Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

341 results about "Methylene diphenyl diisocyanate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

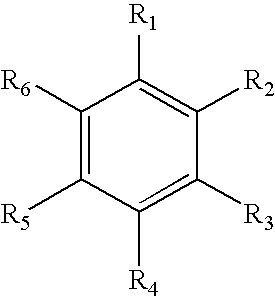

Methylene diphenyl diisocyanate, most often abbreviated as MDI, is an aromatic diisocyanate. Three isomers are common, varying by the positions of the isocyanate groups around the rings: 2,2'-MDI, 2,4'-MDI, and 4,4'-MDI. The 4,4' isomer is most widely used, and is also known as 4,4'-diphenylmethane diisocyanate. This isomer is also known as Pure MDI. MDI reacts with polyols in the manufacture of polyurethane. It is the most produced diisocyanate, accounting for 61.3% of the global market in the year 2000.

Process for the manufacturing of an improved core for decorative laminates and a decorative laminate obtained by the process

InactiveUS6841023B2Improve brittlenessImprove the overall coefficientOrganic chemistryLamination ancillary operationsPolyesterFiber

A process for the manufacturing of a core forming a carrying structure for decorative laminates. The core comprises particles of cured, and optionally foamed, rigid, polyurethane, polyisocyanurate and / or phenolic resin. The particles are bonded to each other in a pressing procedure with a bonding agent comprising an adhesive such as a polymerizing monomer.i) The particles are achieved by grinding cured, and optionally foamed, rigid, polyurethane, polyisocyanurate and / or phenolic resin so that it passes through a 2 mm screen, preferably a 1 mm screen,ii) 100 parts per weight of particles is mixed with 1-100 parts per weight of fiber, the fiber additive having an average length in the range 1-15 mm.iii) The particle-fiber mixture is allowed to absorb a selected amount of water, the amount of water being in the range 1-15% by weight, The water is either added at any stage before the adding of bonding agent, and / or being used as a solvent in the bonding agent, and that,iv) 85 parts per weight of the particle mixture is mixed with 2-15 parts per weight of a bonding agent, the bonding agent selected from the group consisting of,a) A mixture of polyols, such as polyester or polyether, crude methylene diphenyl diisocyanate and possibly a small amount of blowing agent in a ratio forming a polymeric resin with a density in the range 600-1400 kg / m3.b) A formaldehyde based resin such as phenol-formaldehyde resin, urea-formaldehyde resin, melamine-urea-formaldehyde resin, melamine-urea-phenol-formaldehyde resin or phenol-resorcinol-formaldehyde resin, orc) Polyvinyl acetate resin.v)The mixture is applied between the belts of the continuos belt press or the press plates of a static press, optionally with at least one intermediate carrier web, the belts or press plates allowing a mainly uniform and specified material thickness to form. A slightly porous and preconditioned core with a selected water content in the range 0.8-12% is hereby achieved. The invention also relates to a decorative laminate achieved through the process.

Owner:PERGO

Polyurethane prepolymer, polyurethane grouting material and preparation method thereof

InactiveCN102093536AImprove foaming rateImprove shrinkage resistanceOther chemical processesPolyesterPolyphenyl isocyanate

The invention relates to a preparation method of a polyurethane prepolymer, which comprises: mixing polyisocyanate and an organic polyol compound for reaction, wherein the molar ratio of the -NCO in the polyisocyanate and the -OH in the organic polyol compound is (4-15):1; the polyisocyanate is two or more of polymethylene polyphenyl isocyanate (PAPI), methylene diphenyl diisocyanate (MDI) and carbodiimide modified MDI 5412; and the organic polyol compound comprises one or more of polyether glycol with functionality of 2 to 4 and number-average molecular weight of 300 to 5,000, polyester polyol and polyether-polyester polyol. The invention also relates to the polyurethane prepolymer and a polyurethane grouting material. The polyurethane grouting material is a single-component grouting material, has little toxicity to the environment and construction personnel and can well improve foaming rate and anti-contraction performance; during packaging, the need of independent packaging of a catalyst is obviated, so the packaging cost is lowered; and the material is more convenient to use and transport and has a more wide application range and a bright prospect.

Owner:SHANGHAI DONGDA CHEM

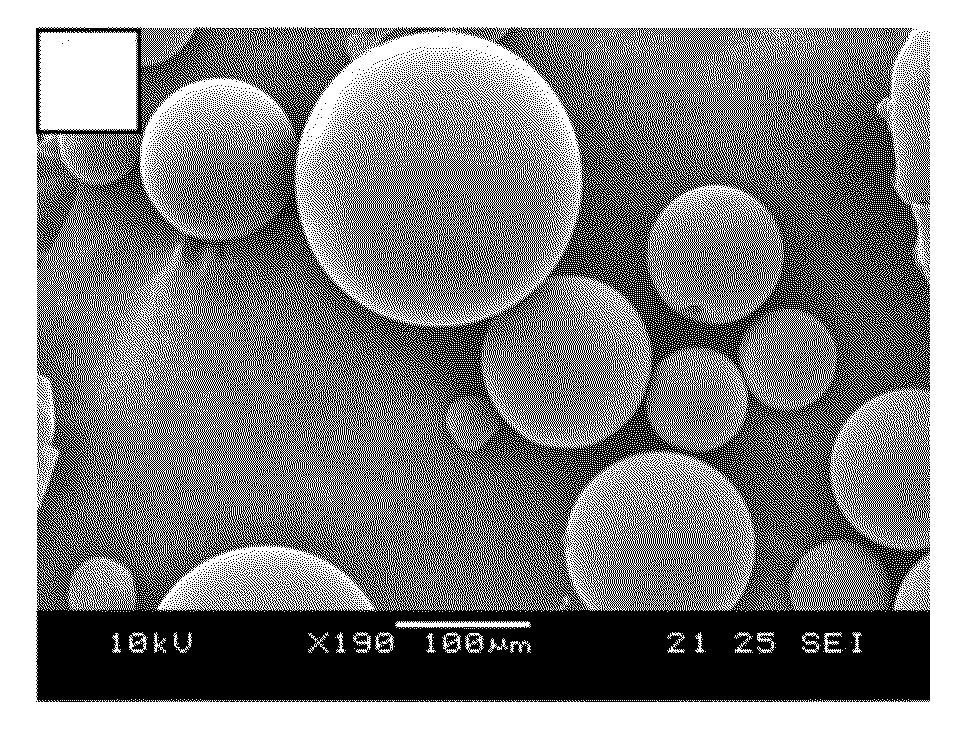

Microencapsulation of reactive diisocyanates and the application to self-healing anticorrosion coatings

InactiveUS20130196071A1Prevent downgradePreventing and slowing corrosionPretreated surfacesAnti-corrosive paintsSelf-healingPrepolymer

The disclosure provides a polyurethane microcapsule consisting of a polymerization product of methylene diphenyl diisocyanate (MDI) prepolymer with a polyol, the polyurethane microcapsule comprising a liquid isocyanate compound encapsulated within the microcapsule. The disclosure also provides self-healing coating compositions comprising such polymeric microcapsules and methods of preventing or slowing corrosion using such coating compositions.

Owner:NANYANG TECH UNIV

Monocomponent moisture cure urethanes adhesive

InactiveCN101629061AModerate viscosityEasy to operateNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterAntioxidant

The invention provides a monocomponent moisture cure urethanes adhesive. The adhesive comprises the following compositions in portion by weight: 100 portions of isocyanate terminated polyurethane prepolymer, 0.025 to 0.25 portion of composite catalyst, 0.001 to 0.3 portion of stabilizer, 0.5 to 2 portions of coupling agent, 0.05 to 0.30 portion of antioxidant and 0 to 25 portions of diluting agent which react and are mixed, wherein the isocyanate terminated polyurethane prepolymer is prepared by reactions of polyisocyanates which is mixed by carbodiimide modified methyl diphenylene diisocyanate or 4,4'-methyl diphenylene diisocyanate and polyaryl polymethylene isocyanate, and polyester polyol with number average molecular weight of Mn of between 400 and 2,500 or polyether polyol with number average molecular weight of Mn of between 400 and 4,000 and a chain extender. The adhesive has higher curing speed and longer applicable time, can be bonded with an aluminum alloy with shearing strength more than or equal to 8MPa after curing at room temperature, has plump fluff and good hand feeling in electrostatic flocking products with abrasion resistance of a spinning machine roller reaching over 10,000 times.

Owner:SHANGHAI XINGUANG CHEM

Polyurethane combined material, method for preparing polyurethane composite through polyurethane combined material, and application of prepared product

The invention discloses a polyurethane combined material. The polyurethane combined material is prepared from an isocyanate reactivity component A and an isocyanate component B. The component A is prepared from combined polyether polyol, chain extender, surface active agents, internal releasing agents, catalysts and foaming agents. The component B is prepared from at least one of polyaryl polymethylene isocyanate, methylene diphenyl diisocyanate and isocyanate prepolymers. The weight ratio of the component A to the component B is 100 to 130-180. The combined material has excellent storage stability and can be used for preparing a polyurethane composite. The prepared composite has high strength, high temperature-resistant performance and a larger mold release time number, and the prepared composite can be used for automobile skylights, automobile spare wheel cover plates, building decoration and furniture.

Owner:WANHUA CHEM GUANGDONG

Low hardness polyurethane elastic body composite

The invention relates to a low hardness polyurethane elastic body composite, composed of two components of prepolymer and polymer by adopting bi-component system; wherein the prepolymer is obtained through reaction of diphenyl-methane-diisocyanate and polypropylene oxide polyatomic alcohol at 70-90 DEG C and isocyano content thereof is 7-14%, and polymer component is prepared by polypropylene oxide polyatomic alcohol, catalyst and antiaging agent. The polymer component and the prepolymer component are mixed in matching ranging from 100-20 to 100-35, so as to obtain Shaw brothers 0-20A products; the invention is mainly used for producing health care protective articles such as shoe-pad, automobile no-slip mat, bicycle seat cushion and handicapped wheelchair cushion. The obtained product is environmentally friendly and safe, has good processing performance and has comfortable handfeel.

