Preparation method of low-surface energy fluorinated polysiloxane modified acrylic acid anti-fouling resin and product

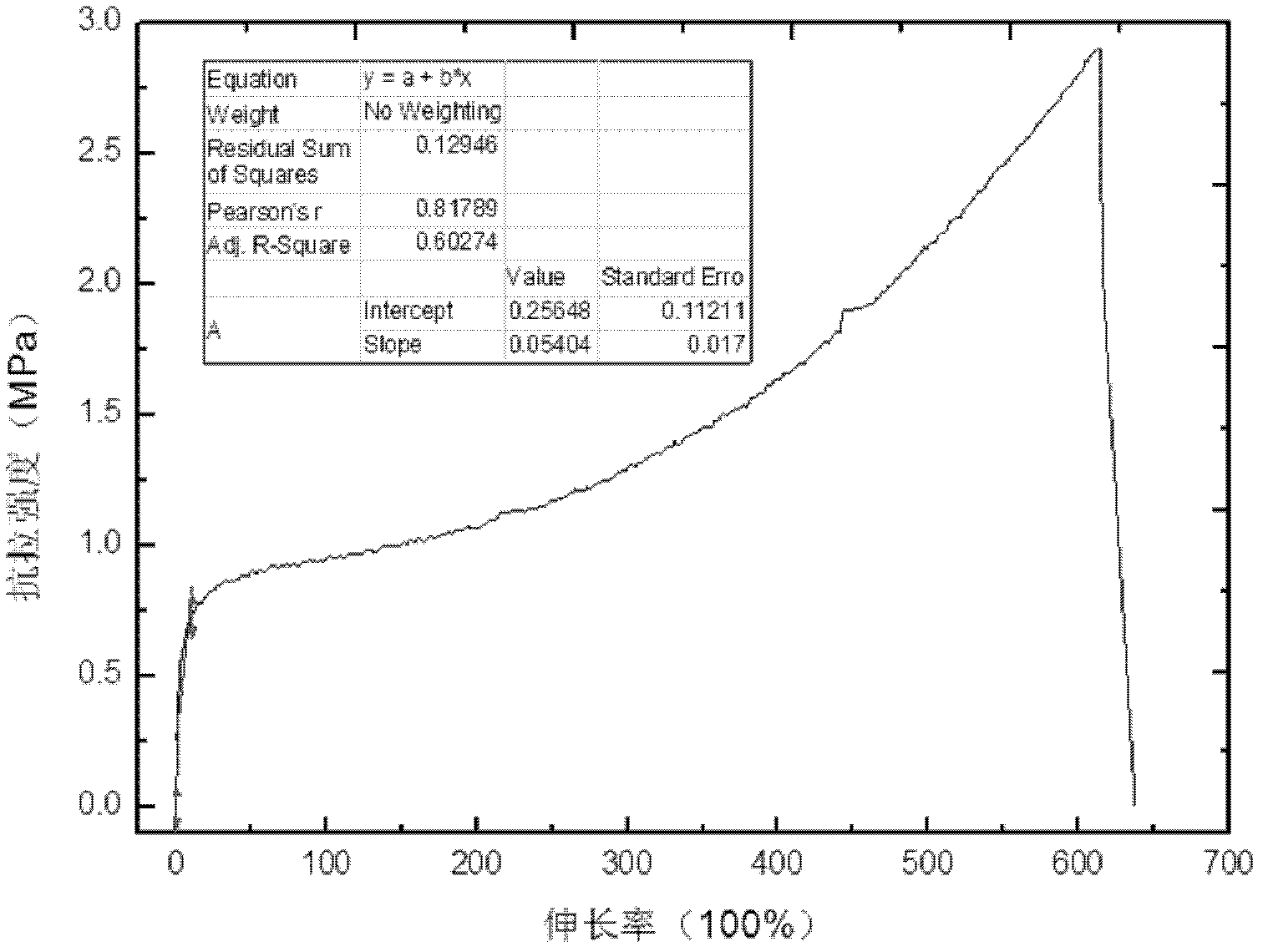

A fluorosilicon modified, antifouling resin technology, used in antifouling/underwater coatings, biocide-containing paints, coatings, etc., can solve the problems of low resin solid content, environmental pollution, complex synthesis steps, etc. The effect of low elastic modulus, reduced coating cost, and simple synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: the preparation method of a kind of low surface energy fluorine silicon modified acrylic acid antifouling resin of the present invention, it comprises the following steps: by weight percentage,

