Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

54results about How to "Reduce painting process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

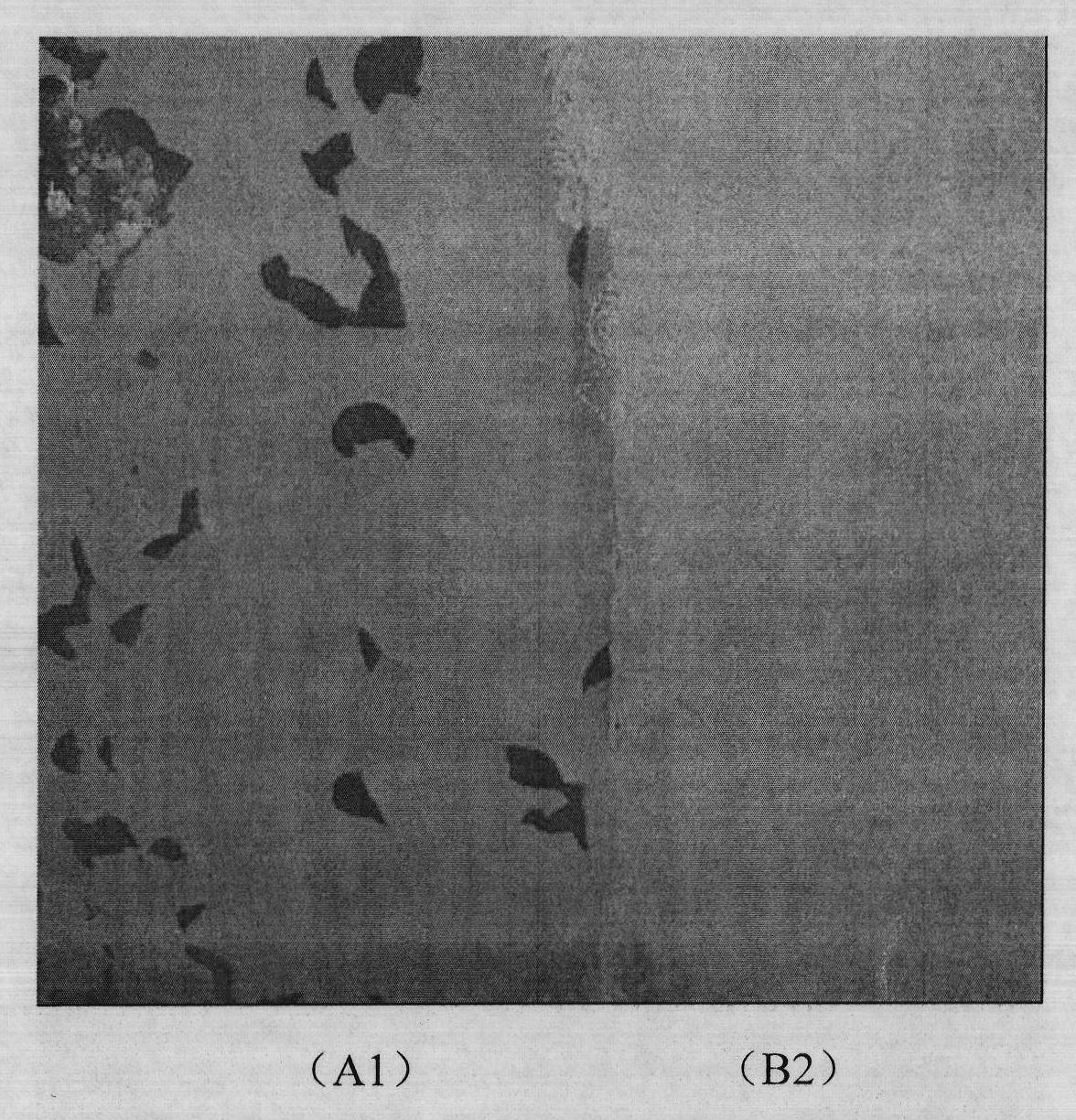

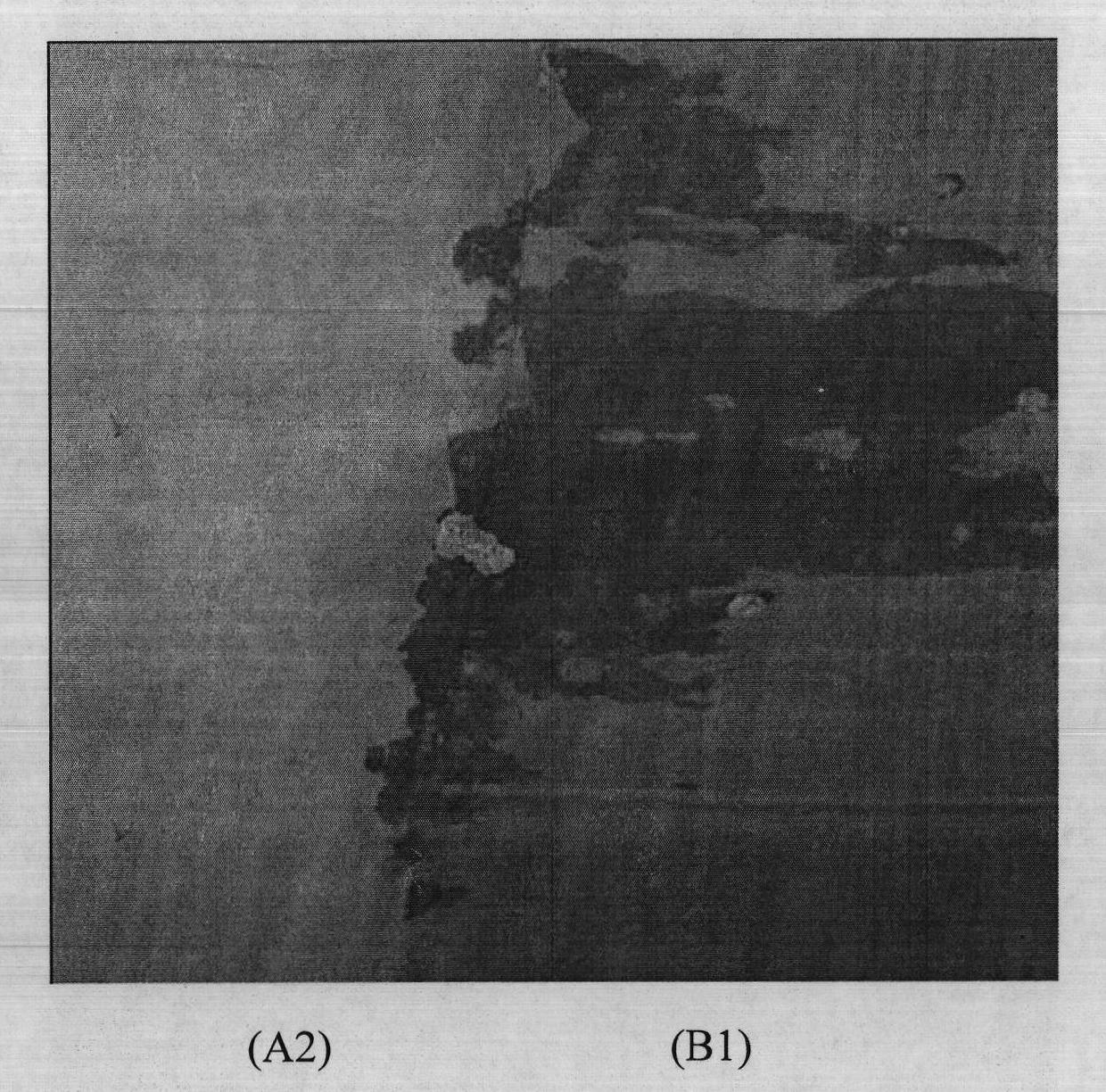

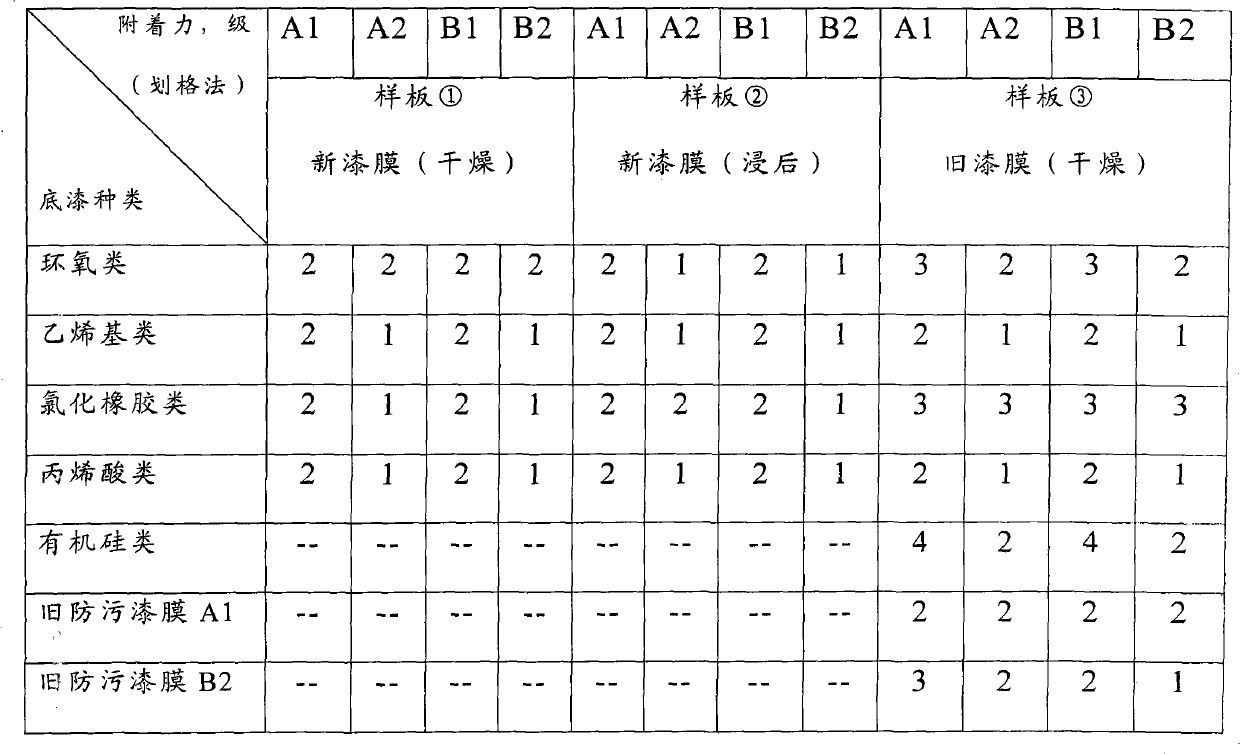

Anti-fouling coating material with excellent compatibility and use thereof

InactiveCN102558989AGood compatibilityImprove antifouling performanceAntifouling/underwater paintsPaints with biocidesAcrylic resinSolvent

The invention relates to the field of anti-fouling coating materials, in particular to an anti-fouling coating material with excellent compatibility. The anti-fouling coating material with excellent compatibility contains liquid bisphenol A epoxy resin, polished acrylic resin, at least two thermoplastic resins for a coating film-forming material, at least two antifouling agents, at least two pigments and fillers, at least two solvents and at least two additives. With the adoption of the anti-fouling coating material with excellent compatibility, the excellent compatibility between a new / old anti-corrosion coating layer and an old antifouling coating layer can be provided, a connecting layer cannot be a coating layer necessary to be coated any more, the processes of coating are reduced, and excellent attachment and antifouling performances are shown after the long-term application of the anti-fouling coating material.

Owner:MARINE CHEM RES INST

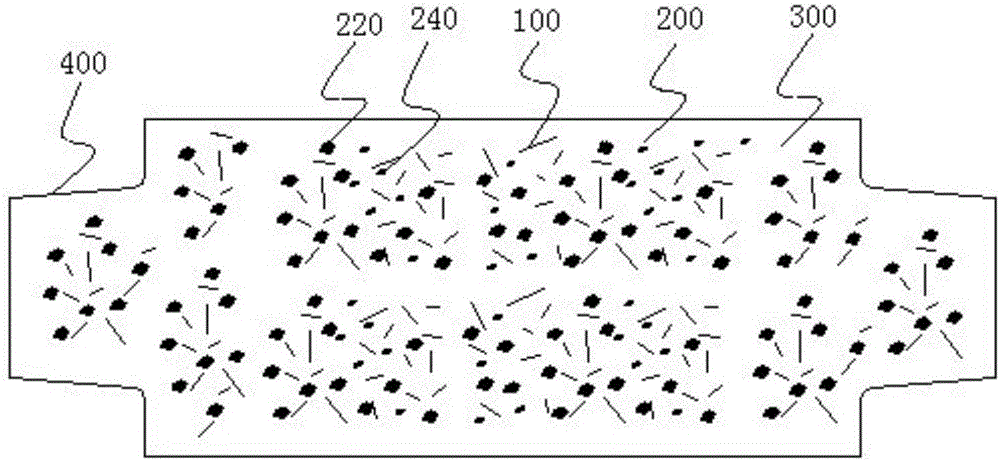

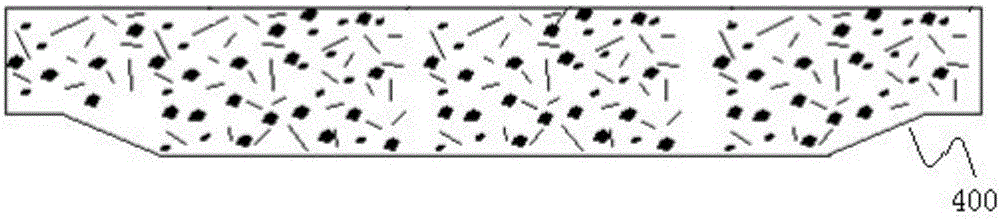

Resin mixture and glass reinforced plastic section bar prepared thereby

InactiveCN101157795ALightweight and high strengthThermal insulationPolymer scienceLow temperature curing

The invention relates to a resin mixture used for producing FRP (fiberglass-reinforced plastics) profile, the FRP profile made from the mixture and a preparation method thereof. The resin mixture comprises the following materials according to weight proportion: 10 of resin, 0.4 to 3 of low shrinkage agent, 2 to 15 of fillers, 0.05 to 0.2 of low temperature curing agent, 0.05 to 0.2 of high temperature curing agent, 0.05 to 0.2 of parting agent, 0.02 to 0.5 of pigment and appropriate amount of coupling agent and ultraviolet absorbent. The preparation method of the FRP profile by using the mixture is that: a reinforcing material is immersed into the resin mixture. The obtained material is extruded to get forming under high temperature and high pressure through a die; during the extrusion forming, the die is heated after being separated into three segments, and the temperature of the three segments is respectively 60 DEG C to 100 DEG C of a first segment, 100 DEG C to 150 DEG C of a second segment, 100 DEG C to 148 DEG C of a third segment; the haulage speed is 320 mm / min.

Owner:潘锦荣

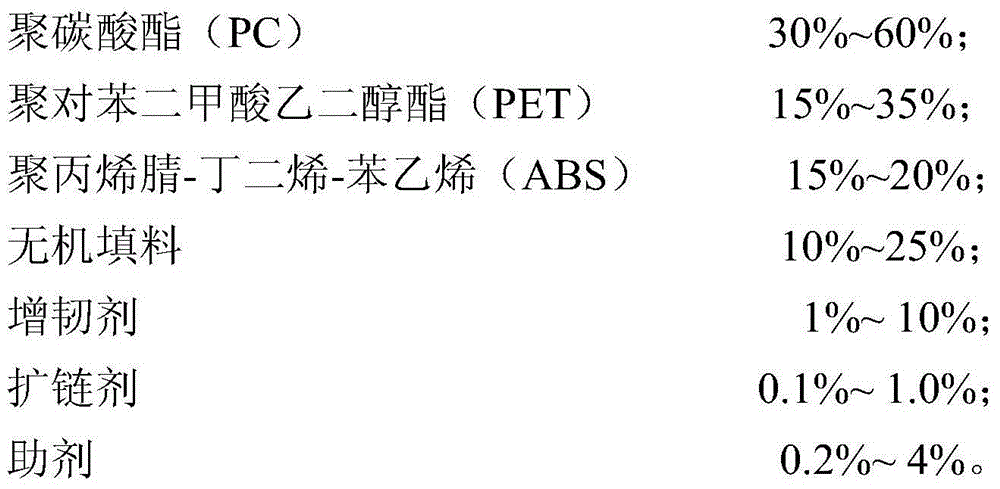

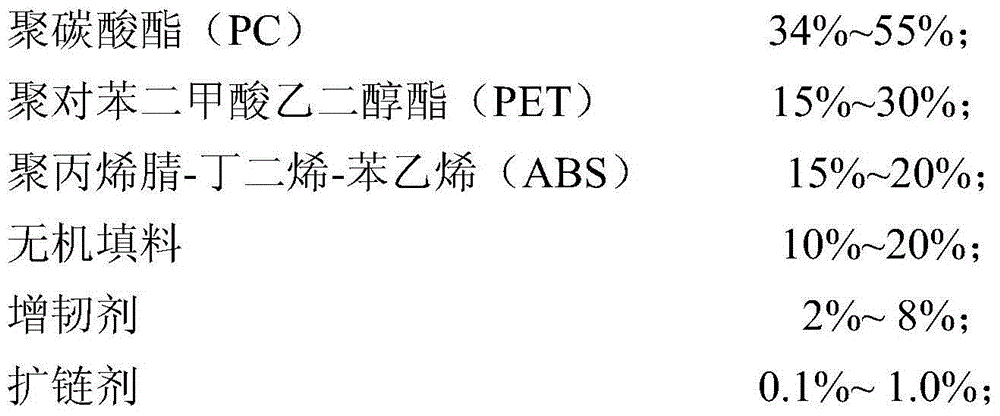

PC/PET (polycarbonate/polyethylene terephthalate) alloy material and preparation method thereof

ActiveCN104559110AImprove toughnessTo achieve the perfect effectPolyethylene terephthalate glycolAlloy

Owner:CGN JUNER NEW MATERIALS +1

Plastic part coating process of electric vehicle

ActiveCN104070001AImprove coating qualityReduce painting processPretreated surfacesCoatingsElectric vehicleMechanical engineering

The invention provides a plastic part coating process of an electric vehicle and relates to the technical field of coating processes. The plastic part coating process of the electric vehicle comprises the steps of firstly cleaning oil stains and dust on the surface of a plastic part, enabling the surface of the plastic part to be smooth through sanding and polishing so as to facilitate coating of a coating layer; then performing first-time primer spraying and second-time primer spraying, supplementing red plaster on the plastic part and then performing plaster scraping and drying; performing first-time polishing, then performing drying treatment, part installation and finish spraying after polishing is finished and finally performing soaking treatment. A traditional coating mode is changed, twice primer spraying is adopted, a refrigerating fluid soaking working procedure is performed, the product coating layer quality is improved, coating working procedures are decreased, the coating cost is reduced, and the plastic part coating process has very good actual application significance.

