Hot rolling weather-resistant steel belt and flexible production method thereof

A technology of flexible manufacturing and weathering steel, applied in the field of metallurgy, can solve the problems of production organization and waste of resources, frequent changes of smelting control, and difficulties in production organization, and achieve the effects of saving construction costs, shortening the construction period, and easy welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

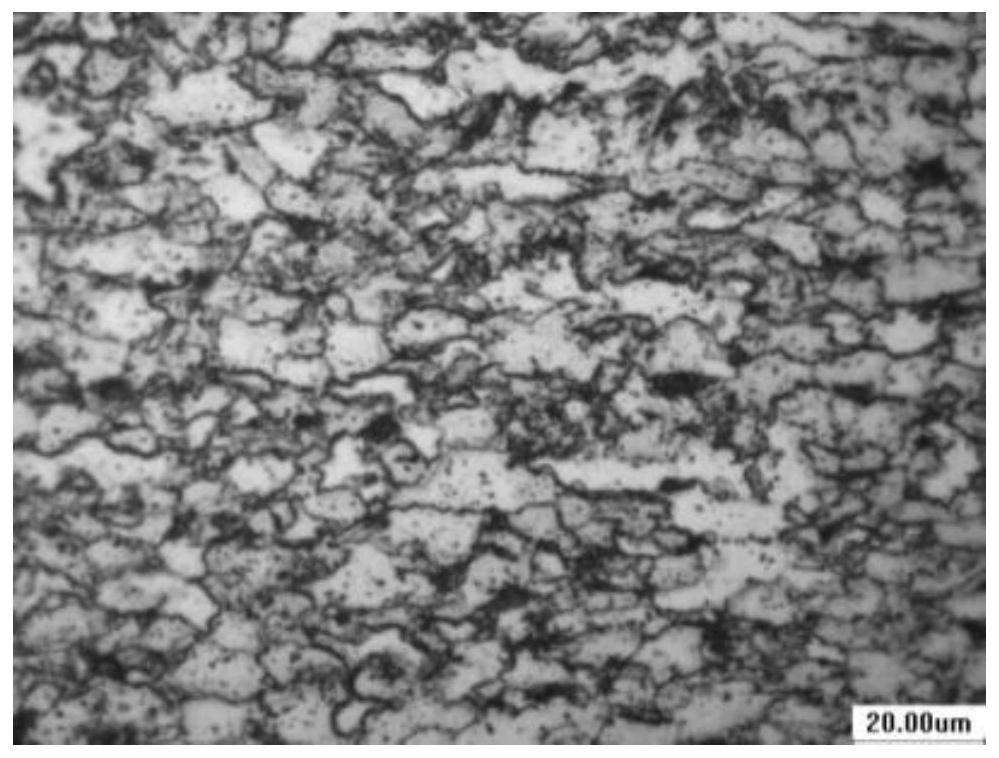

Embodiment 1

[0036] The thickness of the hot-rolled Q355NH weathering steel strip in this embodiment is 3.0 mm, and its chemical composition and mass percentage are shown in Table 1.

[0037] The production method of the hot-rolled Q355NH weather-resistant steel strip in this embodiment includes converter smelting, LF refining, slab continuous casting, heating, rough rolling, finish rolling, cooling and coiling processes, and the specific process steps are as follows:

[0038] (1) Converter smelting and LF refining process: control the chemical composition and mass percentage of molten steel as described in Table 1;

[0039] (2) Slab continuous casting process: continuous casting to obtain a slab with a thickness of 200mm;

[0040] (3) Heating process: heating by a walking heating furnace, the temperature of the billet heating soaking section is 1260°C, the soaking time is 32 minutes, and the total heating time is 200 minutes;

[0041] (4) Rough rolling process: single-stand reciprocating...

