Deflation valve capable of being installed at any depth of underground

A technology of arbitrary depth and deflation valve, which is applied in wellbore/well components, wellbore/well valve devices, earthwork drilling and production, etc. It can solve the problem that the deflation valve is difficult to open and achieve the effect of increasing the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

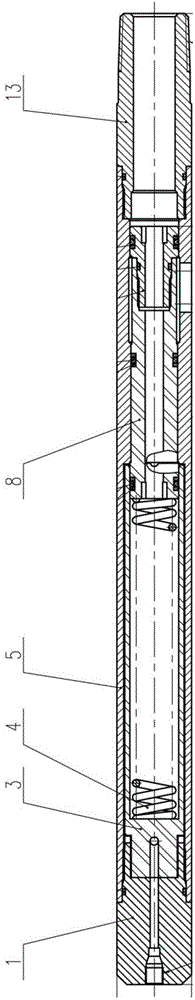

[0009] The present invention will be further described now in conjunction with accompanying drawing.

[0010] see figure 1 , figure 1 What is shown is an embodiment of the present invention, including a pressure cap 1, a valve body 5, and a hollow lower joint 13. The upper end of the valve body 5 is connected to the pressure cap 1, and the lower end is connected to the lower joint 13. The spring 4 in the spring sleeve 3 bears against the piston 8; the side wall of the valve body 5 is provided with an air outlet, and the air outlet is fully opened when the piston 8 is at the stroke end.

[0011] The piston 8 is provided with a through hole passing through its upper end and lower end, and the through hole is connected to the cavity inside the lower joint 13 and the spring sleeve 3; in addition, the cross-sectional area of the upper end and the lower end of the piston 8 is equal.

[0012] Wherein, the piston 8 is formed by connecting an upper piston and a lower piston.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com