Owner:安徽省宏宝莱机车科技有限公司

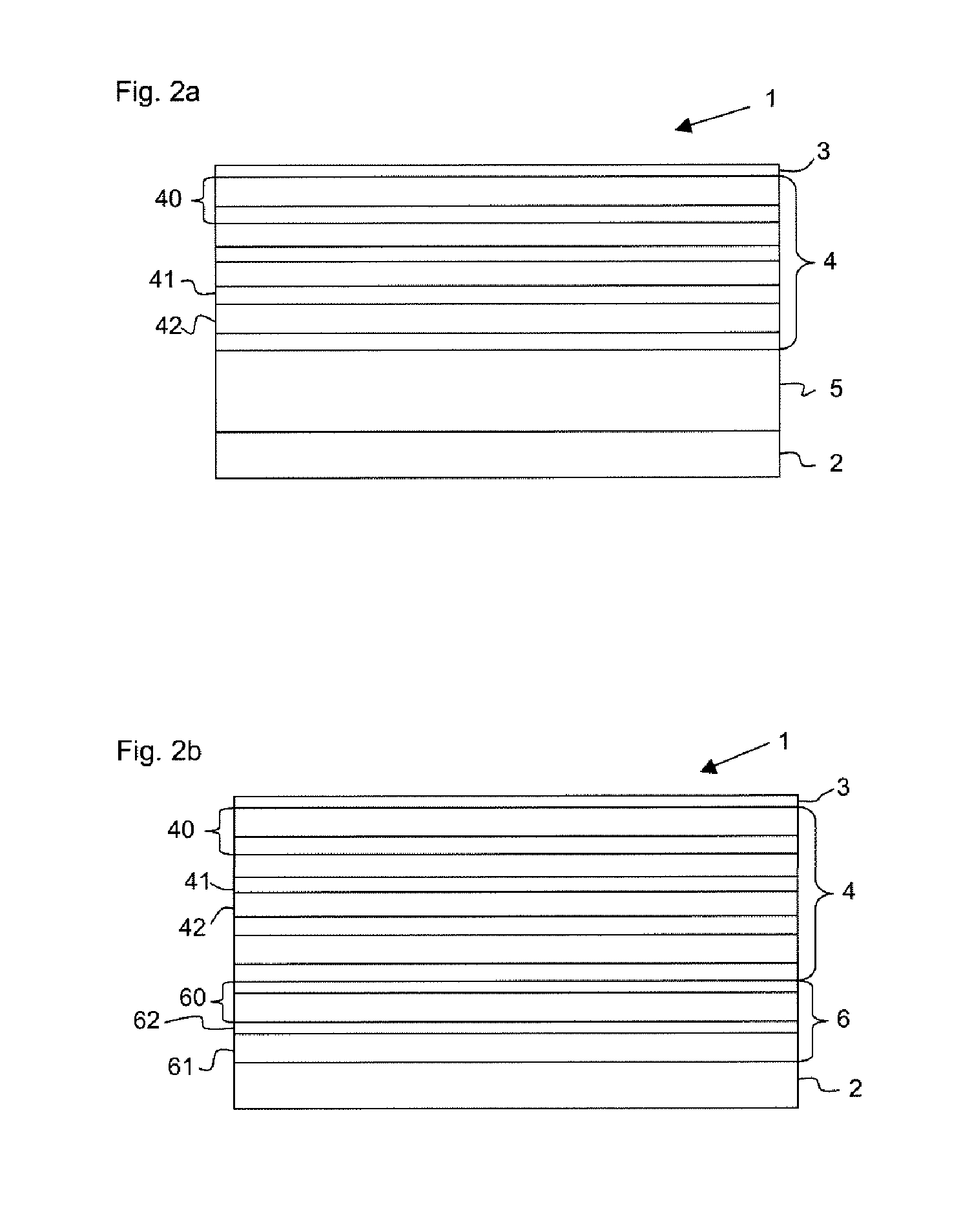

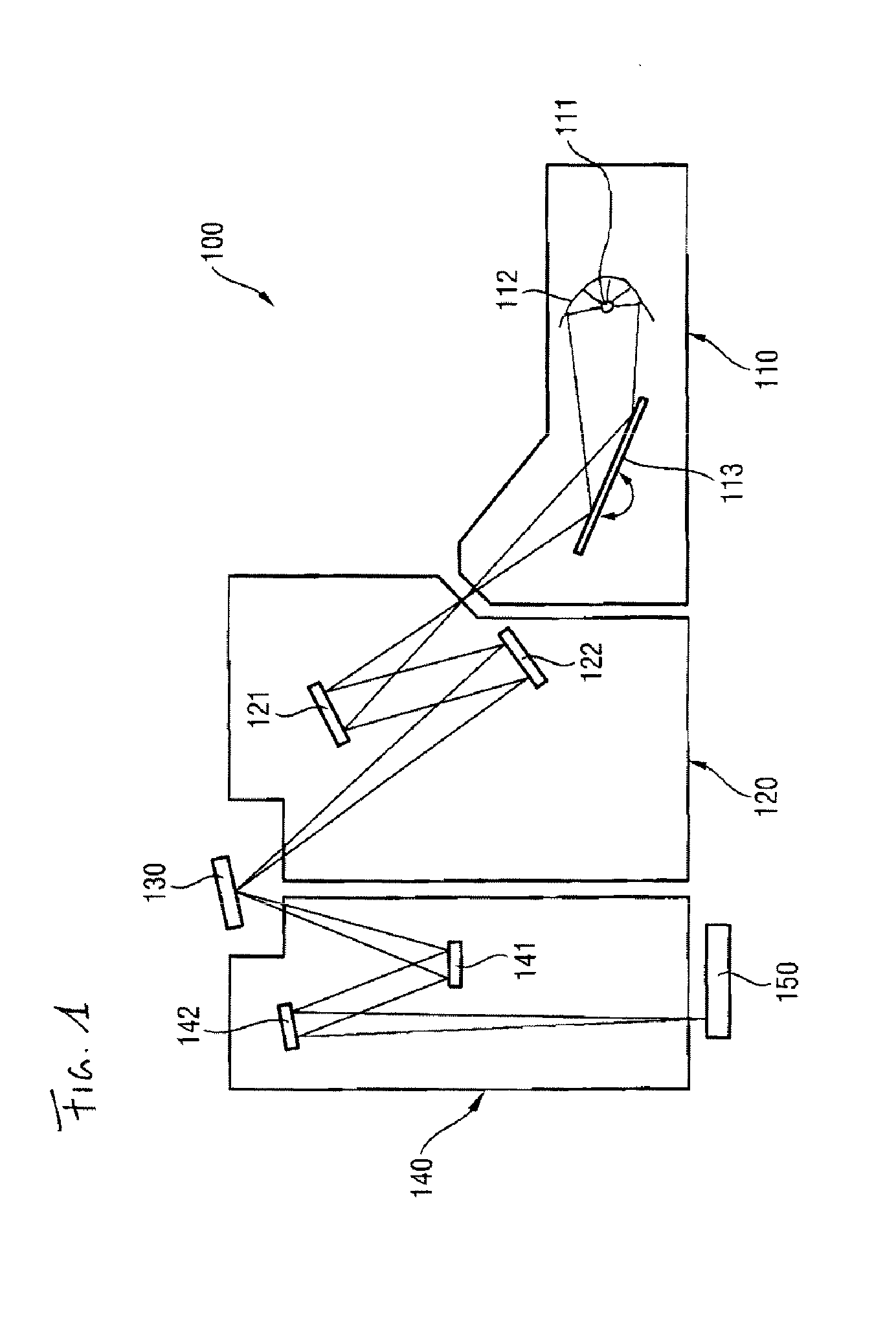

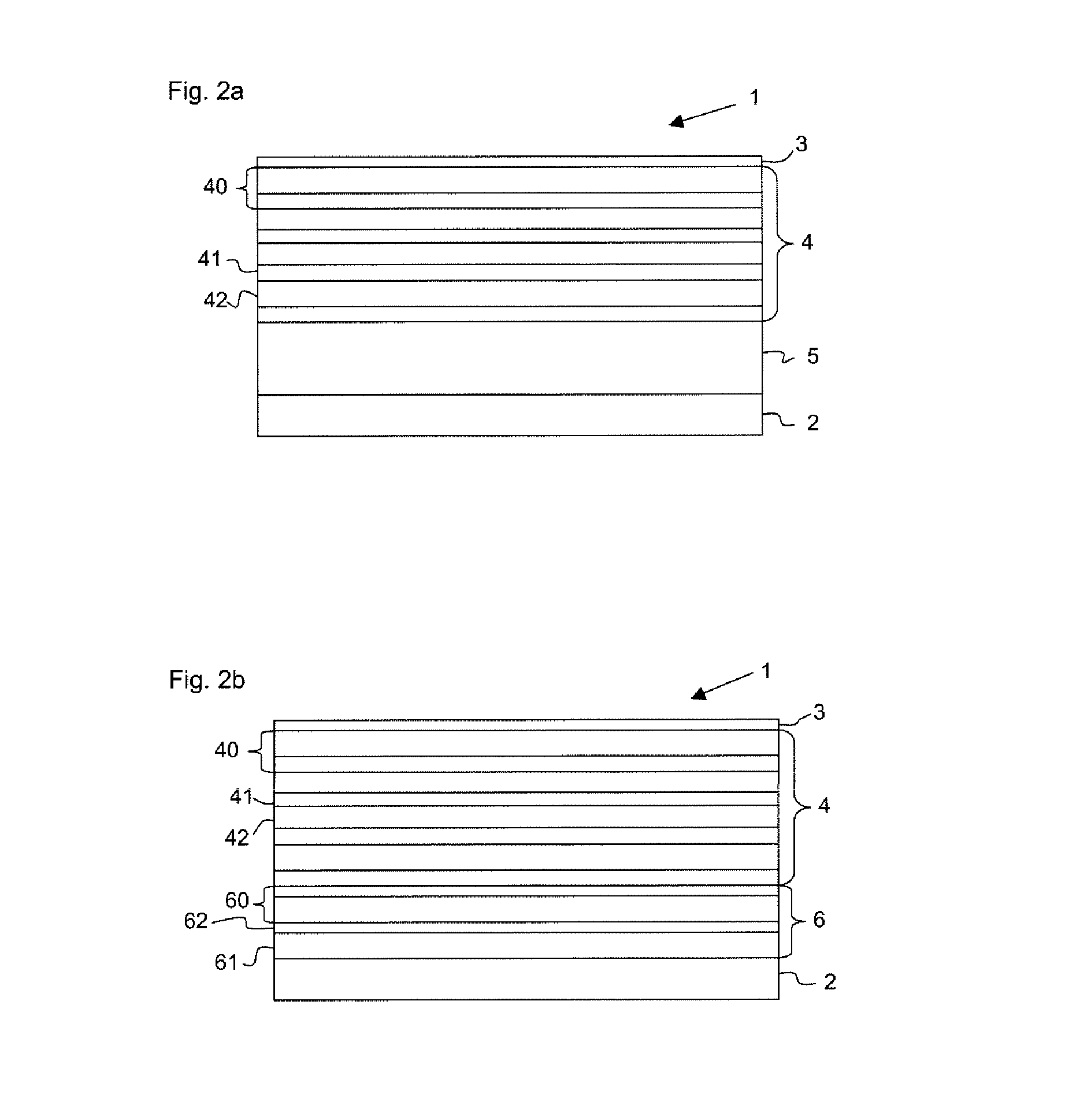

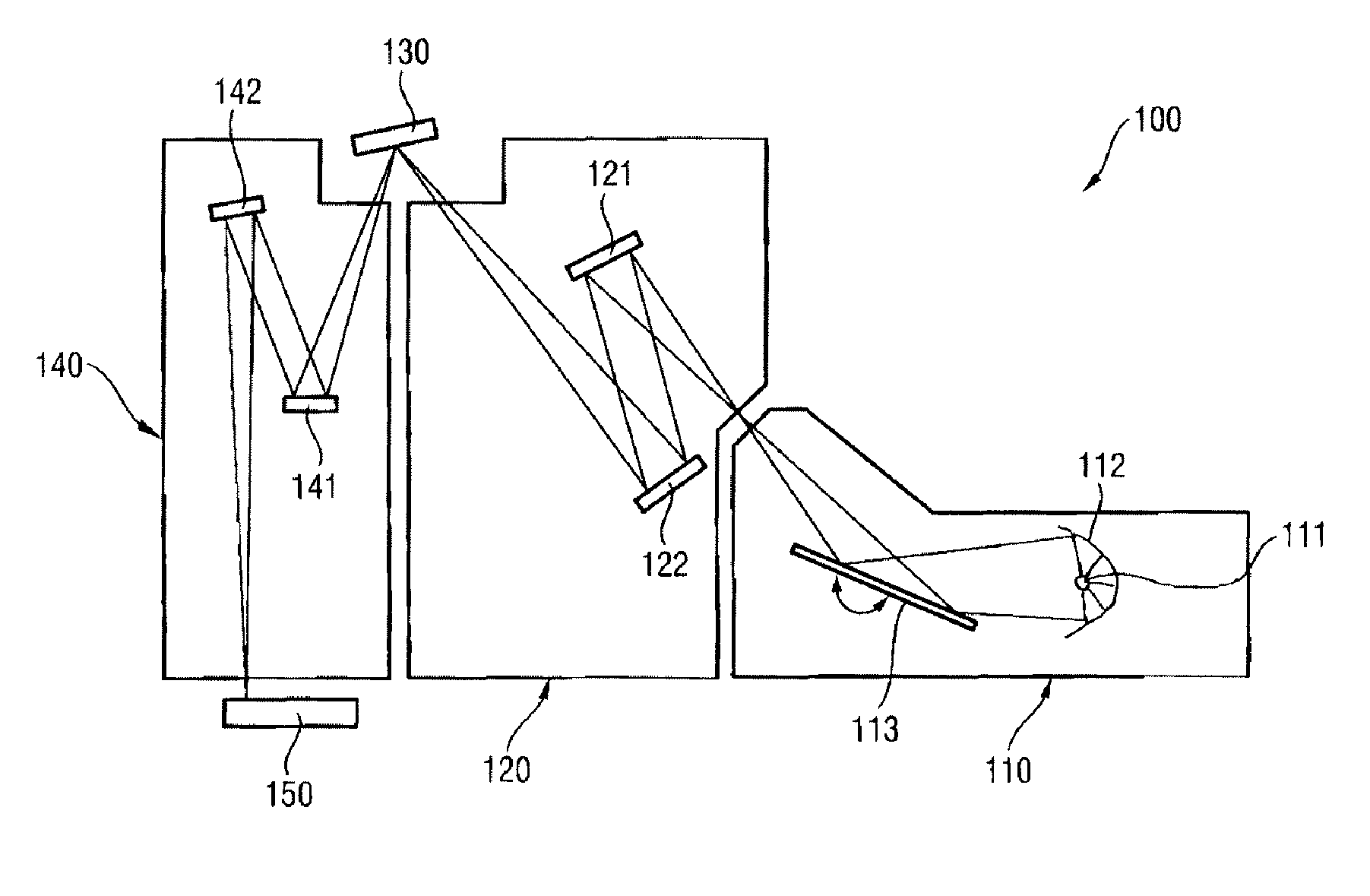

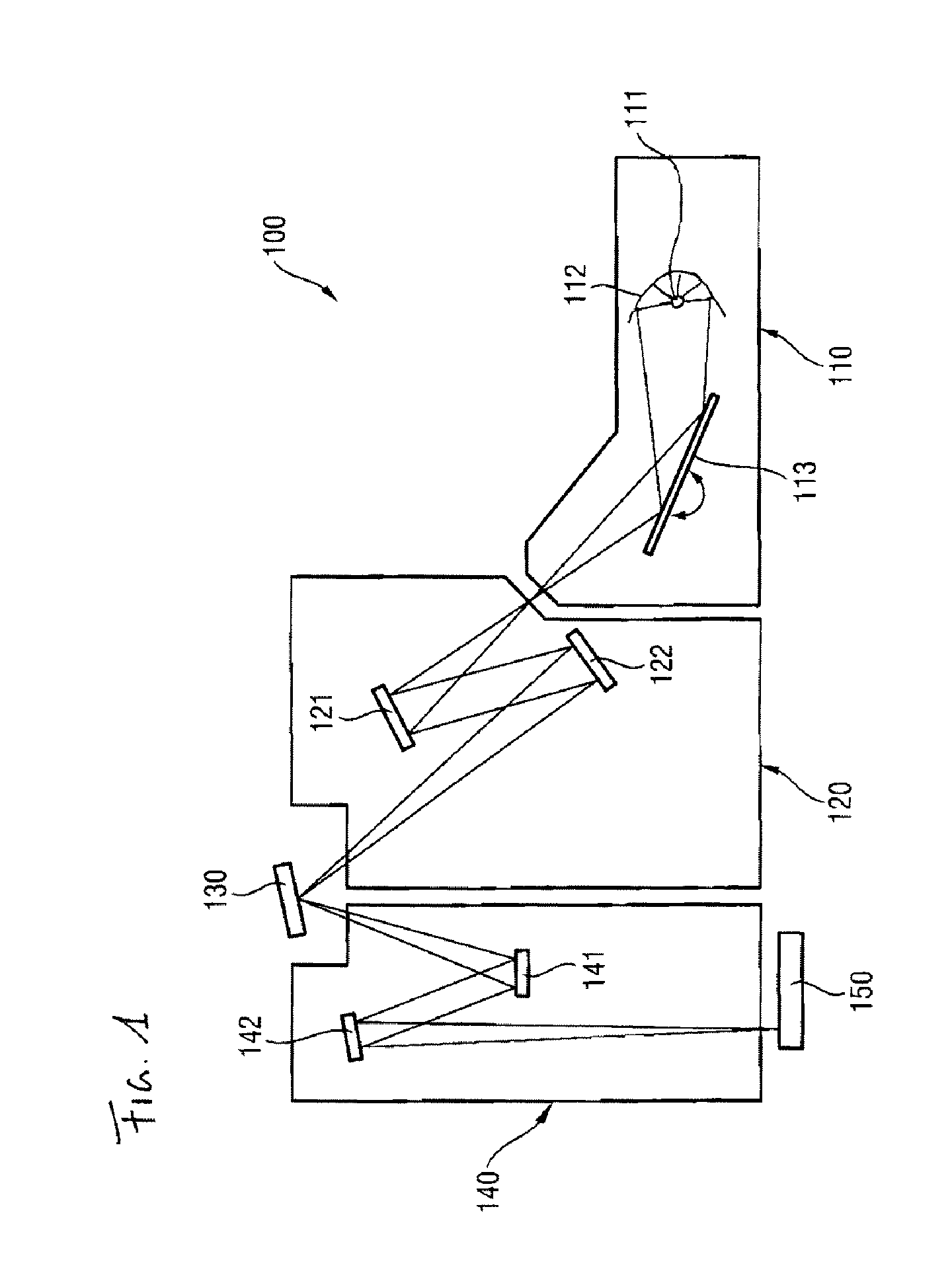

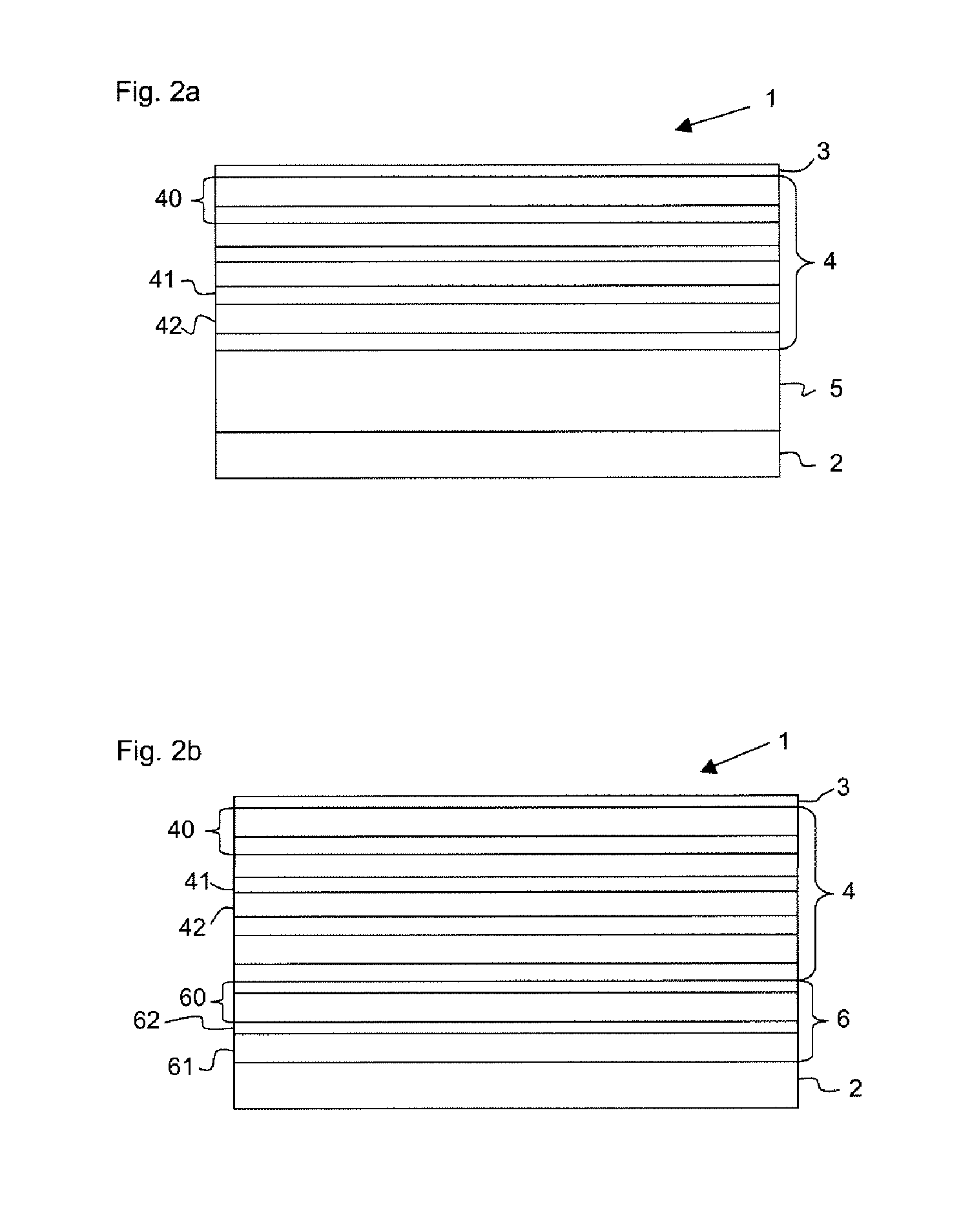

Reflective optical element and method for production of such an optical element

In order to produce stress-reduced reflective optical elements (1) for an operating wave length in the soft X-ray and extreme ultraviolet wavelength range, in particular for use in EUV lithography, it is proposed to apply, between substrate (2) and a multilayer system (4) optimized for high reflectivity at the operating wavelength, a stress-reducing multilayer system (6) with the aid of particle-forming particles having an energy of 40 eV or more, preferably 90 eV or more. Resulting reflective optical elements are distinguished by low surface roughness, a low number of periods in the stress-reducing multilayer system and also high Γ values of the stress-reducing multilayer system.

Owner:CARL ZEISS SMT GMBH

Synthesized counterweight filler

The invention discloses a synthesized counterweight filler. The synthesized counterweight filler comprises, by weight, 1.5%-10% of metal fibers, 60%-80% of ore and metal slags and 10%-38.50% of cement, wherein the water cement ratio is 0.3-0.5. The synthesized counterweight filler is formed by mixing and pouring the metal fibers, the cement, the ore and metal slags and the like according to a certain weight proportion, and then the using strength and weight requirements of an elevator for the synthesized counterweight filler can be met; the metal fibers can replace an outer-layer iron shell and inner reinforcing steel bars of a traditional counterweight filler, on one hand, the steel using amount can be saved, the painting process of the outer-layer iron shell can be reduced, and the pollution to the working environment can be reduced, and on the other hand, the welding operation of the iron shell and the steel bars is not needed, and therefore the labor and manufacture cost for manufacturing the counterweight filler can be significantly lowered; in addition, the counterweight fillers in various shapes can be quickly manufactured through overall pouring molding of the materials and different pouring moulds, and therefore the working efficiency can be improved.

