Method for preparing polymeric nano-micro fiber non-woven fabric

A non-woven fabric, polymer technology, applied in non-woven fabrics, textiles and papermaking, spinning solution preparation and other directions, can solve the problem of not having universal applicability, and achieve the requirements of overcoming thermoplasticity and high melt fluidity, Excellent performance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

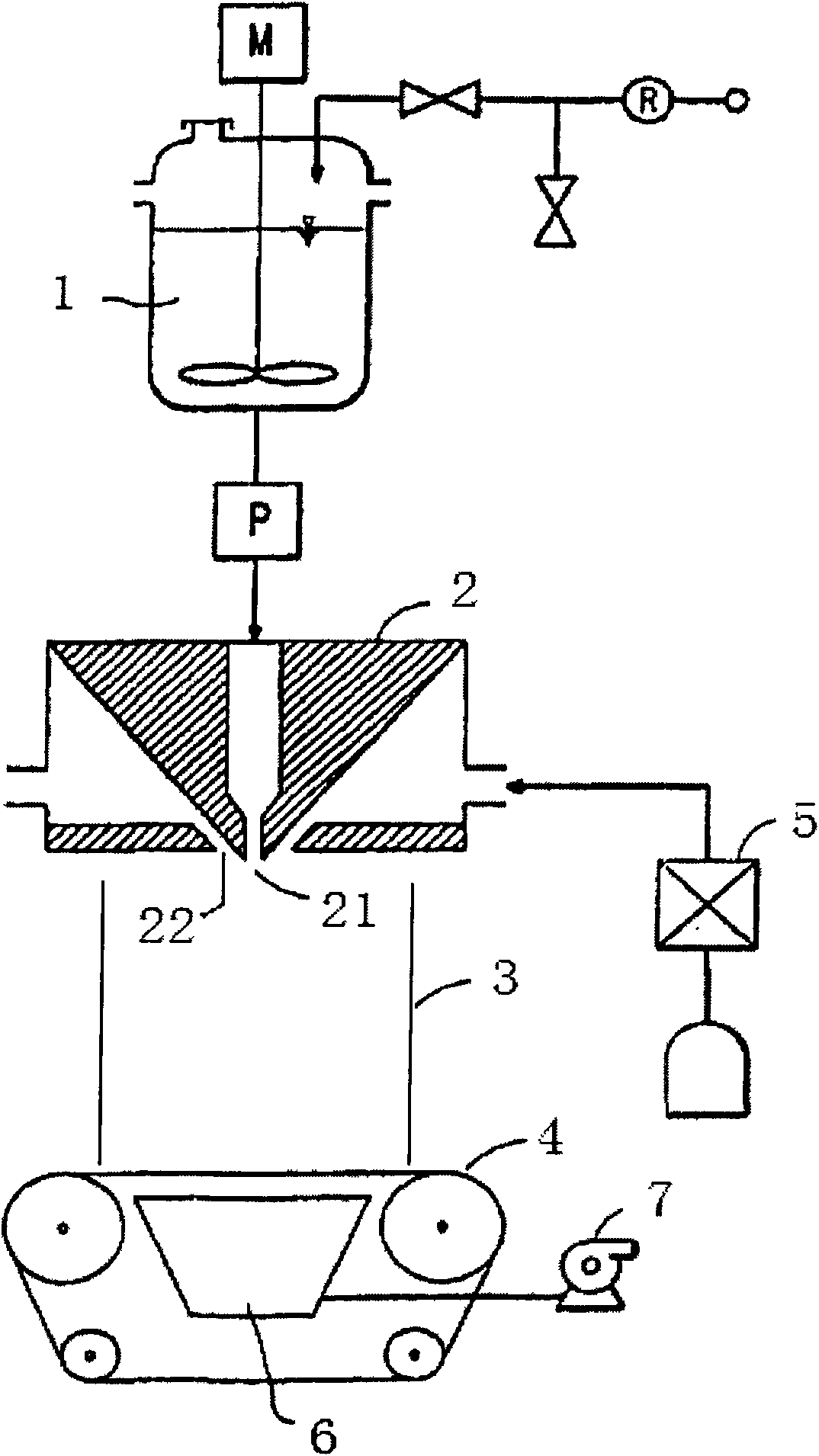

Method used

Image

Examples

Embodiment 1

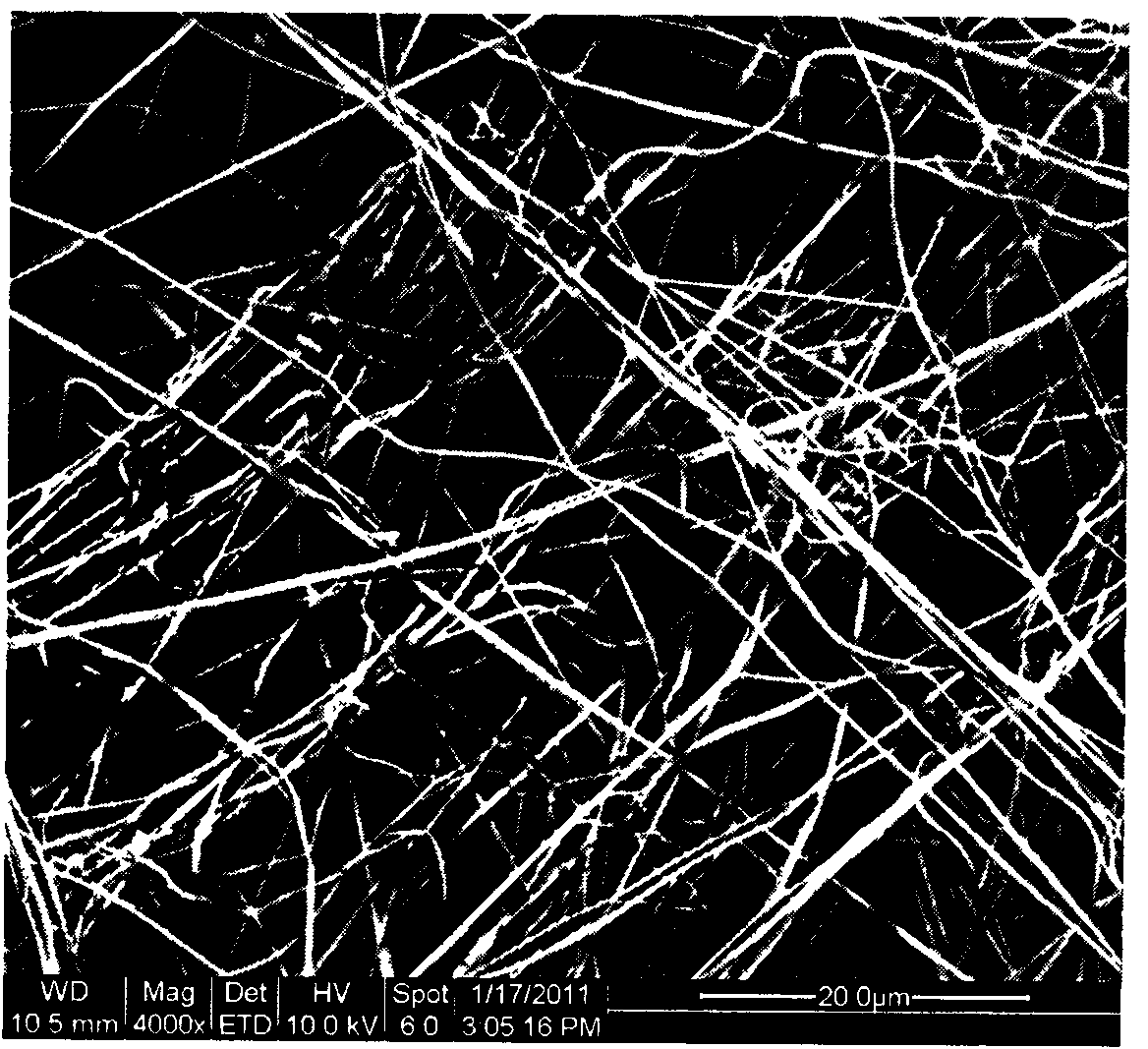

[0030] Polyurethane with an average molecular weight (Mw) of 280,000 is dissolved in N,N-dimethylformamide at a ratio of 12% by mass fraction, stirred until uniformly mixed to make a spinning solution, and the viscosity of the spinning solution is 25 4300mP·s at ℃. The spinning solution is supplied to the spinneret 2 through the delivery pipe through the metering pump, and the supply rate is 200mL / min. The spinning solution is extruded from the spinneret hole 21 under the pressure of the pump, and is sprayed out through the air gap 22. The high-speed jet stream is drafted and refined, and the high-speed jet stream is provided by an air compressor, the outlet pressure (jet pressure) of the air gap 22 is set to 0.6 MPa, and the temperature is room temperature. The high-speed airflow stretches the thin stream of spinning solution, the solvent volatilizes to form nanofibers, and the nanofibers are collected on the metal mesh curtain 4 under the action of high-speed jet airflow and...