Owner:SHANDONG INOV POLYURETHANE

Preparation method of methylene diphenyl diisocyanate

ActiveCN106748887AImprove conversion rateInhibition of byproductsIsocyanic acid derivatives preparationOrganic compound preparationReaction rateOrganic phosphorus

The invention provides a preparation method of methylene diphenyl diisocyanate. The method comprises the following steps: performing a salt forming reaction on m-xylylenediamine and hydrogen chloride gas to obtain m-xylylenediamine hydrochloride; mixing the m-xylylenediamine hydrochloride, an organic phosphorus compound and solid phosgene for reaction to obtain methylene diphenyl diisocyanate. In a process of preparing methylene diphenyl diisocyanate, according to the application, an organic phosphorus compound additive is introduced, so that the reaction of m-xylylenediamine hydrochloride is promoted, therefore, the reaction rate and the effective conversion rate are improved.

Owner:SHANDONG EFIRM BIOCHEMISTRY & ENVIRONMENTAL PROTECTION CO LTD

Partially blocked polyurethane curing agent and preparation method thereof

The invention discloses a partially blocked polyurethane curing agent and a preparation method thereof. The preparation method mainly comprises the following steps that end-NCO isocyanate prepolymer is obtained from the addition reaction of diphenylmethane diisocyanate and low-molecular polyol in ester solvent, and then the end-NCO isocyanate prepolymer reacts with isocyanate sealant to form the curing agent. The partially blocked polyurethane curing agent has the following characteristics that: a) according to the calculation of NCO by weight, the blocked-NCO content is between 1.0 and 5.0 percent; b) the solid content by weight of the curing agent is 75+ / -2 percent, and the percentage content of the NCO by weight is between 12.0 and 13.0 percent (according to the calculation of the effective percentage of the NCO, the percentage content of the NCO including blocked NCO radicals); and c) the viscosity of the curing agent at 25 DEG C is between 1,500 and 2,500 mPa. s. The invention has the advantages of low toxicity, good storage stability, adjustable curing speed and the like.

Owner:WANHUA CHEM BEIJING +1

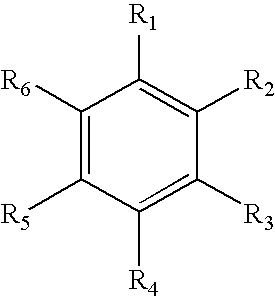

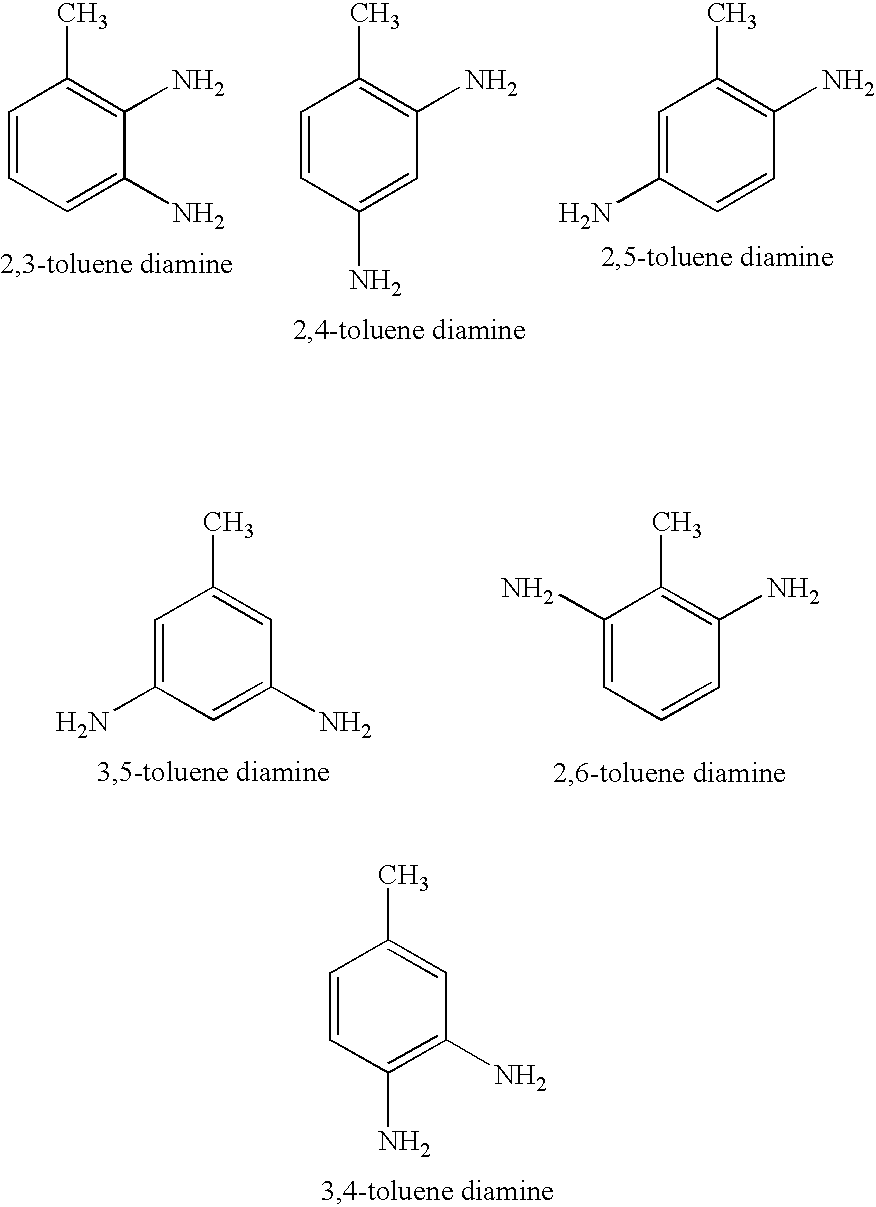

Polyurethane-encapsulated particle comprising polyol derived from aromatic amine-based initiator

ActiveUS7416785B2Efficient mixingBiocideBio-organic fraction processingToluene diisocyanatePhosphate

An encapsulated particle includes a core particle. The core particle includes a fertilizer selected from the group of nitrogen, phosphate, potash, and sulfur, and combinations thereof. The core particle may also include herbicides, insecticides, and fungicides. The encapsulated particle also includes a polyurethane layer disposed about the core particle. The polyurethane layer includes the reaction product of an aromatic isocyanate component and a polyol that is reactive with the aromatic isocyanate component. The aromatic isocyanate component includes methylene diphenyl diisocyanate, toluene diisocyanate, and mixtures thereof. The polyol that is reactive with the aromatic isocyanate component is derived from an aromatic amine-based initiator and includes a toluene diamine. The aromaticity of the aromatic isocyanate component and the polyol serves to insure complete miscibility between the aromatic isocyanate and the polyol thereby forming the polyurethane layer without defects preventing water from permeating the polyurethane layer and dissolving the core particle.

Owner:BASF CORP

Method for preparing polyurethane adhesive

InactiveCN101838514AFast curingGood adhesionPolyureas/polyurethane adhesivesPolyurethane adhesivePolyurea

The invention provides a method for preparing polyurethane adhesive, comprising the following steps: compounding small-molecule chain extender, inorganic filler, organosilicon coupling agent and hydroxyl-terminated polyurethane prepolymer which is synthesized from the reaction of trifunctional polyether glycol, methylene diphenyl diisocyanate and plasticizer under a certain condition to obtain the first component of the polyurethane adhesive, and compounding the first component and the second component of polyisocyanate proportionally to obtain the polyurethane adhesive. Due to the structuraldesign of the hydroxyl-terminated polyurethane prepolymer, the selection of the small-molecule chain extender, the proportioning adjustment of the inorganic filler and the match of the appropriate curing system, the prepared polyurethane adhesive has the advantages of rapid curing speed, convenient construction and good adhering effect on the concrete slab, the polyurea waterproof layer, the geotextile and the high-strength extruded sheet without the application of any base glue and can fully reach the standard of the unballasted track sliding layer technology and normalize the technology of two geotextile and one geo-membrane which are suitable for the unballasted high-speed railway track sliding layer.