[0041] (1) Prepare 5-30% of the first mixed solution comprising butyl acetate and xylene; wherein the mass fraction of butyl acetate in the first mixed solution is 30-70%;

[0042](2) Add 5-30% of the first mixed solution and 5-30% of silicone oil as a solvent in a four-necked flask equipped with a mechanical stirrer, a constant pressure dropping funnel and a thermometer;

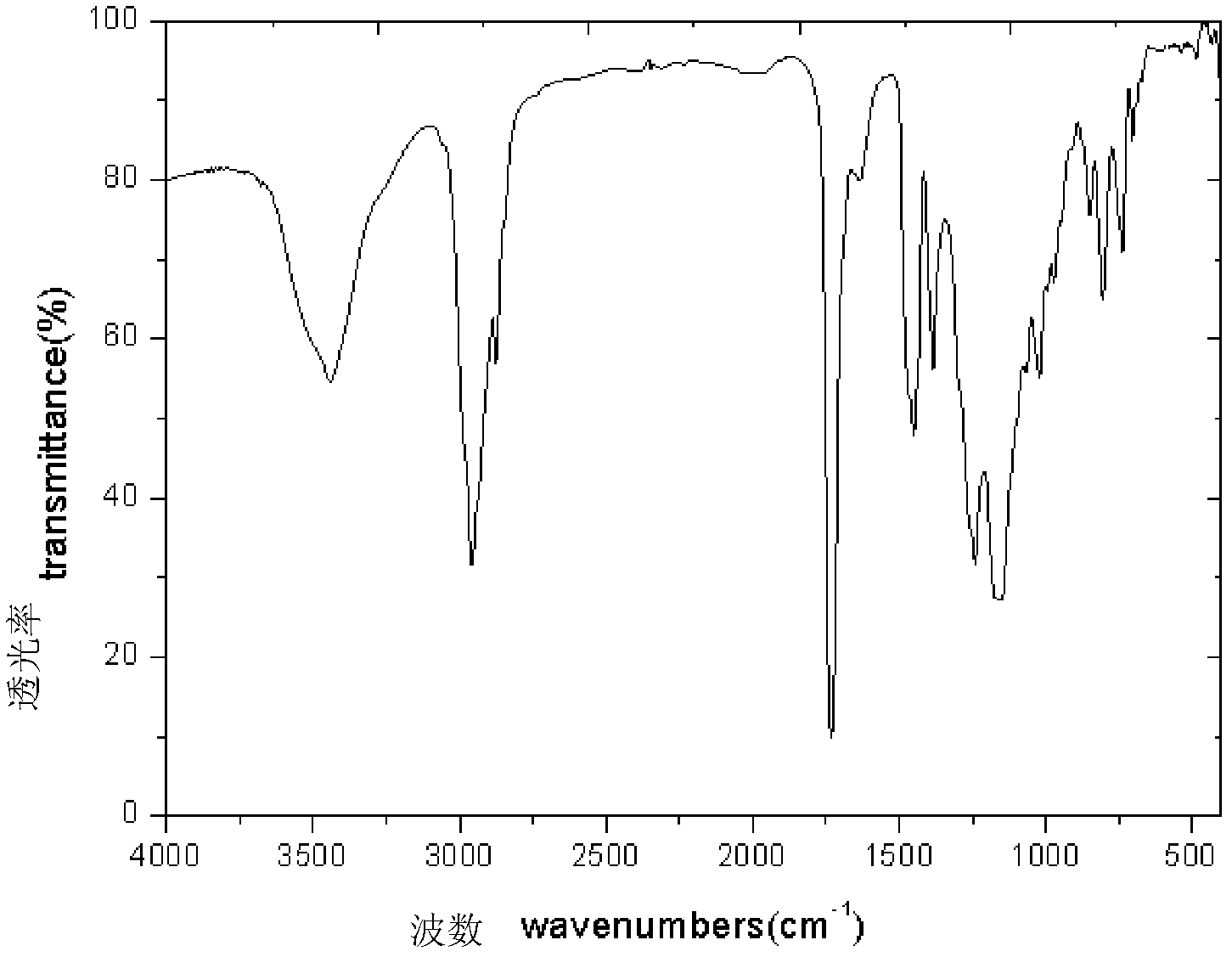

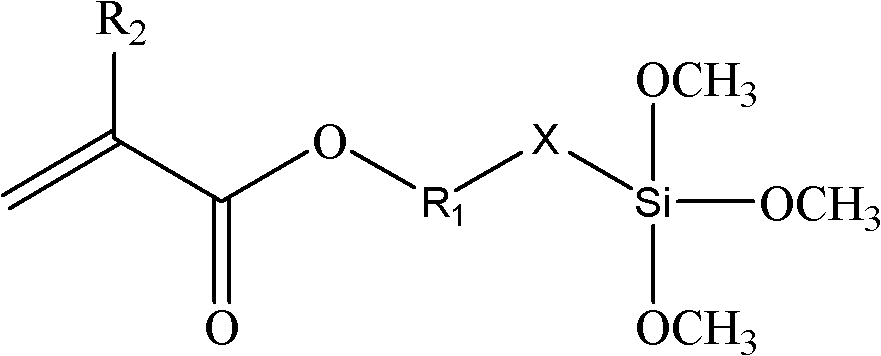

[0043] (3) Prepare a second mixed solution comprising acrylate monomers and acrylate functional monomers, and dissolve the initiator in the second mixed solution, the second mixed solution is composed of methyl methacrylate 20-50 %, 10-20% of butyl acrylate, 3-20% of the mixed solution of fluorine-containing (meth)acrylate monomer and silicon-containing (meth)acrylate monomer, 3-10% of hydroxye...

Embodiment 2

[0067] Embodiment 2: the preparation method of a kind of low surface energy fluorine silicon modified acrylic acid antifouling resin of the present invention, it comprises the following steps: calculate by weight percentage,

[0068] (1) Prepare 5-30% of the first mixed solution comprising butyl acetate and xylene;

[0069] (2) Add 5-30% of the first mixed solution and 5-30% of silicone oil as a solvent in a four-necked flask equipped with a mechanical stirrer, a constant pressure dropping funnel and a thermometer;

