Addition type organic silicon rubber tackifier, preparation method and application thereof

A technology of silicone rubber and addition molding, which is applied in the direction of adhesives, adhesive additives, polymer adhesive additives, etc., can solve the problems of poor bonding performance of contact materials, and achieve improved design space, good bonding performance, The effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

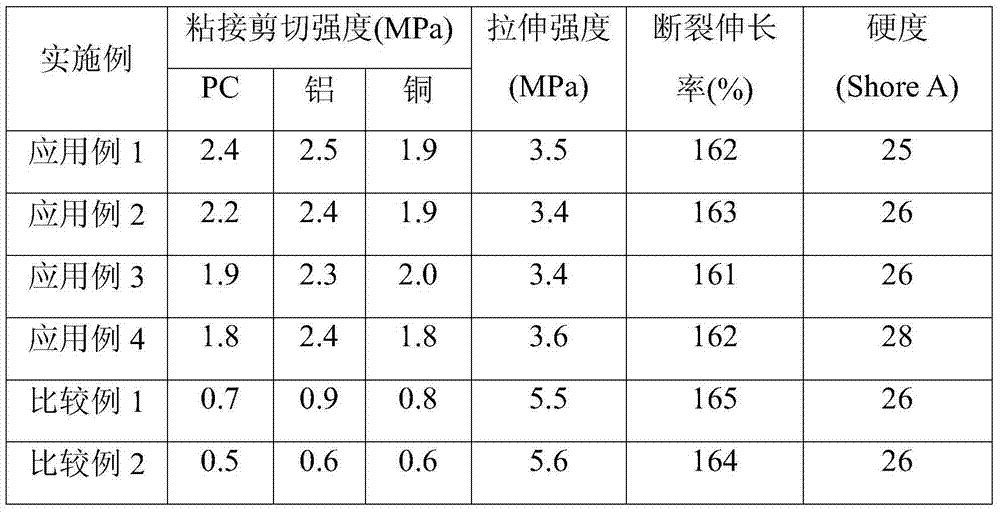

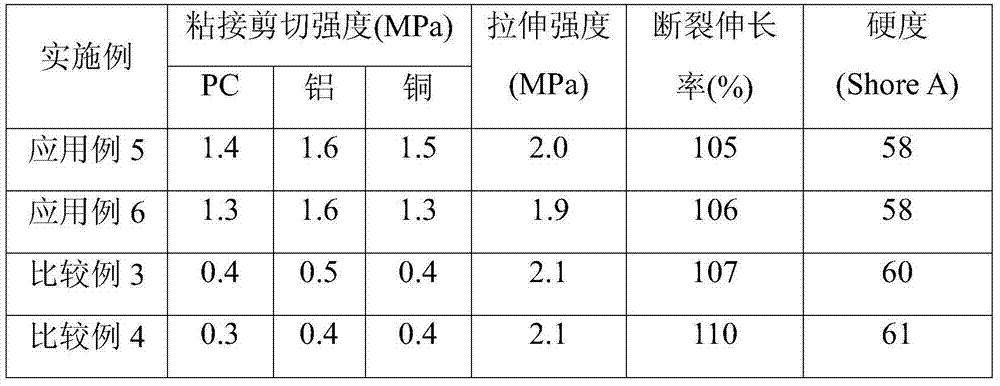

Examples

Synthetic example 1

[0029] Add 51.00g vinyl hydroxy silicone oil (containing 0.18mol-OH, vinyl content is 6.5%wt, hydroxyl content is 6%wt) and 42.54g γ-glycidyl etheroxypropyltrimethoxysilane (0.18 mol), stirred at room temperature for 10 min, added 0.18 g of tetrabutyl titanate dropwise with a pipette, then heated to 90 °C for 2 hours under nitrogen protection, and then distilled at 50-90 °C for 2 hours to remove small molecules. Under the condition of keeping the vacuum degree, it was lowered to room temperature, and the tackifier 1 was prepared, and the yield was 96%.

Synthetic example 2

[0031]Add 51.00g of vinyl hydroxy silicone oil (containing 0.18mol–OH, vinyl content of 6.5%wt, hydroxyl content of 6%wt) and 50.12g of γ-glycidyl etheroxypropyl triethoxysilane ( 0.18mol), stirred at room temperature for 10min, added dropwise 0.20g tetrabutyl titanate with a pipette, then raised the temperature to 90°C for 2 hours under nitrogen protection, and then distilled under reduced pressure at 50-90°C for 2 hours to remove small molecules. Decrease to room temperature under the condition of maintaining the vacuum degree to prepare tackifier 2 with a yield of 95%.

Synthetic example 3

[0033] Add 51.00g of vinyl hydroxy silicone oil (containing 0.18mol–OH, vinyl content of 6.5%wt, hydroxyl content of 6%wt) and 39.66g of γ-glycidylpropylmethyldimethoxysilane into a 250mL three-necked bottle (0.18mol), stirred at room temperature for 10min, added dropwise 0.25g of ethyl acetoacetate complexed isopropyl titanate with a pipette, then raised the temperature to 70°C for 4 hours under the protection of nitrogen, and then distilled under reduced pressure at 50-90°C for 2 hours to remove small molecules. Decrease to room temperature under the condition of maintaining the vacuum degree to prepare tackifier 3 with a yield of 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com