Owner:BEIJING COMENS NEW MATERIALS

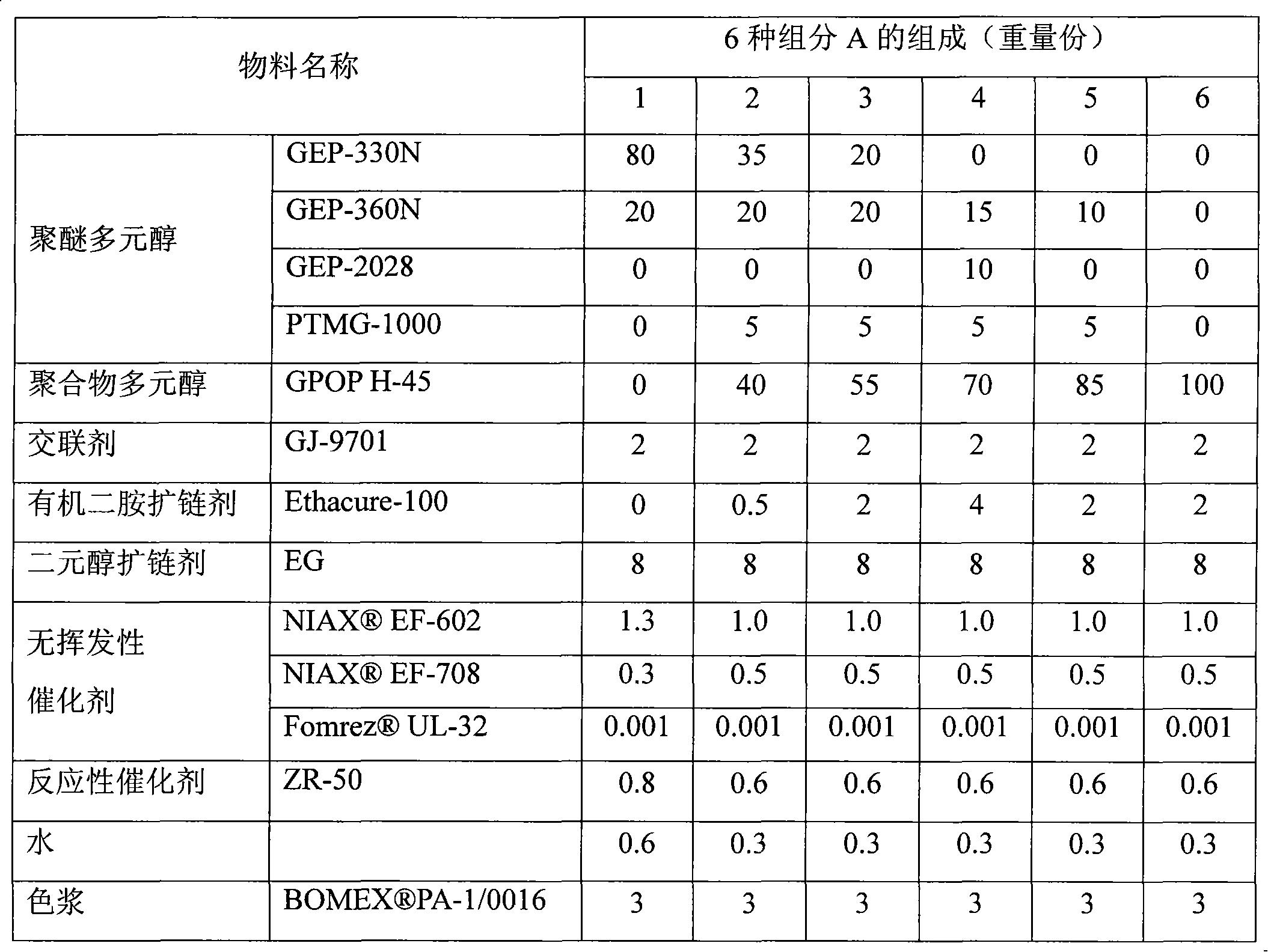

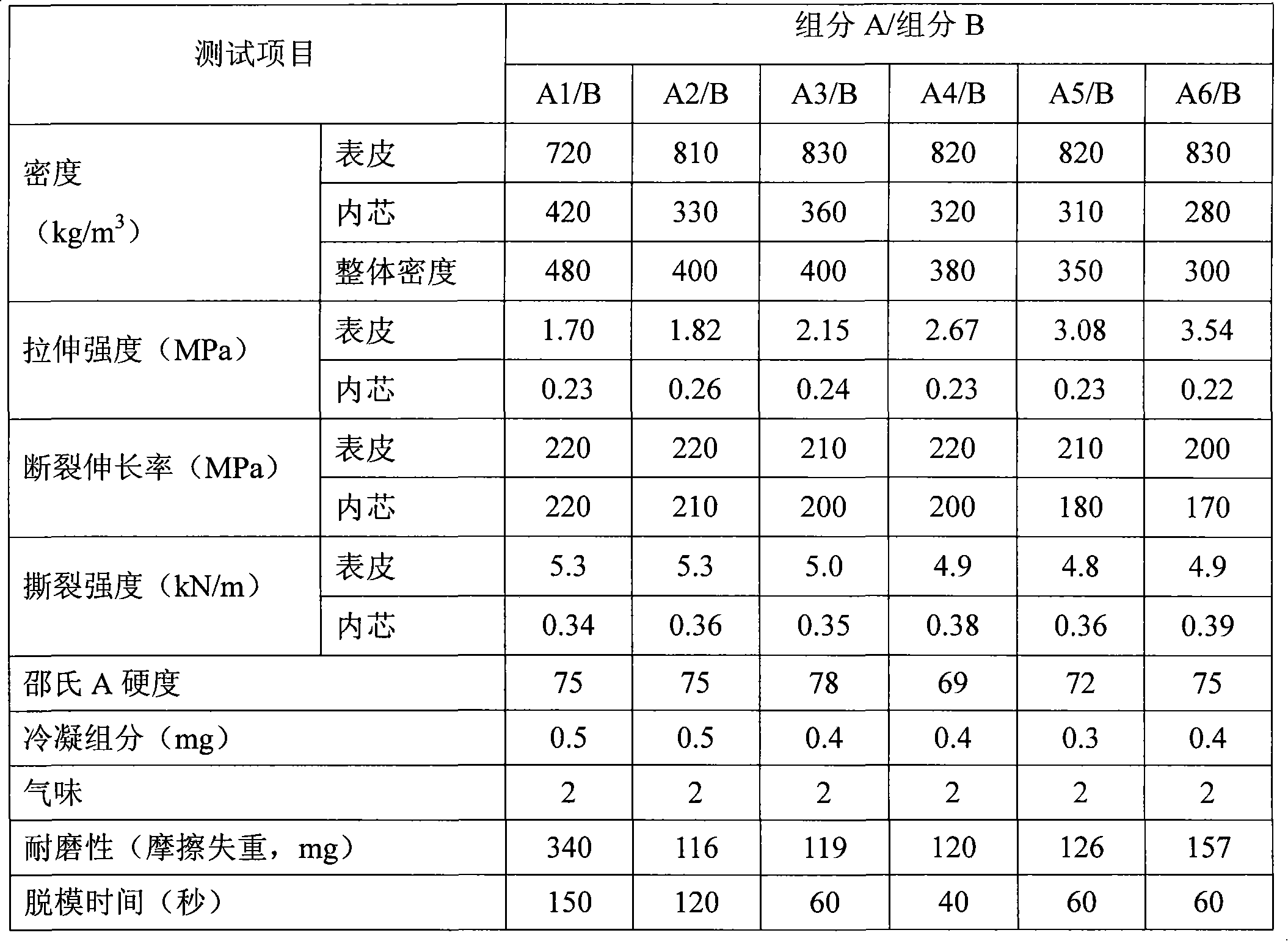

Integral skin polyurethane-urea composition, preparation method and application thereof

The invention discloses a quick demoulding water-blown low-density integral skin polyurethane-urea composition which comprises a polyalcohol mixture component A and a modified isocyanate component B, wherein the component A is a polyalcohol mixture which comprises polyether glycol, polymer polyol, a cross linking agent, organic diamine, a divalent alcohol chain extender, a nonvolatile catalyst and / or a reactive catalyst, water and color paste; the component B is allophanate modified isocyanate containing 22-31 wt percent of NCO and is formed by polymerizing methyl diphenylene diisocyanate (MDI) and polyalcohol with molecular weight of 62-3000. The component A and the component B according to a weight ratio of 100:40-100 are polymerized into integral skin polyurethane-urea with integral intensity of 260-400 kg / m, and the integral skin polyurethane-urea can be demoulded within 60 seconds.

Owner:湖州合达图宏新材料技术股份有限公司

Polyurethane material and preparation method thereof

The invention provides a polyurethane material which is obtained through a reaction of a first polyurethane prepolymer, a second polyurethane prepolymer and a chain extender. The first polyurethane prepolymer is obtained through a reaction of a polyhydroxy compound and one or two kinds of toluene diisocynate and benzene diisocyanate. The second polyurethane prepolymer is obtained through a reaction of a polyhydroxy compound and one or two kinds of 4,4'-diphenylmethane diisocyanate and naphthalene diisocyanate. The polyurethane material can be decomposed through the effect of water or microorganisms, and pollution is avoided; meanwhile, on the basis of the combination of the specific aromatic diisocyanate and the chain extender, the finally-obtained polyurethane material has the good strength and toughness.

Owner:JILIN NORMAL UNIV

Process for making a flexible polyurethane foam

Process for preparing a flexible polyurethane foam comprising reacting at an isocyanate index of 70 to 130, 1) 40-65 parts by weight of a polyisocyanate composition comprising a) 80-100% by weight of a diphenylmethane diisocyanate component comprising, based on 100 parts by weight of the diphenylmethane diisocyanate component, i) 75-100 parts by weight of diphenylmethane diisocyanate comprising 15-75 parts by weight of 4,4′-diphenylmethane diisocyanate, and 25 to 85 parts by weight of 2,4′-diphenylmethane diisocyanate, and 2,2′-diphenylmethane diisocyanate and / or a liquid variant of such diphenylmethane diisocyanate, and ii) 0 to 25 parts by weight of homologues of diphenylmethane diisocyanates having an isocyanate functionality of 3 or more; and b) 20-0% by weight of toluene diisocyanate; 2) 20 to 45 parts by weight of a polyether polyol having an average molecular weight of 4500-10000, an average nominal functionality of 2-6 and comprising oxypropylene and optionally oxyethylene groups, the amount of oxypropylene groups being at least 70% by weight calculated on the weight of this polyol; 3) 3 to 20 parts by weight of a polyether polyol having an average molecular weight of 700-4000, an average nominal functionality of 2-6 and an hydroxyl value of at most 225 mg KOH / g and comprising oxyethylene and optionally oxypropylene groups, the amount of oxyethylene groups being at least 70% by weight calculated on the weight of this polyol; and 4) 2-6 parts by weight of water, wherein the amount of the polyisocyanate composition, polyol 2), polyol 3), and water being 100 parts by weight.

Owner:HUNTSMAN INT LLC +1

Preparation of CFC-free, highly resilient, flexible polyurethane foams, and diphenylmethane diisocyanate-based polyisocyanate mixtures modified by means of urethane groups which can be used for this purpose

InactiveUS6096238AIncrease elasticityEasy to processOther chemical processesDiphenylmethaneCarbamate

The present invention relates to a process for the preparation of CFC-free, flexible polyurethane (molded) foams by reacting A) liquid polyisocyanate mixtures containing bonded urethane groups having a content of NCO groups of from 22 to 30% by weight which are themselves prepared by reacting a mixture of diphenylmethane diisocyanates and polyphenyl-polymethylene polyisocyanates having a content of diphenylmethane diisocyanate isomers of from 55 to 99% by weight, based on the total weight, with at least one trifunctional polyoxypropylene-polyol having a hydroxyl number of from 20 to 60, with B) relatively high-molecular-weight polyhydroxyl compounds and, if desired, C) low-molecular-weight chain extenders and / or crosslinking agents, in the presence of D) blowing agents, E) catalysts and, if desired, F) auxiliaries and / or additives, and to the polyisocyanate mixtures (A) modified by means of urethane groups which can be used according to the invention.

