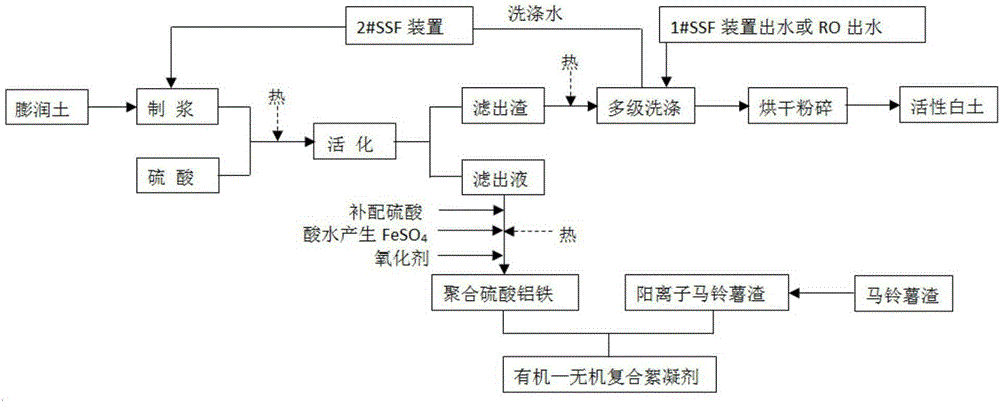

Method for recycling waste acid generated in production of sulfuric acid from smelting flue gas

ActiveCN105217869AReduce processingSolving Seasonal Storage ProblemsEnergy inputMultistage water/sewage treatmentAluminium saltsFlue gas

The invention provides a method for recycling waste acid generated in production of sulfuric acid from smelting flue gas. The method comprises the following steps: reducing waste acid by using Fe, performing evaporative crystallization to obtain FeSO4 crystals, enabling FeSO4 crystals to react with filter liquor, sulfuric acid and an oxidant generated in the activation step of producing activated clay from bentonite, so as to obtain polymeric aluminum ferric sulfate; selectively, enabling polymeric aluminum ferric sulfate to react with an organic flocculating agent, so as to obtain an organic-inorganic composite flocculating agent. According to the recycling method, the waste acid generated in the production process of sulfuric acid from smelting flue gas is adopted as a main raw material, and waste heat of smelting flue gas is utilized to produce the activated clay and the organic-inorganic composite flocculating agent which have broad markets in various industries, so that the problems about recovery of waste heat of high-temperature flue gas, treatment of waste acid, and seasonal storage of by-product sulfuric acid are solved; besides, plenty of valuable industrial products can also be produced; therefore, the method has quite high social benefit, environmental benefit and economic benefit.

Owner:BEIJING OTC ENERGY & ENVIRONMENT ENGINEERING PUBLIC LIMITED COMPANY

Chinese medicine for treating femoral head necrosis

InactiveCN101020023AEffective treatmentEasy to useAnthropod material medical ingredientsInorganic active ingredientsEpimediumCurative effect

The present invention is one kind of Chinese medicine for treating femoral head necrosis and belongs to the field of medicine technology. The material for the Chinese medicine includes prepared rhizome of rehmannia, drynaria rhizome, epimedium, cistanche, astragalus root and other 20 kinds of Chinese medicinal materials. The present invention has the advantages of high curative effect, high safety and low cost, and opens one new way for the non-operation treatment of femoral head necrosis.

Owner:赵文海 +1

Low-carbon, environment-friendly and energy-saving high-level ecotype door and manufacture method thereof

InactiveCN103144179ASave resourcesProtect environmentPaper/cardboardWood veneer joiningSpray coatingSingle plate

The invention provides a low-carbon, environment-friendly and energy-saving high-level ecotype door and a manufacture method of the ecotype door. According to the ecotype door on the market currently, a base material is generally made from the China fir and the African soft and impure pine batten, a low-level agglutinate plywood is taken as an edge frame, and the corner crushed aggregates and the honeycomb paper are taken as filler. The manufacture method of the low-carbon, environment-friendly and energy-saving high-level ecotype door comprises the following five steps of 1, symmetrically arranging single boards by a transverse-lengthways-transverse structure to form a multi-layer board; 2, overlapping two door boards with the thickness of 15-25cm into a standard door board; 3, pressing melamine impregnating resin-impregnated surface-layer decorative paper and shortened density board; 4, thermally pressing the milled door surface board and the door board into the ecotype door; and 5, printing wood grain on the side edge of the door in a transferring way, and carrying put spray coating. The method is used for manufacturing the low-carbon, environment-friendly and energy-saving high-level ecotype door.