Owner:HITACHI ELEVATOR CHINA

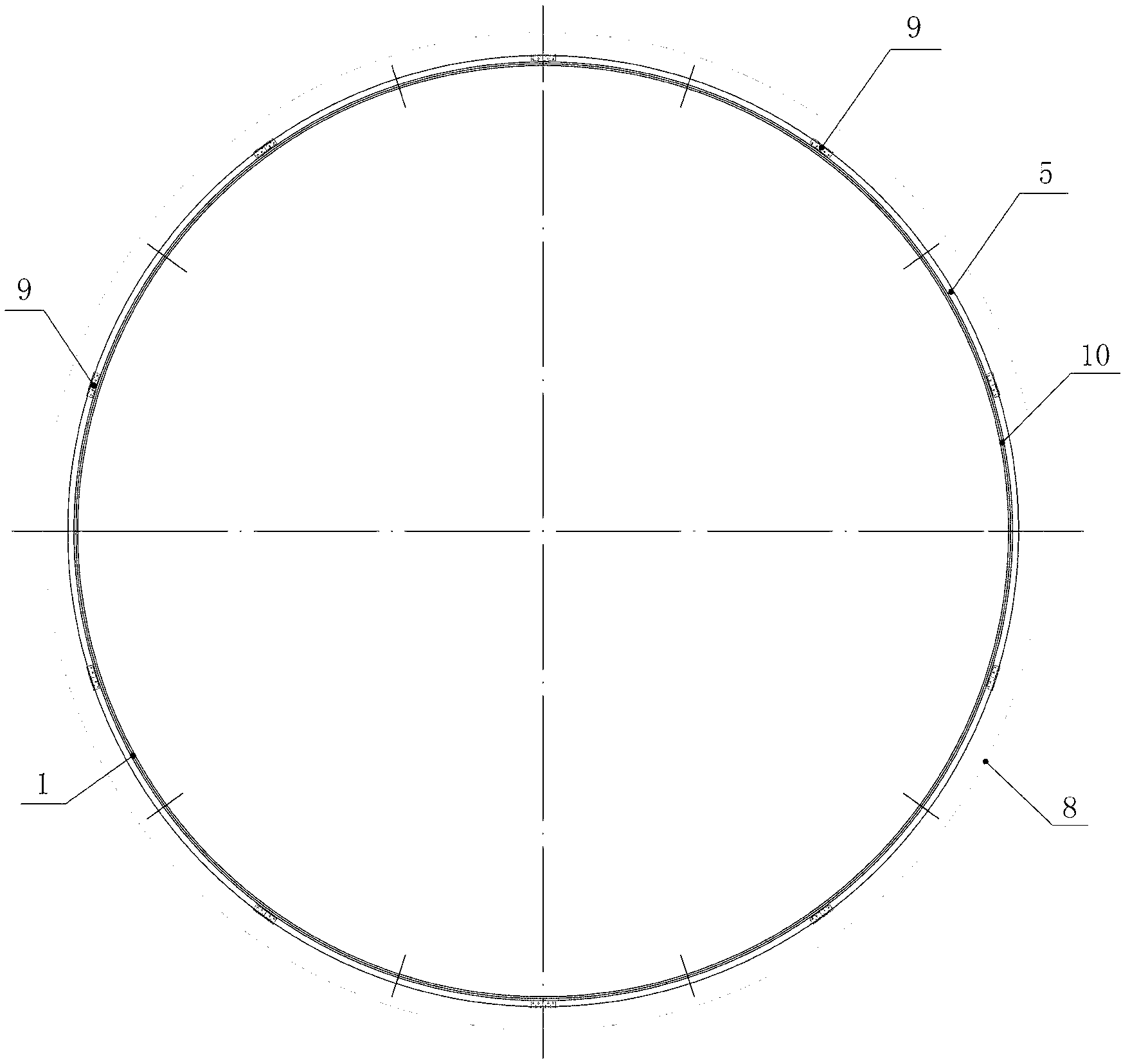

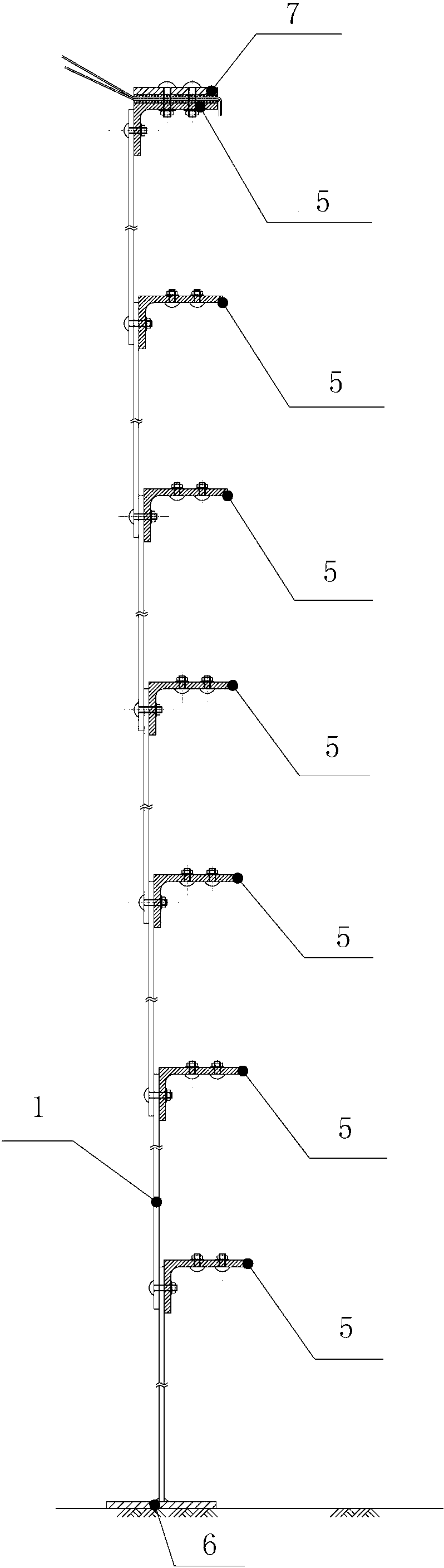

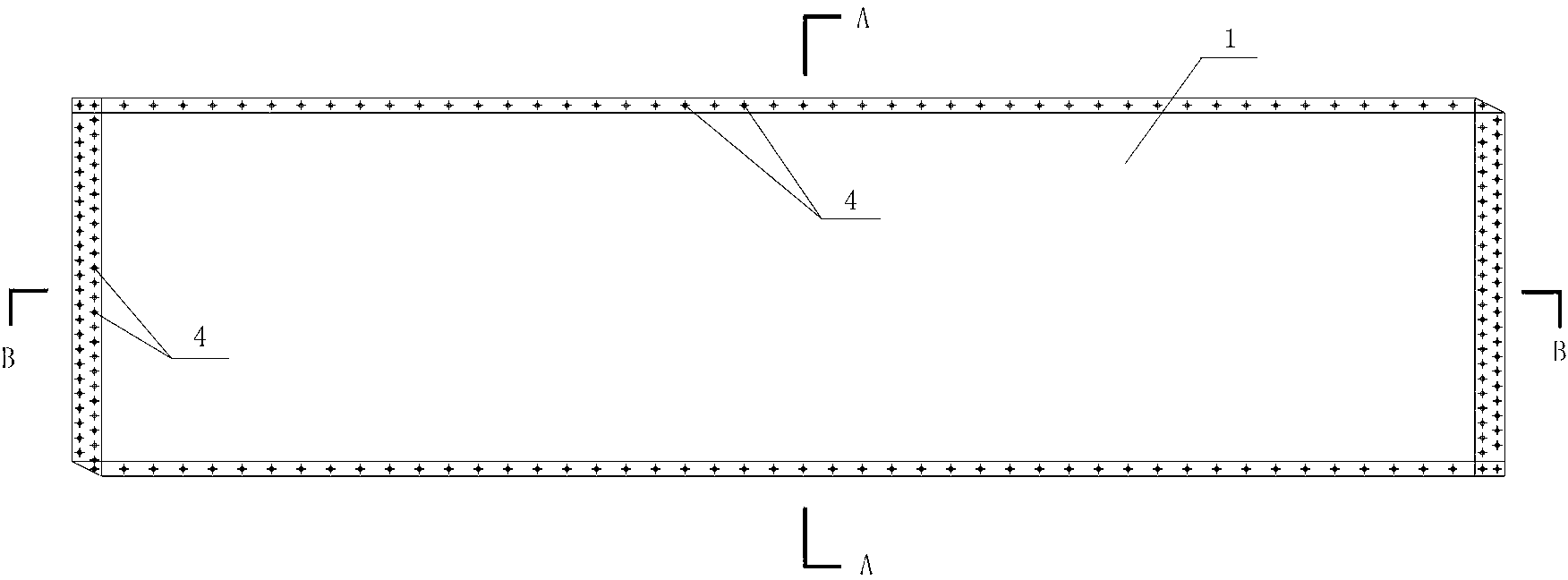

Insulating composite assembly board methane fermentation tank

InactiveCN103074209AImprove reusabilityAchieve maximum utilizationGas production bioreactorsMetal layered productsMethane fermentationEngineering

The invention discloses an insulating composite assembly board methane fermentation tank, which comprises an assembly tank wall body formed by fixedly splicing assembly boards. Stirrups are arranged on the circumference of the assembly tank wall body; joints between the stirrups and the assembly boards are fixed together through bolts, and the joints are sealed by adopting sealing materials; the assembly boards respectively consist of a middle base layer, a covering layer and an insulating layer, wherein the covering layer and the insulating layer are respectively arranged at both sides of the base layer, the base layer is made of carbon steel, and the covering layer is made of stainless steel; the assembly boards are rectangular; bolt holes are arranged at four sides of each assembly board; the stirrups are respectively made of hot galvanizing angle steel; each layer of adjacent stirrups along the peripheral direction of the assembly tank wall body are connected through a stirrup connecting piece; both sides in the length direction of the corresponding assembly board are respectively provided with a row of bolt holes; both sides in the width direction of the corresponding assembly board are respectively provided with two rows of bolt holes in parallel; and the lower end of the assembly tank wall body is fixedly connected with an embedded steel board in a concrete foundation. The insulating composite assembly board methane fermentation tank disclosed by the invention has the advantages that the corrosion is resisted; the installation rate is high; the service life is long; the reusability is high; processes can be reduced; and the construction period is shortened.