Owner:BASF AG

Micropore polyurethane elastomer material and preparation method and use thereof

The invention discloses a micropore polyurethane elastomer material and a preparation method and use thereof. The micropore polyurethane elastomer material is composed of two components. The A component includes polyether polyatomic alcohol P1, polyether polyatomic alcohol P2, chain extension agents, foam stabilizers, water, tertiary amine catalysts and hollow glass microspheres by weight percentage. The B component comprises methylene diphenyl diisocyanate (MDI), TODI, and polyether polyatomic alcohol P1. P1 is selected from polytetrahydrofuran polyatomic alcohol with number-average molar mass as 1000-6000 and functionality as 2-3. P2 is selected from propylene oxide polythene oxide copolyether polyatomic alcohol with number-average molar mass as 2000-6000, functionality as 3-4 and primary hydroxyl content larger than or equal to 70%. The isocyanate index number of the A component and the B component is 1.1. The A component and the B component are prepared respectively, quickly and evenly mixed according to proportion, poured in a mould and solidified to obtain the micropore polyurethane elastomer which can be used as an elastic bearing plate of high speed railways.

Owner:LIMING RES INST OF CHEM IND

Film base material for adhesive skin patch and adhesive skin patch

InactiveUS20050169975A1Change physical propertiesFailure in characteristicAdhesive dressingsAbsorbent padsFilm basePolypropylene glycol

To have acceptable moisture permeability and enable prevention of deformation due to swelling, the film base material for an adhesive skin patch includes an ether-based urethane resin obtained from at least one member selected from the group consisting of polyoxytetramethylene glycol, butanediol, polyethylene glycol, and polypropylene glycol as a diol component, and methylene diphenyl-diisocyanate as an isocyanate component. The film base material for an adhesive skin patch has a moisture permeability of preferably 800 to 4,000 g / m2·24 hrs. The adhesive skin patch can be produced by forming a pressure-sensitive adhesive layer on one side of the film base material for an adhesive skin patch.

Owner:NITTO DENKO CORP

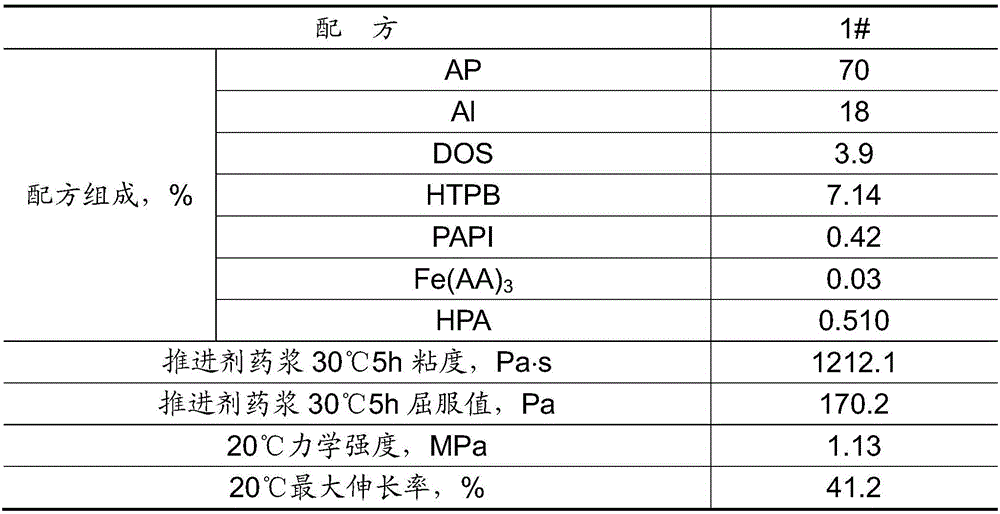

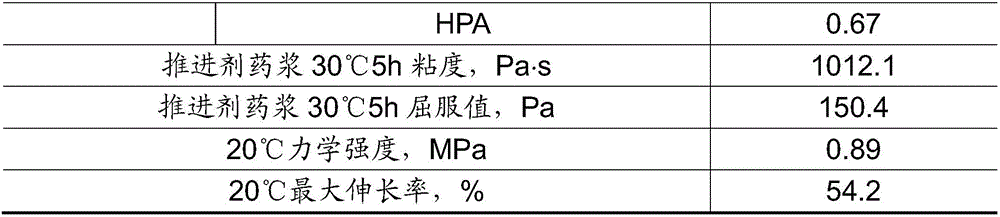

Room-temperature curing propellant

ActiveCN106831279AGood mechanical propertiesReduced activityExplosivesPressure gas generationAnilineMethylene diphenyl diisocyanate

The invention relates to a room-temperature curing propellant. The room-temperature curing propellant is prepared from the following components in percentage by mass: 69 to 77% of AP (ammonium perchlorate), 10 to 18% of Al (aluminum) powder, 1 to 5% of plasticizer DOS, 7 to 10% of adhesive HTPB and curing agent, 0.005 to 0.05% of curing catalyst, and 0.2 to 2.0% of network adjusting agent, wherein the network adjusting agent is an alcohol or amine compound with two degrees of functionality, and is one or combination of N-isopropyl alcohol-N-isopropyl ether-aniline, anionic HTPB (hydroxyl-terminated polybutadiene) or N,N'-dihydroxy(diisopropyl)aniline HPA; the curing agent is one or combination of PAPI (polyaryl polymethylene isocyanate), MDI (methylene diphenyl diisocyanate), XDI (xylylene diisocyanate), or TDI (toluene diisocynate). The room-temperature curing propellant has the advantages that the propellant with effective solid content of more than 85% is mixed and cast at the temperature of 20 to 35 DEG C, and can reach a curing point within 7d after curing; the normal-temperature mechanical strength can reach 0.85MPa or above, and the elongation rate is more than 35%.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

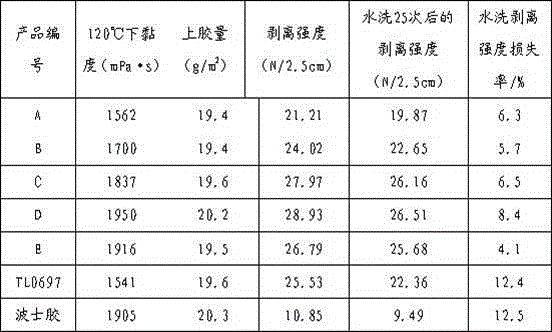

PTMG (polyoxytetramethylene glycol) modifying moisture curing polyurethane melt adhesive and preparation method thereof

ActiveCN104449537AImprove hydrolysis resistanceReduced flexibilityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesSilanesAntioxidant

The invention discloses a PTMG (polyoxytetramethylene glycol) modifying moisture curing polyurethane melt adhesive and a preparation method thereof. The melt adhesive product comprises the following raw materials in parts by weight: 18-35 parts of polypropylene glycol, 15-30 parts of polytetrahydrofuran glycol, 8 parts of poly adipic acid-1, 6 hexanediol esterdiol, 0.5 part of an antioxidant, 15-20 parts of tackifying resin, 24-25 parts of 4, 4'- ditan diisocyanate, 0.01 part of a catalyst, 0-0.5 part of a chain extender, 0-2 parts of a silane coupler, and 0-0.5 part of white carbon black. The PTMG modifying moisture curing polyurethane melt adhesive prepared by the preparation method disclosed by the invention has the advantages of high stripping strength, good washing resistant performance, good flexibility, environmental protection and the like.

Owner:SHANGHAI TIANYANG HOT MELT ADHESIVE CO LTD +2

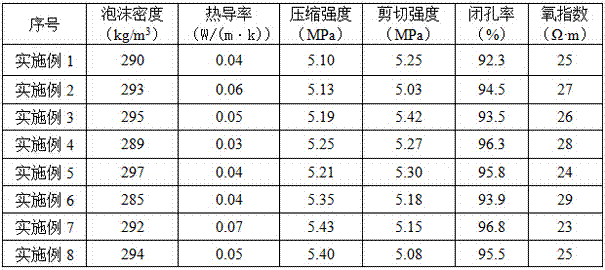

Spray rigid polyurethane foam heat insulation waterproof integrated material

InactiveCN102181144AFast curingWith thermal insulationHeat proofingBuilding insulationsEngineeringVolumetric Mass Density

The invention provides a spray rigid polyurethane foam heat insulation waterproof integrated material. The spray rigid polyurethane foam heat insulation waterproof integrated material is double-component foamed plastic which is formed by field spraying and consists of a component A and a component B in an equal volume ratio; the component A consists of 0 to 30 weight parts of toluene diisocynate, 0 to 30 weight parts of methylene diphenyl diisocyanate, and 70 to 100 weight parts of polymethylene polyphenyl isocyanate; the component B consists of 30 to 50 weight parts of polyatomic alcohol, 10 to 20 weight parts of catalyst, 5 to 10 weight parts of foam stabilizer, 10 to 30 weight parts of foaming agent, and 10 to 30 weight parts of fire retardant; the material comprises a foamed plastic layer with fire resistance, high intensity and density, and functions of watertightness, heat insulation, corrosion prevention, solvent resistance and the like; and the material can be mainly used for the watertightness, and heat insulation and the like of various roofs, wall bodies, and large-span light metal rooves with grid structures of industrial and civil buildings, and high-rise buildings, accessible rooves or roof gardens.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD +2

External wall thermal insulation material and preparation method thereof

InactiveCN105440657AImprove flame retardant performanceGood heat release rateFiberThermal insulation

The invention discloses an external wall thermal insulation material and a preparation method thereof. The external wall thermal insulation material is prepared from the following raw materials in parts by weight: 80-90 parts of methylene diphenyl diisocyanate, 65-75 parts of polyether polyol, 20-30 parts of straw fiber, 10-15 parts of glass fiber, 20-25 parts of organic nano-montmorillonite, 30-35 parts of flame retardant, 25-30 parts of smoke suppressor, 1-5 parts of reaction catalyst, 8-15 parts of crosslinking catalyst, 1-5 parts of coupling agent, 15-25 parts of deionized water and 1.5-5 parts of foam stabilizer. The prepared external wall thermal insulation material has the advantages of good fireproof property, high thermal insulation property, high wear resistance, high stability, high physical and mechanical properties, low cost and saving of energy.

Owner:NANYANG INST OF TECH

Water-insensitive polyurethane injecting paste material, and preparation method thereof

The invention discloses a water-insensitive polyurethane injecting paste material, and a preparation method thereof. The water-insensitive polyurethane injecting paste material comprises a component A and a component B at a volume ratio of 1:1-1:1.2; the component A is a mixture of polyhydric alcohol-modified methylene diphenyl diisocyanate and polyaryl polymethylene isocyanate; and the component B is a mixture of a polyhydric alcohol, a plasticizer, a chain extender, a catalyst, a surfactant, and a foaming agent. According to the preparation method, the raw materials with excellent structures are selected, mixing of the raw materials at a certain ratio is carried out, and the water-insensitive polyurethane injecting paste material is provided with excellent water insensitivity because of physical and chemical synergistic effects of the raw materials, so that bearing capacity and durability of the water-insensitive polyurethane injecting paste material at a water-rich environment are improved greatly.

