Rotary shear failure performance determination test device of asphalt mixture

A technology of asphalt mixture and rotary shearing, which is applied in the direction of applying a stable shear force to test the strength of the material, and can solve the effects of asymmetry and incompatibility, uneven distribution of maximum shear stress, and uneven distribution of shear stress Uniformity and other issues to achieve the effect of improving test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

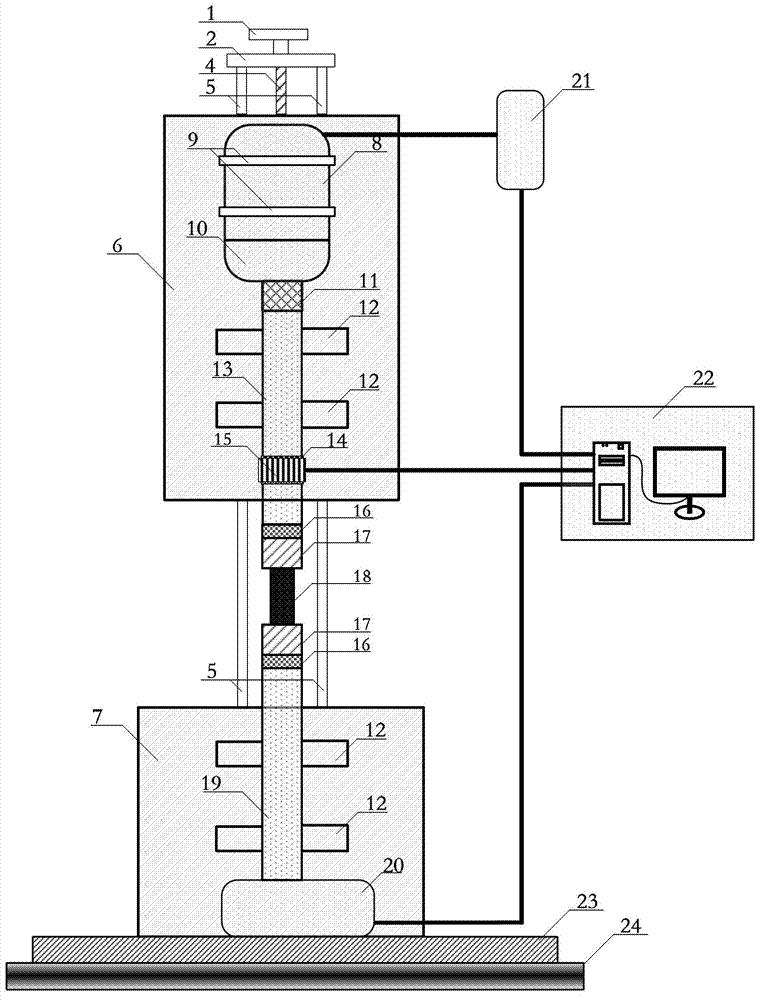

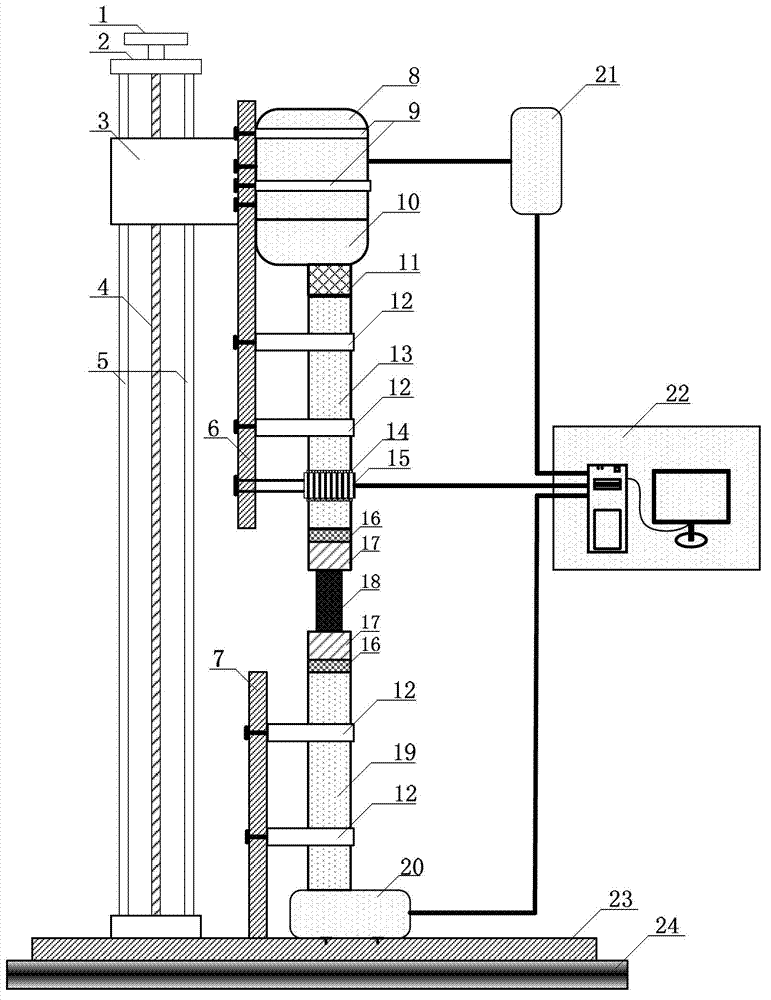

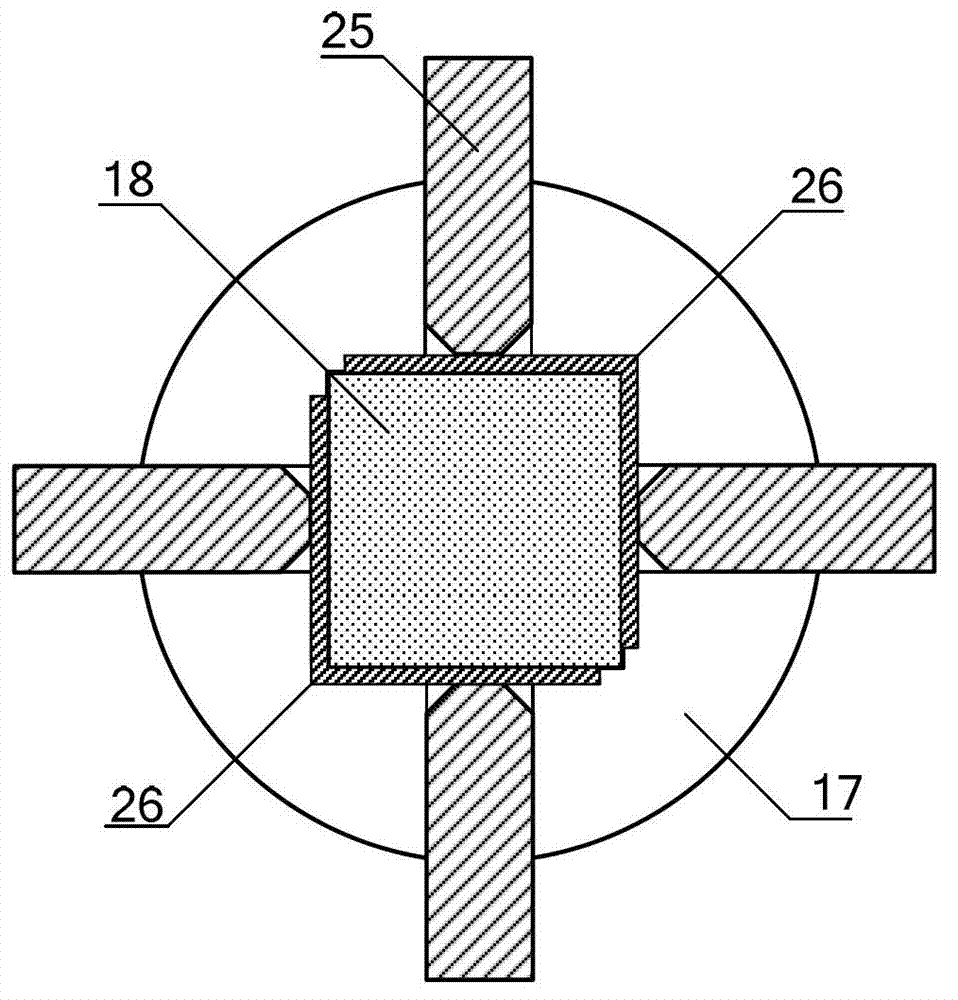

[0024] The test device for the determination of the rotational shear failure performance of asphalt mixture consists of a test platform, a loading system and a computer control system; the loading system performs rotational shear loading on the asphalt mixture specimen according to the set shear rate; the computer control system collects data in real time information.

[0025] The test platform consists of a spiral gantry 2, a base steel plate 23, a fixed steel plate 7, a lifting steel plate 6, a rotating shaft 13, a fixed shaft 19, a bearing seat 12, a torque sensor and an encoder 20, and an angular displacement sensor and an encoder; the spiral gantry 2 consists of a slide bar 5 fixed on the door frame, a slider 3 sliding along the slide bar 5 and a ball screw 4 fixed on the screw door frame 2 and controlling the movement of the slide bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com