Owner:HENAN SENGDA ENERGY ENVIRONMENTAL PROTECTION

Environment-friendly high-glossiness colorful polypropylene material and manufacturing method thereof

The invention relates to an environment-friendly high-glossiness colorful polypropylene material and a manufacturing method thereof. The polypropylene material comprises the following components in parts by weight: 10-80 parts of polypropylene resin, 1-70 parts of stuffing, 1-5 parts of dispersing agent EBS (ethylene bis stearamide), 0.1-5 parts of colorant, 1-10 parts of toughener POE (polyolefin elastomer), 0.1-0.3 part of antioxidant, 0.1-0.5 part of coupling agent and 0.1-20 parts of pearlescent pigment or metal powder. The manufacturing method comprises the following steps: grinding the stuffing and dispersing agent EBS in a high-speed grinder until the particle size is less than light wavelength, and dissolving the pearlescent pigment or metal powder in the coupling agent solution to implement oriented arrangement; premixing the polypropylene and micronized stuffing in a high-speed stirrer by a double screw extruder blending process; and adding into the double screw extruder, adding the oriented-coupled pearlescent pigment or metal powder through the front part of the double screw extruder, extruding, cooling, granulating and packaging.

Owner:SHANDONG DAWN POLYMER CO LTD

Aluminum alloy surface coating and method for forming coating

InactiveCN106423805AEmission reductionSmall footprintPretreated surfacesCoatingsSpray coatingPollutant emissions

The invention provides an aluminum alloy surface coating and a preparation method thereof. The aluminum alloy surface coating comprises an aluminum alloy matrix, a colorful bottom powder layer and a transparent powder layer in turn, wherein the resin bottom powder is arranged on the colorful bottom powder layer; the thickness of the colorful bottom powder layer is 50-300 microns; the resin bottom powder is arranged on the transparent powder layer; the thickness of the transparent powder layer is 50-350 microns; the colorful bottom powder layer is composed of resin, auxiliaries, pigment, padding and metal powder; and / or the transparent powder layer is composed of resin, auxiliaries and curing agent. Through the spray coating of the colorful bottom powder, the paint spraying process is avoided; the functions of covering the workpiece surface defects and acquiring elegant appearance color can be realized; the intrinsic problems of long process route and long production period of the traditional technique can be solved. The aluminum alloy surface coating is capable of greatly increasing the production efficiency, reducing the material and labor cost, reducing the pollutant emission, shortening the spray coating line, reducing the floor area of the spray coating workshop, protecting the environment and easily realizing industrial large-scale popularization.

Owner:CITIC DICASTAL

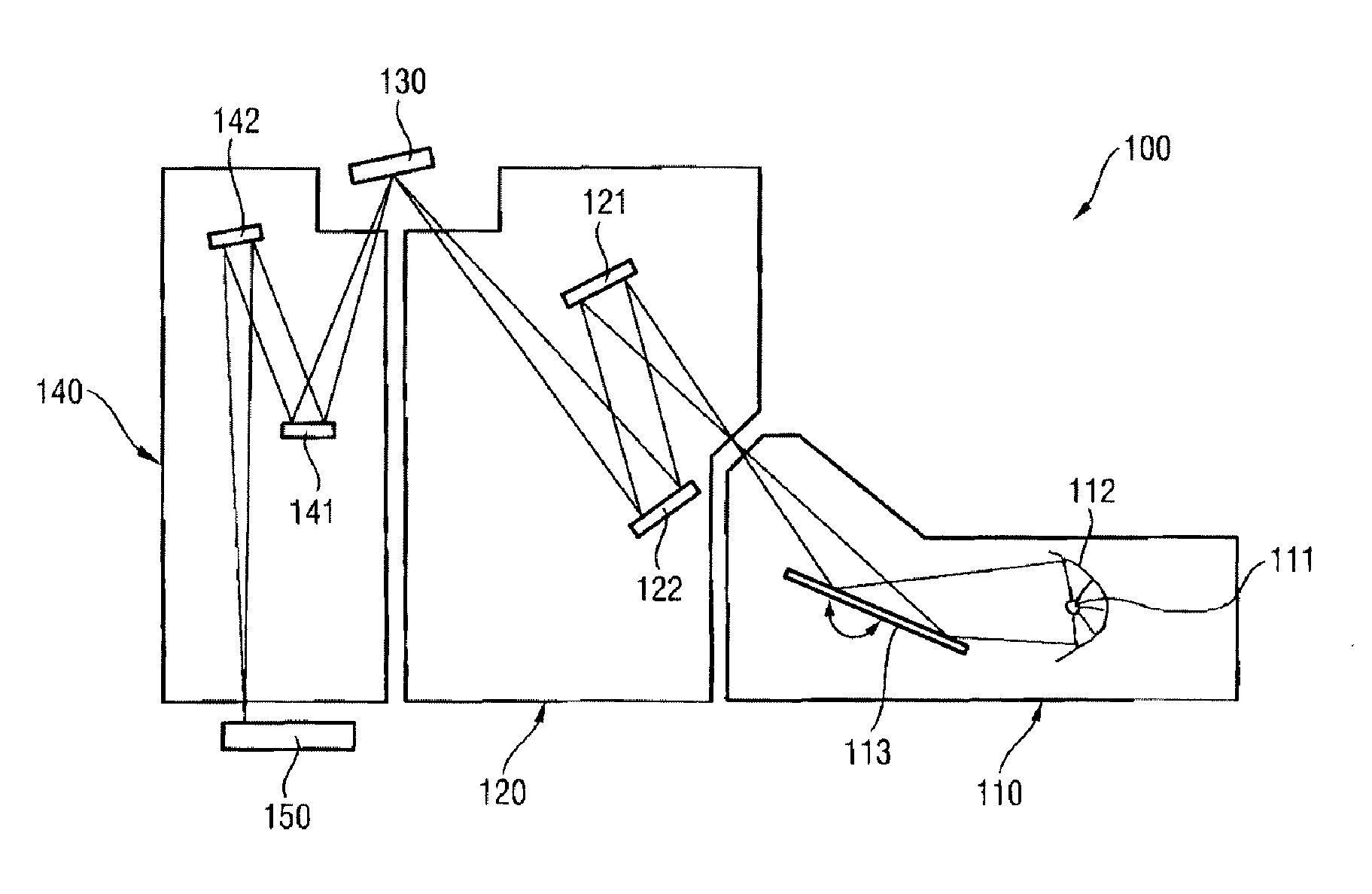

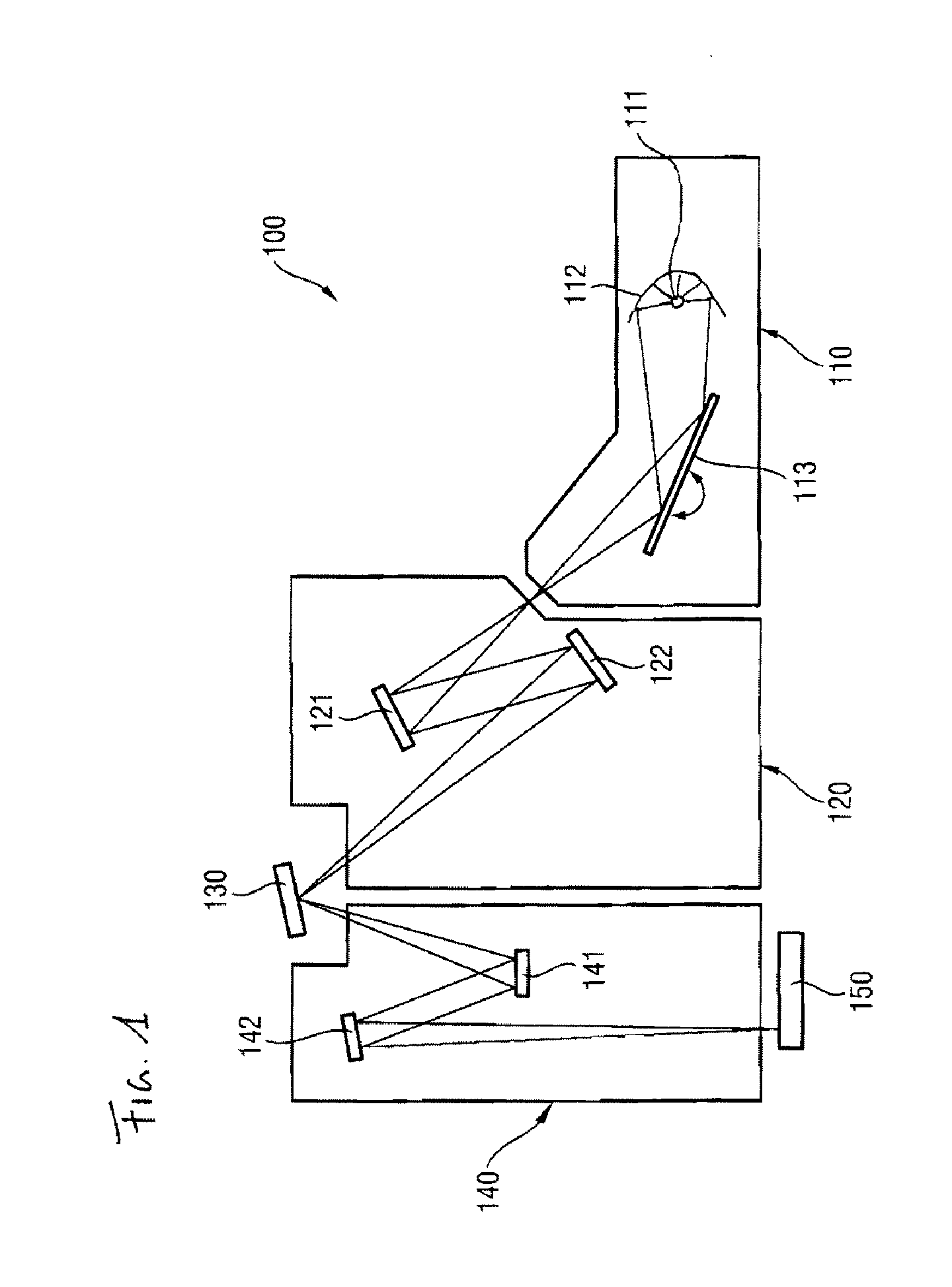

Reflective optical element and method for production of such an optical element

ActiveUS20120314281A1Relieve pressureImprove reflectivityLiquid surface applicatorsElectric discharge heatingSoft x rayCatoptrics

In order to produce stress-reduced reflective optical elements (1) for an operating wave length in the soft X-ray and extreme ultraviolet wavelength range, in particular for use in EUV lithography, it is proposed to apply, between substrate (2) and a multilayer system (4) optimized for high reflectivity at the operating wavelength, a stress-reducing multilayer system (6) with the aid of particle-forming particles having an energy of 40 eV or more, preferably 90 eV or more. Resulting reflective optical elements are distinguished by low surface roughness, a low number of periods in the stress-reducing multilayer system and also high values of the stress-reducing multilayer system.

Owner:CARL ZEISS SMT GMBH

Synthesized counterweight block for elevator

InactiveCN106241574AReduce usageReduce painting processBuilding liftsMine liftsSlagWorking environment

The invention discloses a synthesized counterweight block for an elevator. A counterweight block body is of a blocky structure formed through mixed pouring of metal fiber, ore, metal slag, cement and a proper amount of water, wherein the counterweight block body comprises, by weight, 32-39 parts of the metal fiber, 55-63 parts of the ore, 12-23 parts of the metal slag and 9-20 parts of the cement. The metal fiber material is adopted for replacing an iron shell on the outer layer of a traditional counterweight block and strengthening steel bars in the traditional counterweight block, the usage amount of steel is reduced, the welding procedures are reduced, the painting procedure of the iron shell on the outer layer is omitted, and pollution to the work environment is reduced.

Owner:XUANCHENG VALIN PRECISION TECH

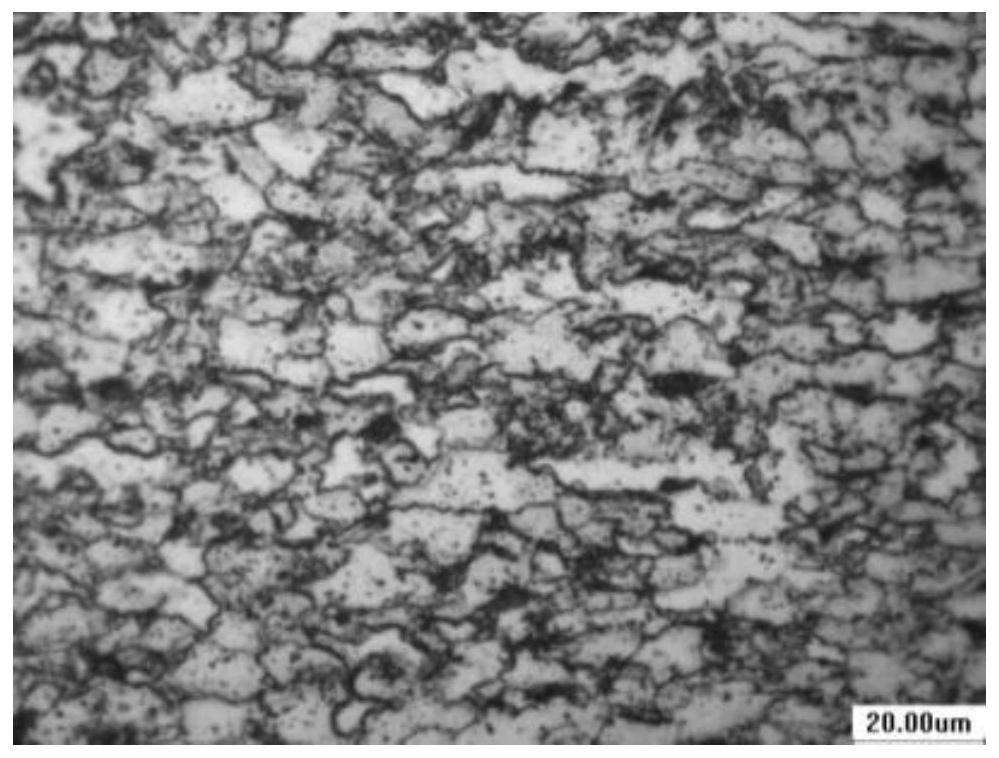

Hot rolling weather-resistant steel belt and flexible production method thereof

The invention discloses a hot rolling weather-resistant steel belt and a flexible production method thereof. Marks of the weather-resistant steel belt are Q355NH, Q460NH, Q500NH. Chemical components of the hot rolling weather-resistant steel belt comprise, by weight, 0.08-0.10% of C, 0.80-1.00% of Mn, less than or equal to 0.010% of S, less than or equal to 0.025% of P, less than or equal to 0.30%of Si, 0.020-0.050% of Als, 0.020-0.040% of Ti, 0.50-0.75% of Cr, 0.12-0.20% of Ni, 0.25-0.35% of Cu and the balance Fe and inevitable impurity elements. The production method comprises the procedures of converter smelting, LF refining, slab continuous casting, heating, rough rolling, finish rolling, cooling and coiling. By means of the hot rolling weather-resistant steel belt and the flexible production method thereof, the hot rolling weather-resistant steel belts of three levels can be produced from the same components; and performance of the hot rolling weather-resistant steel belts meetsrequirements for welding structure weather-resistant steel.

