High-performance polyurethane-modified butyronitrile latex gloves and preparation method thereof

A technology of polyurethane modification and polyurethane latex, applied in gloves, clothing, protective clothing, etc., can solve few problems, achieve good chemical protection and increase chemical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

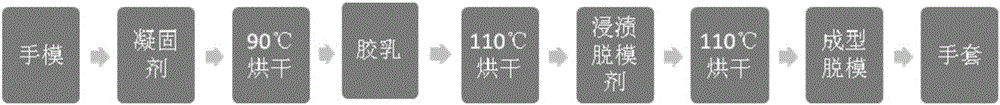

Method used

Image

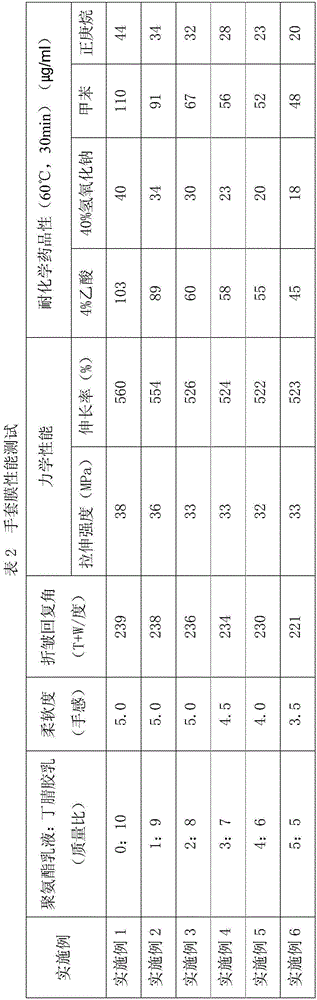

Examples

Embodiment Construction

[0024] Table 1 Nitrile Latex Formula

[0025] raw material

Nitrile Latex

Accelerator

Titanium dioxide

Dispersant

pure water

Dosage (number of servings)

86.4

1.55

0.94

0.93

1.94

0.04

167.4

[0026] Polyurethane emulsion is synthesized as follows:

[0027] First get 33 parts of polytetrahydrofuran glycol (PTMG) and add in the reaction kettle, under the situation of stirring, add 22 parts of isophorone diisocyanate (IPDI), then weigh 2.5 parts of dimethylol propionic acid (DMPA) and 3 Add 20 parts of diethylene glycol into the kettle, stir well, then add 20 parts of acetone and 0.02 parts of catalyst dibutyltin dilaurate in sequence. At 60-80°C, start timing and react for 3 hours. Then 1.6 parts of trimethylolpropane (TMP) and 25 parts of acetone were added, and the reaction was timed for 3 hours. After the reaction was completed, the temperature was lowered to below 50° C., and 33 parts of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com