Servo high frequency heating plug

A high-frequency heating and plug-in technology, which is applied in the field of heating appliances, can solve the problems of affecting the effect of metal parts, loss, and long time spent on distributing and retrieving materials, and achieve the effects of avoiding heat loss, stable temperature, and short time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but those skilled in the art will understand that the following descriptions are only for illustrating the present invention, and should not be regarded as limiting the protection scope of the present invention.

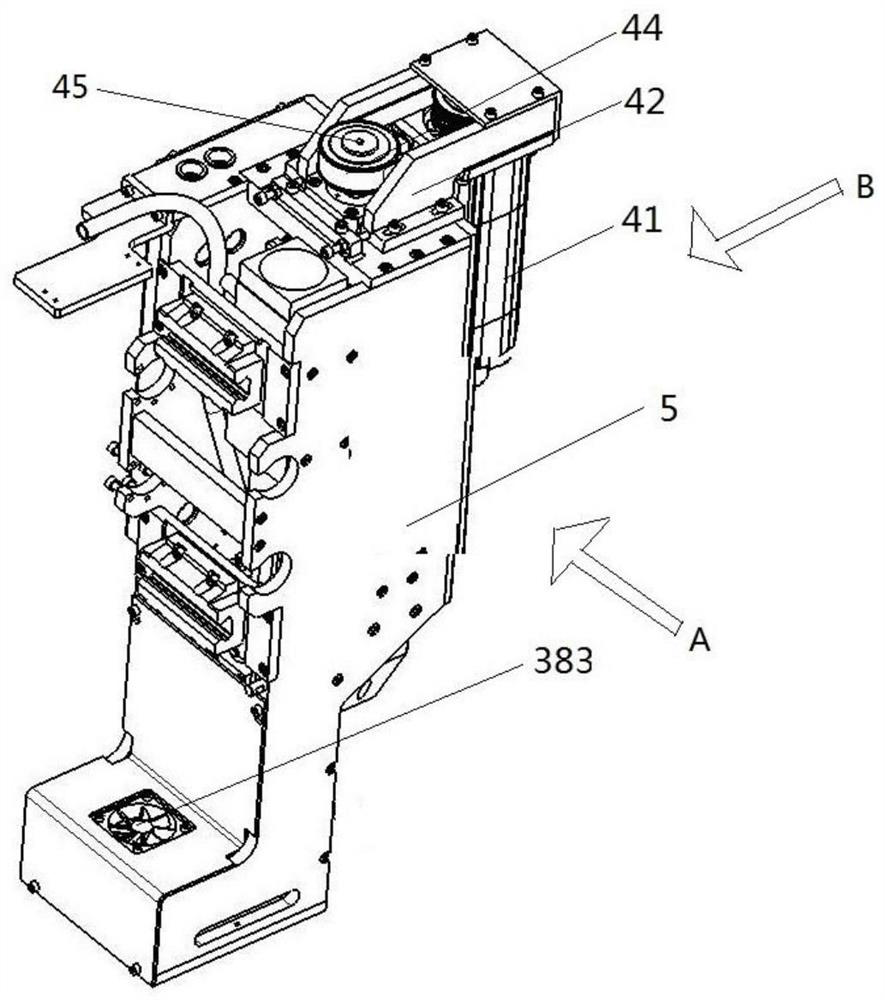

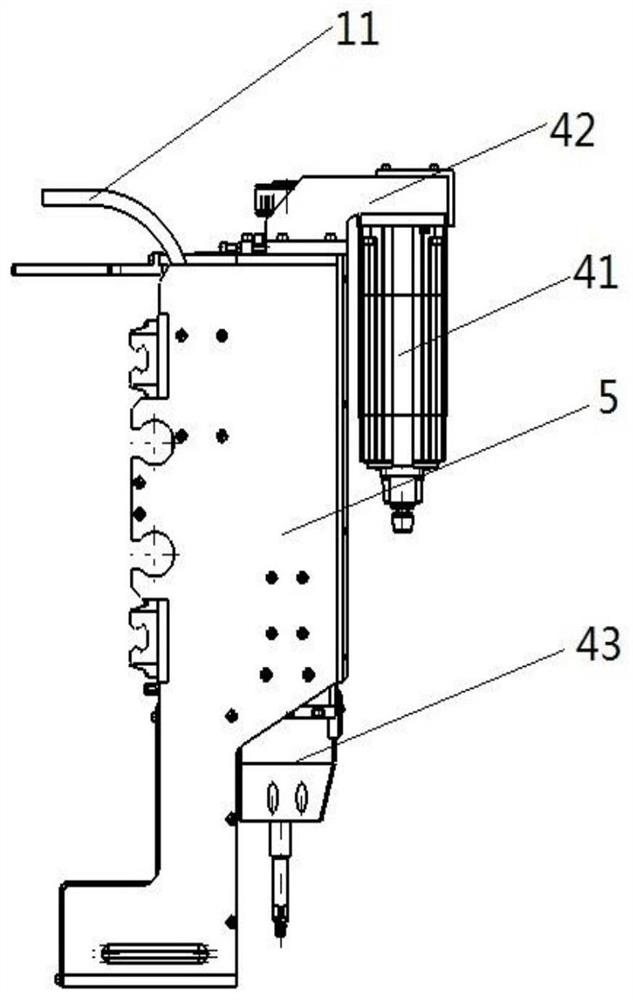

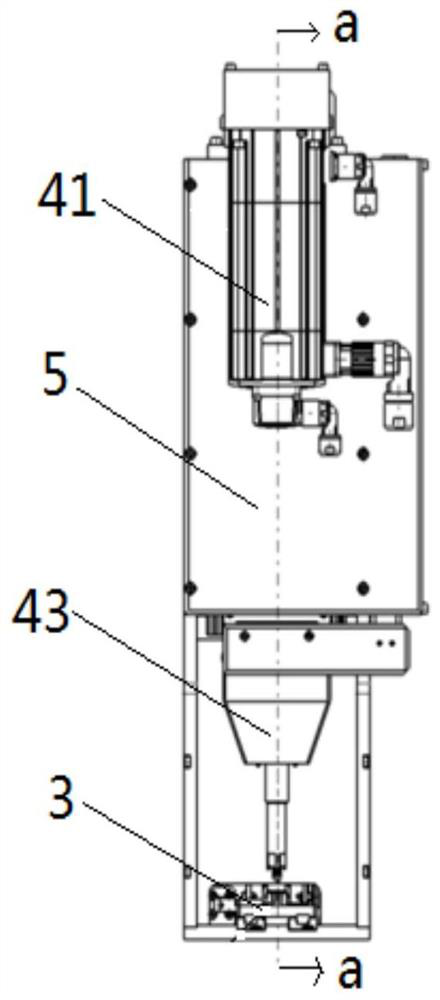

[0039] refer to Figure 1-3 , Figure 7 , a servo high-frequency heating plug, including a feeding mechanism 1, a heating mechanism 2, a feeding mechanism 3 and a hot-plug mechanism 4, the feeding mechanism 1 includes a blowing tube 11, a feeding tube 12 and a top-down arrangement. A ceramic tube 13, the blowing tube 11 and the feeding tube 12, the feeding tube 12 and the ceramic tube 13 are connected by a fixing block 14, and a first avoidance hole 131 is provided on one side of the ceramic tube 13;

[0040] The feeding mechanism 1 , the heating mechanism 2 and the supply mechanism 3 are covered by an outer frame 5 .

[0041] refer to Figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com