Insulating composite assembly board methane fermentation tank

A biogas fermentation and assembling board technology, which is applied in the directions of gas production bioreactors, biochemical instruments, biochemical equipment and methods, etc., can solve the problems of increasing the difficulty of biogas project construction and post-maintenance, short service life, and high cost, and achieves The effect of strong reusability, reduction of painting process and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

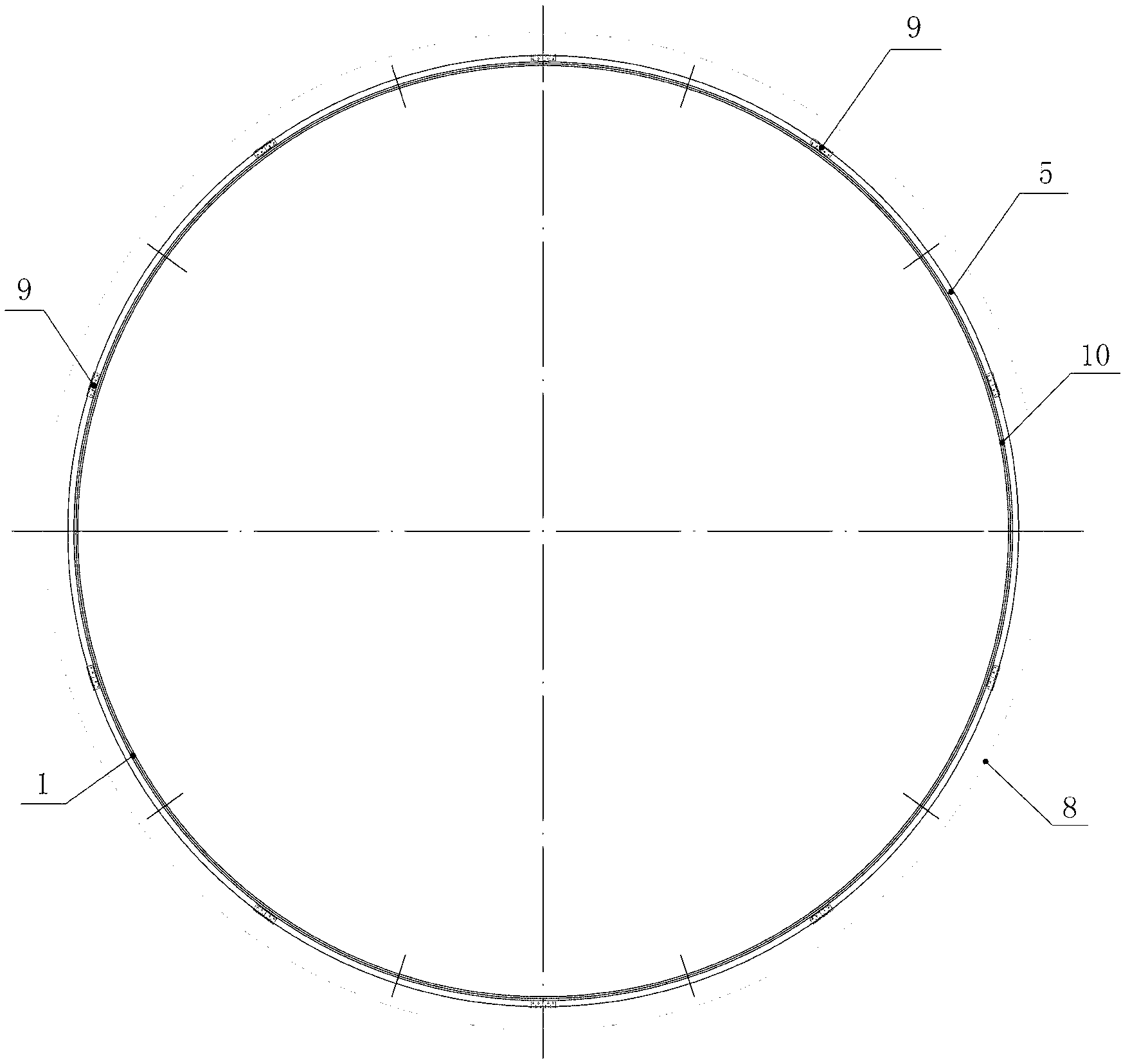

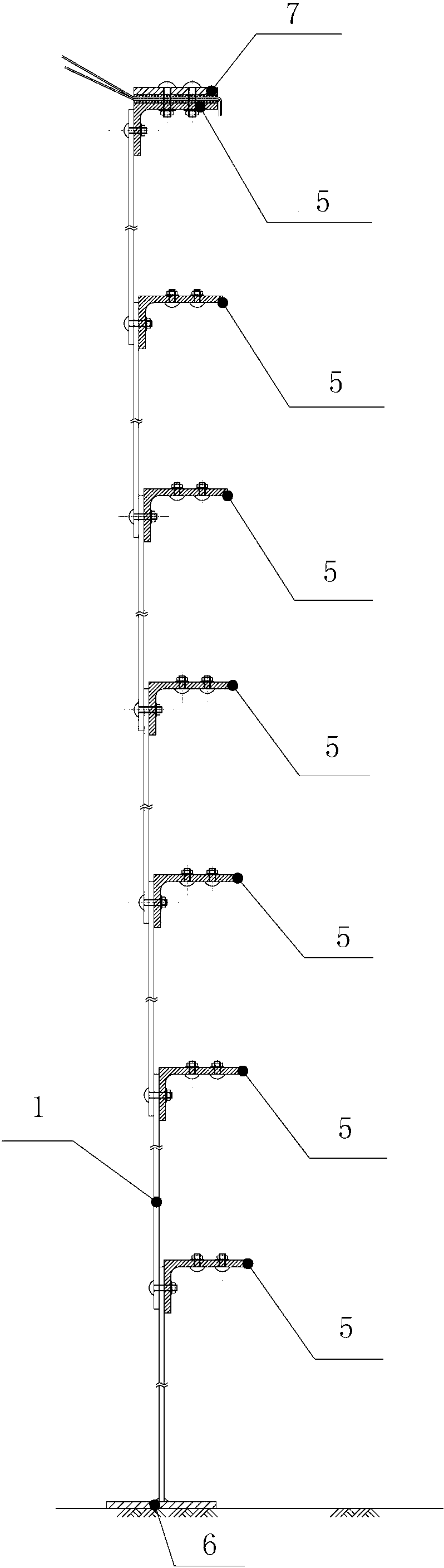

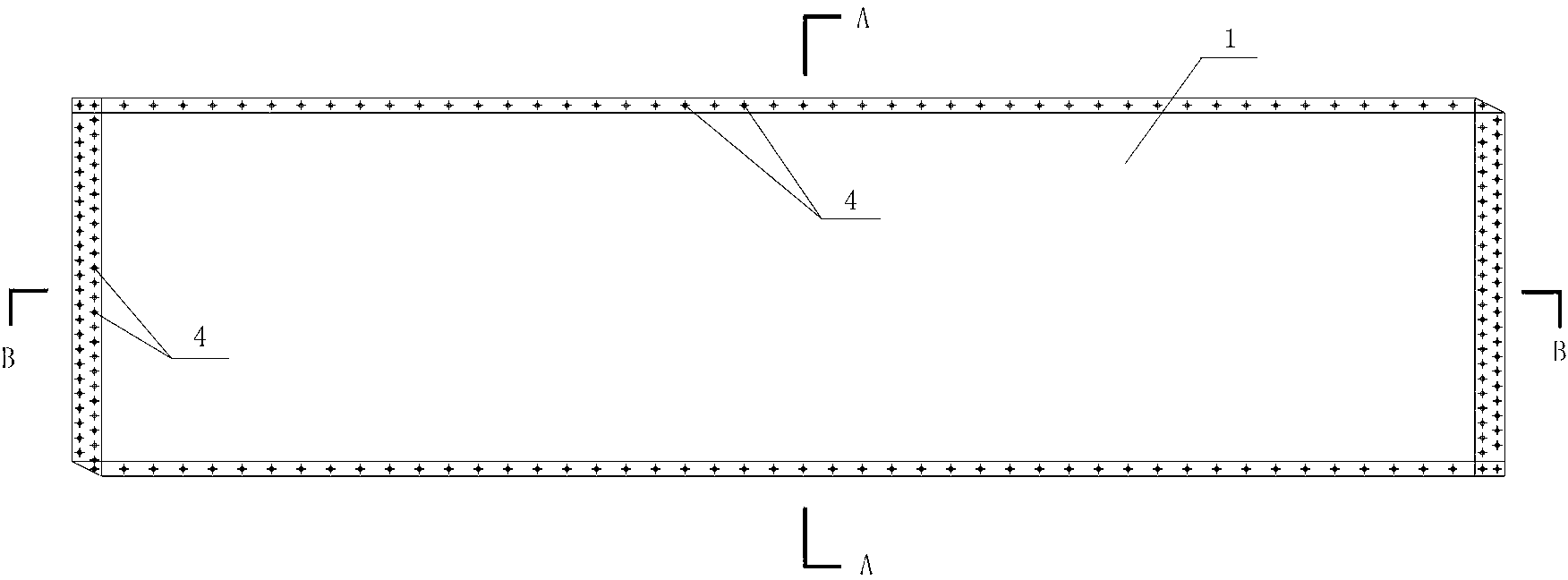

[0016] Example: such as Figure 1-5 As shown, a composite assembled board biogas fermentation device includes an assembled tank wall body 10 formed by splicing and fixing assembled boards 1. The assembled tank wall body 10 is provided with multiple layers of stirrups 5, and each layer of stirrups 5 is connected with the assembled board The joints between 1 are fixed together by bolts, and sealing materials are used to seal the joints; the assembled board 1 is composed of the base layer 3 in the middle, the cladding layer 2 and the insulation layer 5 arranged on both sides of the base layer, and the base layer 3 is made of carbon steel , the cladding layer 2 is stainless steel, and the insulation layer 11 is polyurethane or polyethylene; the assembly board 1 is rectangular, and the four sides of the assembly board 1 are provided with bolt holes 4 . One row of bolt holes 4-1 are respectively arranged on the two sides of the assembled board 1 in the length direction, and two rows...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com