Room-temperature curing propellant

A room temperature curing, propellant technology, applied in the direction of offensive equipment, compressed gas generation, explosives, etc., to achieve the effect of reducing activity, improving mechanical properties, and ensuring mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The preparation method of room temperature curing propellant of the present invention is as follows:

[0050] After the components in the formula are mixed uniformly according to the specified ratio, it becomes a slurry with good fluidity and leveling properties. The slurry is poured into the charge combustion chamber or a mold with a specified shape, and heated at 20-35°C After curing for 5-7 days under ambient conditions, the desired composite solid propellant product can be obtained.

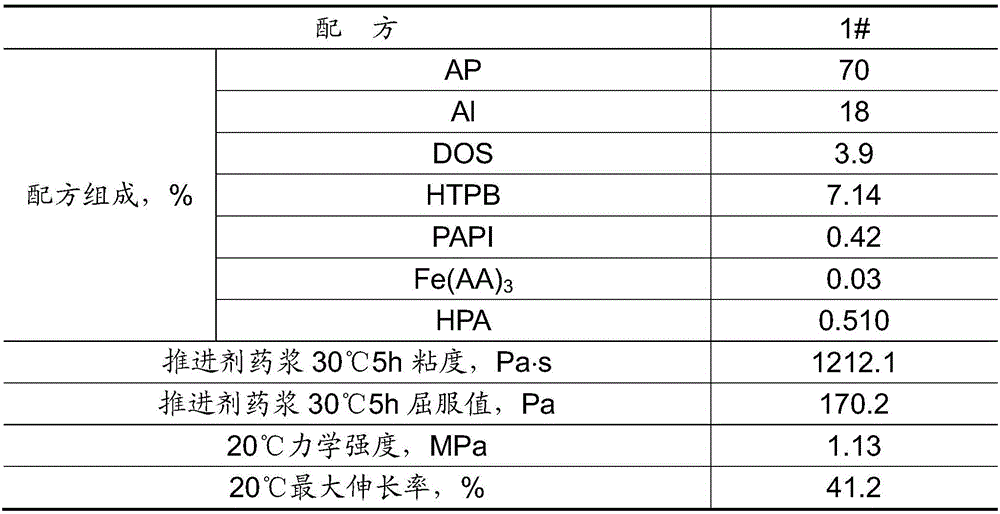

Embodiment 1

[0052] Table 1 formula composition and process, mechanical properties

[0053]

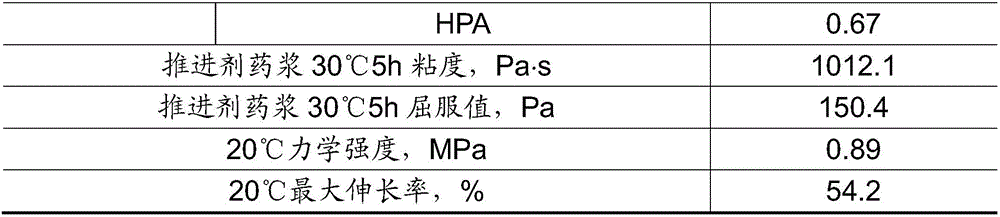

Embodiment 2

[0055] Table 2 formula composition and process, mechanical properties

[0056]

[0057]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com