High-elasticity-recovery-rate silicone elastic sealant for hollow glass and preparation method of silicone elastic sealant

An elastic sealing and high-elasticity technology, applied in the field of sealants, can solve problems such as lack of satisfaction, and achieve the effects of low volatility, good weather resistance, and improved elasticity and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A high elastic recovery rate silicone sealant for insulating glass, which is composed of the following raw materials in parts by weight:

[0044] Component A: 30 parts of α,ω-dihydroxypolydimethylsiloxane with a viscosity of 80000mmPa.s at 25°C and α,ω-dihydroxypolydimethylsiloxane with a viscosity of 5000mmPa.s at 25°C 60 parts, the viscosity is 350mm 2 / s 20 parts of simethicone oil and 150 parts of calcium carbonate were added into a high-speed planetary mixer and stirred evenly.

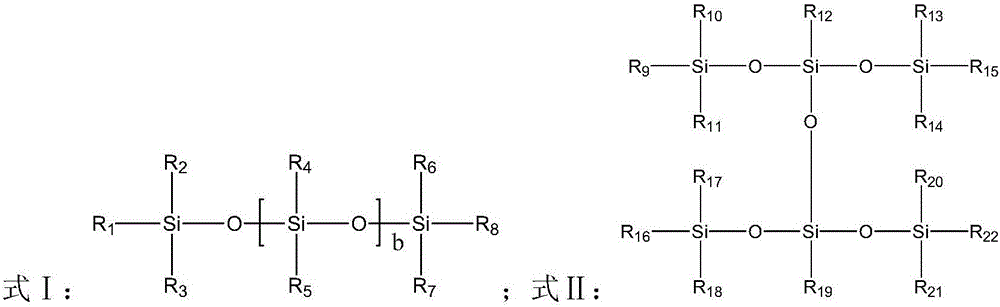

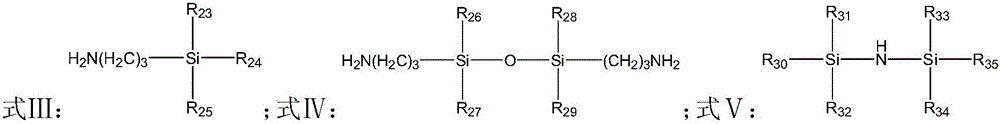

[0045] Component B: 90 parts of silane crosslinking agent oligomers containing formula I and formula II, 40 parts of organosilane coupling agent containing formula III, formula IV and formula V, 0.5 parts of dibutyltin dilaurate, Viscosity is 350mm 2 / s 30 parts of simethicone oil and 130 parts of carbon black are added to the planetary mixer at a vacuum of 0.08MPa and stirred evenly.

[0046] At room temperature, mix the two components A and B according to the mass ratio A:B=15:1 befor...

Embodiment 2

[0056] A high elastic recovery rate silicone sealant for insulating glass, which is prepared from the following raw materials in parts by weight:

[0057] Component A: 40 parts of α,ω-dihydroxypolydimethylsiloxane with a viscosity of 80000mmPa.s at 25°C, and α,ω-dihydroxypolydimethylsiloxane with a viscosity of 5000mmPa.s at 25°C 70 parts, the viscosity is 350mm 2 / s 30 parts of simethicone oil and 180 parts of calcium carbonate were added into a high-speed planetary mixer and stirred evenly.

[0058] Component B: 100 parts of silane crosslinking agent oligomers containing formula I and formula II, 50 parts of organosilane coupling agent containing formula III, formula IV and formula V, 0.8 parts of dibutyltin dilaurate, Viscosity is 350mm 2 / s 38 parts of simethicone oil and 135 parts of carbon black were added into the planetary mixer at a vacuum of 0.095 MPa and stirred evenly.

[0059] At room temperature, mix the two components A and B according to the mass ratio A:B=1...

Embodiment 3

[0069] A high elastic recovery rate silicone sealant for insulating glass, which is prepared from the following raw materials in parts by weight:

[0070] Component A: 35 parts of α,ω-dihydroxypolydimethylsiloxane with a viscosity of 80000mmPa.s at 25°C, and α,ω-dihydroxypolydimethylsiloxane with a viscosity of 5000mmPa.s at 25°C 65 parts, the viscosity is 350mm 2 / s 25 parts of simethicone oil and 200 parts of calcium carbonate were added into a high-speed planetary mixer and stirred evenly.

[0071] Component B: 95 parts of silane crosslinking agent oligomers containing formula I and formula II, 45 parts of organosilane coupling agent containing formula III, formula IV and formula V, 0.6 parts of dibutyltin dilaurate, Viscosity is 350mm 2 / s 35 parts of simethicone oil and 133 parts of carbon black are added into the planetary mixer at a vacuum of 0.09MPa and stirred evenly.

[0072] At room temperature, mix the two components A and B according to the mass ratio A:B=18:1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com