Owner:TANGSHAN STAINLESS STEEL +1

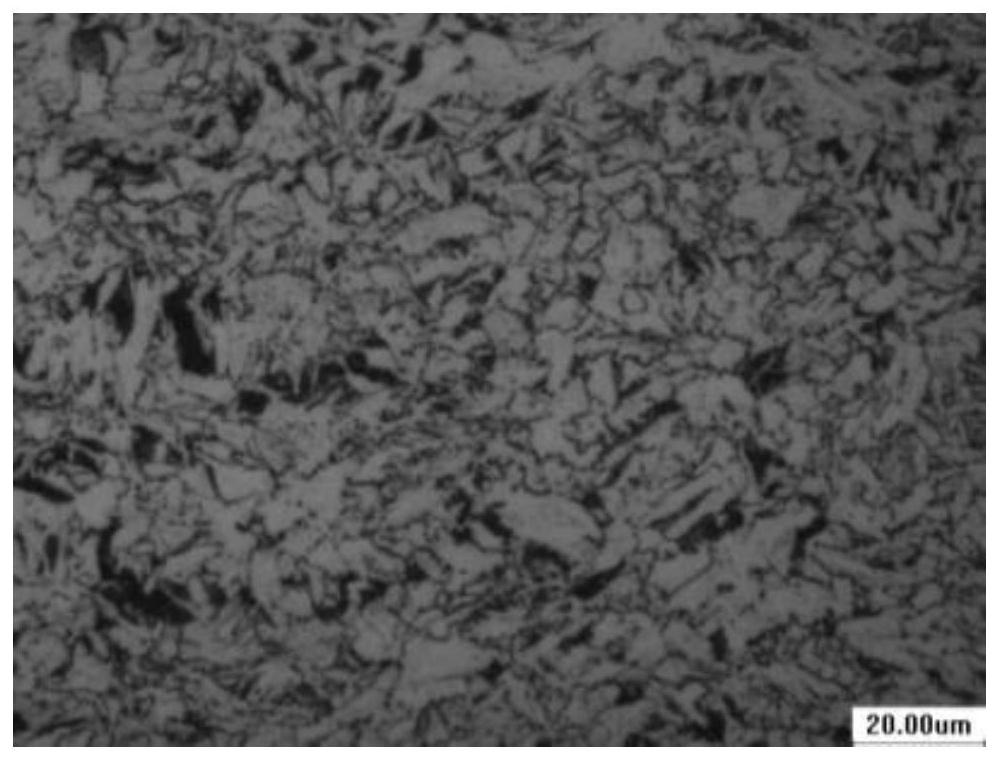

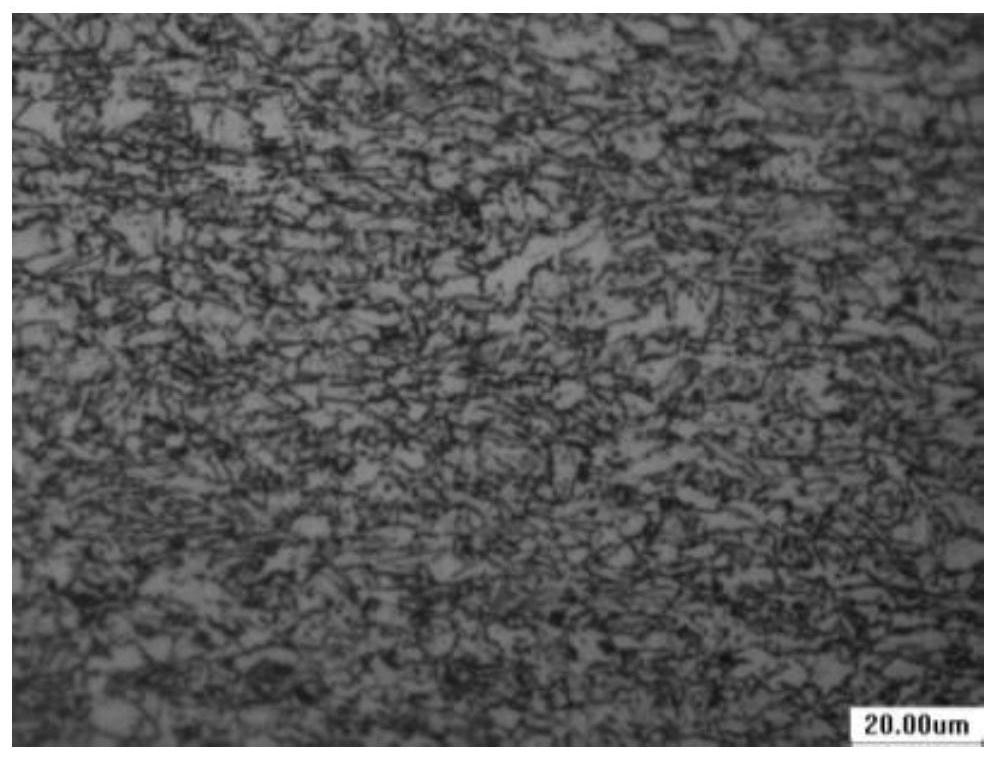

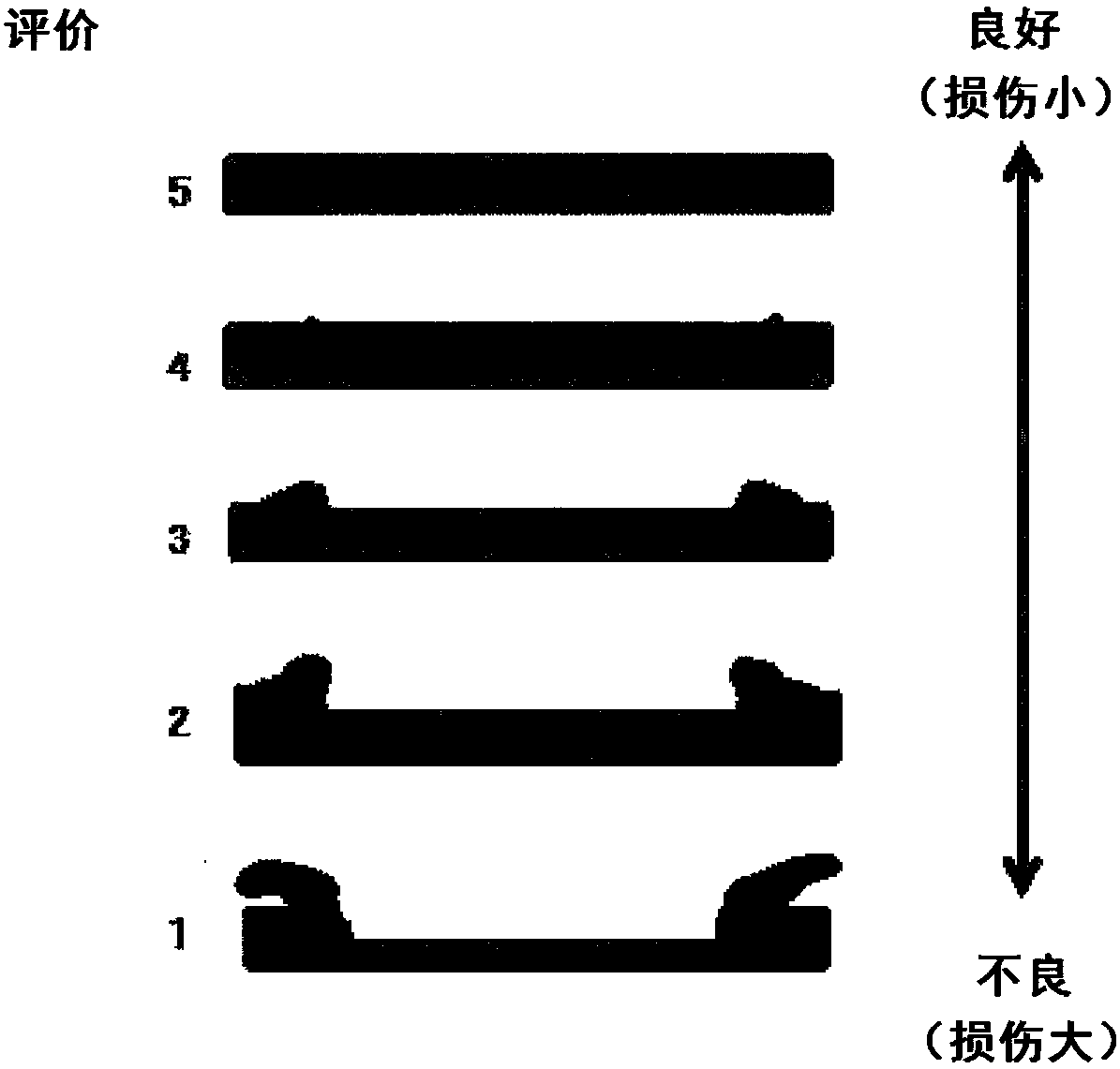

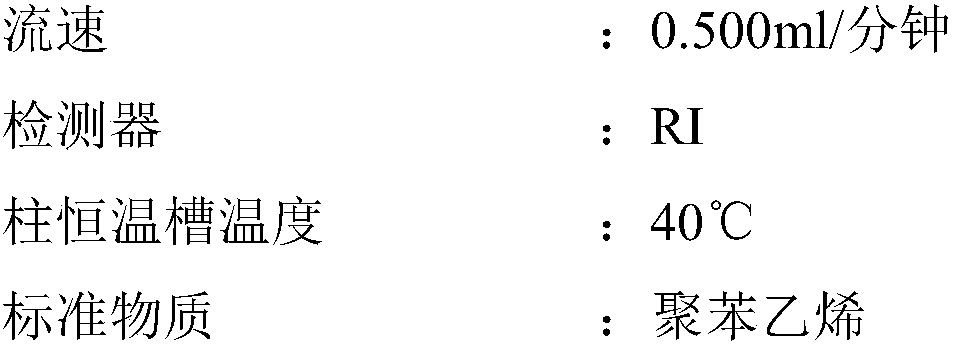

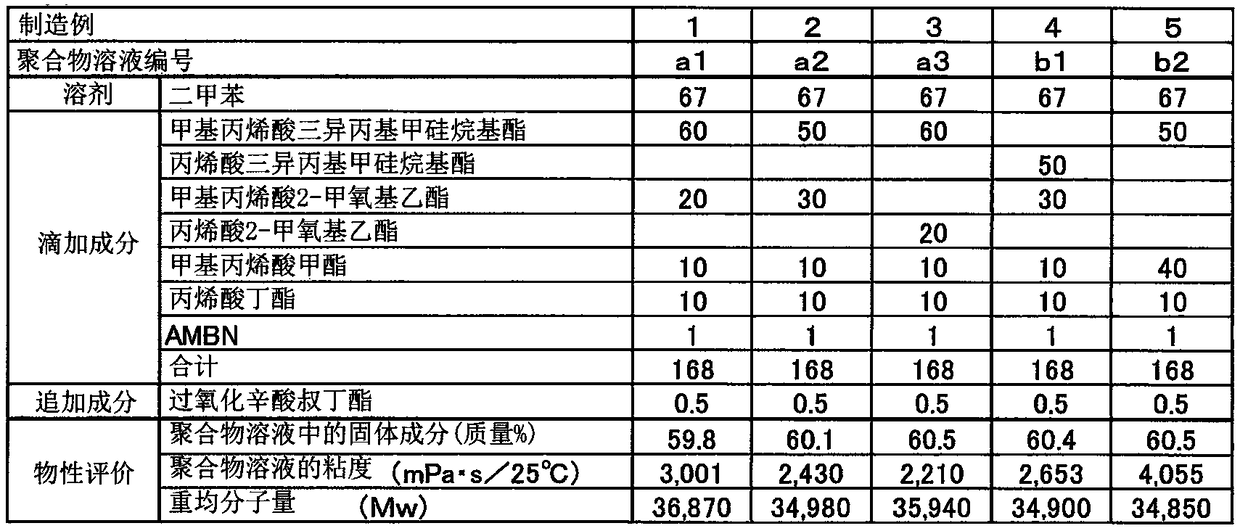

Antifouling composite coating film, antifouling substrate, and method for manufacturing antifouling substrate

ActiveCN108307625AImprove resistance to damageGood adhesionVessel cleaningAntifouling/underwater paintsEpoxyPolymer science

To provide an antifouling composite coating film having excellent long-term antifouling properties, long-term water resistance, damage resistance, and long-term adhesion. This antifouling composite coating film is obtained by laminating an epoxy resin coating film (P) and an antifouling coating film (Q) formed from a hydrolysis-type antifouling coating composition (q), wherein the hydrolysis-typeantifouling coating composition (q) contains: a hydrolyzable copolymer (A) comprising a structural unit (1) derived from triisopropyl silyl methacrylate (i), a structural unit (2) derived from 2-methoxyethyl (meth)acrylate (ii), and a structural unit (3) derived from a polymerizable monomer (iii) that has a polymerizable double bond (excluding triisopropyl silyl methacrylate and 2-methoxyethyl (meth)acrylate); and a rosin and / or a monocarboxylic acid compound (B).

Owner:CHUGOKU MARINE PAINTS

Nano graphene polysiloxane composite paint and preparation method thereof

InactiveCN107722824AImprove adhesionImprove anti-corrosion performanceAnti-corrosive paintsFirming agentGraphite

The invention discloses nano graphene polysiloxane composite paint. The paint is prepared from, by mass, 69.5%-72.5% of organopolysiloxane resin, 18%-20% of titanium dioxide, 2%-5% of talcum powder, 2%-5% of graphene, 0.1%-0.15% of a flatting agent and 4.4%-8% of a curing agent, and the sum of the mass fractions of the components is 100%. By means of introduction of graphene, the adhesive force and corrosion resistance of the composite paint can be improved, the film thickness is lowered, the impact strength is enhanced, and the bending elongation percentage is effectively increased; after curing is conducted at normal temperature, the paint can be directly spread on the surface of an alcohol-soluble inorganic zinc-rich coating, the painting process can be reduced, construction is easy, and the construction efficiency is effectively improved.

Owner:贾生斌

A kind of preparation method of plain colored high-gloss shell of green home appliances

ActiveCN102294828AImprove environmental protection effectThe process is simple and fastFlat articlesMolding machineUltrasonic welding

The invention discloses a method for preparing a plain high-gloss shell of a green home appliance. The invention comprises the following technical steps: co-extruding recycled plastics and flame-retardant plastics into boards; using a special surface non-contact gas pressure forming machine to form; The semi-finished green home appliance shell is cut in three dimensions; according to the size requirements of the cut shell semi-finished product, the insert is injected; the green home appliance shell semi-finished product after forming and cut is assembled with the injection molded insert; the assembly is performed using an ultrasonic welding machine After welding the inserts; apply glue to the above welded inserts. Adopting the present invention not only satisfies the requirement of high-gloss flame-retardant properties of green home appliances, but also improves the reutilization rate of industrial waste and reduces environmental pollution; the production process is simple and fast, reducing equipment investment; the produced products are plain, reducing the painting process and meeting environmental protection requirements .