Owner:SHANGHAI HUAFON NEW MATERIAL R&D TECH CO LTD +1

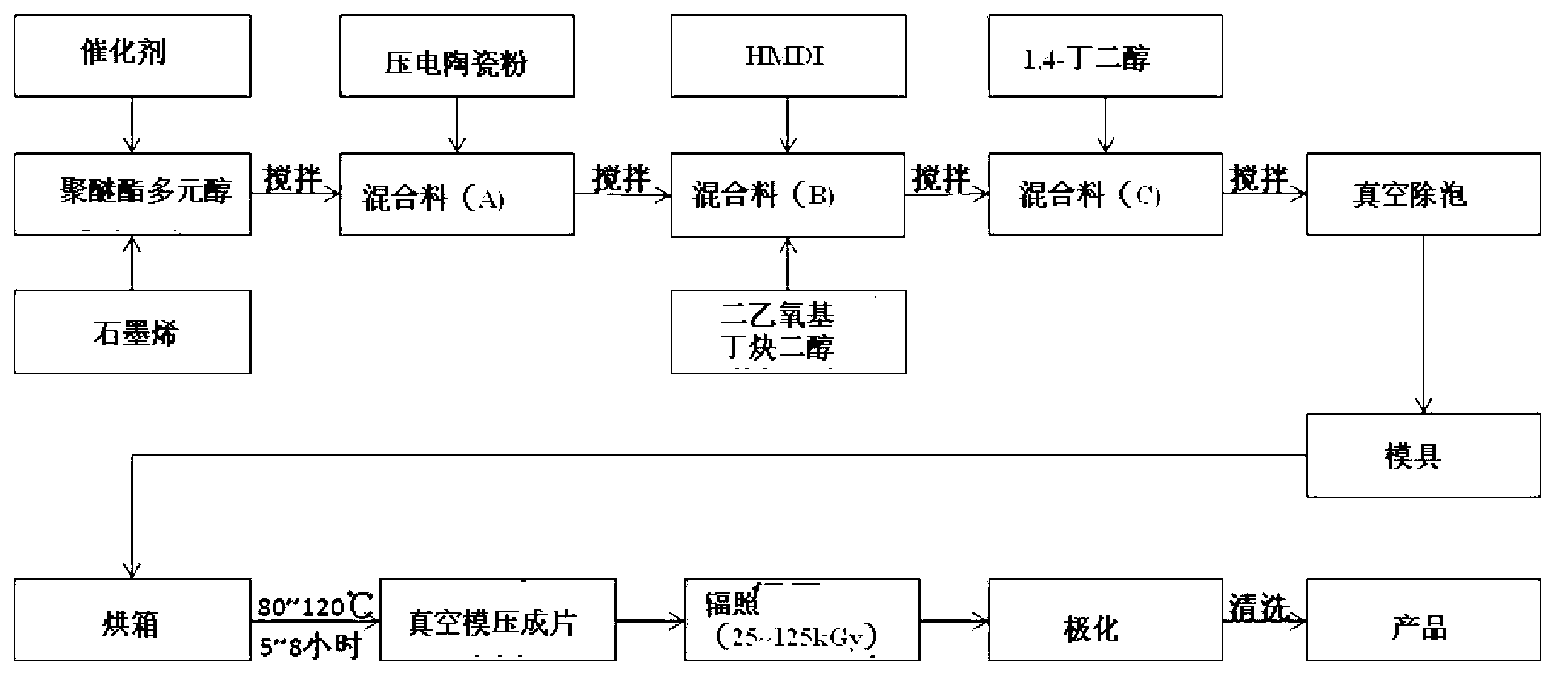

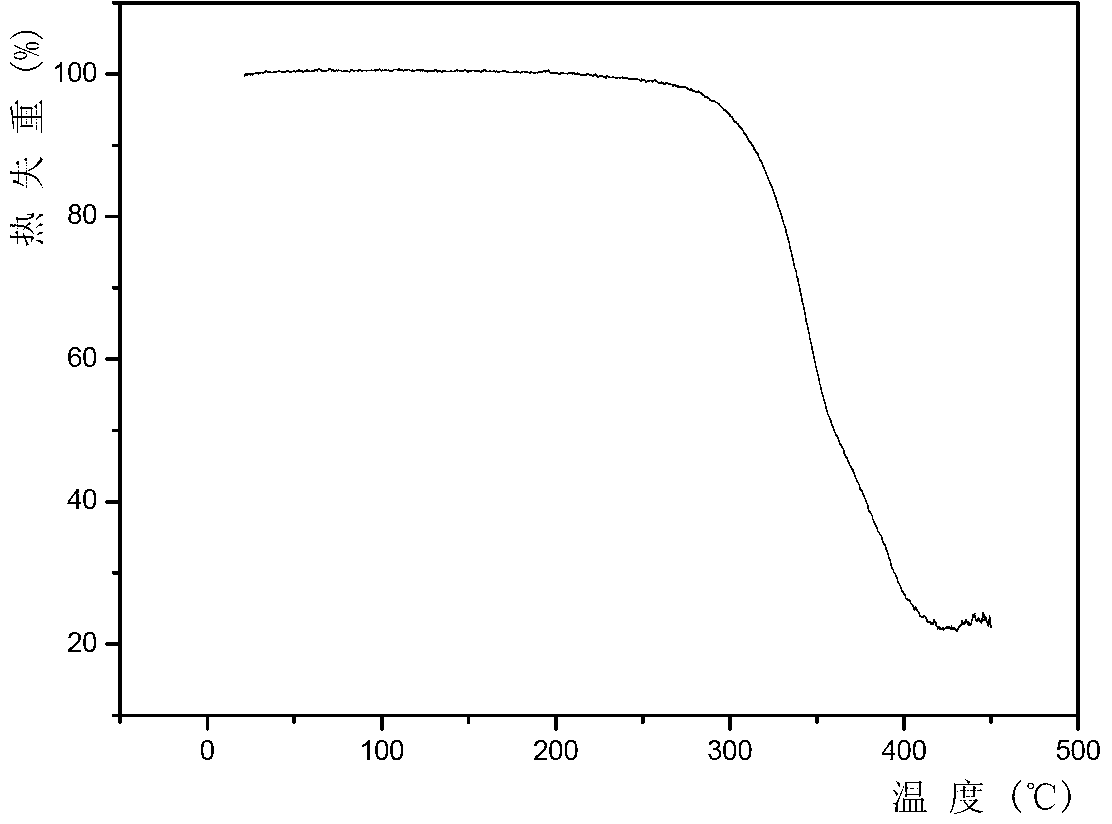

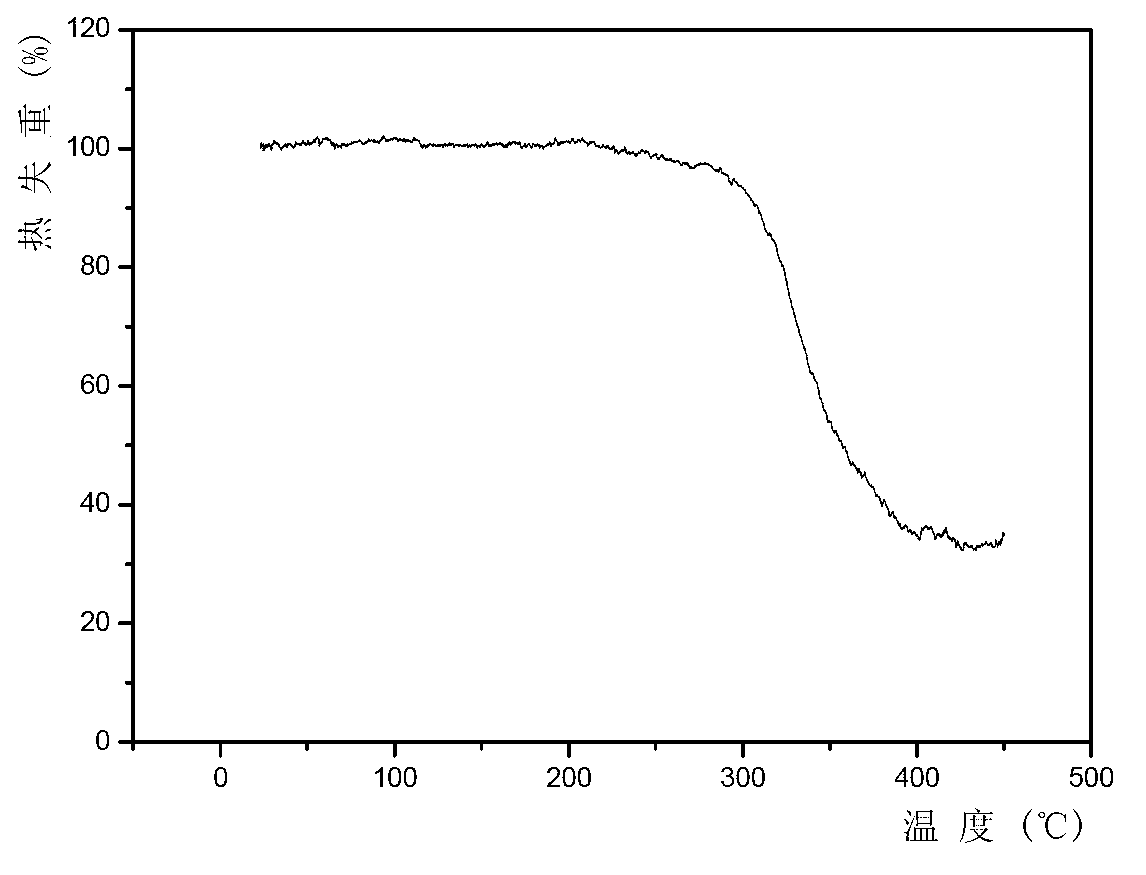

Irradiation-modified polyurethane piezoelectric damping material with conductive channel prepared from graphene and preparation method for same

The invention discloses an irradiation-modified polyurethane piezoelectric damping material with a conductive channel prepared from graphene and a preparation method for the same. The method comprises the following steps of: (1) mixing polyether ester polyol, 4,4'-dicyclohexyl methylene diphenyl diisocyanate, a catalyst, graphene, piezoelectric ceramic powder, dioxethyl butynediol and 1,4-butanediol to obtain a mixed material, performing vacuum defoaming on the mixed material, then pouring the mixed material in a mould, and sheeting via tape-casting to obtain sheets; (2) thermally curing the sheets, and then performing vacuum mould pressing to obtain a plate; and (3) irradiating the plate, and then performing electric polarization treatment to obtain the product. According to the method disclosed by the invention, via the introduction of the graphene conductive channel, the dielectric constant of the material is greatly increased, and the damping performance of the material is greatly improved. According to the method disclosed by the invention, crosslinking treatment is performed on the material via irradiation, so that the mechanical performance of the material is improved under the action of irradiation; and simultaneously, the post-curing time of the material is reduced, the production process is simplified, and the damping performance of the material is good.