Owner:张福贵

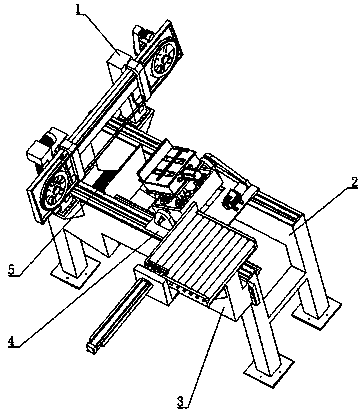

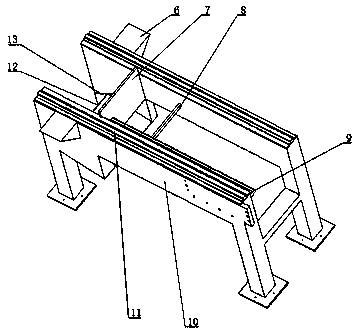

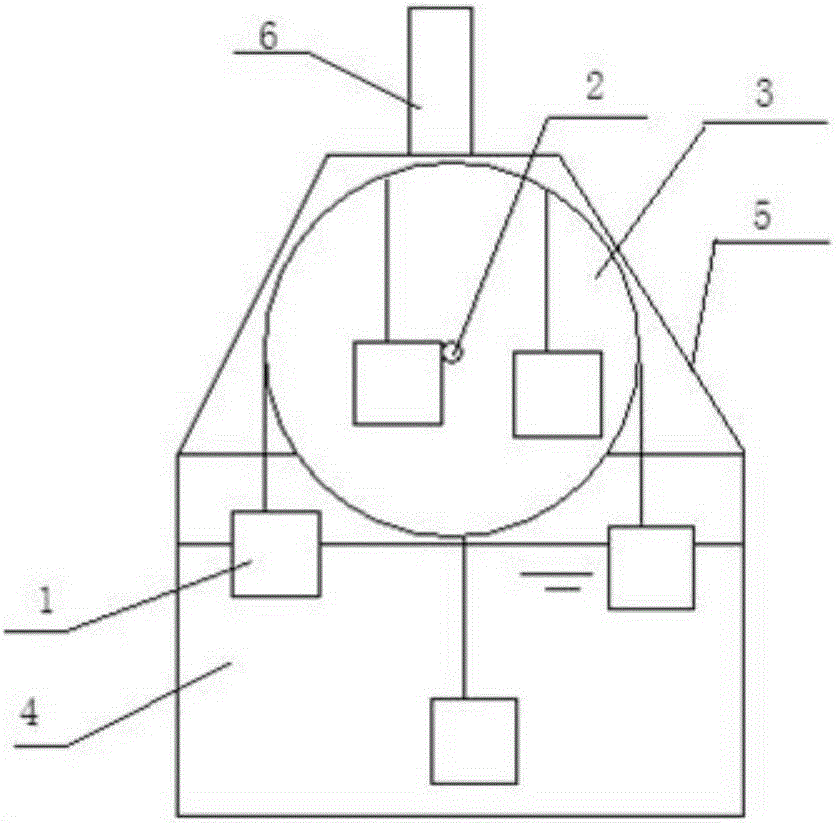

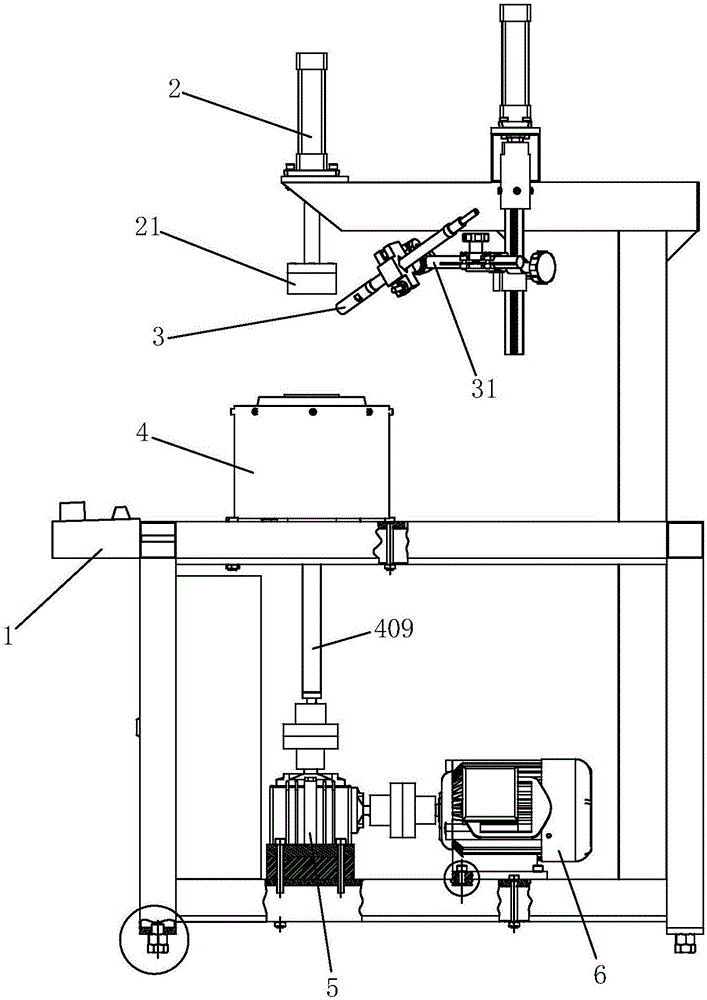

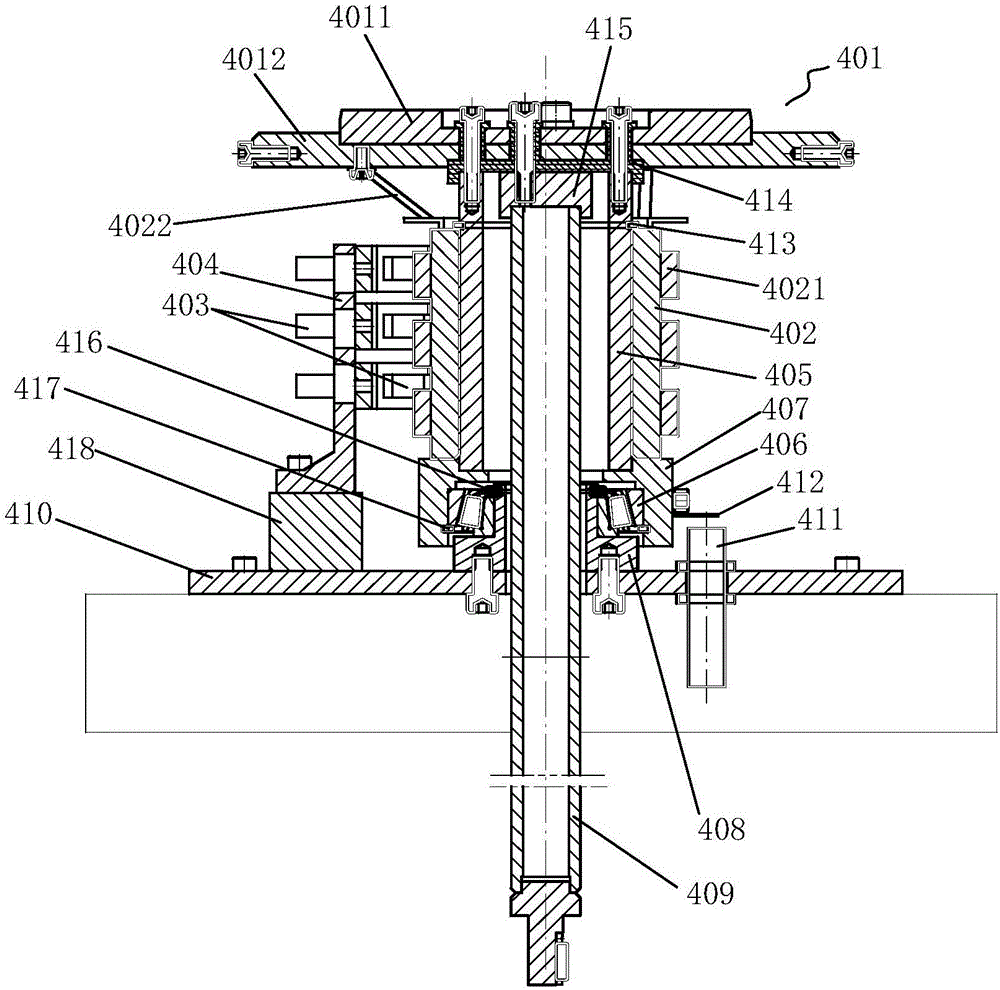

Fully-automatic vertical type circular seam welder

The invention relates to a fully-automatic vertical type circular seam welder which comprises a control console, a pressing mechanism, a welding gun, a rotary mechanism, a speed reducer and a motor, wherein the rotary mechanism is fixedly arranged on a rack of the control console in a vertical mode; the rotary mechanism is connected with the motor through the speed reducer; both the pressing mechanism and the welding gun are arranged above the rotary mechanism through the bracket; the pressing mechanism is equipped with a workpiece pressing column; the workpiece pressing column is in controlled connection with an air cylinder; the welding gun is equipped on the bracket through a welding gun clamp and is in controlled connection with the air cylinder; and an air cylinder on the pressing mechanism, an air cylinder connected with the welding gun and the motor are in controlled connection with a relay. The machine body of the circular seam welder adopts a vertical type structure, so that the circular seam welder is compact in structure and is small in floor space. In a welding process, a workpiece rotates on the horizontal plane, so that complex clamping positioning is not needed, and therefore, the operation is convenient and quick.