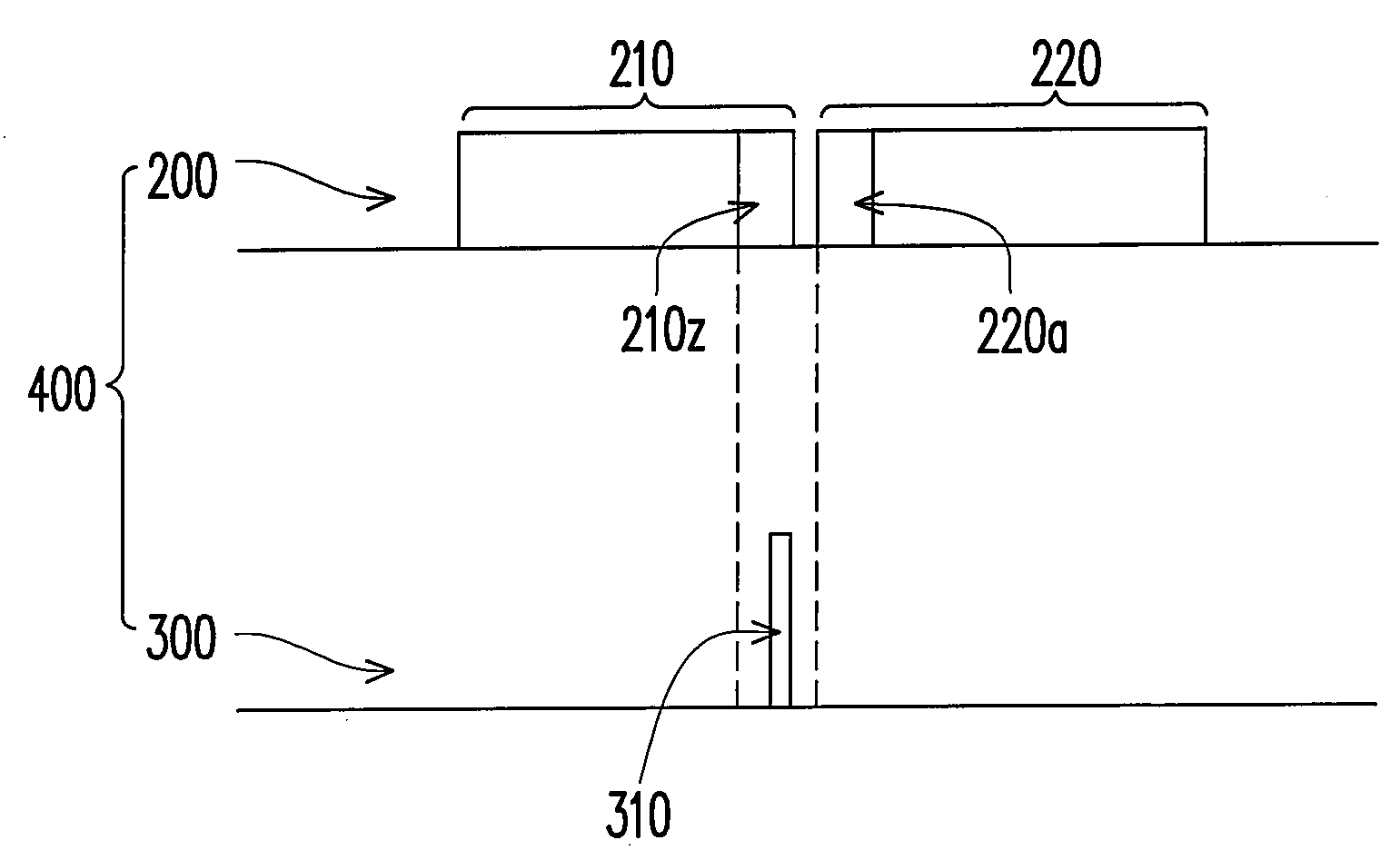

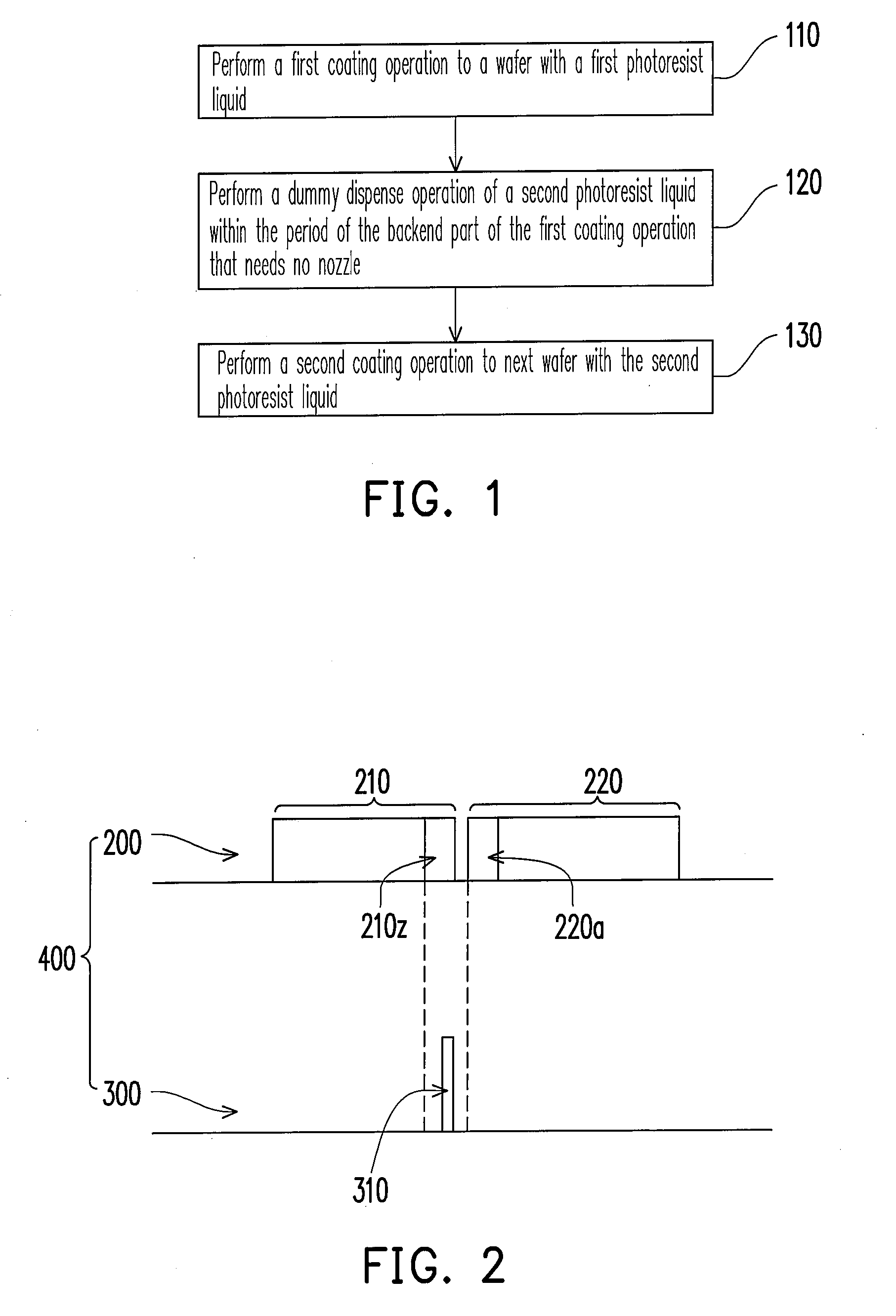

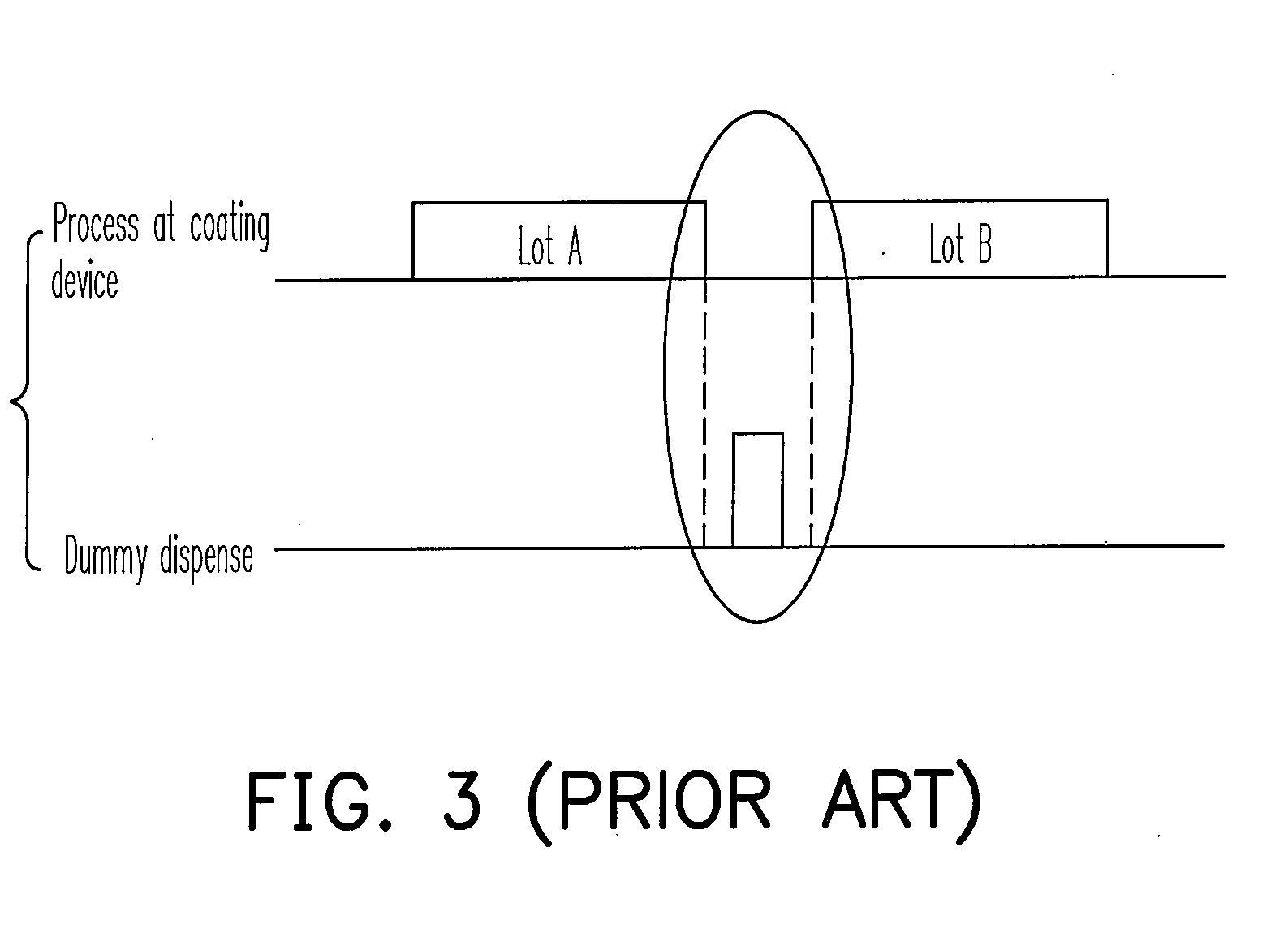

Method of shortening photoresist coating process

InactiveUS20090011612A1Shorten cycle timeOperation efficiency can be improvedPhotomechanical apparatusSemiconductor/solid-state device manufacturingProcess engineeringPhotoresist

A method of shortening a photoresist coating process for a plurality of wafers is provided, wherein the photoresist coating process includes a first coating operation to a first wafer using a first photoresist liquid and a second coating operation to a second wafer using a second photoresist liquid. The method includes performing a dummy dispense operation of the second photoresist liquid within the period of the backend part of the first coating operation that needs no nozzle.

Owner:UNITED MICROELECTRONICS CORP

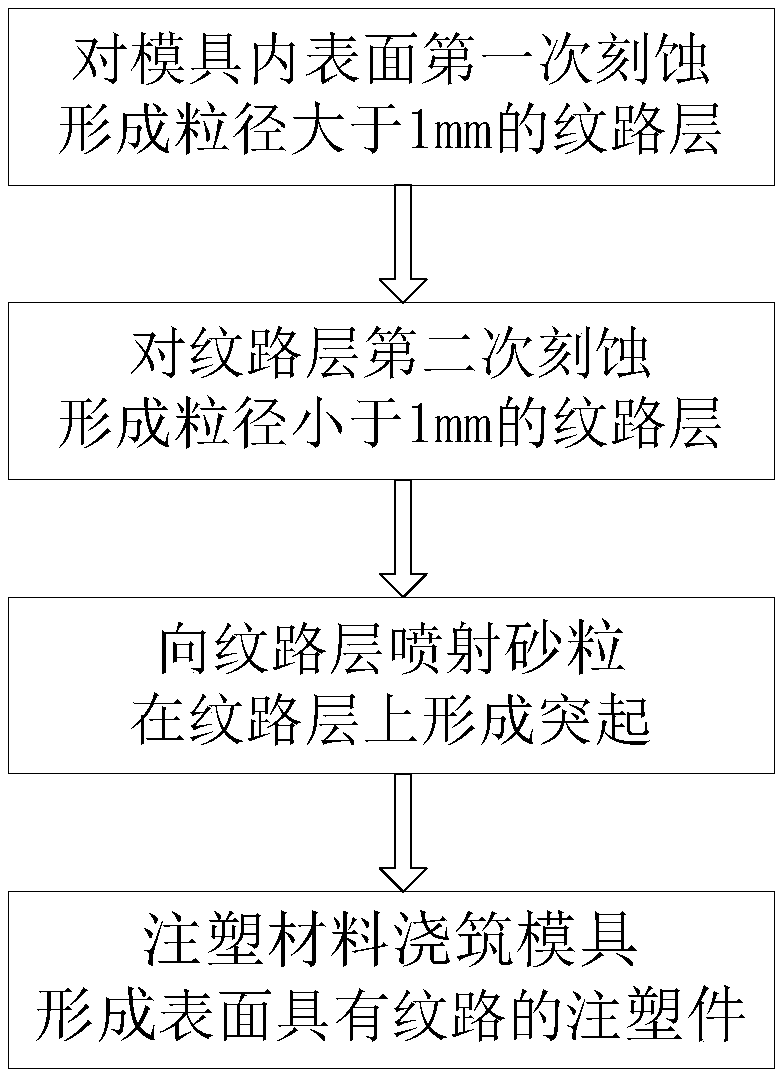

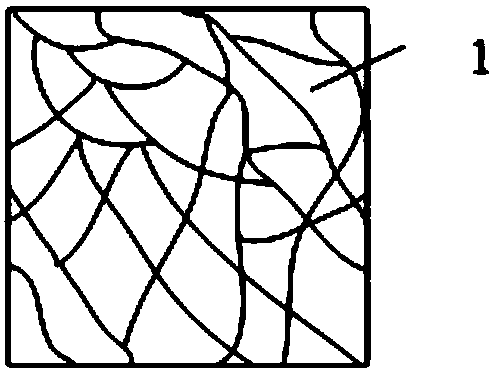

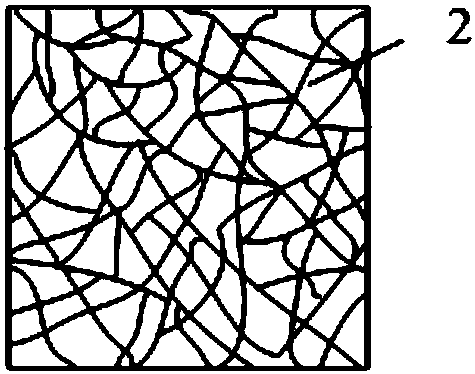

Surface shaping method of injection molding element and injection molding element

The invention discloses a surface shaping method of an injection molding element and the injection molding element. The surface shaping method comprises the following steps that (1) the inner surfaceof a mold for forming the injection molding element is subjected to primary corrosion; a grain layer is formed at the inner surface of the mold; (2) a grid layer is paved on the grain layer; the grainlayer is subjected to secondary corrosion by the grid layer, so that the dispersion degree of the grain particle diameter in the grain layer is reinforced; (3) sand grains are sprayed at the inner surface of the mold; bulges are formed at the surface of the grain layer; (4) an injection molding material is cast into the mold to form the injection molding element; the grain layer forms the grainsat the surface of the injection molding element. The surface shaping method of the injection molding element and the injection molding element provided by the invention have the advantages that the surface glossiness of the injection molding element can be reduced; the surface quality is improved; the production cost is reduced; the product competitiveness is improved.

Owner:SAIC GENERAL MOTORS +1

Method for producing high-shielding and high-gloss sheet

InactiveCN102658659AImprove environmental protection effectHigh glossPlastic recyclingFlat articlesPolycarbonate plasticPlastic materials

The invention relates to the technical field of sheets made from styrene copolymer or polycarbonate plastic, in particular to a method for producing a high-shielding and high-gloss sheet. The method comprises the following steps of: mixing the common plastic raw material particles and pigment or paint; co-extruding the mixture and color raw material particles to form a double-layer or multi-layer color high-shielding and high-gloss film; classifying the recycled plastic material, crushing, cleaning, drying and recycling; attaching and extruding the recycled plastic and the color high-shielding and high-gloss film to form a high-gloss sheet; forming a high-gloss shell by using a surface non-contact compressed air forming machine; and cutting a semi-finished shell to form a three-dimensional shape. By the method, the requirements of a product on high gloss and exquisite appearance are met, the shielding rate is high, the recycling rate of industrial wastes is improved, and the pollution of the wastes to the environment is reduced; the production process is simple, and equipment investment is reduced; the paint spraying process is eliminated, and the environment-friendly requirement of recycling the plastic material is met.

Owner:上海旭坤塑胶原料有限公司

Process For Coating Electrically Conductive Subsstrates

InactiveUS20070224337A1Improve interlayer adhesionIncrease resistanceElectrolysis componentsVolume/mass flow measurementEpoxyVitrification

A process for coating electrically conductive substrates by (1) applying an electrocoat film to an electrically conductive substrate and curing it to give an electrocoat and then (2) applying a layer of a pulverulent coating material to the electrocoat and curing it to give a powder coat or alternatively (1) applying an electrocoat film to an electrically conductive substrate and drying it without fully curing it, (2) applying a layer of a pulverulent coating material to the dried electrocoat film(s) and (3) jointly curing the dried electrocoat film and the layer of the pulverulent coating material to give the electrocoat and the powder coat wherein the pulverulent coating material comprises (A) at least one epoxy resin having a melting point, melting range or glass transition temperature >30° C., (B) at least one carboxyl-containing polyester resin having a melting point, melting range or glass transition temperature >30° C., and (C) at least one polycarboxylic acid having a melting point of between 80 and 160° C.

Owner:BASF COATINGS AG

Bottom closing paint for wood pen holder

The invention discloses wooden penholder sealing primer which is characterized in that the sealing primer is composed of polyvinyl acetate emulsion, plasticizing agent, alkali N-hydroxymethyl acrylamide, acetone and ethyl acetate, and the weight percentages of the ingredients are as follow: polyvinyl acetate emulsion 60-75%, plasticizing agent 1-5%, alkali N-hydroxymethyl acrylamide1-0.8%, acetone10-20% and ethyl acetate10-20%. The wooden penholder bottom sealing primer is high in solid content and low in viscidity and is quick to dry(in 5 seconds) and convenient to use. The wooden penholder bottom sealing primer has obvious effect during the coating process in penholder manufacturing; the wooden penholder sealing primer is the first domestically and is internationally advanced in performance index in all aspects.