Owner:BEIJING RADIATION APPL RES CENT

Double-component polyurethane waterproofing paint and preparation method thereof

InactiveCN102212307APromote environmental protectionPolyurea/polyurethane coatingsSolventChlorinated paraffins

The invention relates to double-component polyurethane waterproofing paint and a preparation method thereof. The waterproofing paint consists of a component A and a component B, wherein the mass proportion of component A to component B is 1:3; the component A comprises polyoxypropylene ether polyol with a molecular weight of 1500-2500 and a functionality of 2, polyoxypropylene ether polyol with a molecular weight of 3000-5000 and a functionality of 3, 4,4'-diphenylmethane diisocyanate, 2,4'-diphenylmethane diisocyanate and chlorcosane; and the component B comprises vacuum distillate 4 line oil, the chlorcosane, dibutyl phthalate, methine di-ortho-chloro aniline (MOCA), talcum powder, ground calcium carbonate, kaolin, inorganic pigment, a high-boiling-point non-toxic aromatic hydrocarbon solvent, a T-12 catalyst and triethylamine. The preparation method has the beneficial effects that nontoxic diphenylmethane diisocyanate is used instead of virulent toluene diisocynate; and in addition, toxic raw materials such as coal tar, toluene, dimehtylbenzene and the like are not added any more. Thus, the paint and preparation method are beneficial to environment protection.