Owner:LUSHAN COLLEGE OF GUANGXI UNIV OF SCI & TECH

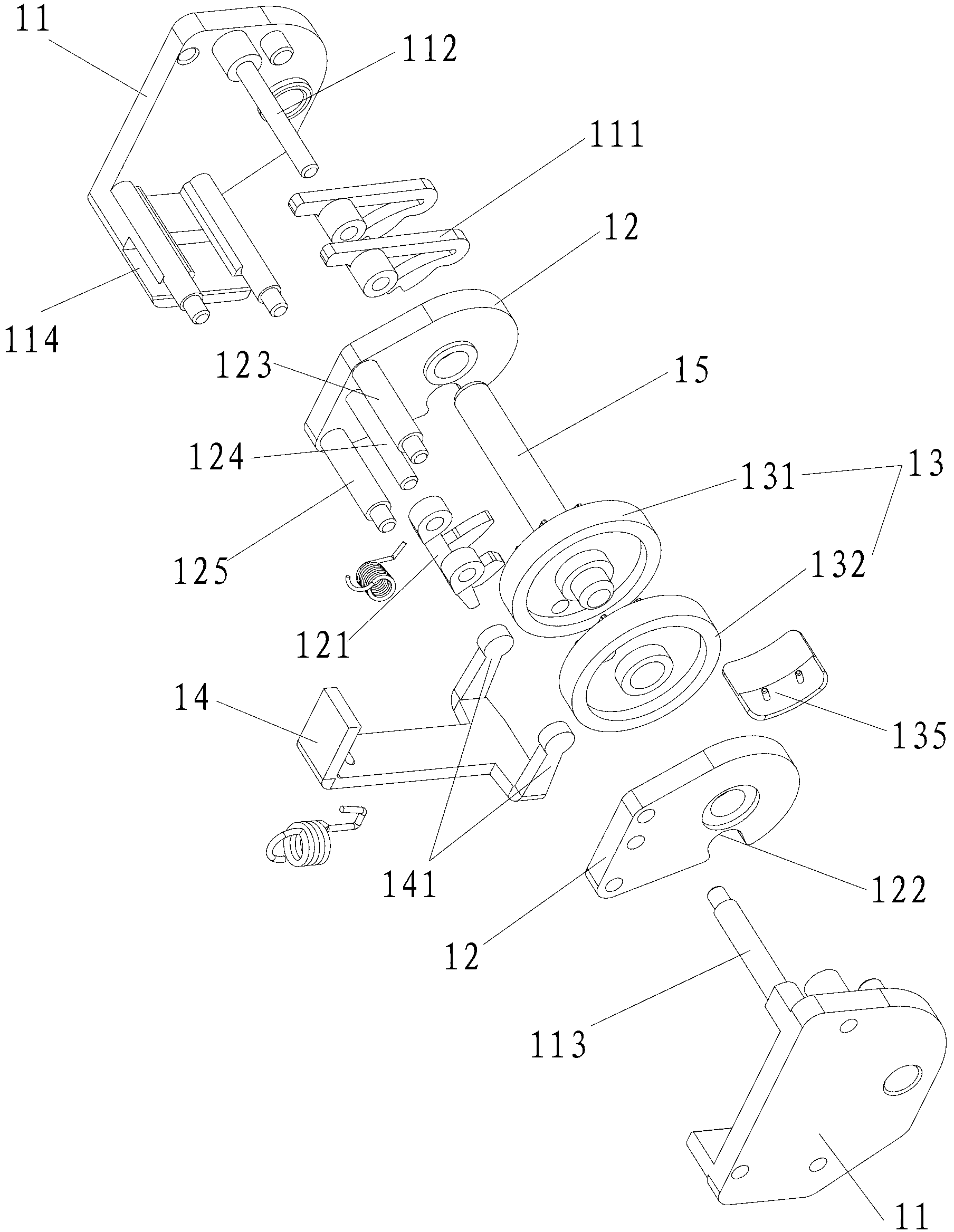

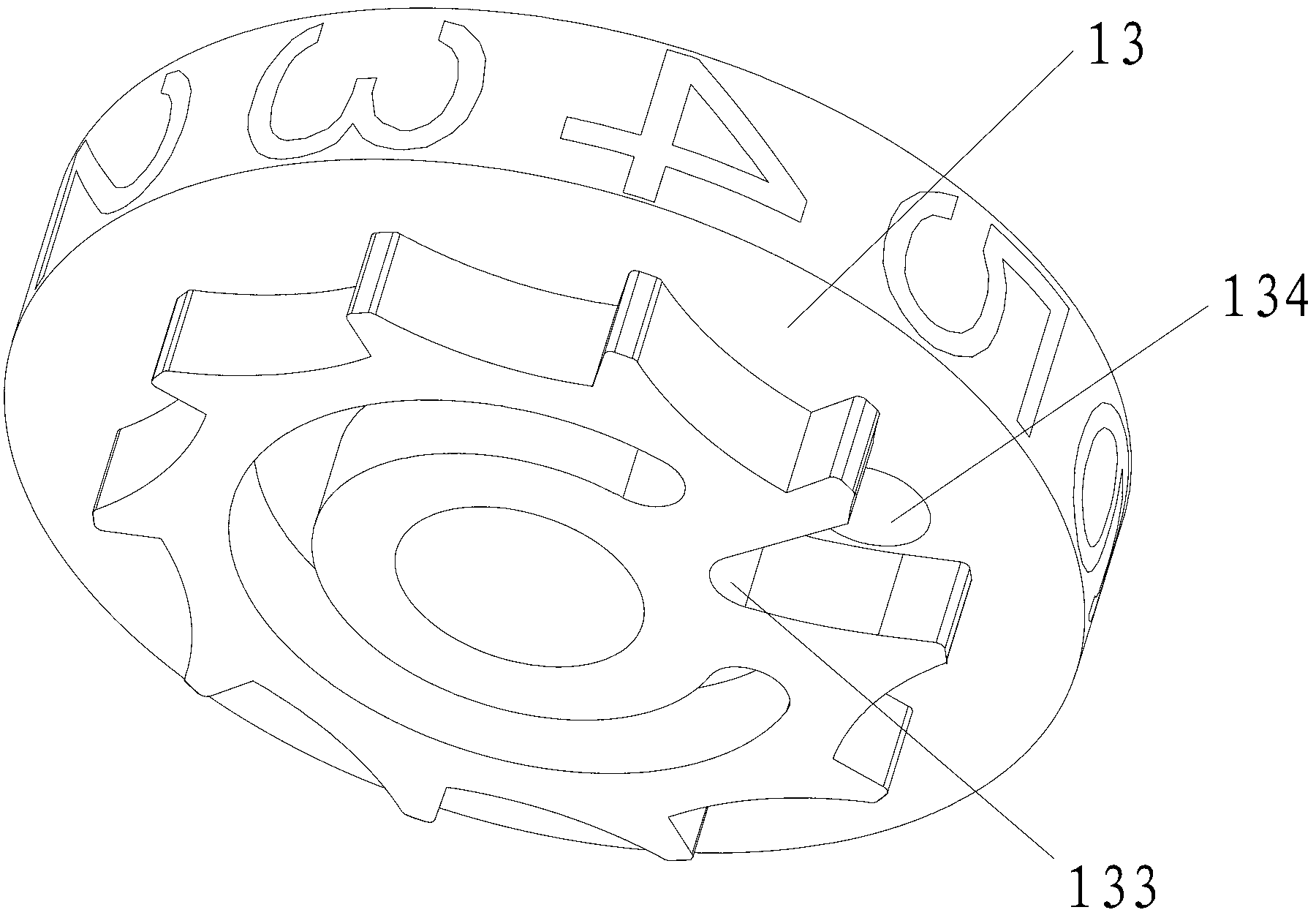

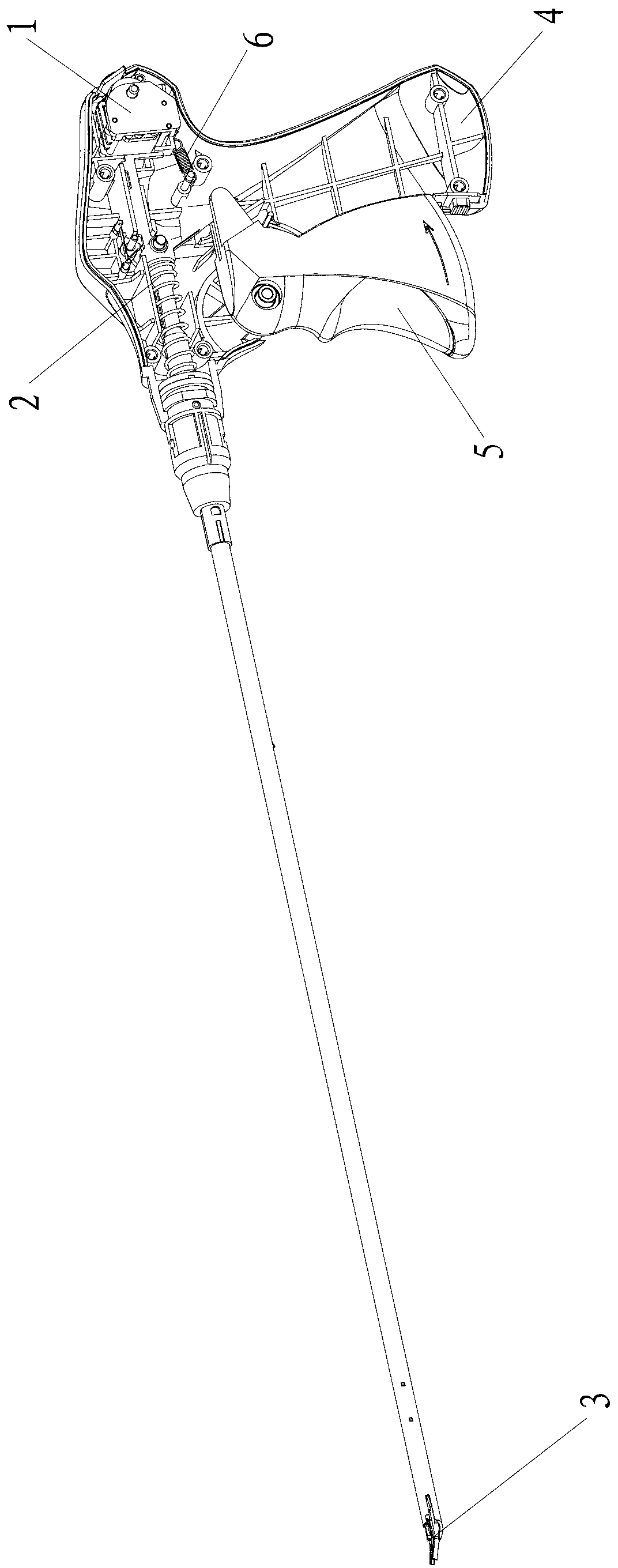

Mechanical counting device and titanium ligating and marking clip applying counting device

ActiveCN102799934AAccurate countImprove performanceDiagnosticsCounting mechanisms/objectsPush pullTitanium

The invention relates to a mechanical counting device and a titanium ligating and marking clip applying the counting device. The counting device mainly comprises a fixed support which is connected in a rotatable way, a character wheel support and a counting character wheel, wherein figures are marked on the circumference of the counting character wheel, and one side of the counting character wheel is provided with a ratchet wheel; retaining devices and a pushing block which are matched with the ratchet wheel are arranged on the fixed support and the character wheel support respectively; and an arc-shaped groove is formed on the character wheel support, and is connected with a push-pull sheet which is provided with arc-shaped vertical posts. The titanium ligating and marking clip comprises a pushing component, a head component, a fixed handle, a movable handle and the counting device, wherein the counting device is arranged at the tail end of the fixed handle; a tension spring is arranged between the push-pull sheet and the front end of the fixed handle; and the tail end of the pushing component is pressed against the front end of the push-pull sheet. The counting device can count conveniently and accurately, has stable performance, completely eradicates the potential safety hazard of power supplies and circuits, shortens the registration period of products, and can be widely applied to the recording and display of various quantity values.