Owner:上海英诺威新材料科技有限公司

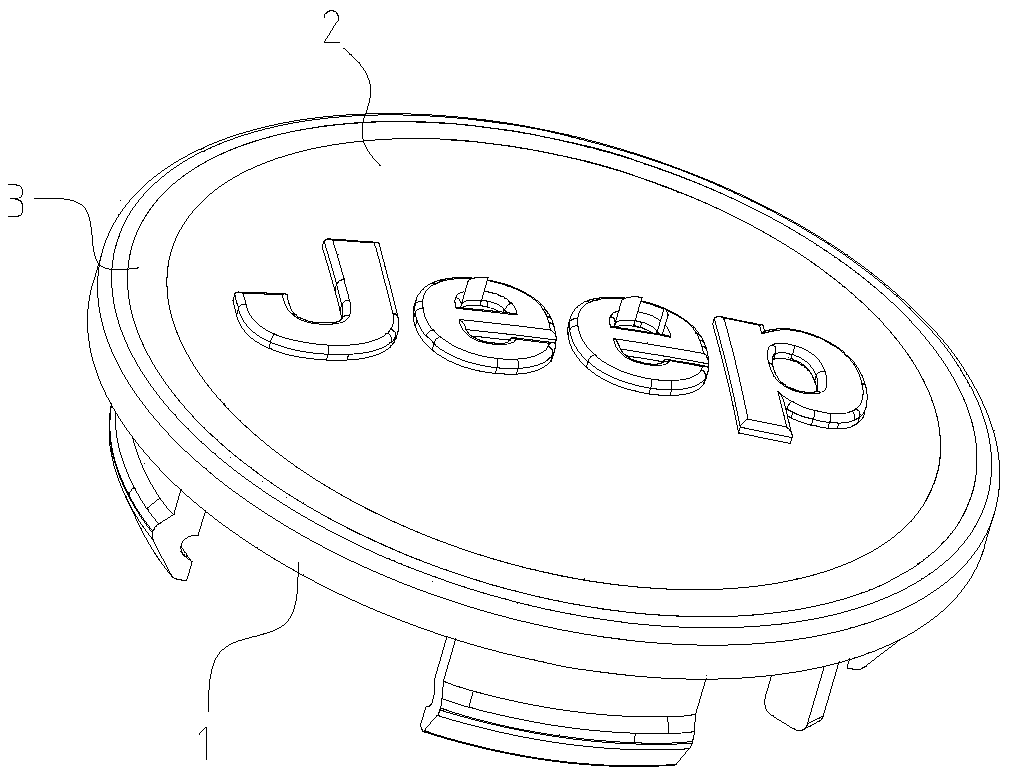

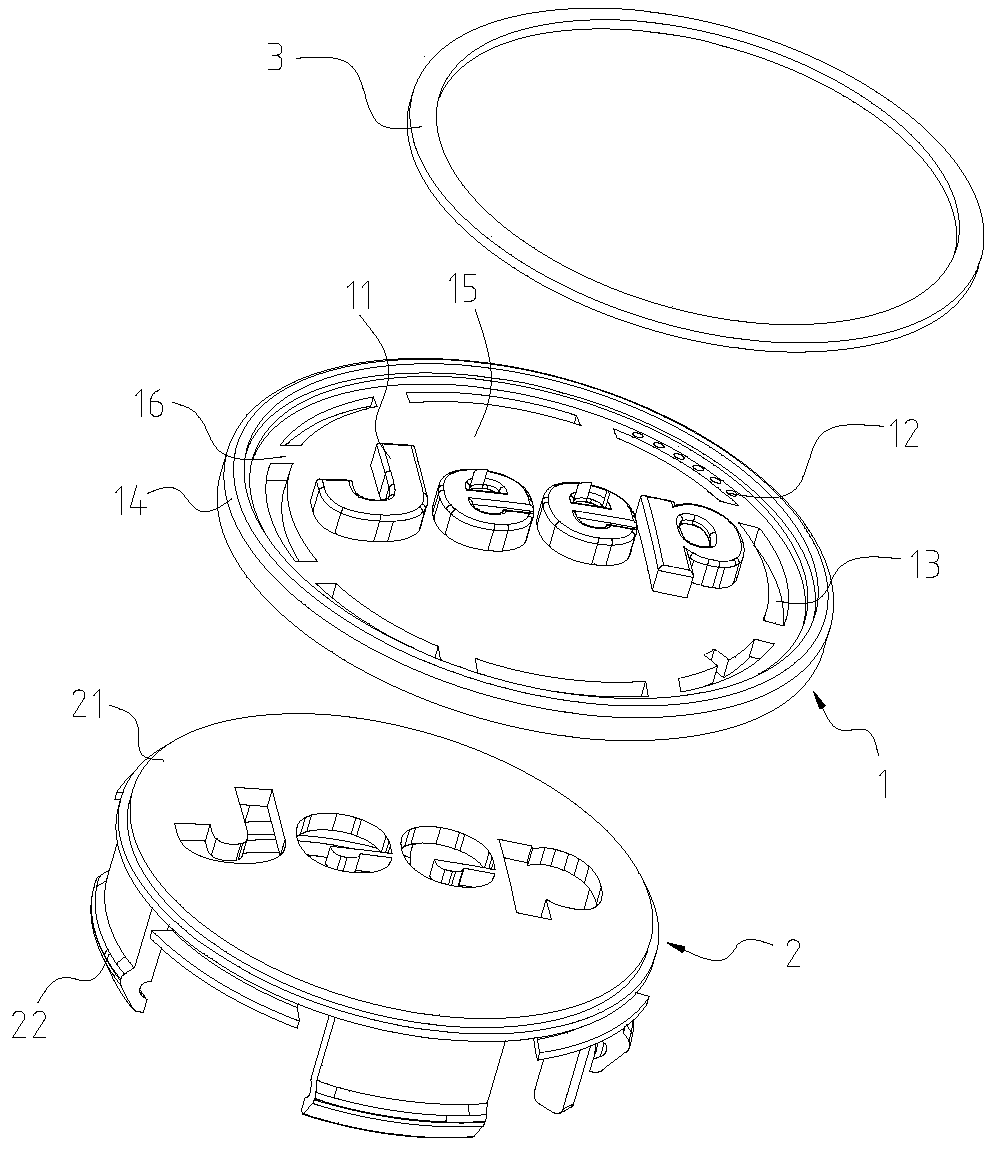

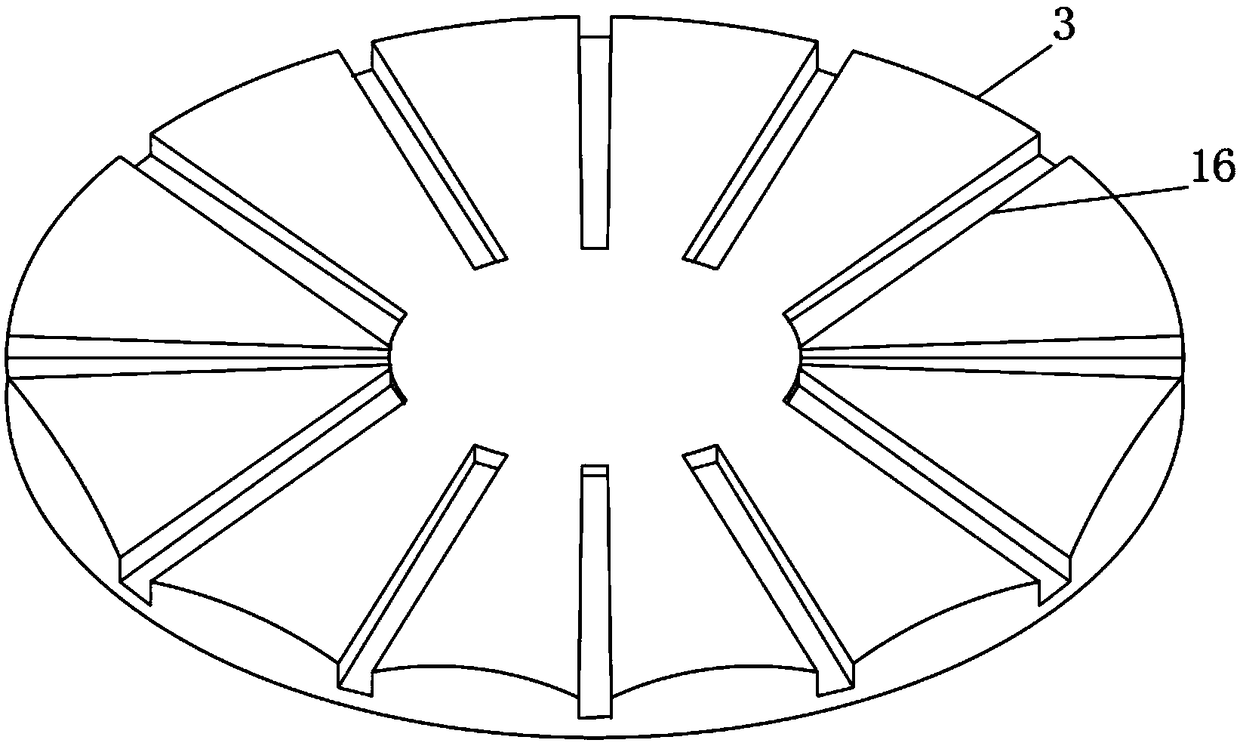

Manufacturing method of automobile mark

ActiveCN108995132AReduce toughnessGuaranteed toughnessVehicle componentsCoatingsEngineeringInjection moulding

The invention relates to a manufacturing method of an automobile mark. The manufacturing method of the automobile mark comprises the following steps: (1) performing injection molding by utilizing fistplastic to form a first part through and performing overall electroplating on the first part to form an electroplating piece; and (2) performing injection molding on the electroplating piece by utilizing second plastic to form a second part. By the process, internal and external integration is realized, structure separation and many-time electroplating are avoided and the whole process is simplified; injection molding is conducted by using coating-free plastic with different colors, so that the coating processes are reduced as well as energy conservation and environmental friendliness are realized; the toughness of the plastic after electroplating is reduced and assembling buckle feet are commonly coated with insulating oil before electroplating to prevent the buckle feet of the product of the electroplating piece from being broken, so that the toughness of the buckle feet is guaranteed; and insulating oil coating is not needed during injection molding for the second time after electroplating and the toughness of the assembling buckle feet can be guaranteed.

Owner:清远市金钟汽车零部件有限公司

Traffic guardrail reflective tape automatic smearing device

InactiveCN109382253AReasonable structureFunctionalLiquid surface applicatorsCoatingsRoad surfaceEngineering

The invention discloses a traffic guardrail reflective tape automatic smearing device. The traffic guardrail reflective tape automatic smearing device comprises a surrounding protecting rack, a rotating disk, a smearing cylindrical body, and smearing sponge blocks; the internal side bottom surface of the surrounding protecting rack is fixedly connected with a motor; the top of a rotating shaft ofthe motor is fixedly connected with the bottom surface of the rotating disk; the panel surface of the rotating disk is fixedly connected with positioning columns; the top of each positioning column isrotatingly connected with a gear; the top surface of each gear is fixedly connected with a stand column; the rod body of each stand column is fixedly connected with one end of a telescopic rod, and the other end of the telescopic rod is fixedly connected with a panel surface of a supporting protecting plate; the panel surface of the rotating disk is fixedly connected with the smearing cylindricalbody; the top end of the smearing cylindrical body is fixedly arranged at the bottom surface of a top plate. The traffic guardrail reflective tape automatic smearing device can be used for batch spraying coating before traffic guardrail installation, and reducing workload of workers in spraying coating along streets; operation is not limited by weather conditions; and cleaning work caused by dropping of paint on the roads is avoided.

Owner:何振中

Reflective optical element and method for production of such an optical element

ActiveUS8246182B2Relieve pressureImprove reflectivityMirrorsOptical filtersSoft x rayLithographic artist

In order to produce stress-reduced reflective optical elements (1) for an operating wave length in the soft X-ray and extreme ultraviolet wavelength range, in particular for use in EUV lithography, it is proposed to apply, between substrate (2) and a multilayer system (4) optimized for high reflectivity at the operating wavelength, a stress-reducing multilayer system (6) with the aid of particle-forming particles having an energy of 40 eV or more, preferably 90 eV or more. Resulting reflective optical elements are distinguished by low surface roughness, a low number of periods in the stress-reducing multilayer system and also high Γ values of the stress-reducing multilayer system.

Owner:CARL ZEISS SMT GMBH

Reinforced counterweight for elevator

InactiveCN106315367AMeet strength requirementsMeet the weight requirementBuilding liftsMine liftsSlagWorking environment

The invention discloses a reinforced counterweight for an elevator. The counterweight is prepared from raw materials in parts by weight as follows: 11-12 parts of metal fibers, 30-45 parts of ores, 22-34 parts of metal slag, 26-39 parts of cement in the water-cement ratio being 0.3-0.5 and 2-15 parts of albite, wherein the metal fibers are high-strength steel short filaments and have the length ranging from 5 mm to 30 mm. The metal fibers and the slag are recovered, a lot of resources are saved, meanwhile, the steel consumption is reduced by replacing an outer-layer iron casing and internal reinforcing steel bars of a traditional counterweight with the metal fibers, the procedure for painting the outer-layer iron casing is omitted, and the pollution to the working environment is reduced.