Owner:SHANGHAI ORIENTAL YUHONG WATERPROOF TECH

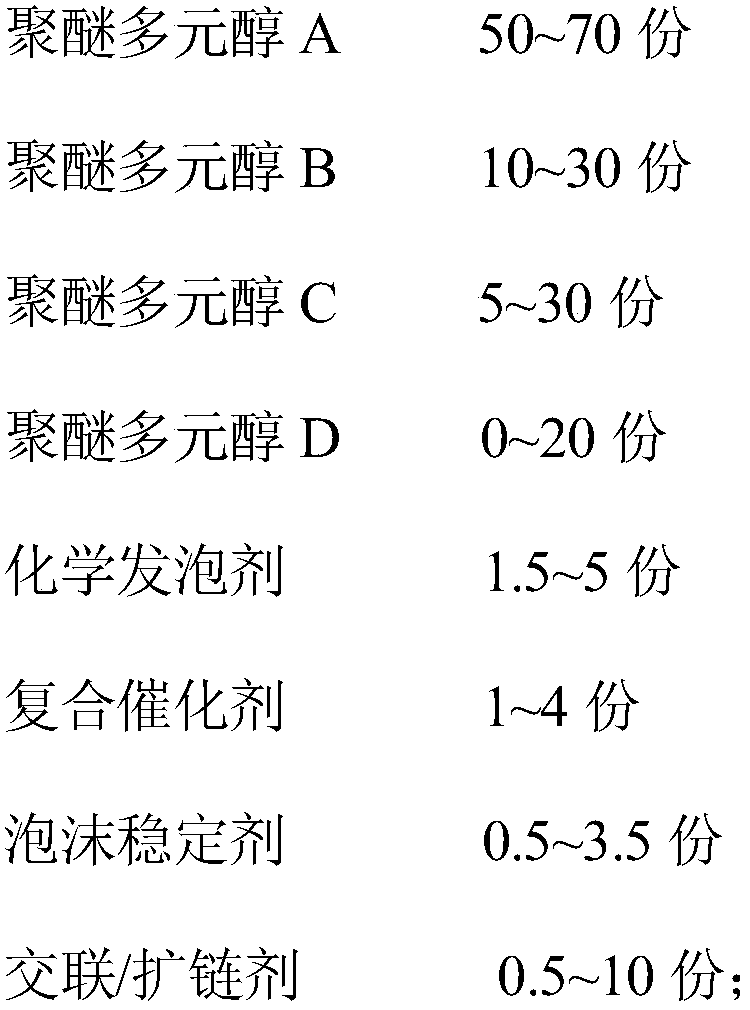

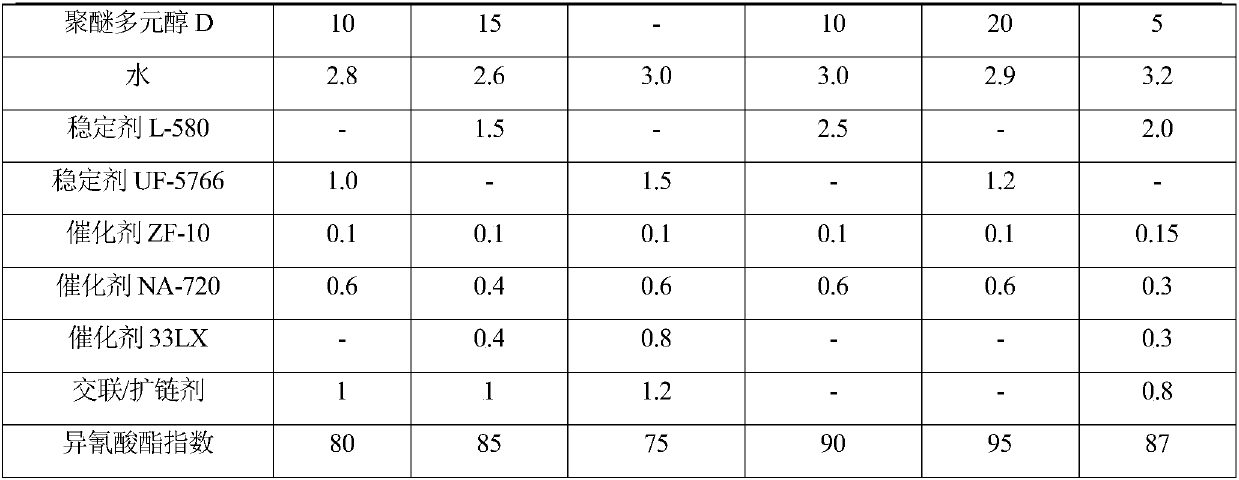

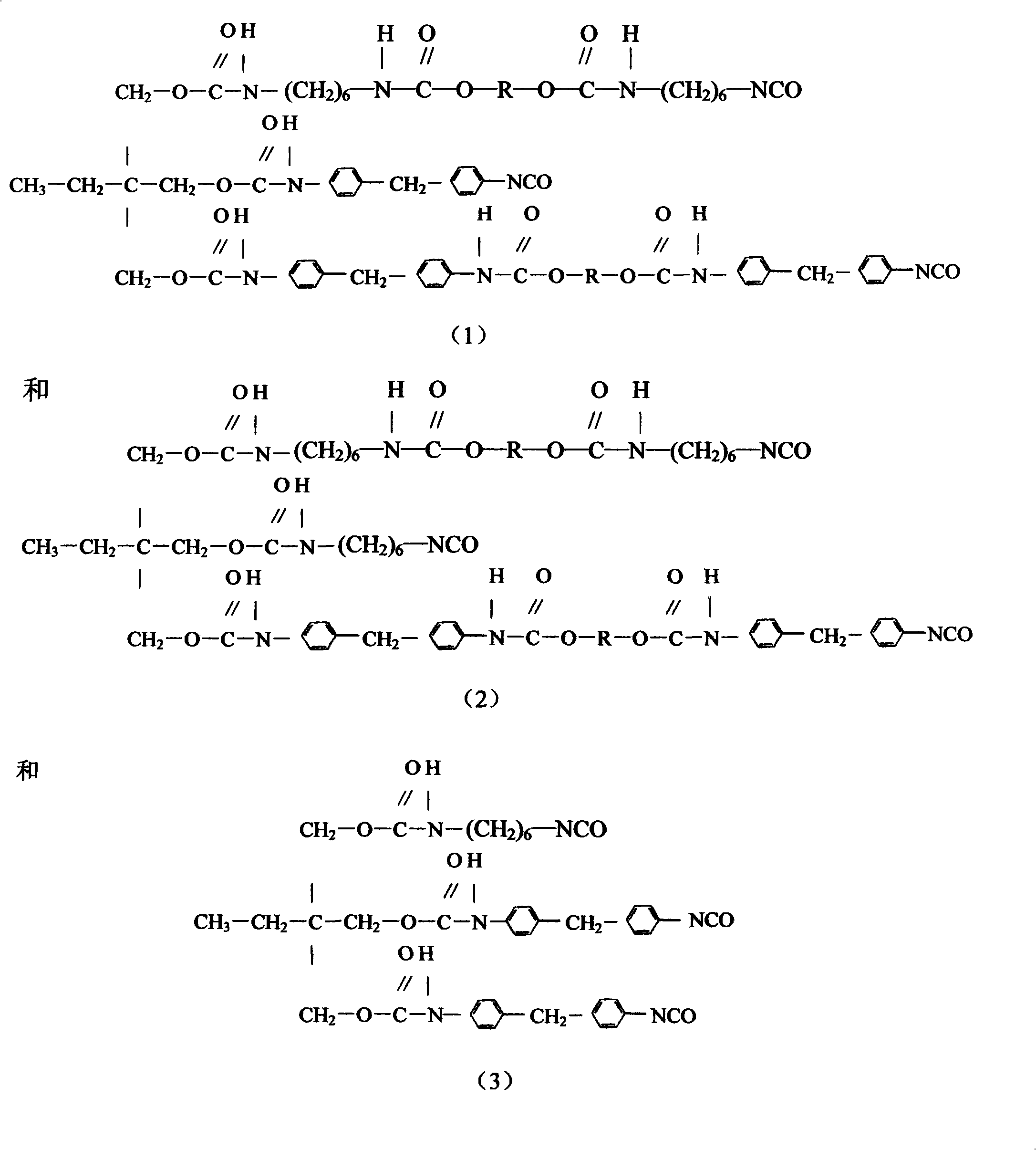

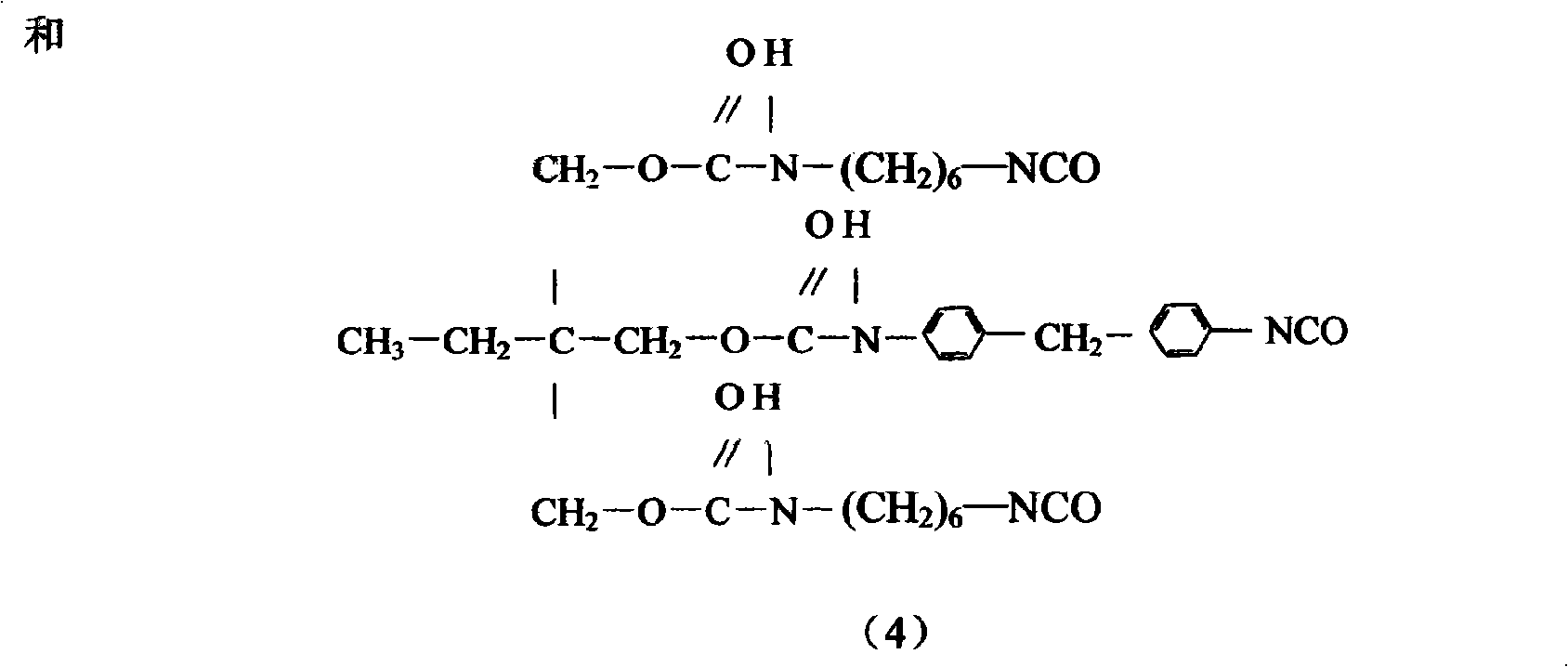

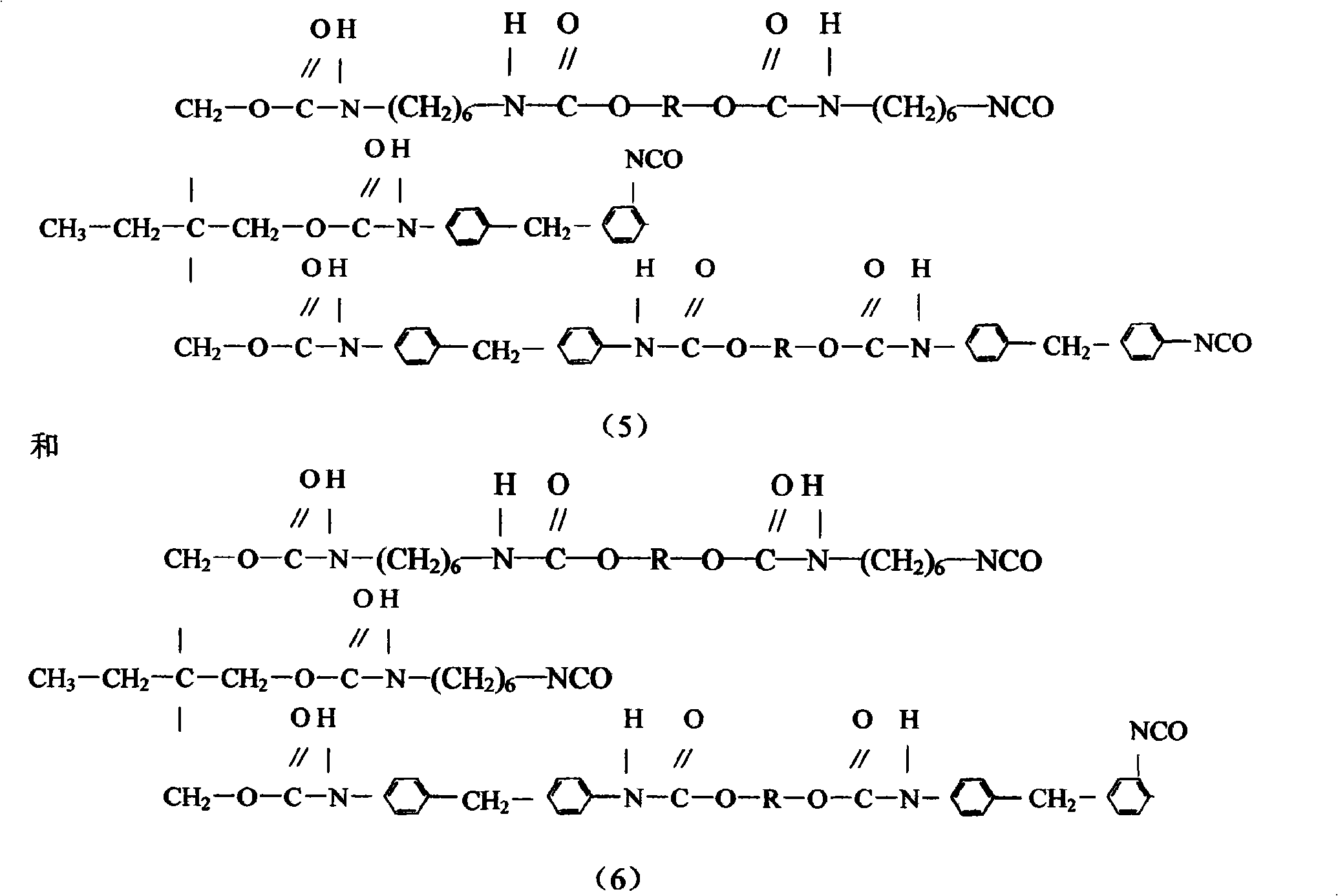

All-water environment-friendly and flame-retardant inflation memory polyurethane foam for automobile seat and preparation method of all-water environment-friendly and flame-retardant inflation memory polyurethane foam

The invention provides all-water environment-friendly and flame-retardant inflation memory polyurethane foam for an automobile seat and a preparation method of the all-water environment-friendly and flame-retardant inflation memory polyurethane foam. The all-water environment-friendly and flame-retardant inflation memory polyurethane foam is prepared from polyether polyol A, polyether polyol B, polyether polyol C, polyether polyol D, a chemical foaming agent, a composite catalyst, a foam stabilizer, a crosslinking / chain extender and full MDI (Methylene Diphenyl Diisocyanate) system isocyanate.According to the preparation method of the all-water environment-friendly and flame-retardant inflation memory polyurethane foam, disclosed by the invention, by scientifically matching the use amounts of all reactive components, adopting an all-water foaming and low-odor reactive environmental-friendly aid and selecting proper isocyanate formed by compounding, the obtained foam is flame-retardant, no flame retardant is added, and the odor of the foam is relatively-low; the foam is applied to the automobile seat, so that environmental protection can be improved.