Owner:B J ZH F PANTHER MEDICAL EQUIP

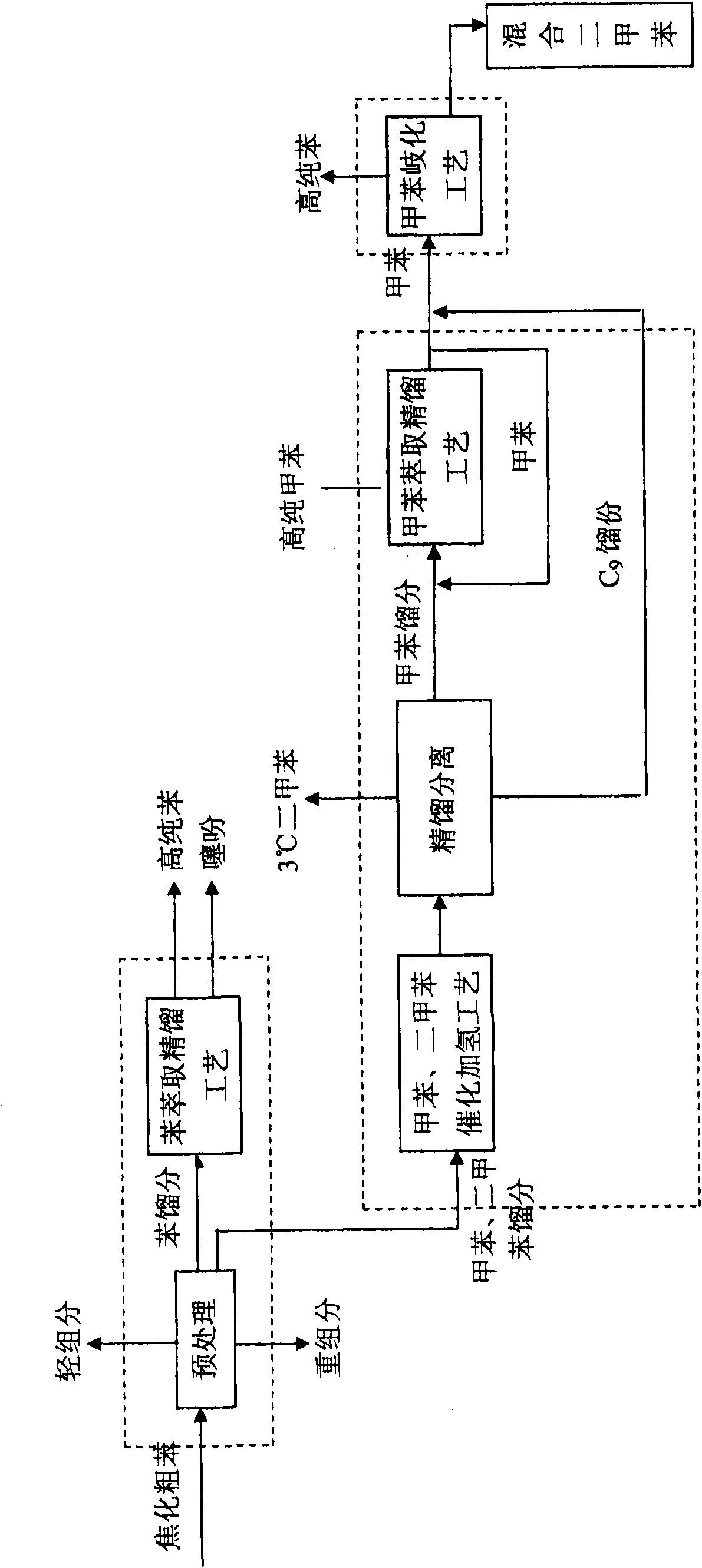

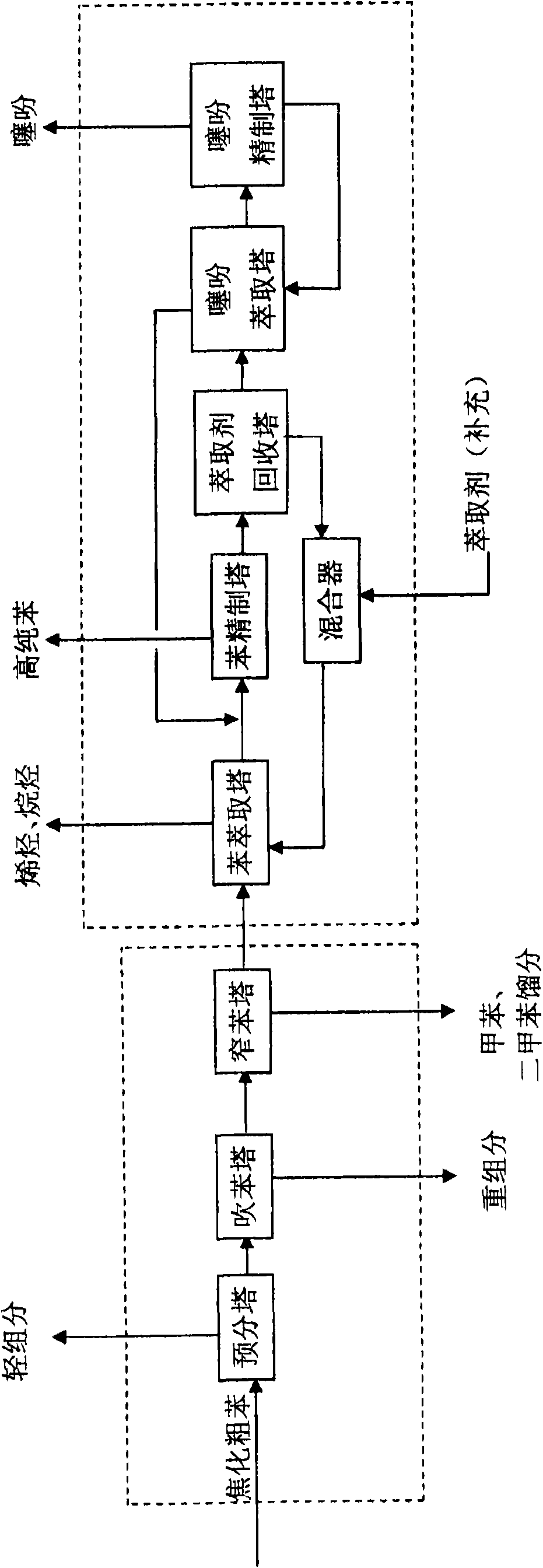

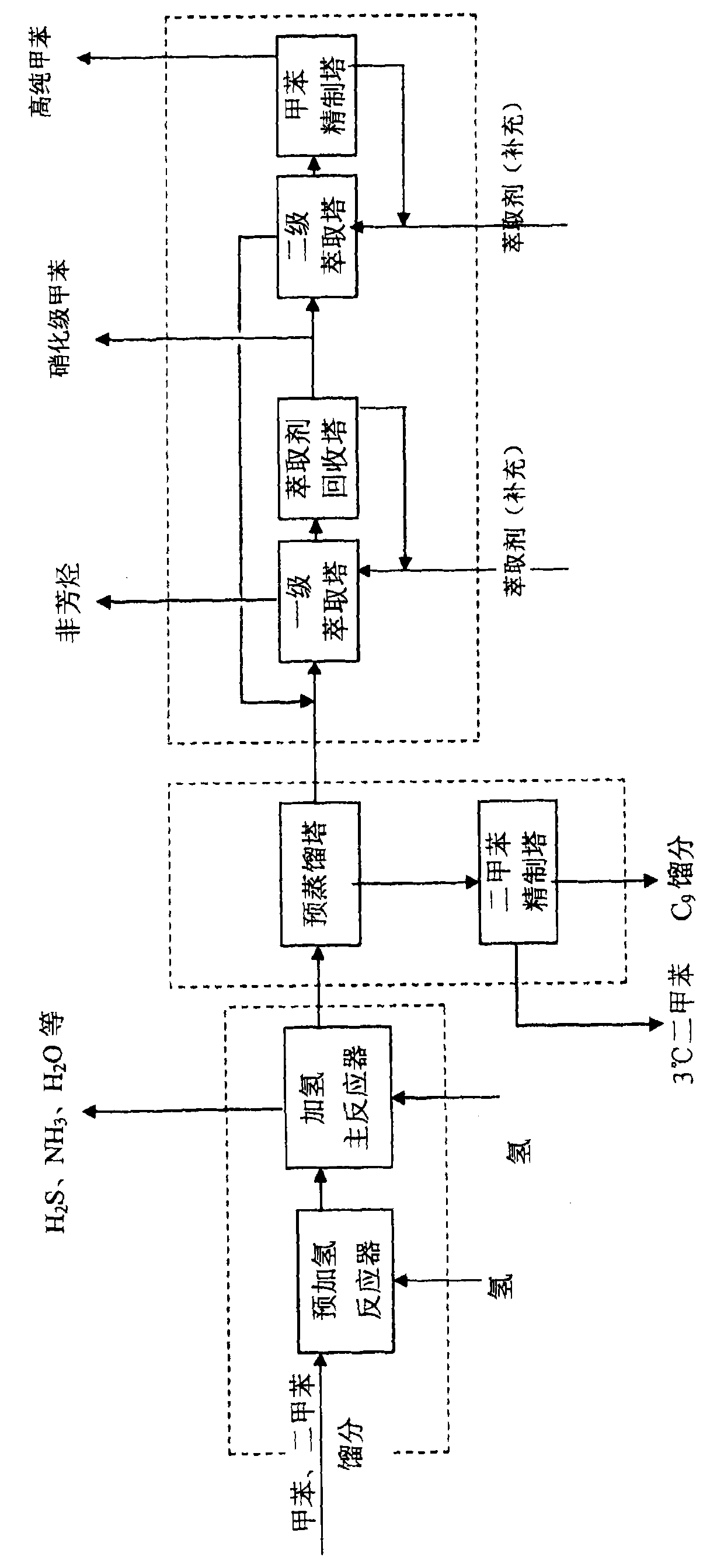

Coked crude benzene refining method

InactiveCN102001906AHigh purityIncrease added valueDistillation purification/separationHydrocarbonsMethyl benzeneExtractive distillation

The invention relates to a coked crude benzene refining method, including crude benzene pre-treatment, benzene fraction extractive distillation and methyl benzene, dimethyl benzene fraction hydrorefining. The invention has the advantages that products with high purity and high quality of benzene, methyl benzene and / or methyl benzene and thiophene can be obtained, equipment investment is reduced greatly, processing cost is also greatly reduce, no environmental pollution is produced, and product ratio can be regulated according to market requirement.

Owner:TAIYUAN QIAOYOU CHEM IND

Preparation method of light-weighted autoclaved unburned block

ActiveCN101804659ALow densityHigh strengthCeramic shaping apparatusFlexural strengthVolumetric Mass Density

The invention relates to a preparation method of a light-weighted autoclaved unburned block, which relates to the integrated utilization of a solid waste. Aerated concrete block waste is crushed into aggregate; dry FGD is mixed with the aggregate, added with water during the stirring and formed, to prepare an adobe; and the adobe is sent into steam to be cured, to prepare the light-weighted autoclaved unburned block. The preparation method of the light-weighted autoclaved unburned block has small finished product density, high strength and lighter weight, realizes the 'zero emission' of the dry FGD in a dry desulfurization process, solves the problem of enterprise product waste piling of the aerated concrete block, and reduces piling sites; the compressive strength and the flexural strength of the unburned block exceed the standard of a national autoclaved lime sand brick superior product; the weight of the produced autoclaved unburned block is 20 percent less than that of the traditional clay brick and autoclaved sand-lime brick on the basis of reaching all strength standards of the traditional red brick; no secondary pollution is produced, and the integrated utilization of resources is realized; and the process is simple, and the investment and treatment cost is low. The preparation method of the light-weighted autoclaved unburned block is universal.