[0070] (3) Prepare a second mixed solution comprising acrylate monomers and acrylate functional monomers, and dissolve the initiator in the second mixed solution, the second mixed solution is composed of methyl methacrylate 20-50 %, 10-20% of butyl acrylate, 3-20% of the mixed solution of fluorine-containing (meth)acrylate monomer and silicon-containing (meth)acrylate monomer, 3-10% of hydroxyethyl methacrylate and Initiator 0.5-5%;

[0071] (4) The solvent in s...

Embodiment 3

[0094] The method of present embodiment 3 is basically the same as resin and embodiment 1 or 2, and its difference is that the raw material composition and weight percent of this resin are:

[0095]

[0096] Specifically, add 10 grams of butyl acetate, 11 grams of xylene, and 60 grams of simethicone into a four-necked flask equipped with a stirrer, a constant-pressure dropping funnel, and a thermometer, raise the temperature to 80°C, and then weigh the butyl acrylate 44 grams of methyl methacrylate, 48 grams of methyl methacrylate, 8 grams of trifluoroheptyl methacrylate, 5 grams of silicon-containing (meth)acrylate, 13 grams of hydroxyethyl methacrylate, 1 azobisisobutyronitrile gram, through the constant pressure dropping funnel with a constant rate of 2 to 4 hours to complete the dropwise. After continuing to keep warm for 8 hours, stop to obtain fluorosilicone modified acrylic antifouling resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com