Damping material for dust collector motor

A vibration-absorbing material and technology for vacuum cleaners, which are applied to electromechanical devices, electrical components, electric components, etc., can solve the problems affecting the use effect and service life of vacuum cleaners, poor mechanical strength and anti-aging performance, and large working noise of the vacuum cleaner. To achieve the effect of improving stability and elasticity, improving elasticity and aging resistance, and improving hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

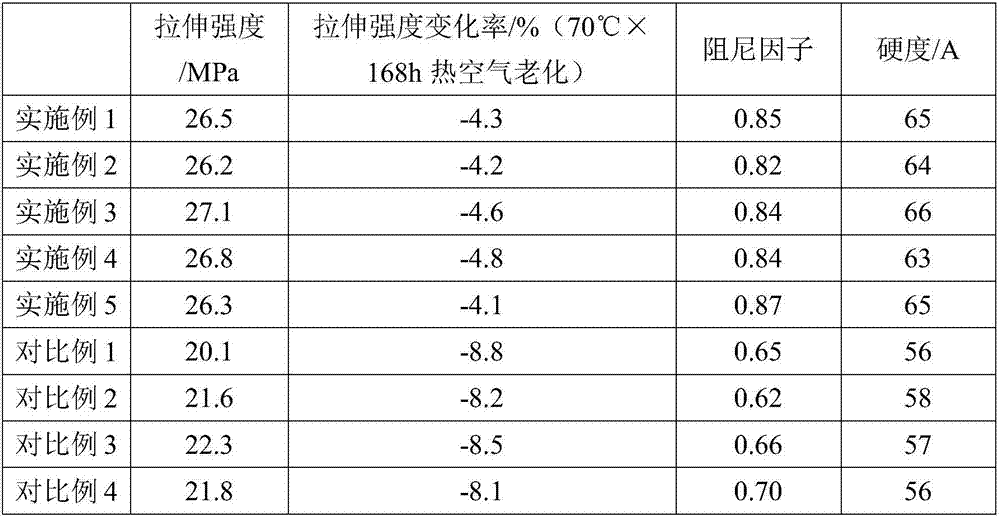

Examples

preparation example Construction

[0021] Provide below the preparation method of vacuum cleaner motor vibration-damping material of the present invention, it may further comprise the steps:

[0022] 1) Add styrene-butadiene rubber and EPDM rubber into the internal mixer, heat to 50-90°C, and knead for 1-5min;

[0023] 2) Add styrene-butadiene-styrene block copolymer, polypropylene thermoplastic elastomer, polyurethane elastomer, and coupling agent to the internal mixer in sequence, heat to 40-90°C, and knead for 5-45 minutes;

[0024] 3) Add acrylate, nano-silicon carbide, phosphate, nano-magnesia powder, nano-zirconia, carbon fiber powder, boron fiber powder, wollastonite powder, glass beads, methyl silicone oil, carboxymethyl Base starch, control the temperature at 60-90°C, and knead for 10-60min;

[0025] 4) Add polyethylene wax and anti-aging agent to the internal mixer in turn, control the temperature at 80-150°C, and mix for 10-60 minutes; discharge the glue after cooling to room temperature and let it ...

Embodiment 1

[0031] 2. The vibration-damping material for a vacuum cleaner motor according to claim 1, wherein the vibration-damping material for a vacuum cleaner motor is made of the following materials in parts by weight: 50 parts of styrene-butadiene rubber, 50 parts of EPDM rubber 40 parts, 40 parts of styrene-butadiene-styrene block copolymer, 40 parts of polypropylene thermoplastic elastomer, 30 parts of polyurethane elastomer, 30 parts of acrylate, 10 parts of nano silicon carbide powder, 10 parts of phosphate, nano 10 parts of magnesium oxide powder, 5 parts of nano-zirconia powder, 5 parts of carbon fiber powder, 5 parts of boron fiber powder, 5 parts of wollastonite powder, 10 parts of glass microspheres, 20 parts of methyl silicone oil, 20 parts of carboxymethyl starch, 15 parts of polyethylene wax, 15 parts of coupling agent, 10 parts of accelerator, 10 parts of initiator, 8 parts of anti-aging agent.

[0032] Wherein, the accelerator is dibenzothiazole disulfide, N-cyclohexyl-...

Embodiment 2

[0034] 3. The vibration-damping material for a vacuum cleaner motor according to claim 1, wherein the vibration-damping material for a vacuum cleaner motor is made of the following materials in parts by weight: 55 parts of styrene-butadiene rubber, 450 parts of EPDM 45 parts, 45 parts of styrene-butadiene-styrene block copolymer, 35 parts of polypropylene thermoplastic elastomer, 35 parts of polyurethane elastomer, 40 parts of acrylate, 5 parts of nano silicon carbide powder, 8 parts of phosphate, nano 12 parts of magnesium oxide powder, 5 parts of nano-zirconia powder, 8 parts of carbon fiber powder, 8 parts of boron fiber powder, 8 parts of wollastonite powder, 12 parts of glass microspheres, 25 parts of methyl silicone oil, 25 parts of carboxymethyl starch, 25 parts of polyethylene wax, 18 parts of coupling agent, 18 parts of accelerator, 12 parts of initiator, 10 parts of anti-aging agent.

[0035] Wherein, the accelerator is dibenzothiazole disulfide, N-cyclohexyl-2-benzo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com