Owner:FUJIAN LONGKING DSDN ENGINEERING CO LTD

Method for directly reducing and recycling iron powder by red mud

InactiveCN111389859ASolve the problem of solid waste utilizationReduce pollutionSolid waste disposalMagnetic separationPtru catalystIron powder

The invention provides a method for directly reducing and recycling iron powder by red mud, and relates to the technical field of metallurgy and environmental protection. The method comprises the steps that the red mud is used as a main raw material, a carbon-based compound is used as a reducing agent, by matching with a catalyst, the red mud, the reducing agent and the catalyst are blended and pelletized according to a certain proportion, and reduction is carried out under a low-temperature condition. The prepared reduced iron powder is high in metallization ratio, the technology is simple, and the investment is less; and the problem of the utilization of bulk metallurgical solid waste such as the red mud is solved, so that high added-valve utilization is obtained, the environmental pollution is reduced, and good economic benefits, ecological and environmental benefits and social benefits are achieved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Decomposition of tert-leucine with optical activity

A method for disassembling optical active tertiary leucine is carried out by reacting RS-tertiary leucine with phenacerine to generate RS-phenyl tertiary leucine, selectively hydrolyzing for phenyl of S-phenyl tertiary leucine to generate S-tertiary leucine by fixed Aspergillus oryzae amino acidylating enzyme, adding into organic solvent, phase-split separating for inactivated R-phenyl tertiary leucine, concentrating for S-tertiary leucine in aqueous-phase, crystallizing, adding acid into R-phenyl tertiary leucine in oil-phase, hydrolyzing to obtain R-tertiary leucine. It's cheap and simple and has no environmental pollution.

Owner:成都威克药业有限责任公司

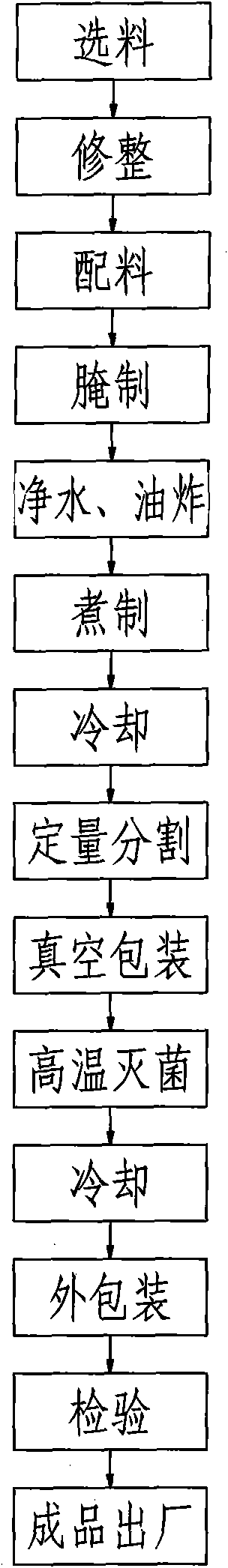

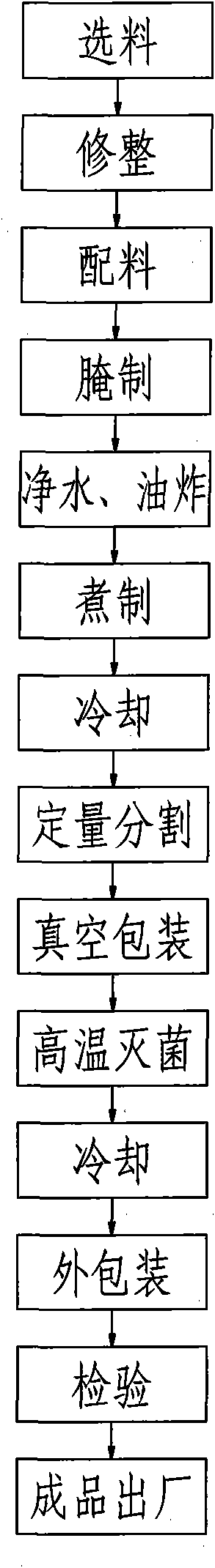

Preparation method of marinated duck

InactiveCN102018225AImprove water retentionGood oil retentionFood preparationMonosodium glutamateBoiling process

The invention discloses a preparation method of a marinated duck, which comprises the following process steps of material selection, trimming, material mixing, curing, drying, frying, boiling, cooking, quantitative dividing, vacuum packaging, high-temperature sterilization, cooling, external packing, inspection and finished product delivery, wherein the ratio of salt, peppers, fried aniseeds added in the curing process is 100:(0.4-0.6):(0.8-1.2); in the boiling process, the boiling stewing materials comprise the following components in percentage by weight: 0.8 to 1.2 percent of salt, 0.2 to 0.4 percent of monosodium glutamate and 0.8 to 1.2 percent of cooking wine, and the materials are stewed for 30 to 40 minutes at the temperature of between 93 and 100 DEG C; and the high-temperature sterilization process comprises the steps of: putting the vacuum-packaged cooked duck into a high-temperature sterilization boiler, adjusting the pressure in the boiler to be between 0.15 and 0.25 kPa, then raising the temperature to be between 112 and 121 DEG C in 4 to 6 minutes, and performing constant-temperature sterilization for 25 to 30 minutes. The preparation method is suitable for preparing the marinated duck.

Owner:吕岳财

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com