Irradiation-modified polyurethane piezoelectric damping material with conductive channel prepared from graphene and preparation method for same

A polyurethane piezoelectric and conductive channel technology, applied in the coating and other directions, can solve the problems of large amount of addition, limited conductive effect of conductive graphite and polyaniline, limiting the efficiency of converting electrical energy into thermal energy in conductive channels, etc., and achieves simplified production process, The effect of reducing the post-curing time and increasing the dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1. Preparation of radiation-modified polyurethane piezoelectric damping material using graphene as a conductive channel

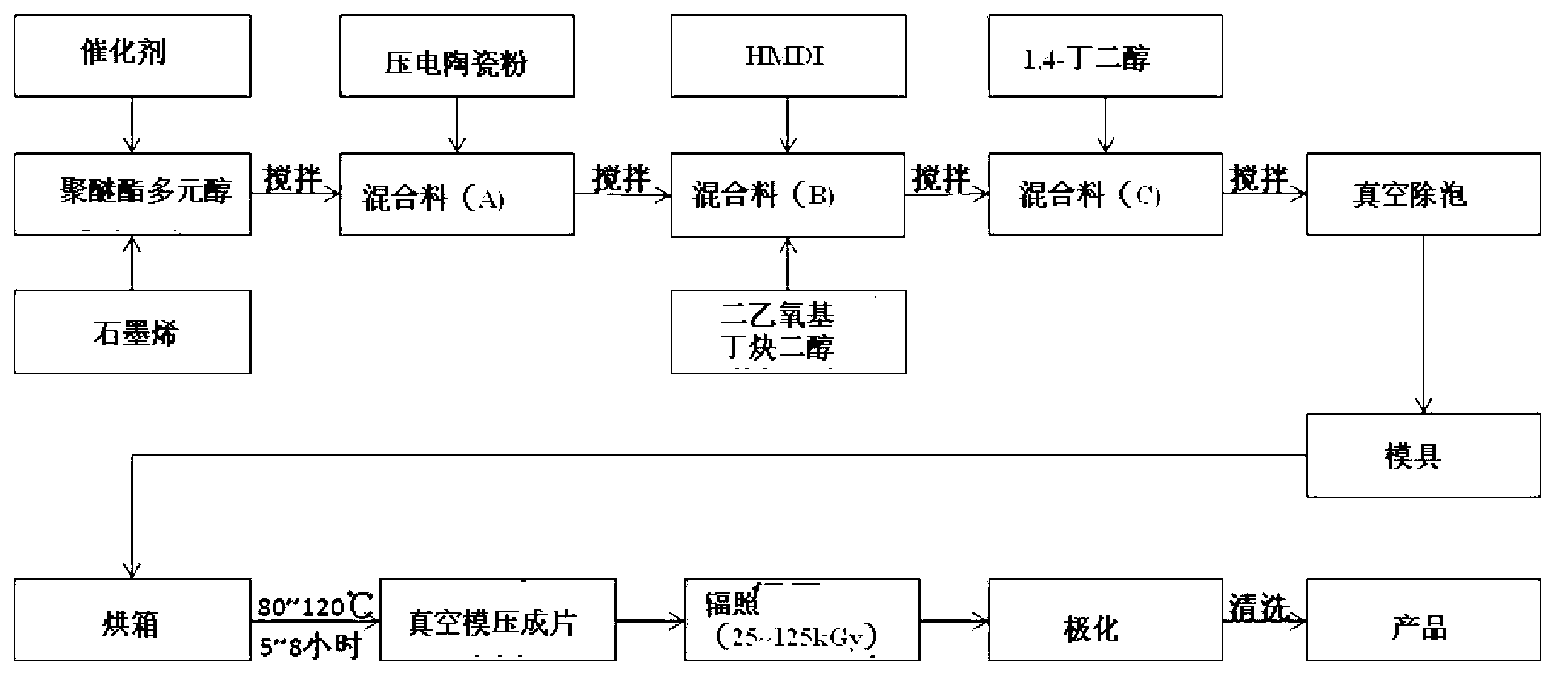

[0032] The process flow chart prepared by the present invention is as figure 1 shown.

[0033] Weigh 100g of polyether ester polyol JES-101 (Shanxi Kaixirui Technology Co., Ltd.) into a beaker, and add 1.0g of stannous octoate and graphene SGE-070 (Beijing Naxintiandi Technology Development Co., Ltd.) to the beaker in turn 0.125g, piezoelectric ceramic powder (PZT-4) 40g, hydrogenated MDI (HMDI) 50g, diethoxybutynediol 4g and 1,4-butanediol 5g, vacuum defoaming and stirring evenly, pour into the mold, Cast into a sheet, and wait for the sheet to solidify for later use;

[0034] (2) Place the sheet prepared in step (1) in a vacuum oven at 80°C for heat aging for 6 hours;

[0035] (3) Place the heat-cured sheet in step (2) in a vacuum flat vulcanizing machine, and mold it at 80°C to form a flat sheet;

[0036] (4) Carry out irradiation trea...

Embodiment 2

[0045] Example 2, preparation of radiation-modified polyurethane piezoelectric damping material using graphene as a conductive channel

[0046] The process flow chart prepared by the present invention is as figure 1 shown.

[0047] (1) Weigh 1 kg of polyether ester polyol JES-102 (Shanxi Kaixirui Technology Co., Ltd.) Company) 2.5g, piezoelectric ceramic powder (PZT-4) 200g, hydrogenated MDI (HMDI) 600g, diethoxybutynediol 50g and 1,4-butanediol 90g, vacuum defoaming and stirring evenly, pour into The mould, which is cast into a sheet, is ready for use after the sheet is solidified;

[0048] (2) heat-cure the sheet prepared in step (1) in a vacuum oven at 100°C for 4 hours;

[0049] (3) Place the heat-cured sheet in step (2) in a vacuum flat vulcanizing machine, and mold it at 100°C to form a flat sheet;

[0050] (4) Carry out irradiation treatment on the plate after finishing in step (3), and the irradiation dose is 50kGy;

[0051] (5) Cover the surface of the plate afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average sound insulation | aaaaa | aaaaa |

| Sound insulation | aaaaa | aaaaa |

| Average sound insulation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com