Hydraulic coal bunker bursting device

A technology for coal bunker and arch breaking, applied in packaging, transportation and packaging, containers and other directions, can solve problems such as damage to the bunker body, coal arch collapse, collapse, etc., to achieve extended service life, strong arch breaking ability, improved strength and elastic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

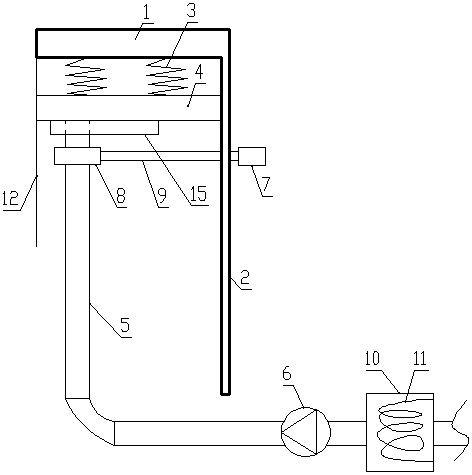

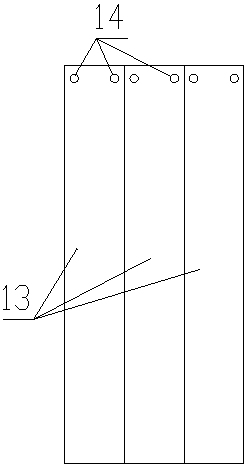

[0036] Such as figure 1 with figure 2 As shown, the hydraulic coal bunker arch breaking device of the present invention includes a mounting seat, the mounting seat includes a top plate 1 and a side wall 2 of the mounting seat connected to one side of the top plate 1, and the side wall 2 of the mounting seat is used to be installed on the coal bunker through the mounting frame. The bottom of the side wall; the installation frame and the coal bunker are all conventional technologies, not shown in the figure.

[0037] The top plate 1 is connected downward with at least one spring 3, the lower end of the spring 3 is connected with a cover plate 4 made of rubber or plastic, the lower part of the cover plate 4 is provided with a water spray pipe 5 with an opening upward, and the water spray pipe 5 is made of rubber , the cover plate 4 is used to prevent coal from falling into the spray pipe 5;

[0038] The water spray pipe 5 extends from the bottom of the mounting seat to the sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com