Embodiment 2

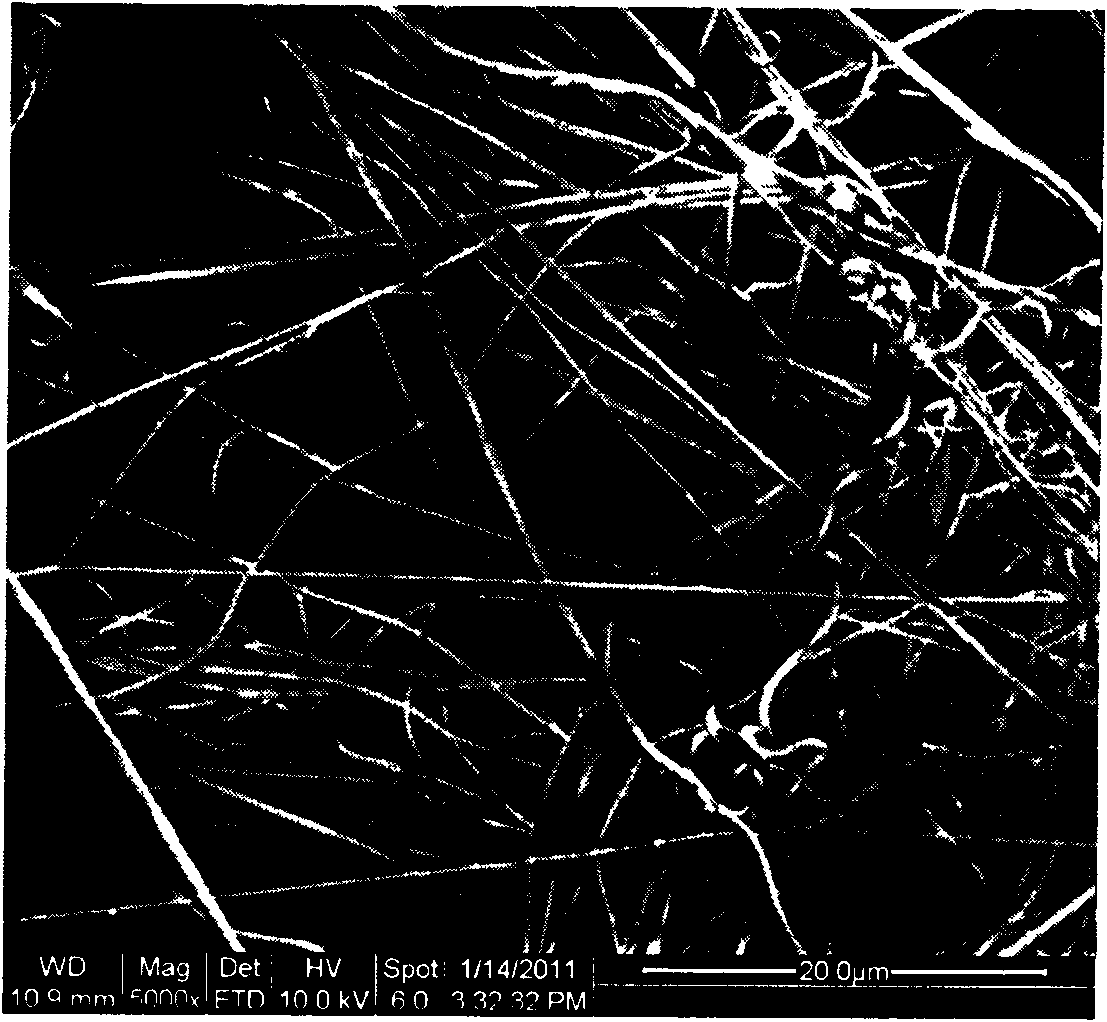

[0033] Dissolve polyacrylonitrile with an average molecular weight (Mw) of 350,000 into N,N-dimethylformamide at a mass fraction of 20%, and stir until it is evenly mixed to make a spinning solution. The viscosity of the solution is at 30°C The lower is 14900mP·s. The spinning solution is supplied to the spinneret 2 through the delivery pipe through the gear pump, and the supply rate is 300mL / min. The spinning solution is squeezed out from the spinneret hole 21 under the pressure of the pump, and is sprayed out through the air gap 22. The high-speed jet airflow is stretched, the high-speed airflow injection pressure is set at 1.2MPa, and the temperature is 35°C. The high-speed jet airflow stretches the thin stream of spinning solution, and the solvent volatilizes to form nanofibers, which are collected on the nylon mesh curtain 4 under the action of the high-speed jet airflow and suction airflow, and then the polymer nanofiber nonwoven fabric is made.

[0034] Utilize the obt...

Embodiment 3

[0036] Poly(ethylene oxide) with an average molecular weight (Mw) of 300,000 was dissolved in deionized water at a ratio of 8% by mass fraction, and silver nitrate (AgNO 3 ), and stirred until uniformly mixed to prepare a spinning solution, the viscosity of which was 1800mP·s at 50°C. The spinning solution is supplied to the spinneret 2 through a delivery pipe through a peristaltic pump, and the supply rate is 10 mL / min. The spinning solution is squeezed out from the spinneret hole 21 under the pressure of the pump, and is sprayed out through the air gap 22 The high-speed jet flow is stretched, the high-speed jet flow is provided by the air compressor, the jet pressure at the outlet of the air gap is set at 2.6MPa, and the temperature is 55°C. The high-speed jet airflow stretches the thin stream of the spinning solution, and the solvent volatilizes to form nanofibers. + ) polymer nano-microfiber nonwoven fabric, can obtain nano-microfiber nonwoven fabric containing nano-silve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com