Owner:ZHENGZHOU JINGYIDA AUTO PARTS

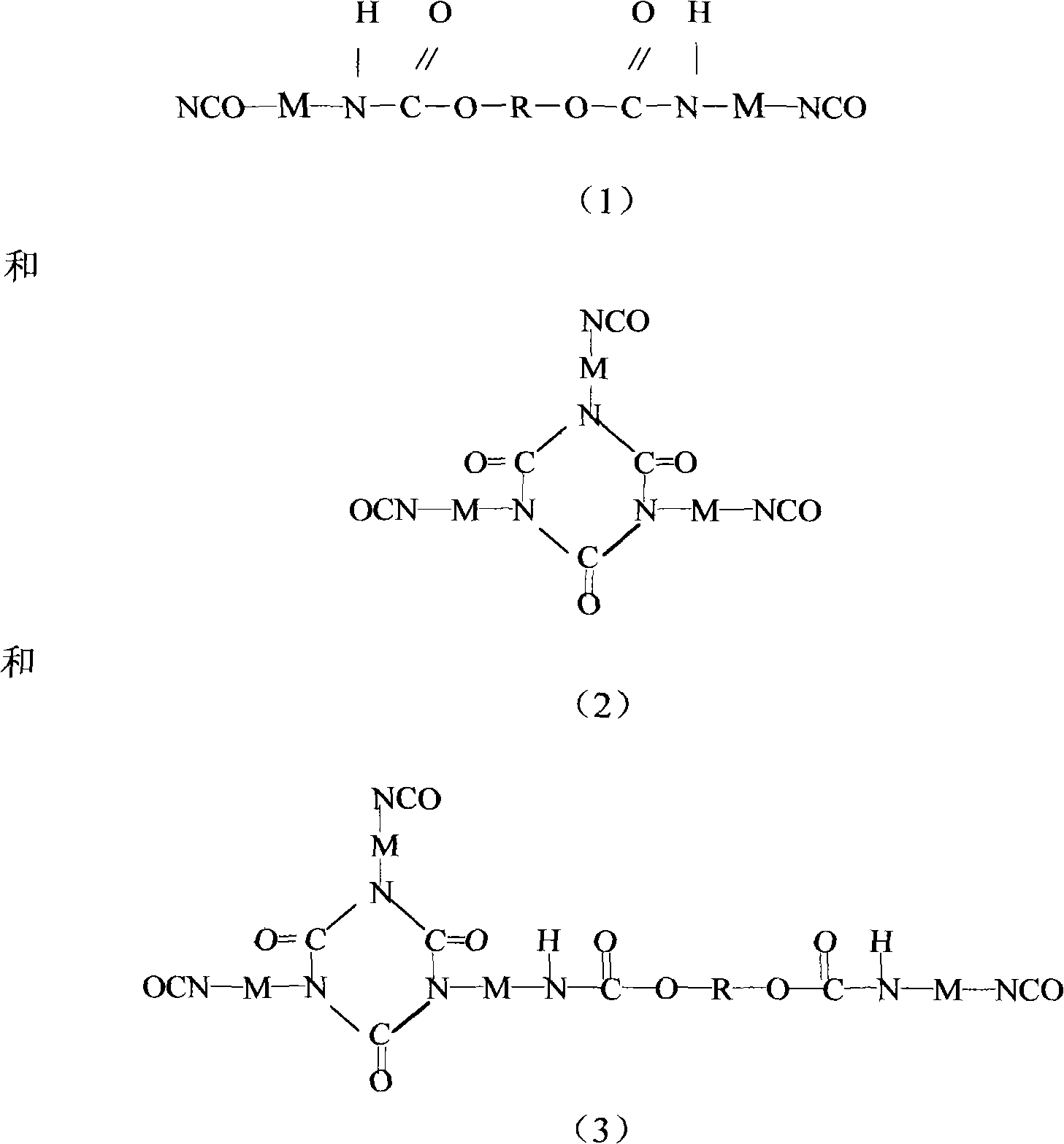

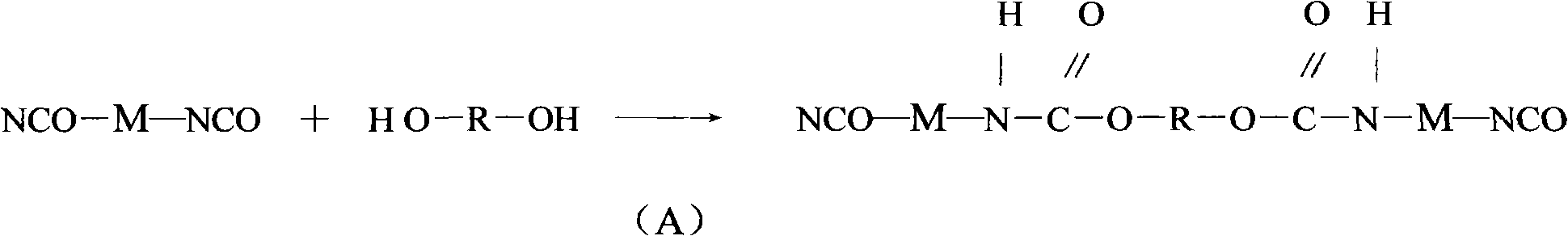

Mixed prepolymer of solidifying agent methyl diphenylene diisocyanate and 1,6-hexamethylene diisocyanate

The invention relates to a curing agent compound prepolymer composed of diphenylmenthane diisocyanate and 1, 6-hexamethylene diisocyanate and a preparation method thereof. The method comprises the following steps: MDI and an organic solvent are added and heated to 65 DEG C, polybasic alcohol is added and reacts with the mixture for 2 hours to 4 hours to obtain an MDI modifier; HID, an organic solvent and polybasic alcohol are added, heated and react for 2 hours to 5 hours, then the temperature is reduced below 70 DEG C, a TMP and organic solvent mixture is added, reaction at 70 DEG C lasts for 1 hour to 4 hours and 1 hour to 4 hours when the temperature is between 60 DEG C and 100 DEG C so as to obtain an HDI-MDI compound prepolymer curing agent. The method mixes and pre-polymerizes MDI and HDI, integrates the excellent performance of the two, produces a series of polyurethane curing agents with wide application range, high strength, good yellow-changing resistance, high curing speed, low toxicity, good storage stability and high solid content and has simple production technique.

Owner:FOSHAN JINGXIN HUIMING TECH CO LTD

Encapsulated particle

ActiveUS20050266245A1Efficient mixingReduce needBiocideBio-organic fraction processingToluene diisocyanatePhosphate

An encapsulated particle includes a core particle. The core particle includes a fertilizer selected from the group of nitrogen, phosphate, potash, and sulfur, and combinations thereof. The core particle may also include herbicides, insecticides, and fungicides. The encapsulated particle also includes a polyurethane layer disposed about the core particle. The polyurethane layer includes the reaction product of an aromatic isocyanate component and a polyol that is reactive with the aromatic isocyanate component. The aromatic isocyanate component includes methylene diphenyl diisocyanate, toluene diisocyanate, and mixtures thereof. The polyol that is reactive with the aromatic isocyanate component is derived from an aromatic amine-based initiator and includes a toluene diamine. The aromaticity of the aromatic isocyanate component and the polyol serves to insure complete miscibility between the aromatic isocyanate and the polyol thereby forming the polyurethane layer without defects preventing water from permeating the polyurethane layer and dissolving the core particle.

Owner:BASF CORP

Cellulose nanocrystals - thermoset resin systems, applications thereof and articles made therefrom

InactiveUS20160002462A1Enhanced interactionAldehyde/ketone condensation polymer adhesivesLignin adhesivesPolymer scienceAdhesive

The present describes wood adhesives reinforced with cellulose nanocrystals (CNC), in liquid and powder forms in which resin system are a phenol-formaldehyde polymer and / or lignin-phenol-formaldehyde polymer and polymeric methylene diphenyl diisocyanate (pMDI), and a method of making this polymer in liquid and powder from and the composite products that can be produced therefrom.

Owner:FPINNOVATIONS INC

Abrasion-resistant and environment-friendly polyurethane sports ground material and preparation method thereof

The invention discloses an abrasion-resistant and environment-friendly polyurethane sports ground material and a preparation method thereof. The material is blended with an elastomer A component and a B component, wherein the elastomer A component comprises methylene diphenyl diisocyanate and polyether glycol; the B component comprises polyether triols, polyether glycol, a cross-linking agent, a plasticizer, epoxy resin, acrylic acid, silica solution, whiskers, aluminium oxide and pigment. The sports ground material is used to overcome the harm to human bodies and unsafe hidden dangers caused by TD1 and MOCA used in conventional sports ground paving materials, and provides an environment-friendly, abrasion-resistant, low-toxicity, harmless, low-cost and high-properties polyurethane sports ground material.

Owner:SHANGQIU NORMAL UNIVERSITY

Curing agent methylene diphenyl diisocyanate tripolymer and method for preparing same

ActiveCN102212182ASolve the problem that can not be three polyEasy to manufacturePolyureas/polyurethane adhesivesPolyurea/polyurethane coatingsOrganic solventAdhesive

The invention discloses a curing agent, namely a methylene diphenyl diisocyanate (MDI) tripolymer and a method for preparing the same. The method comprises the following steps of: adding the MDI and an organic solvent into a reaction kettle, raising the temperature, dissolving the MDI, stirring uniformly, adding dehydrated polyol, and reacting for 1 to 6 hours at the temperature of between 40 and 90 DEG C to obtain modified MDI; reducing the temperature to 40 DEG C, dripping mixed solution of a trimerization catalyst and an organic solvent, reacting at the temperature of between 30 and 80 DEG C, and adding a polymerization inhibitor when the percentage of isocyanate group (NCO) reaches a preset value; and reducing the temperature to obtain the MDI tripolymer curing agent. The invention provides the method for preparing the tripolymer curing agent by using the MDI. The process is simple, the requirements of equipment are low, the content of the tripolymer is high, and the curing agent is well soluble in resins and can substitute a tolylene diisocyanate (TDI) tripolymer with similar performance. The curing agent is mainly used for being matched with two-component polyurethane coatings and main agents of adhesives, and can also be used for other fields.

Owner:J&H XIANGYANG CHEM

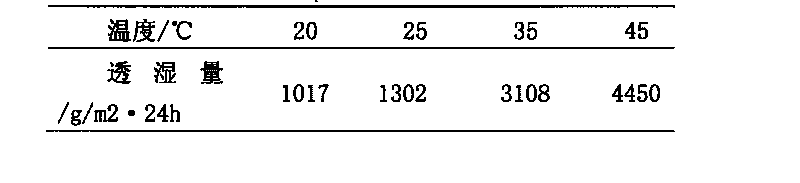

Polyurethane resin with intelligent moisture permeating function for synthetic leather surface coating and preparation method thereof

InactiveCN101693759AGood moisture permeabilityImprove mechanical propertiesFibre treatmentPolyesterToluene diisocyanate

The invention relates to a polyurethane resin with an intelligent moisture permeating function for a synthetic leather surface coating, wherein an organic polyalcohol polymer is a mixture of polyester diol and polyether diol, and the mass ratio of the polyester diol and the polyether diol is 1:0.2-4; diisocyanate is 4,4'-methylene diphenyl diisocyanate, toluene diisocyanate or isophorone diisocyanate; and the extending chain is 1,4-butanediol, ethanediol or diglycol. The invention combines the advantages of polyurethane adopting the polyester diol as a soft segment and polyurethane adopting polyethylene glycol as a soft segment and learns from strong points to offset weakness, and the obtained polyurethane has better moisture permeability and favorable mechanical performance; the intelligent moisture permeating conversion temperature of the polyurethane resin ranges from 20 DEG C to 50 DEG C and can be controlled by adjusting the molecular weight and proportion of the polyester diol and the polyethylene glycol.

Owner:FUJIAN DONGTAI HIGH POLYMER MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com