Integral skin polyurethane-urea composition, preparation method and application thereof

A technology of polyurethane urea and self-skinning, applied in the application field of making automotive interior parts, to achieve good technical performance, fast demoulding time, and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] The preparation of component B can adopt the well-known polymerization method of those skilled in the art, such as "Polyurethane Handbook: The Third Chapter Raw Materials" (edited by [Germany] G Ertel, translated by Yan Jiabin, Lv Yanxian, etc., China Petrochemical Press, 1st edition , 1992, P63) related preparation technology introduced.

[0057] Specifically, preheat 100 parts of MDI to 60-90°C, preferably 80°C; add 0.003-0.05 parts of catalyst, such as 426 cobalt catalyst; slowly add 1-30 parts of dehydrated polyol, such as , polycaprolactone diol; after the polymerization starts, the temperature of the polymerization system rises due to heat release, and the reaction temperature is controlled not to exceed 130°C, and the reaction is 30-120 minutes; add 0.003-0.05 parts of a terminator, such as benzoyl chloride , to deactivate the catalyst to terminate the polymerization reaction; cool to room temperature, and seal the package.

[0058] In the above reaction, the ca...

Embodiment 1

[0084] Preparation of component A:

[0085] According to the formulations of the 6 components A given in Table 1, stir evenly at room temperature to obtain the 6 components A.

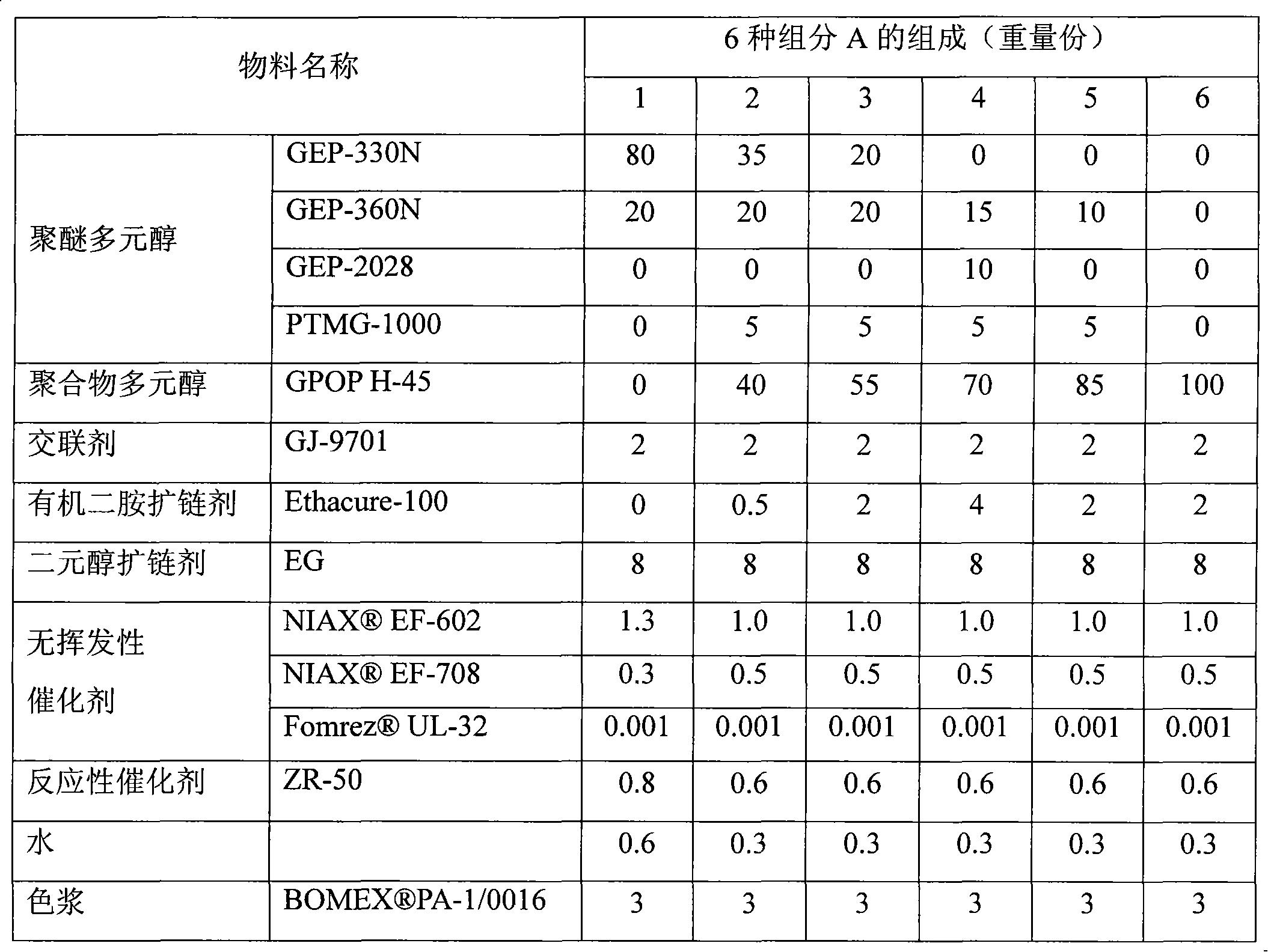

[0086] Table 1. Composition of 6 components A

[0087]

Embodiment 2

[0089] Synthesis of Component B:

[0090] (1) Dehydration of polyalcohols: first, a sufficient amount of polycaprolactone diol Put PL-2000 into a reaction kettle equipped with a stirrer and a vacuum system, heat it to 120°C under stirring, then evacuate it to -0.09MPa, dehydrate it for 120 minutes, and then cool it to room temperature for use.

[0091] (2) Preparation of allophanate modified isocyanate: 40 parts of 4,4'-MDI such as 1810, 20 parts of 4,4'-MDI and 4,4'-MDI mixture 3056, 30 parts of carbodiimide modified MDI 2020 and 10 parts of polymerized MDI were put into another reactor, and under the protection of nitrogen, the temperature was raised to 80°C with stirring; 0.005 parts of 426 cobalt catalyst was added, and then 12.5 parts of polymer dehydrated according to step (1) were added in batches. caprolactone diol PL-2000. The exothermic heat of the polymerization system raises the temperature, and the reaction temperature is controlled not to exceed 130°C. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com