Embodiment 2

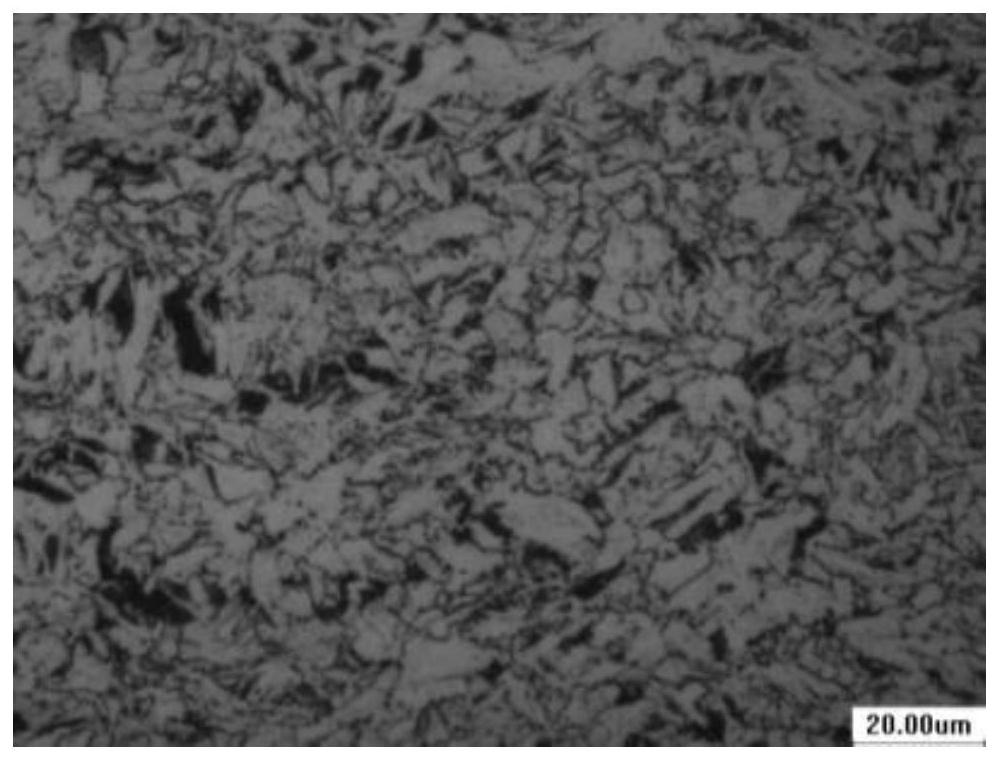

[0047] The thickness of the hot-rolled Q460NH weathering steel strip in this embodiment is 3.0 mm, and its chemical composition and mass percentage are shown in Table 1.

[0048] The production method of the hot-rolled Q460NH weather-resistant steel strip in this embodiment includes converter smelting, LF refining, slab continuous casting, heating, rough rolling, finish rolling, cooling and coiling processes, and the specific process steps are as follows:

[0049] (1) Converter smelting and LF refining process: control the chemical composition and mass percentage of molten steel as described in Table 1;

[0050] (2) Slab continuous casting process: continuous casting to obtain a steel slab with a thickness of 190mm;

[0051] (3) Heating process: heating by a walking heating furnace, the temperature of the billet heating soaking section is 1250°C, the soaking time is 30 minutes, and the total heating time is 190 minutes;

[0052] (4) Rough rolling process: single-stand recipro...

Embodiment 3

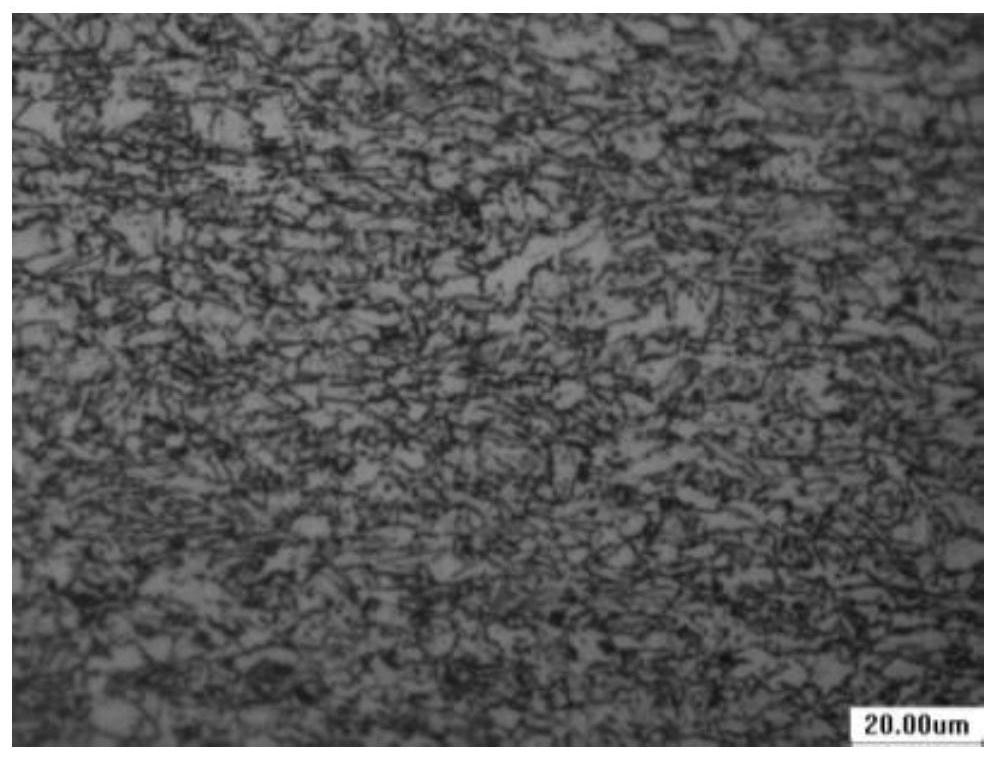

[0058] The thickness of the hot-rolled Q500NH weather-resistant steel strip in this embodiment is 3.0mm, and its chemical composition and mass percentage are shown in Table 1.

[0059] The production method of the hot-rolled Q500NH weather-resistant steel strip in this embodiment includes converter smelting, LF refining, slab continuous casting, heating, rough rolling, finish rolling, cooling and coiling processes, and the specific process steps are as follows:

[0060] (1) Converter smelting and LF refining process: control the chemical composition and mass percentage of molten steel as described in Table 1;

[0061] (2) Slab continuous casting process: continuous casting to obtain a slab with a thickness of 210mm;

[0062] (3) Heating process: heating by a walking heating furnace, the temperature of the billet heating soaking section is 1270°C, the soaking time is 35 minutes, and the total heating time is 230 minutes;

[0063] (4) Rough rolling process: single-stand recipro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com