Owner:XUANCHENG VALIN PRECISION TECH

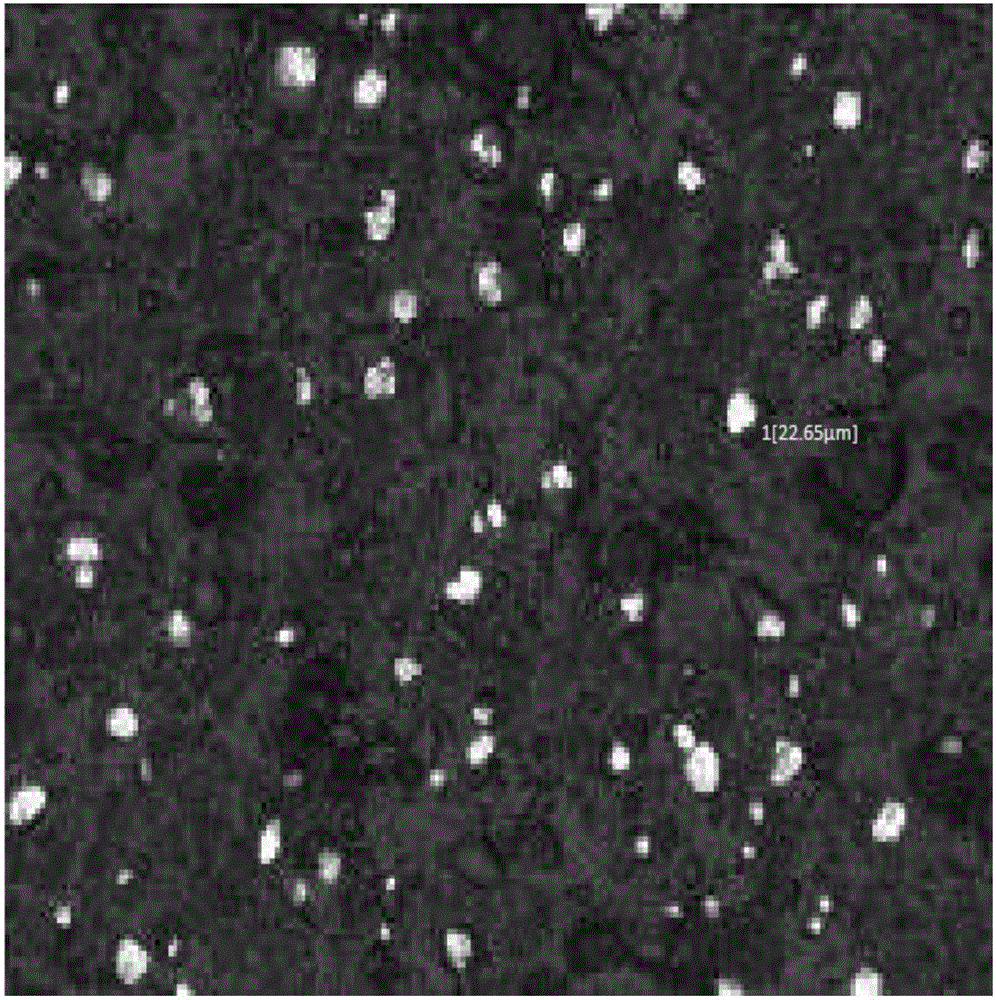

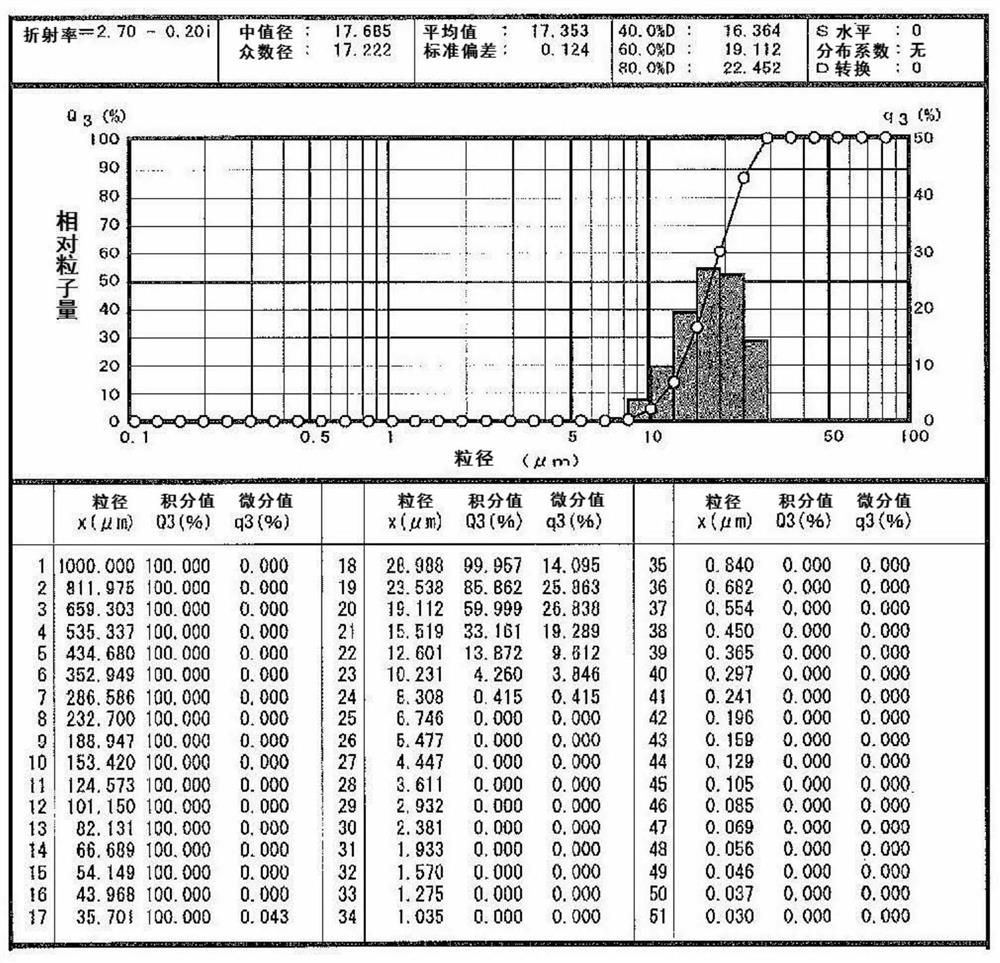

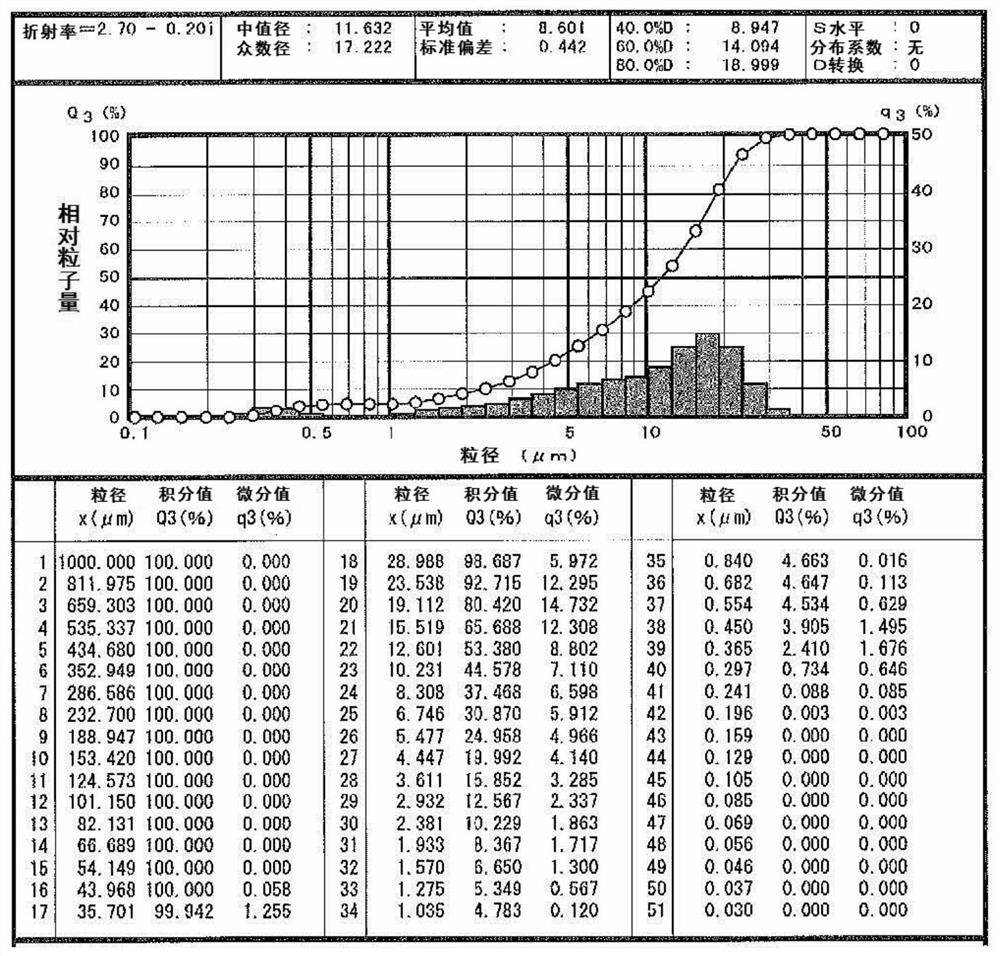

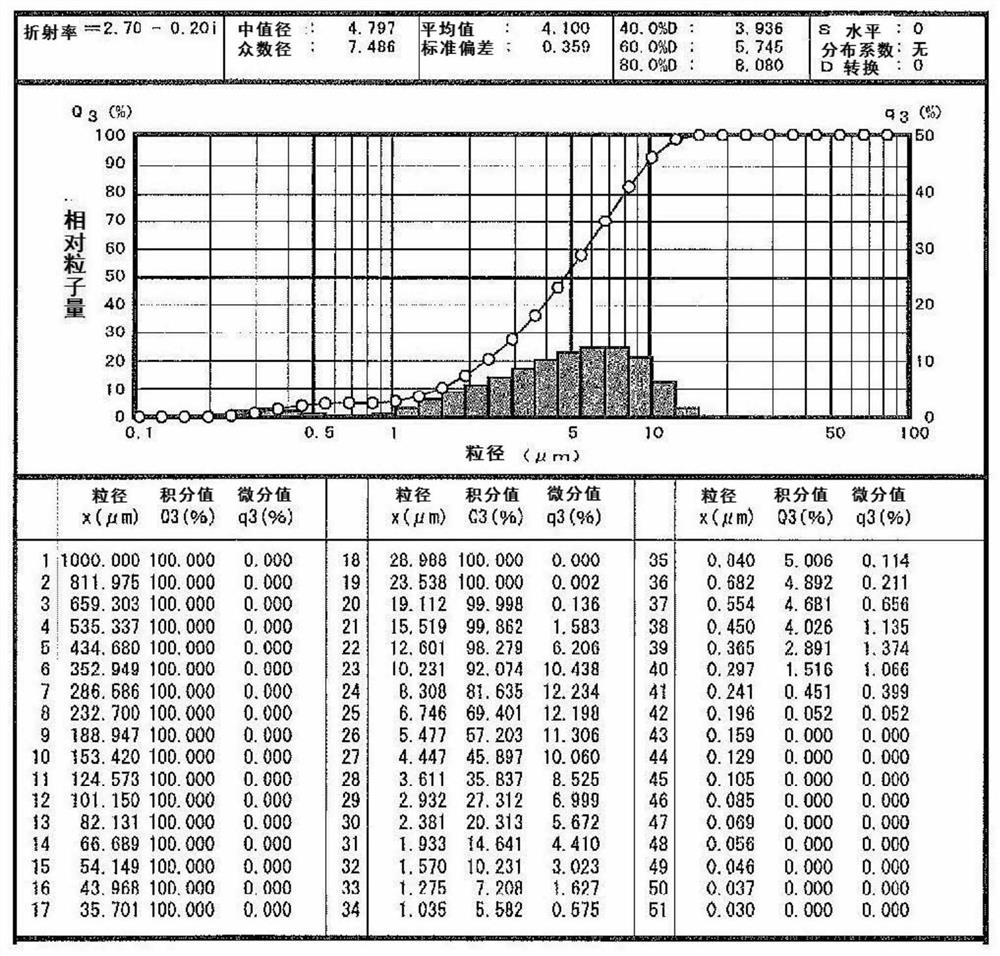

Automobile hub coating film

InactiveCN110588240ANot easy to hangGood blemish filling performanceAnti-corrosive paintsWheel protectionMetallurgyMicrometer

The invention discloses an automobile hub coating film, which comprises a hub body, wherein the surface of the hub body is provided with a primer layer, a middle coating and a finish paint layer frominside to outside in sequence; the primer layer, the middle coating and the finish paint layer are all in spraying and forming arrangement by powder paint; the grain diameter of the powder is 30-45 micrometers, a leveling rate and a powdering rate can be balanced, and surface properties, including coating film gloss, plumpness and the like, are excellent; the powder grain diameter of the finish paint layer is greater than the powder grain diameter of the middle coating and the powder grain diameter of the primer layer in sequence; and the thickness of the middle coating is greater than the thickness of the primer layer and the thickness of the finish paint layer in sequence. By use of a powder paint way, the omission of a base colored paint for automobile hub painting becomes a new development direction, so that the emission of VOCs (Volatile Organic Compounds) in a whole painting process is lowered by about 20% according to the characteristic of zero VOC of the powder paint, paintingworking procedures are reduced, efficiency is improved, a yield is improved, and cost is lowered.

Owner:黄山五环科技有限公司

Process for coating electrically conductive substrates

InactiveUS7862851B2Outstanding mechanotechnological propertyParticularly smoothElectrolysis componentsVolume/mass flow measurementEpoxyLacquer

A process for coating electrically conductive substrates by(1) applying an electrocoat film to an electrically conductive substrate and curing it to give an electrocoat and then(2) applying a layer of a pulverulent coating material to the electrocoat and curing it to give a powder coator alternatively(1) applying an electrocoat film to an electrically conductive substrate and drying it without fully curing it,(2) applying a layer of a pulverulent coating material to the dried electrocoat film(s) and(3) jointly curing the dried electrocoat film and the layer of the pulverulent coating material to give the electrocoat and the powder coatwherein the pulverulent coating material comprises(A) at least one epoxy resin having a melting point, melting range or glass transition temperature>30° C.,(B) at least one carboxyl-containing polyester resin having a melting point, melting range or glass transition temperature>30° C., and(C) at least one polycarboxylic acid having a melting point of between 80 and 160° C.

Owner:BASF COATINGS AG

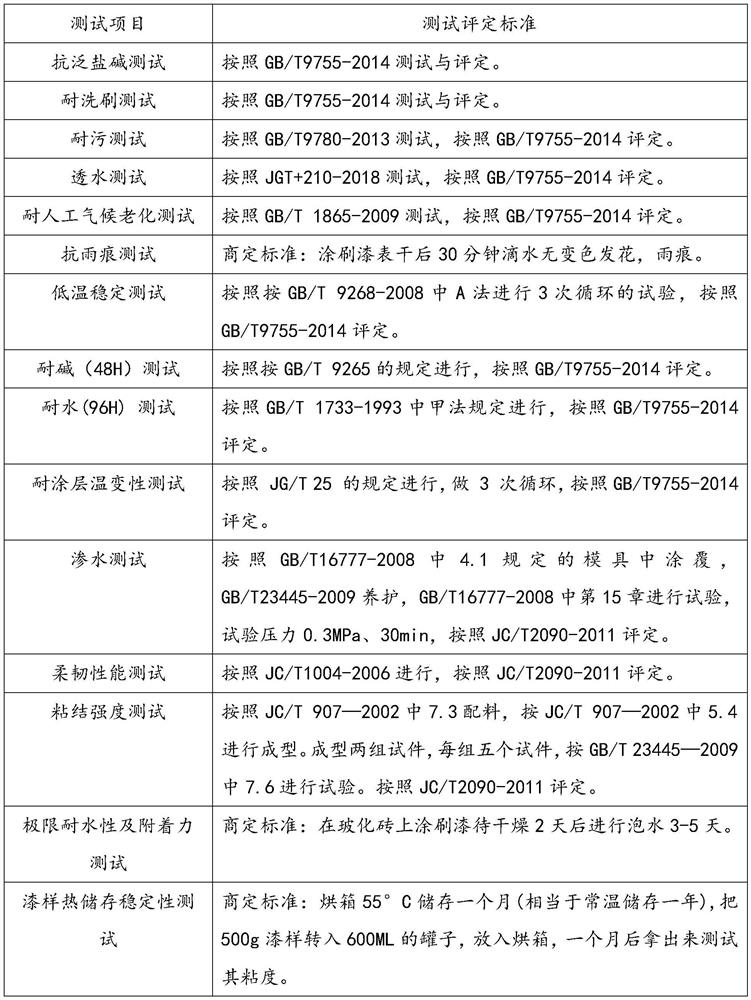

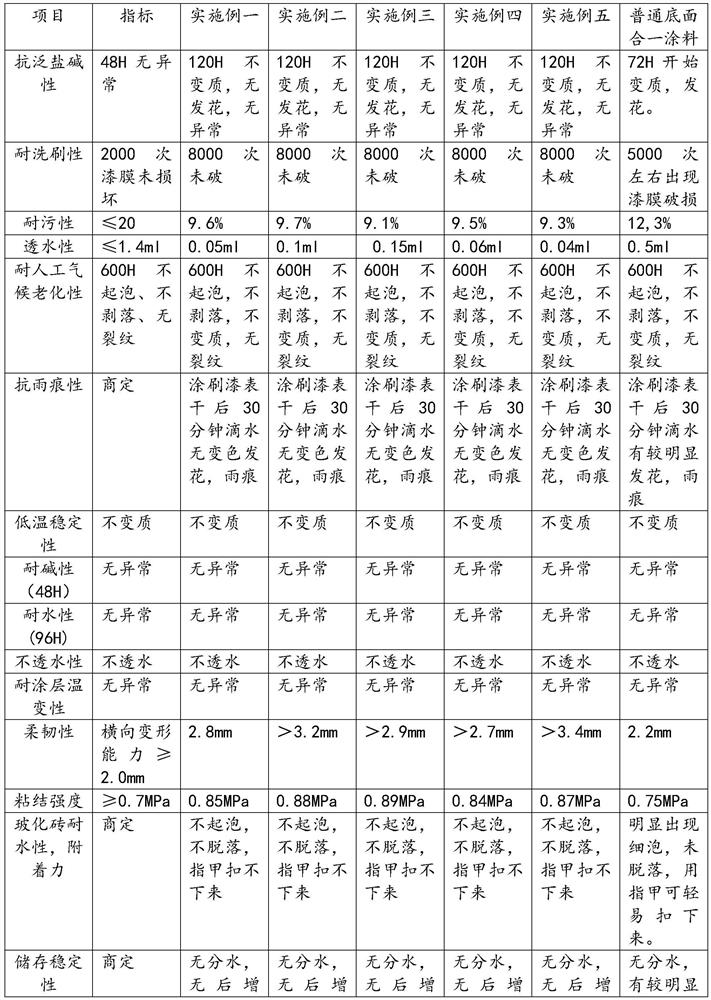

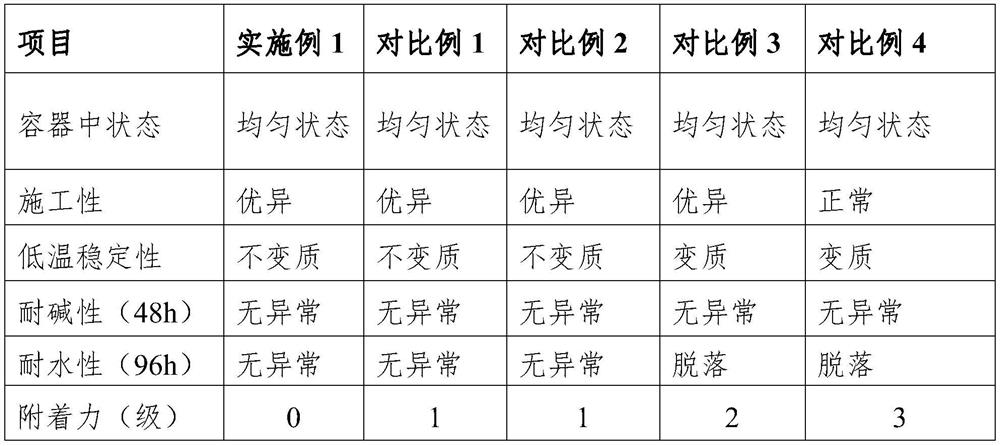

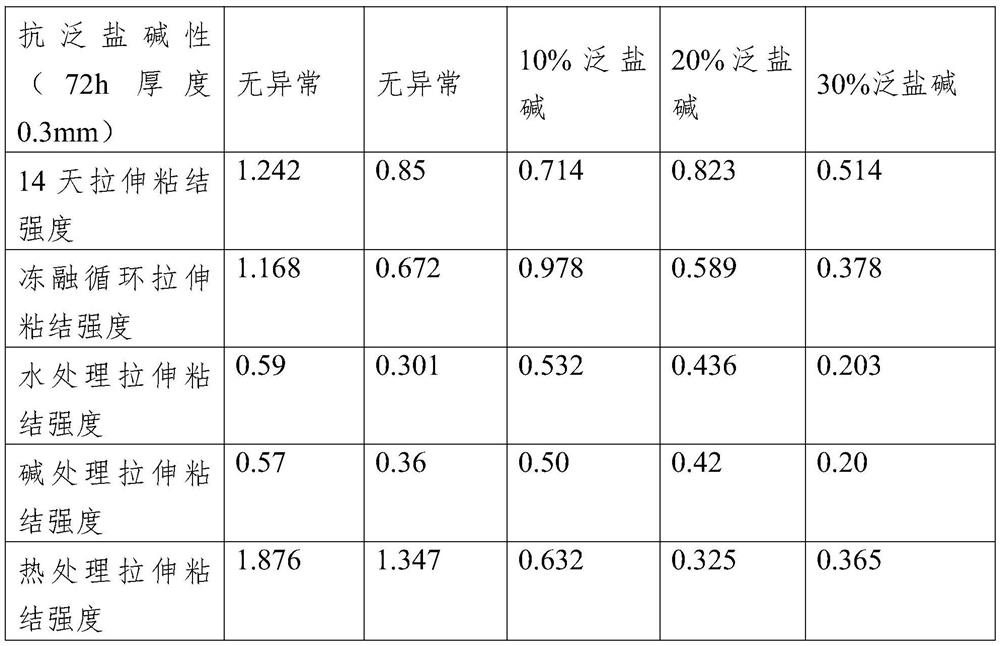

Primer-topcoat coating and preparation method thereof

The invention relates to the technical field of coatings, and discloses a primer-topcoat coating and a preparation method thereof, the primer-topcoat coating comprises the following components by mass: 10-14% of water; 1.2%-1.5% of propylene glycol; 1.3%-1.5% of a dispersing agent; 0.15%-2% of an anionic surfactant; 0.4%-0.5% of a defoaming agent; 0.2%-0.25% of cellulose; 0.1%-0.2% of a pH regulator; 18%-20% of titanium dioxide; 7.5%-8% of calcined kaolin; 6.5%-9.5% of barium sulfate; 45%-50% of a functional emulsion; 0.2%-0.3% of a mildew preventive; 2.5%-3% of a coalescing agent; 0.15%-0.2% of a thickening agent; 0.1%-0.2% of a preservative; and 0.3%-0.5% of a silane coupling agent. The primer-topcoat coating has excellent adsorption characteristic and film forming effect, can be suitable for wall base materials such as coarse porous concrete, cement mortar, red bricks, glass with smooth surfaces, ceramic tiles and the like, reduces coating procedures, and improves coating efficiency.

Owner:GUANGZHOU HAOTE CHEM CO LTD

High-performance paste interface primer two-in-one coating and preparation method thereof

The invention relates to high-performance paste interface primer two-in-one coating. The coating comprises the following components in parts by weight: 10 to 12 parts of water, 0.1 to 0.3 part of a thixotropic lubricant, 40 to 50 parts of a modified silicone acrylic emulsion, 0.3 to 0.5 part of bentonite, 0.3 to 0.5 part of a dispersing agent, 11 to 15 parts of coarse whiting, 25 to 27 parts of sand, 0.05 to 0.1 part of black paste, 0.3 to 0.5 part of titanium dioxide, 0.3 to 0.5 part of hydroxyethyl cellulose, 0.8 to 1.2 parts of a film forming aid, 0.3 to 0.5 part of ethylene glycol, 0.1 to0.3 part of AMP-95, 0.3 to 0.5 part of a defoaming agent, 0.2 to 0.3 part of a thickening agent, and 0.2 to 0.4 part of an antiseptic and anti-mildew agent. The high-performance pasty interface primertwo-in-one coating has excellent adhesion strength, the tensile bonding strength is 1.2 MPa, the coating can replace an interface agent and primer to be used, the filling efficiency is high, and thecoating can replace putty to be used as a leveling material.

Owner:SKSHU PAINT

Spoiler coating technology

InactiveCN106269426AReduce total usageReduce painting processPretreated surfacesCoatingsVarnishAir drying

The invention provides a spoiler coating technology. The technology comprises following steps of pretreatment, color paint spraying, mixing a color paint main agent, a color paint curing assistant and a color paint dilution assistant, spraying a mixture through a spraying gun, varnish spraying, mixing a varnish main agent, a varnish curing assistant and a varnish dilution assistant, spraying a mixture through a spraying gun, leveling, drying, drying in a hot air drying furnace, offline operation and finished product checking. According to the spoiler coating technology, on the basis of original 3C1B, the primer working procedure is reduced, the work efficiency is correspondingly improved by 30%, the total use amount of the coating is reduced by 33%, and the yield of a coating working procedure is improved by 17%.

Owner:TIANJIN JINGMEITE SURFACE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com